Plasma texturing reaction apparatus

a technology of plasma ions and reaction apparatuses, which is applied in the direction of electrical apparatus, basic electric elements, electric discharge tubes, etc., can solve the problems of reducing efficiency, difficult to apply surface texturing to ultrathin wafers, and difficulty in independently adjusting ion energy reaching the surface of wafers, etc., to achieve appropriate control of ion energy and increase the density and uniformity of plasma ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Reference will now be made in greater detail to a preferred embodiment of the present invention, an example of which is illustrated in the accompanying drawings.

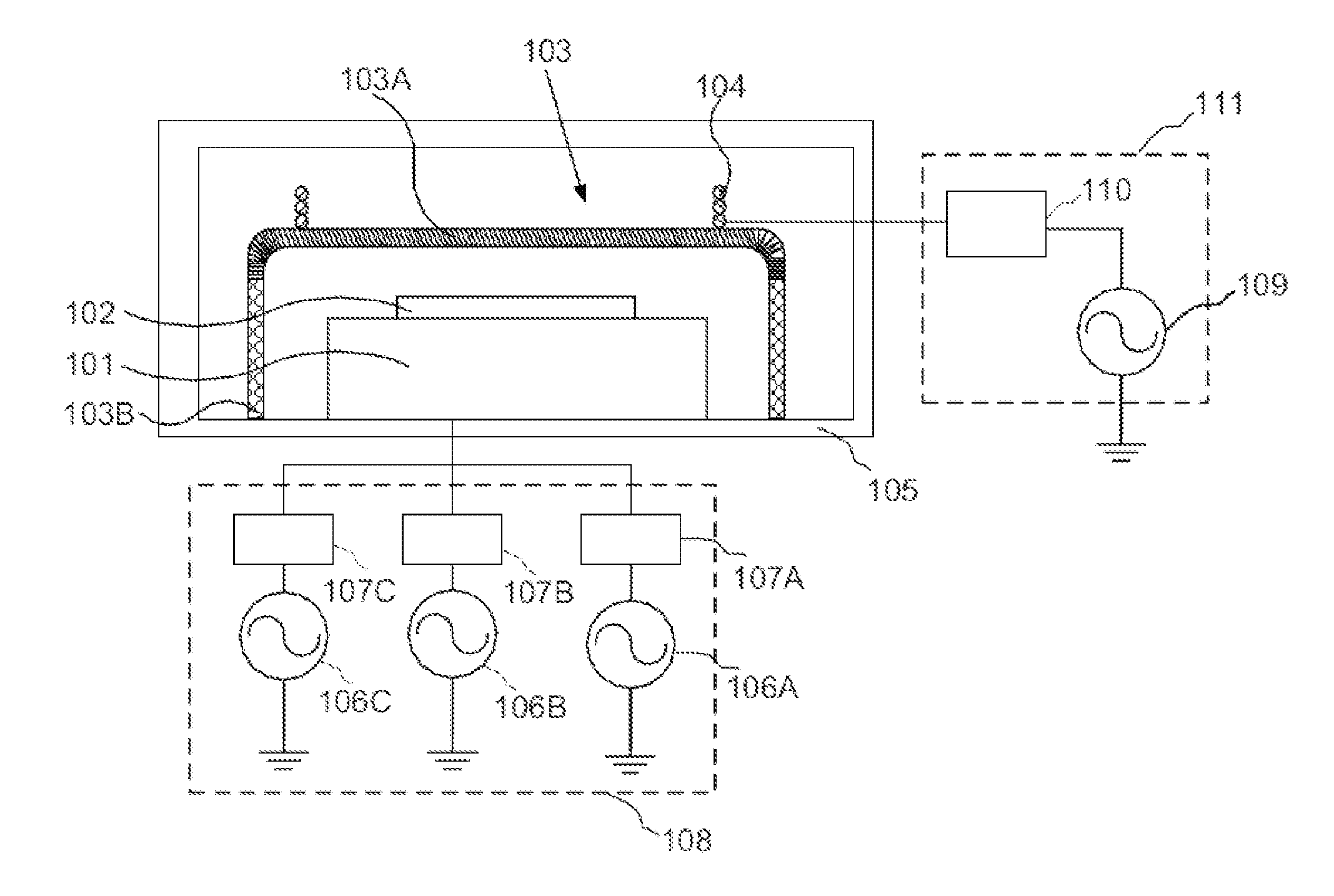

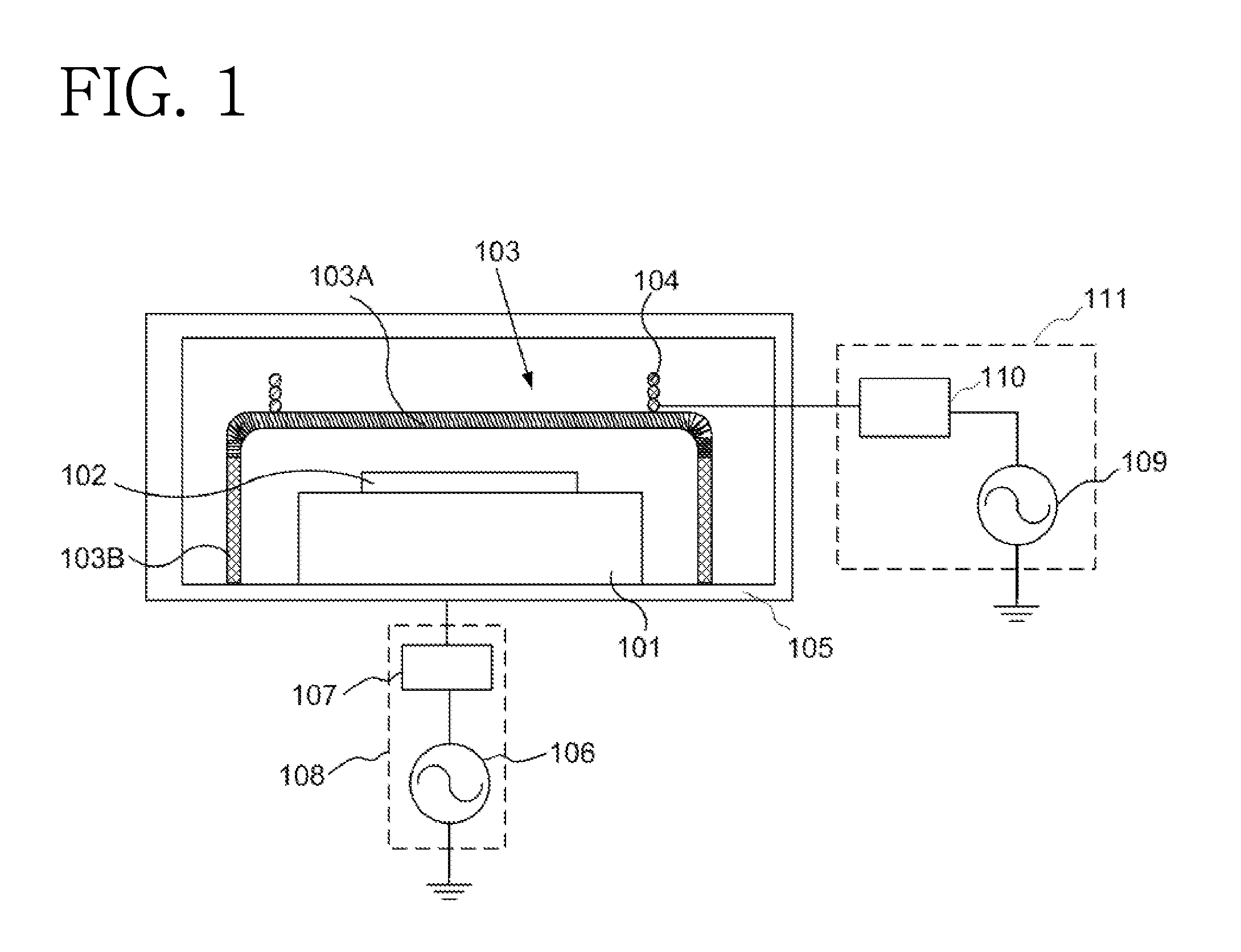

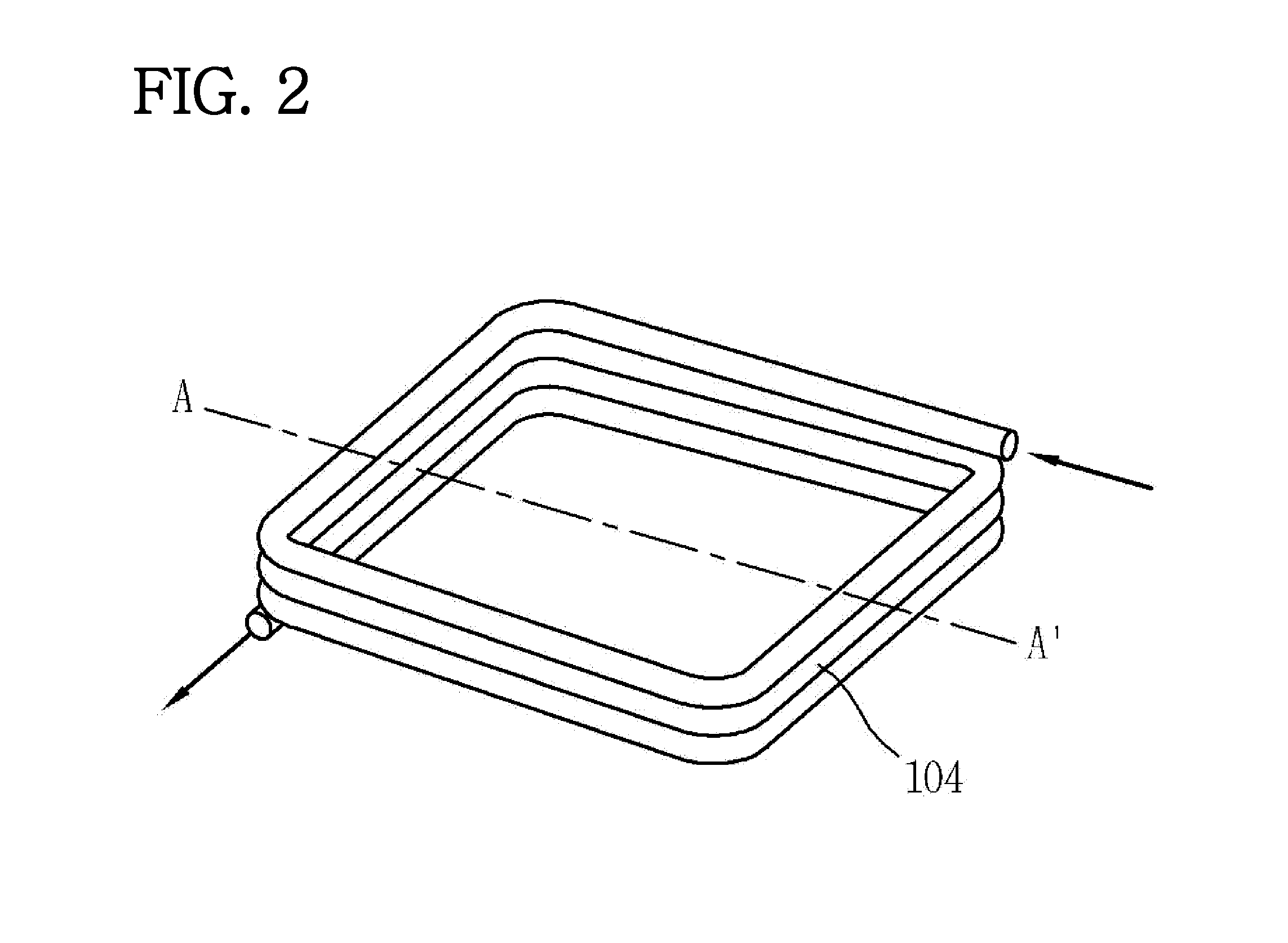

[0023]FIG. 1 is a block diagram illustrating a plasma texturing reaction apparatus in accordance with an embodiment of the present invention. Referring to FIG. 1, the plasma texturing reaction apparatus includes a chamber 103, a polygonal induction coil 104, a high frequency low power supply unit 108, and a high frequency source power supply unit 111. The chamber 103 includes a dielectric window 103A and a chamber body 103B and receives a solar cell wafer 102 to be textured. The polygonal induction coil 104 is provided at an outer upper portion of the dielectric window 103A to generate a magnetic field for generating plasma. The high frequency low power supply unit 108 supplies a cathode 101 of the chamber 103 with high frequency power corresponding to process conditions. The high frequency source power supply unit 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com