Leather care solution and preparation method thereof

A nursing solution and leather technology, which is applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Longevity, hardening and drying of the cortex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

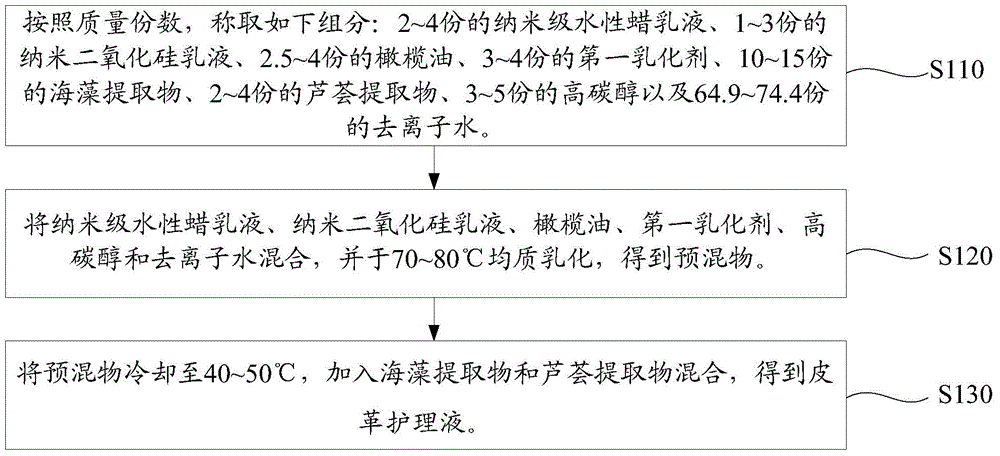

[0048] like figure 1 As shown, the preparation method of the leather care solution of one embodiment can be used to prepare the above-mentioned leather care solution, and the preparation method of the leather care solution comprises the following steps:

[0049] Step S110: According to the parts by mass, weigh the following components: 2-4 parts of nano-scale aqueous wax emulsion, 1-3 parts of nano-silica emulsion, 2.5-4 parts of olive oil, 3-4 parts of An emulsifier, 10-15 parts of seaweed extract, 2-4 parts of aloe extract, 3-5 parts of high carbon alcohol and 64.9-74.4 parts of deionized water.

[0050] Wherein, the solid content of the nanoscale water-based wax emulsion is 20-25wt.%.

[0051] In this example, the nanoscale water-based wax emulsion was prepared by stirring and mixing the liquid wax with a mass ratio of 20:4 to 25:10 and the second emulsifier, and adding deionized water while stirring , to obtain nanoscale aqueous wax emulsion.

[0052] Wherein, the liqui...

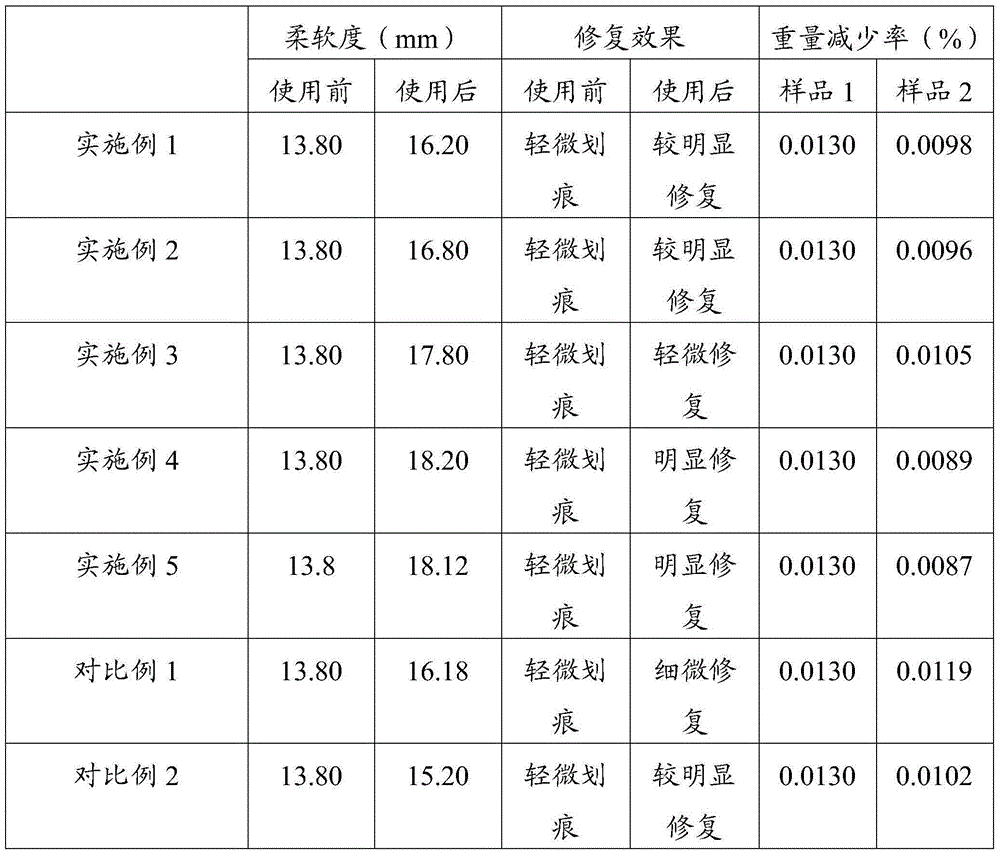

Embodiment 1

[0072] The preparation steps of the leather care solution of the present embodiment are as follows:

[0073] (1) According to the mass ratio of 0.8:7.2, sorbitan monolaurate and polyoxyethylene sorbitan monolaurate are mixed to obtain a composite emulsion; according to the mass ratio of 25:10, liquid paraffin and Mix the composite emulsion, stir and mix for 5 minutes at a rate of 3000 rpm on a magnetic stirrer, then reduce the stirring rate to 1000 rpm, and add deionized water dropwise under the condition of constant stirring at this stirring rate, and the dropping speed 10 drops / min, a nanoscale water-based wax emulsion with a solid content of 25wt.% was obtained.

[0074] (2) Mix the dispersant (high-efficiency general-purpose dispersant from Shanghai Zero Chemical Technology Co., Ltd.) with deionized water, then add silicon dioxide powder with a particle size of 50nm and stir to disperse, to obtain a nanometer silica powder with a solid content of 25wt.%. Silica emulsion, ...

Embodiment 2

[0084] The preparation steps of the leather care solution of the present embodiment are as follows:

[0085] (1) According to the mass ratio of 0.5:8, sorbitan monolaurate and polyoxyethylene sorbitan monolaurate are mixed to obtain a composite emulsion; according to the mass ratio of 20:4, liquid paraffin and Mix the composite emulsion, stir and mix for 5 minutes at a rate of 3000 rpm on a magnetic stirrer, then reduce the stirring rate to 1000 rpm, and add deionized water dropwise under the condition of constant stirring at this stirring rate, and the dropping speed 10 drops / min to obtain a nanoscale water-based wax emulsion with a solid content of 20wt.%.

[0086] (2) Mix the dispersant (high-efficiency general-purpose dispersant from Shanghai Zero Chemical Technology Co., Ltd.) with deionized water, and then add silicon dioxide powder with a particle size of 80nm to stir and disperse to obtain a nano-dioxide with a solid content of 20wt.%. Silica emulsion, wherein the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com