Patents

Literature

32results about How to "Repair scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

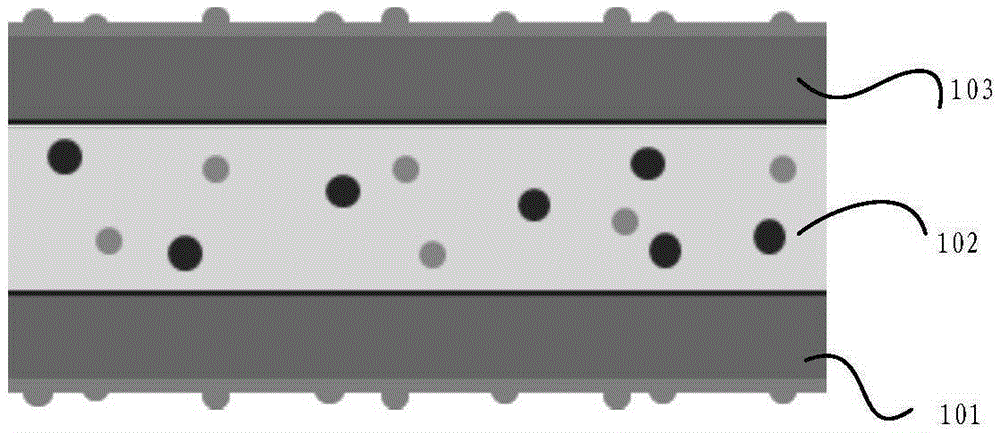

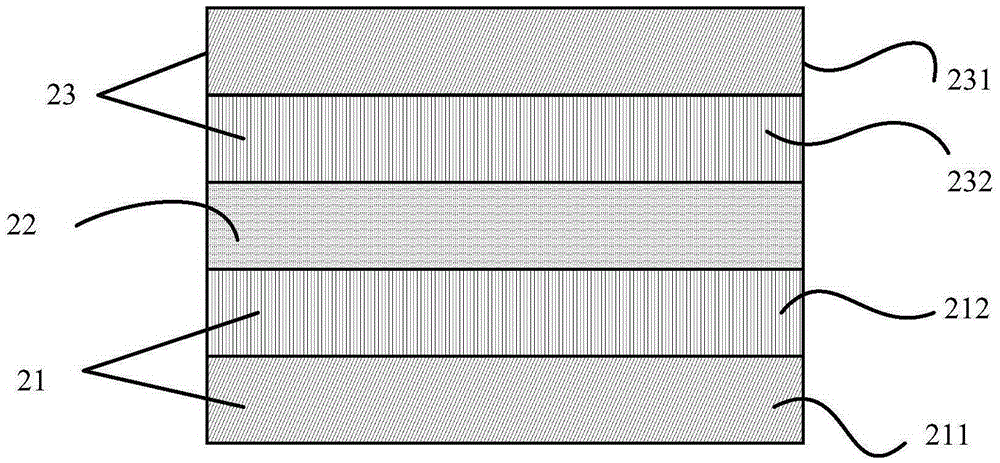

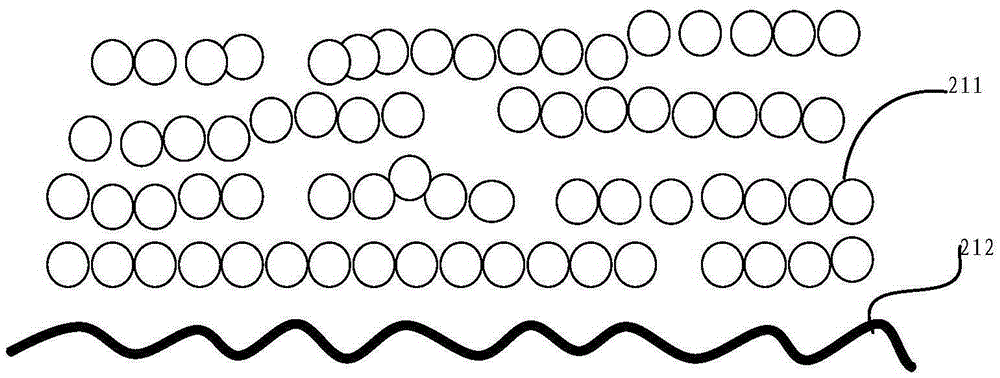

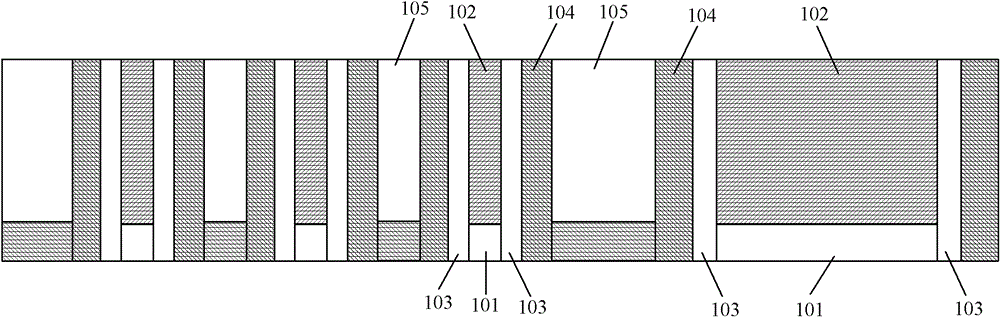

Display device, backlight module, quantum dot optical diaphragm and preparation method thereof

InactiveCN105425463ARepair scratchesEliminate failure areasNon-linear opticsPolyethylene terephthalateDisplay device

The invention discloses a display device, a backlight module, a quantum dot optical diaphragm and a preparation method thereof. The quantum dot optical diaphragm comprises a quantum dot layer, a first composite water oxygen barrier layer which covers the surface of the light inlet side of the quantum dot layer and a second composite water oxygen barrier layer which covers the surface of the light outlet side of the quantum dot layer; the first composite water oxygen barrier layer and the second composite water oxygen barrier layer are each selected from one or a combination of any two of a first film structure, a second film structure and a third film structure, wherein the first film structure is the composite water oxygen barrier layer which is composed of polyethylene terephthalate (PET) and graphene, the second film structure is a graphene layer, and the third film structure is the water oxygen barrier layer which is composed of PET and aluminum oxide. Compared with the prior art, the water oxygen barrier property, the photopermeability and the structural stability of the quantum dot optical diaphragm are obviously improved.

