Blocking-preventing nozzle device used for preparing metal powder through gas atomization method

A nozzle device and gas atomization technology, which is applied in the field of gas atomization metallurgy, can solve problems such as blockage of the diversion tube, and achieve the effects of avoiding blockage, preventing nodules, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

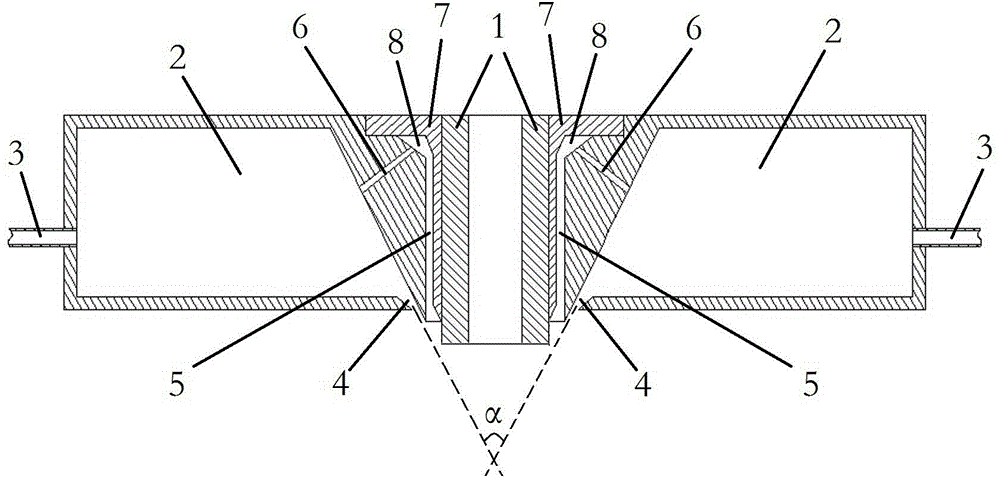

[0026] This embodiment provides an anti-clogging nozzle device for preparing metal powder by gas atomization method, such as figure 1 As shown, it includes a guide tube 1 and an air chamber 2 located around the guide tube 1. The air cavity 2 is connected to the air intake pipe 3. The air cavity 2 is provided with a nozzle ring slit 4 around the lower end of the guide tube 1; the air guide slit 5 Arranged around the guide tube 1, an air guide hole 6 communicating with the air guide slot 5 is provided on the cavity wall of the air cavity 2, and an anti-adhesive device 7 is provided between the air cavity 2 and the guide tube 1, and the air cavity 2 and the anti-adhesive device Between 7, an air guide slot 5 is formed, the opening of the air guide slot 5 is downward, and a buffer chamber 8 is set at the connection between the air guide hole 6 and the air guide slot 5, and four air guide holes 6 are evenly distributed on the wall of the air chamber 2. The width of the air guide sl...