Owner:HISENSE VISUAL TECH CO LTD

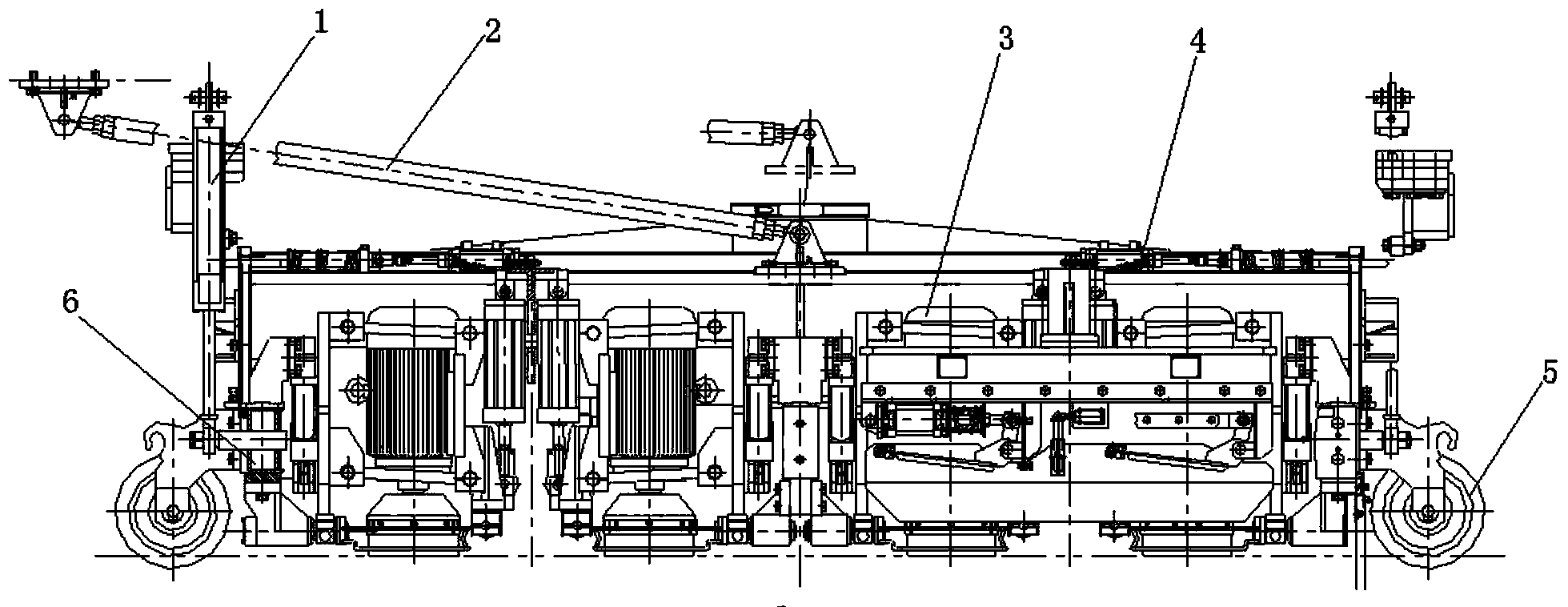

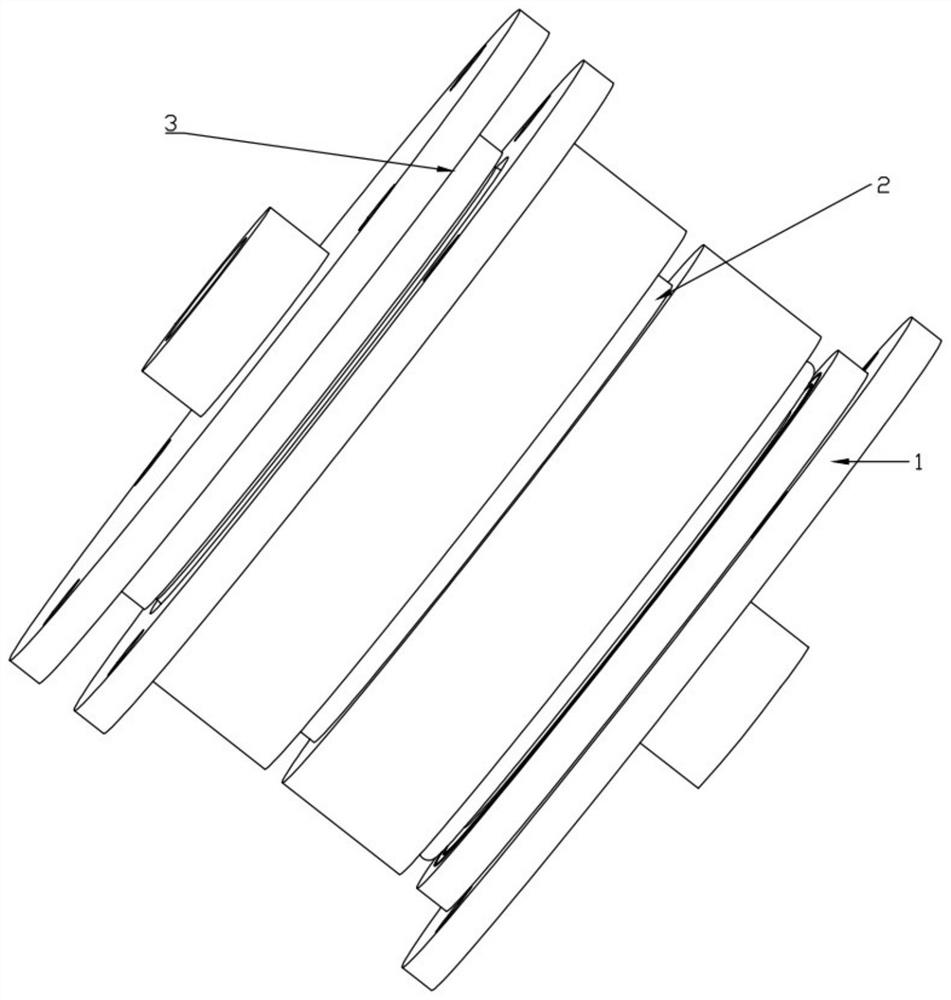

Steel rail polishing vehicle

InactiveCN103911926ACorrection of wavy wearRepair scratchesRailway track constructionHydraulic cylinderVehicle frame

The invention discloses a steel rail polishing vehicle which comprises a vehicle frame. Polishing units are arranged on the vehicle frame, traveling wheels are arranged on the lower portion of the vehicle frame, the vehicle frame is suspended on a polishing train, and a lifting hydraulic cylinder is arranged between the vehicle frame and the polishing train. Locking devices are arranged between the vehicle frame and the polishing train. A traction apparatus is arranged between the vehicle frame and the polishing train. The steel rail polishing vehicle has the advantages that wavy abrasion of tracks and scratching of wheel rails can be amended by the steel rail polishing vehicle, tilting deformation of inner and outer rails can be corrected by the steel rail polishing vehicle, contact surfaces and the like of the wheel rails can be trimmed, accordingly, the defects can be overcome by the steel rail polishing vehicle, and the steel rail polishing vehicle is applicable to polishing straight and curved steel rails for large road maintenance operation.

Owner:北京二七机车工业有限责任公司

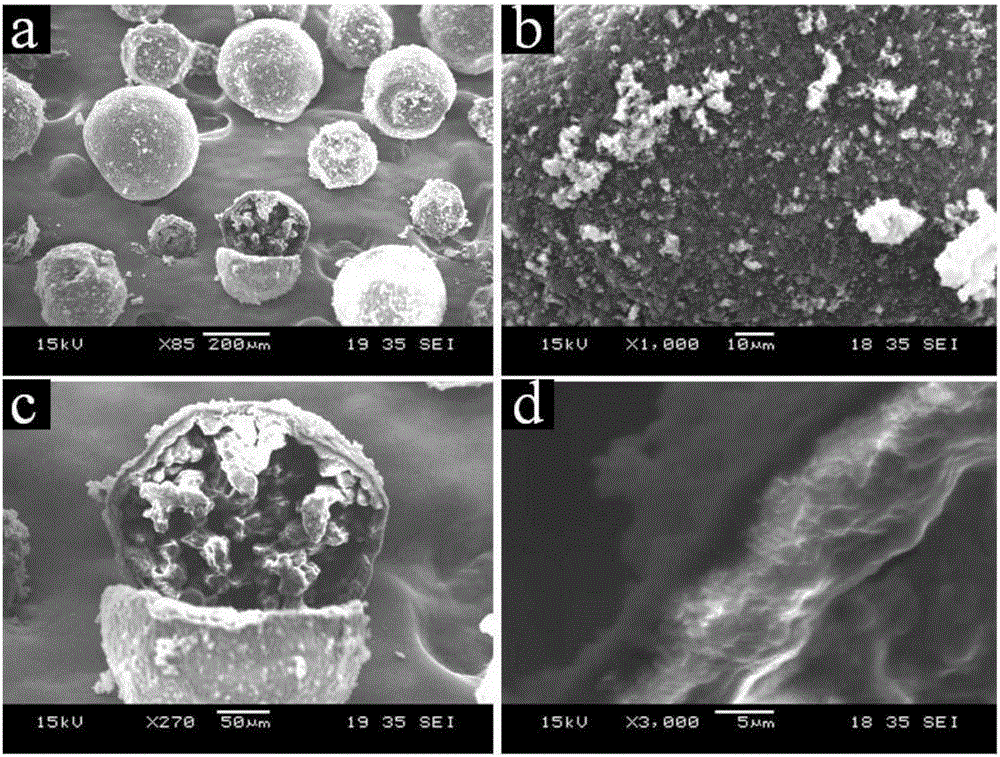

Conductive polymer microcapsule of reactive liquid core material and preparation method thereof

InactiveCN104028184AEffective control contentEasy to prepareCoatingsMicroballoon preparationLiquid coreMaterials preparation

The invention relates to a conductive polymer microcapsule of a reactive liquid core material and a preparation method thereof, which belong to the technical field of functional material preparation. The preparation method comprises the following steps: preparing a surfactant-containing aqueous solution at room temperature; heating the aqueous solution to 30-60 DEG C; adding the reactive liquid core material the mass of which is 0.05-0.25 times that of the aqueous solution; stirring at the speed of 200-2000 rpm for 10-30 minutes; stirring at the lowered speed of 50-200 rpm for 30-120 minutes; after natural cooling, washing a product by deionized water to obtain a suspension; adding an acidic oxidant aqueous solution or an aromatic heterocyclic monomer aqueous solution, the mass of which is 1-5 times that of the core material, into the suspension; reacting at room temperature for 5-20 minutes under the condition of mechanical stirring at the speed of 100-300 rpm; adding an aromatic heterocyclic monomer aqueous solution or an acidic oxidant aqueous solution for 5-20 times at interval of 2-20 minutes, wherein the total mass of the added solution is equivalent to 1-5 times the mass of the core material; polymerizing for 1-12 hours; and finally, washing by deionized water and drying, wherein the firstly added aqueous solution and the later added aqueous solution are not the same substance. The preparation method is simple, the raw materials are cheap and the products are easy to collect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Multicolor ageing-resistant spraying-free polydicyclopentadiene composite material, and preparation method and application thereof

InactiveCN106243279AColorfulAnti-aging and long service lifeBuilding insulationsAging resistanceCarbene

The invention discloses a multicolor ageing-resistant spraying-free polydicyclopentadiene composite material, and a preparation method and an application thereof. Raw materials for preparing the composite material comprise 35-65% of dicyclopentadiene, 1-15% of a copolymer, 10-35% of a functional filler, 0.05-5% of environmentally-friendly color paste or high-mesh toner, and 0.01-0.1% of a ruthenium carbene catalyst. The material is integrally formed after high-efficiency dissolution of the environmentally-friendly color paste or the high-mesh toner with dicyclopentadiene, full mixing of the obtained material with other ingredients, reaction of the obtained mixture with a curing agent, and injection molding polymerization. The spraying-free polydicyclopentadiene composite material has the advantages of brilliant color, ageing resistance, long life, superior mechanical performances, and simple repairing of minimal scratches, and the preparation method is simple.