Embodiment 2

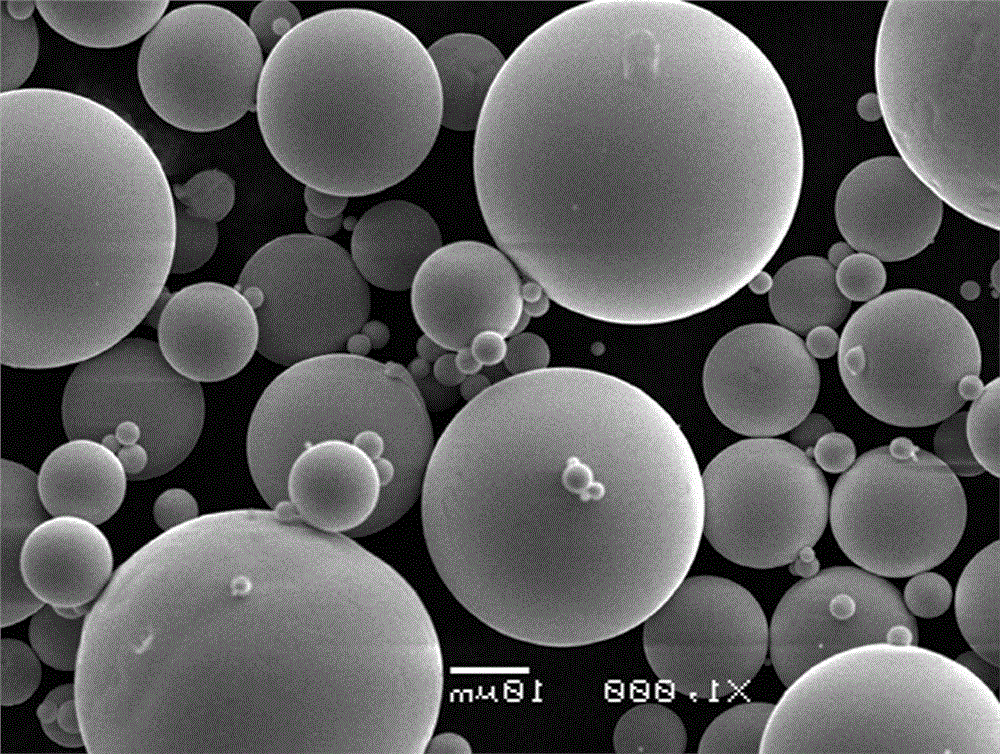

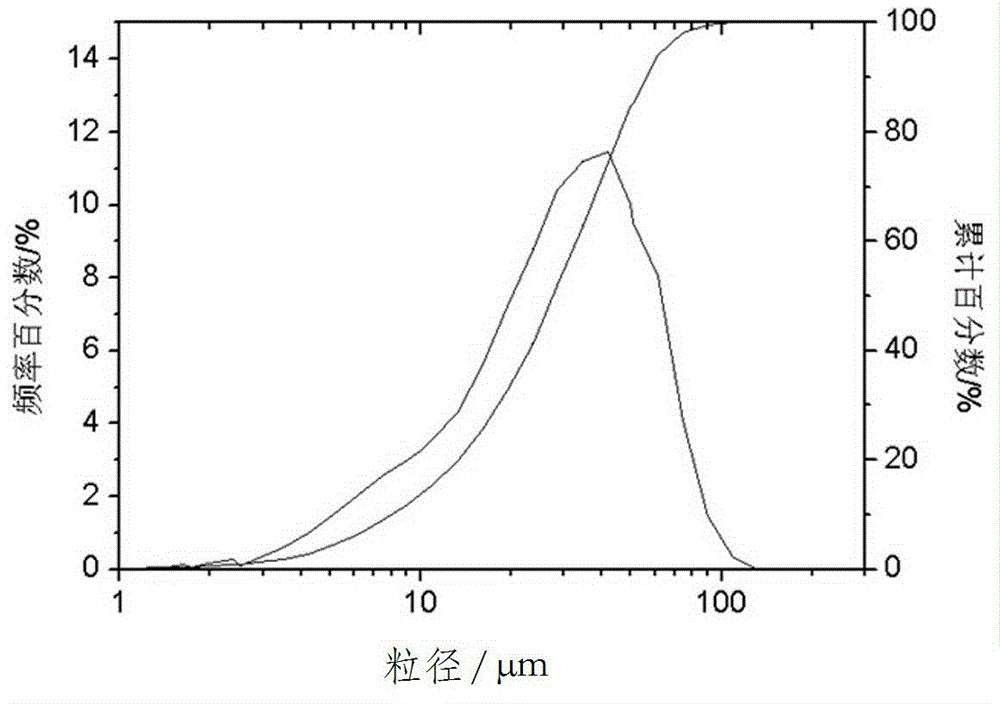

[0028] This embodiment provides another anti-clogging nozzle device for preparing metal powder by gas atomization method, such as Figure 4 As shown, the structure is the same as the anti-clogging nozzle device provided in Example 1, the difference is only that: the air flow duct of the atomizing nozzle has the structural characteristics of Laval (Laval) nozzle, and the nozzle annular seam is designed to shrink first and then expand, so that the spray nozzle The speed of the released gas can exceed the speed of sound, which improves the atomization efficiency of the molten metal. The width of the air guide slot is 0.6 mm; the width of the air guide hole is 1.0 mm; the atomization angle is 55°; the inner diameter of the guide tube is 4.0 mm. 304L stainless steel was used as the atomization object to carry out the atomization test of the powder, the test alloy was 50kg, the atomization temperature was 1600°C, and the atomization pressure was 4.0MPa. After atomization, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com