Owner:SHANGHAI COACHCHEM TECH

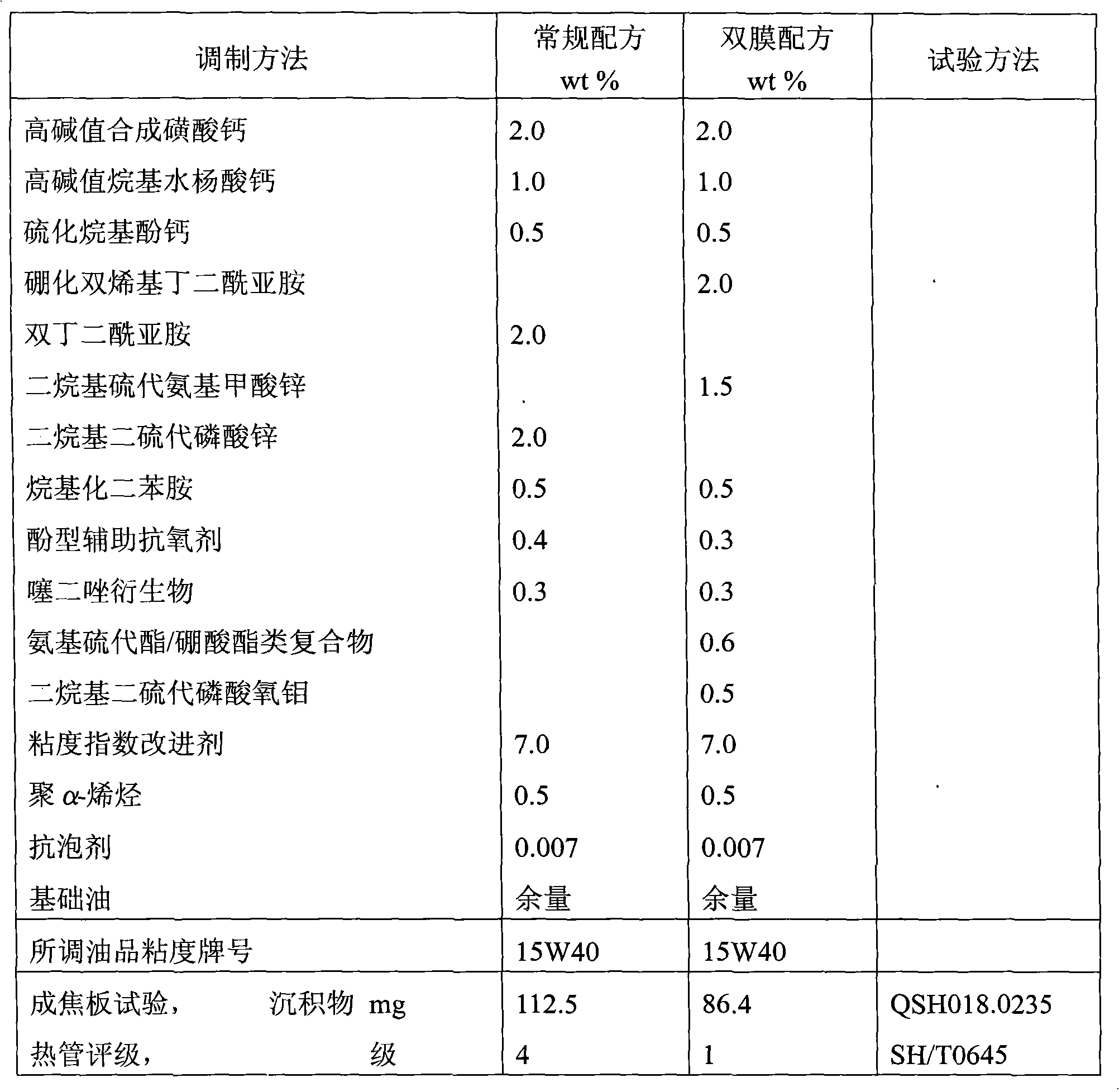

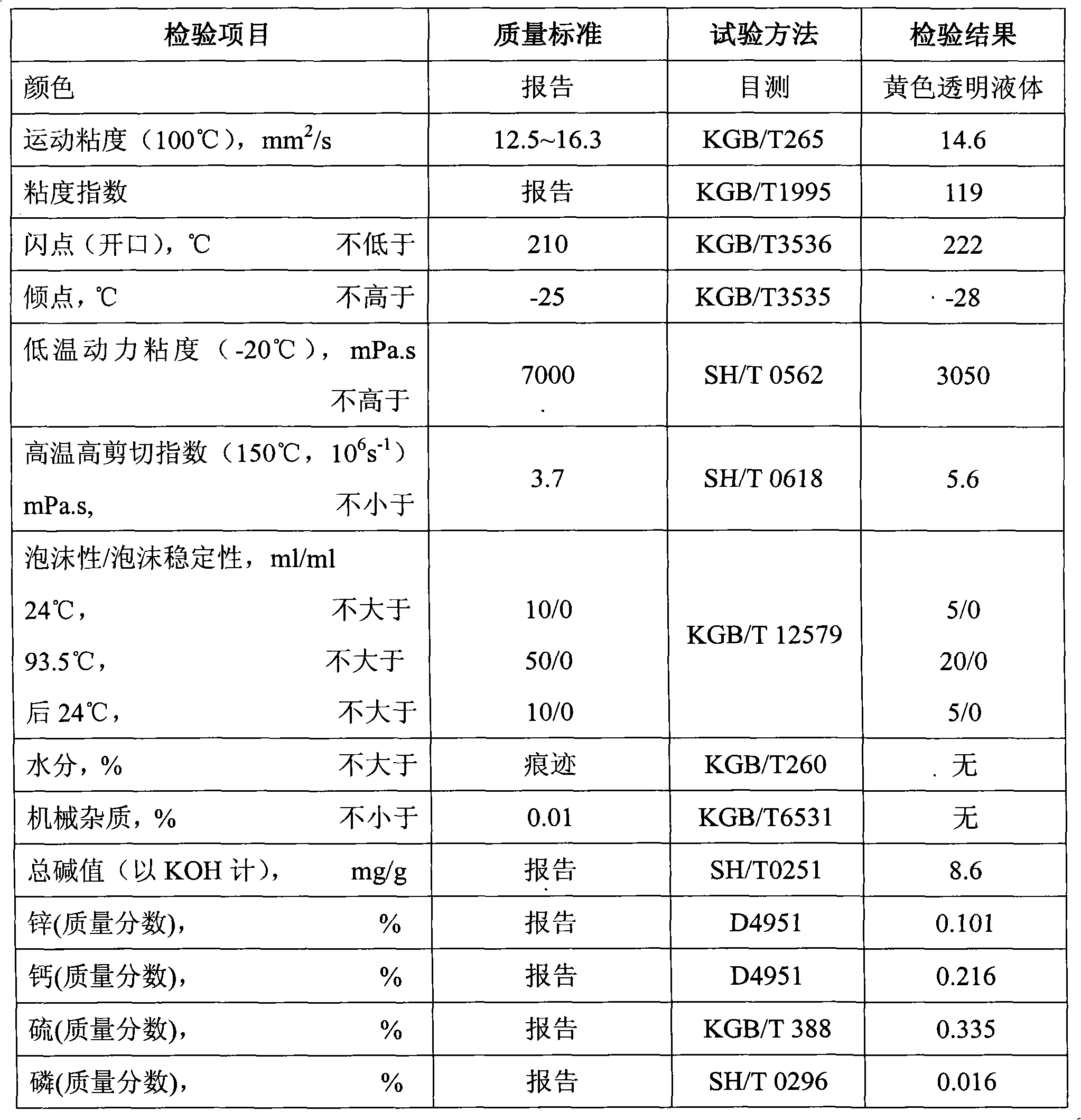

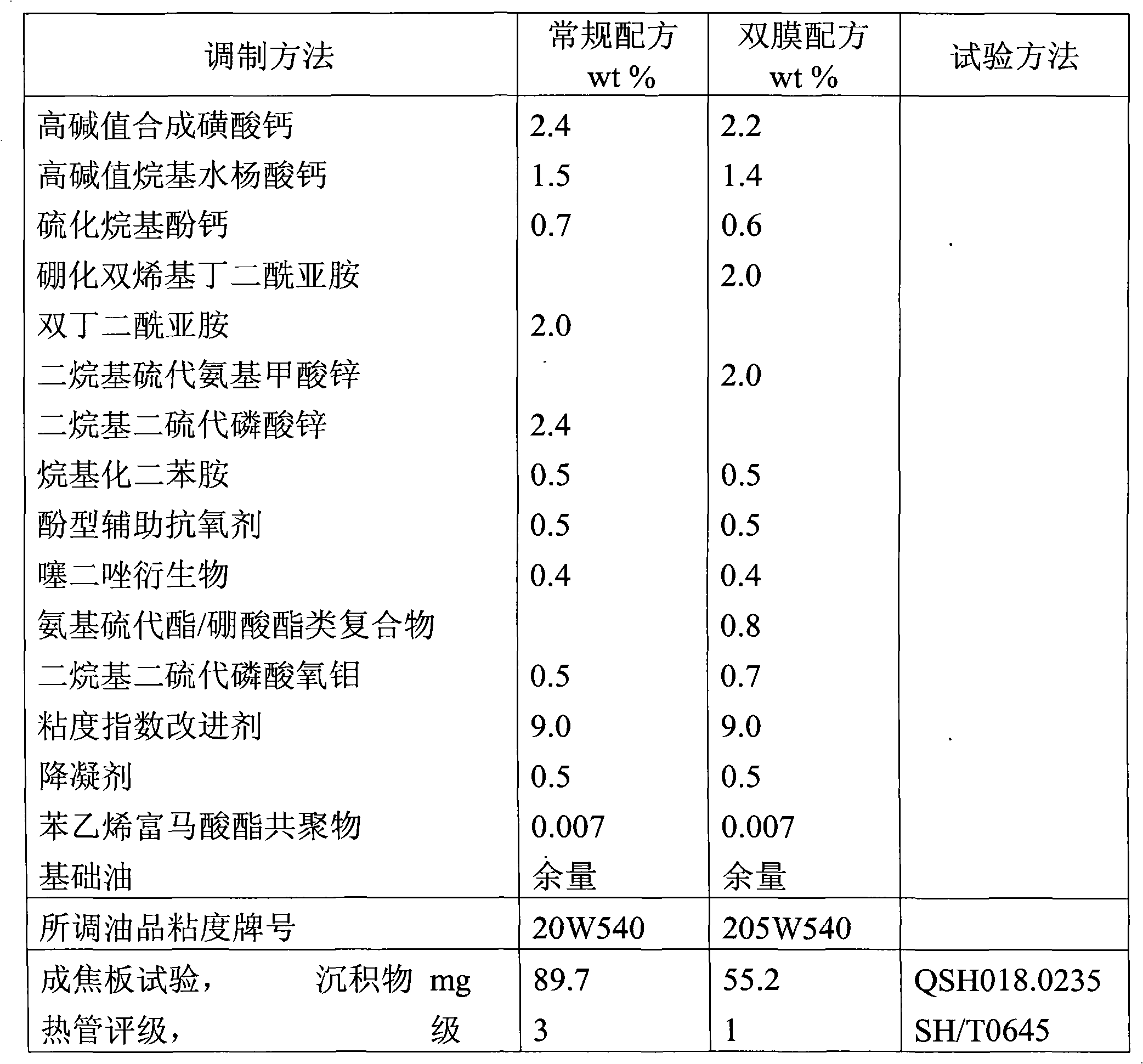

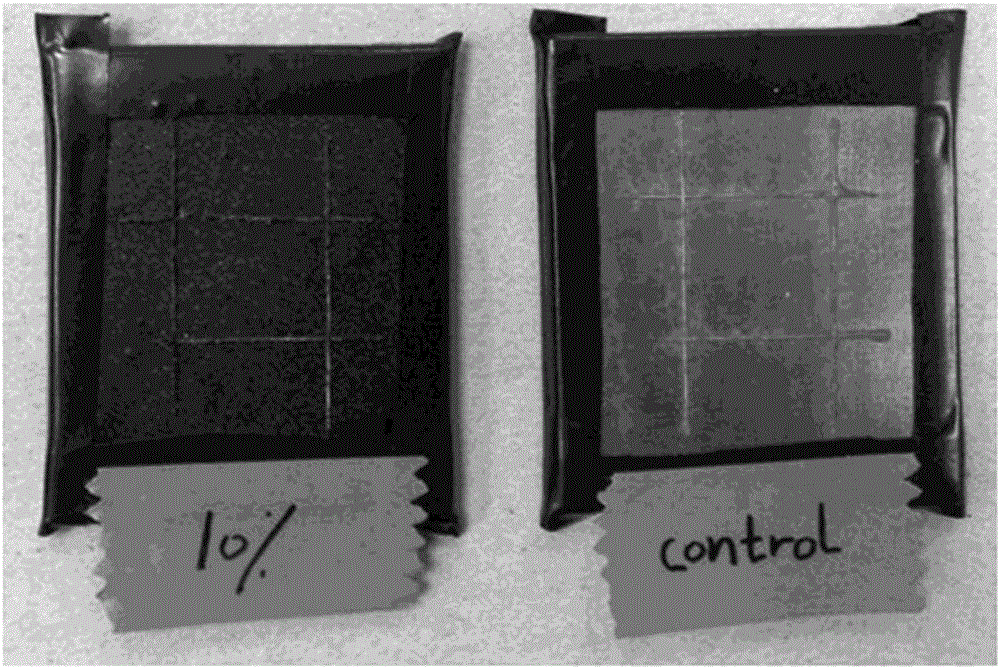

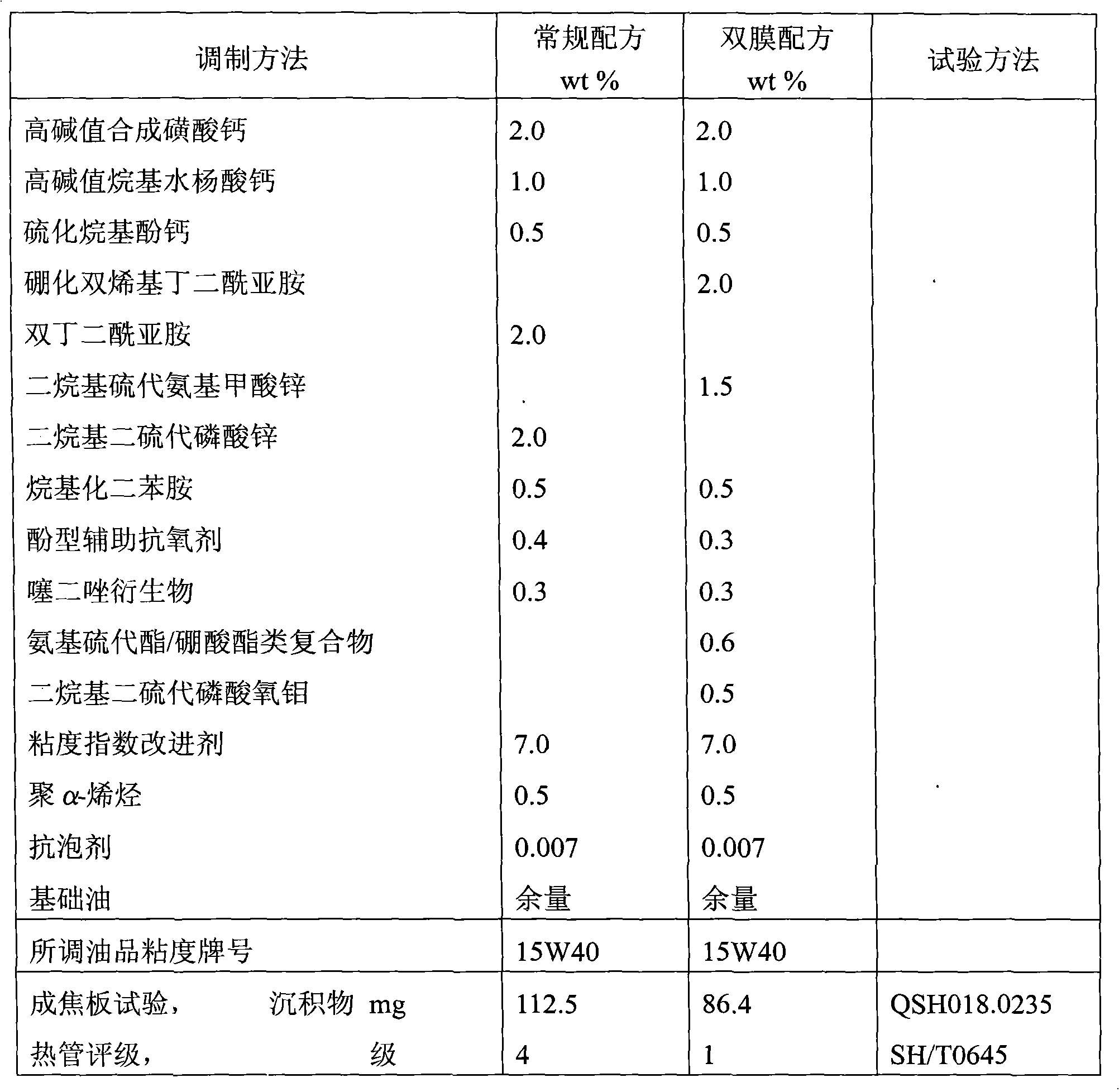

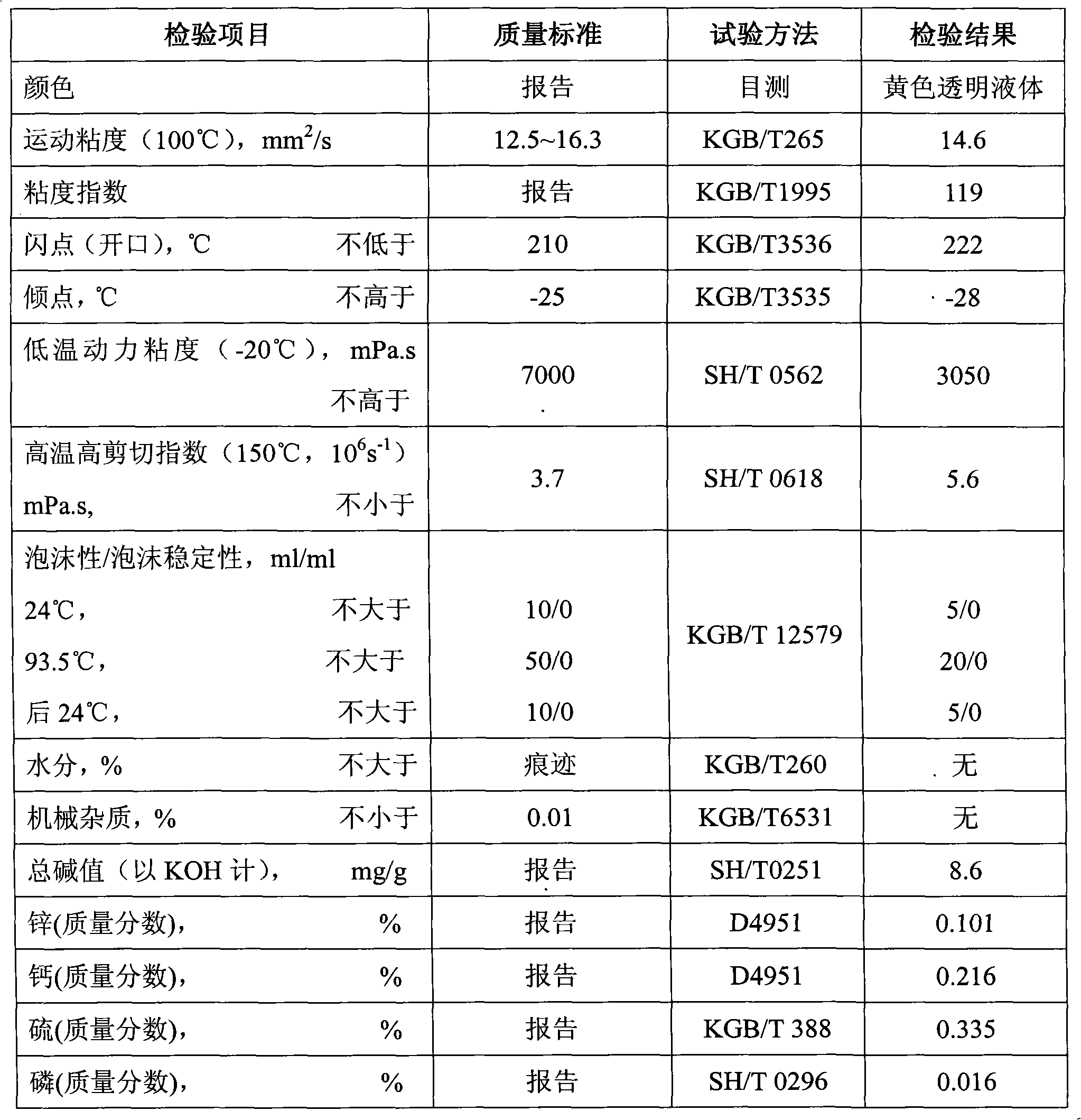

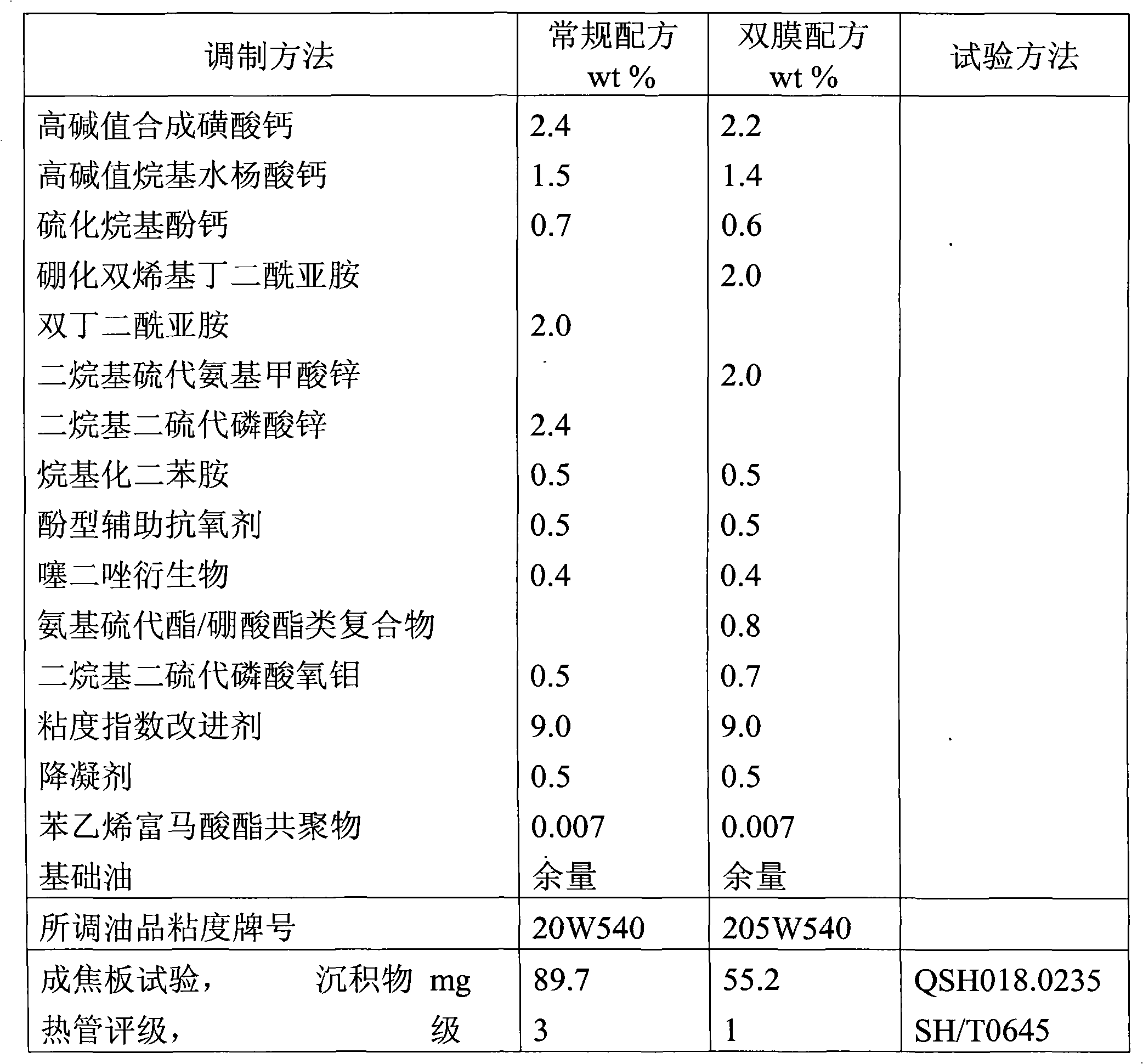

Two-film lubricating oil

The invention relates to two-film lubricating oil, which is prepared from the following raw materials in percentage by mass: 0.8 to 2.5 percent of characteristic additive, 1.7 to 3.8 percent of antioxidant, 1.6 to 4.8 percent of detergent, 1.0 to 3.4 percent of dispersing agent, 1.0 to 9.0 percent of viscosity index improver, 0.3 to 0.8 percent of pour point depressant, 0.006 to 0.01 percent of antifoaming agent and the balance of base oil. The invention has the advantages that: the two-film lubricating oil is anticorrosive and antirust, effectively removes carbon deposit and even removes the original rust stain of an engine, has longer service life and lower cost, is environmentally-friendly, and has high antiwear and antifriction performance and a good fuel saving effect, wherein the fuel saving ratio of an automobile per 100 kilometers is 6 to 10 percent, the fuel saving ratio of a large truck per 100 kilometers is 6 to 9 percent, and the fuel saving ratio of a small sedan per 100 kilometers is 8 to 10 percent.

Owner:BEIJING ALLUBE PETROCHEM

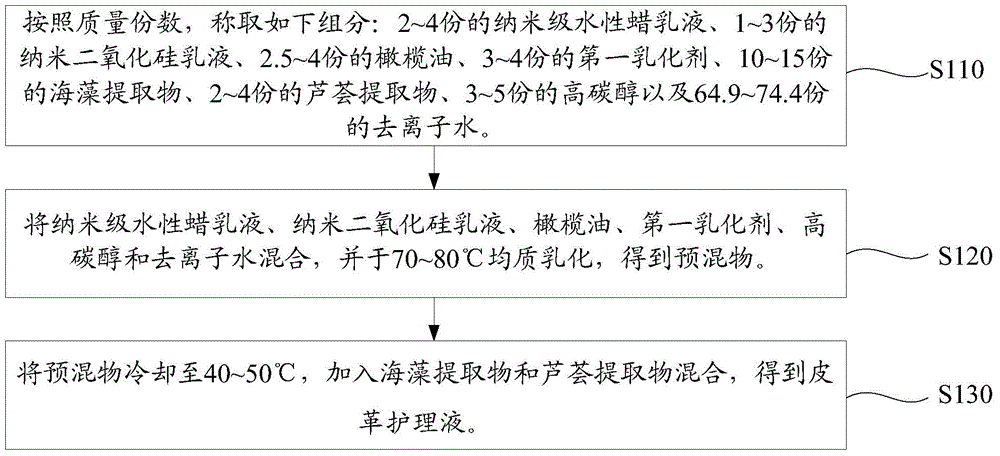

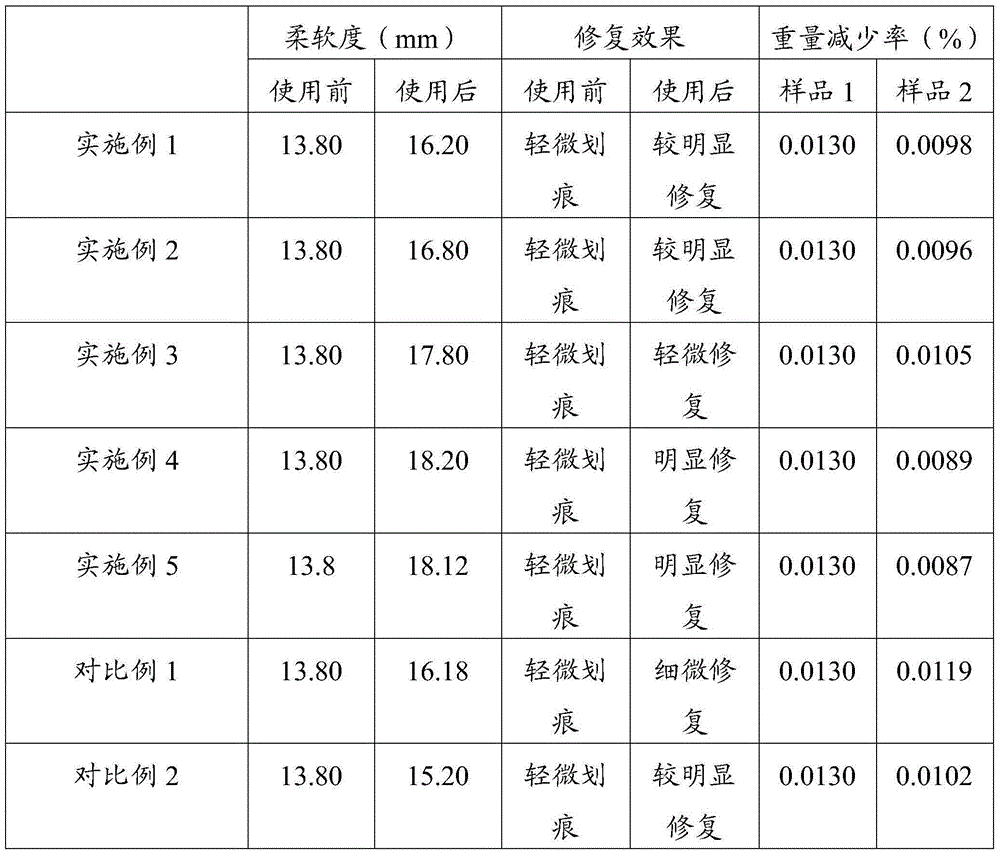

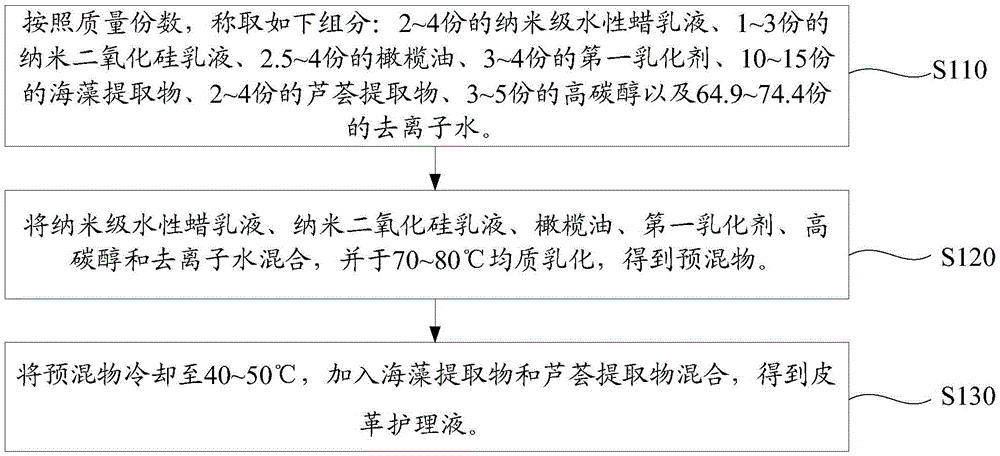

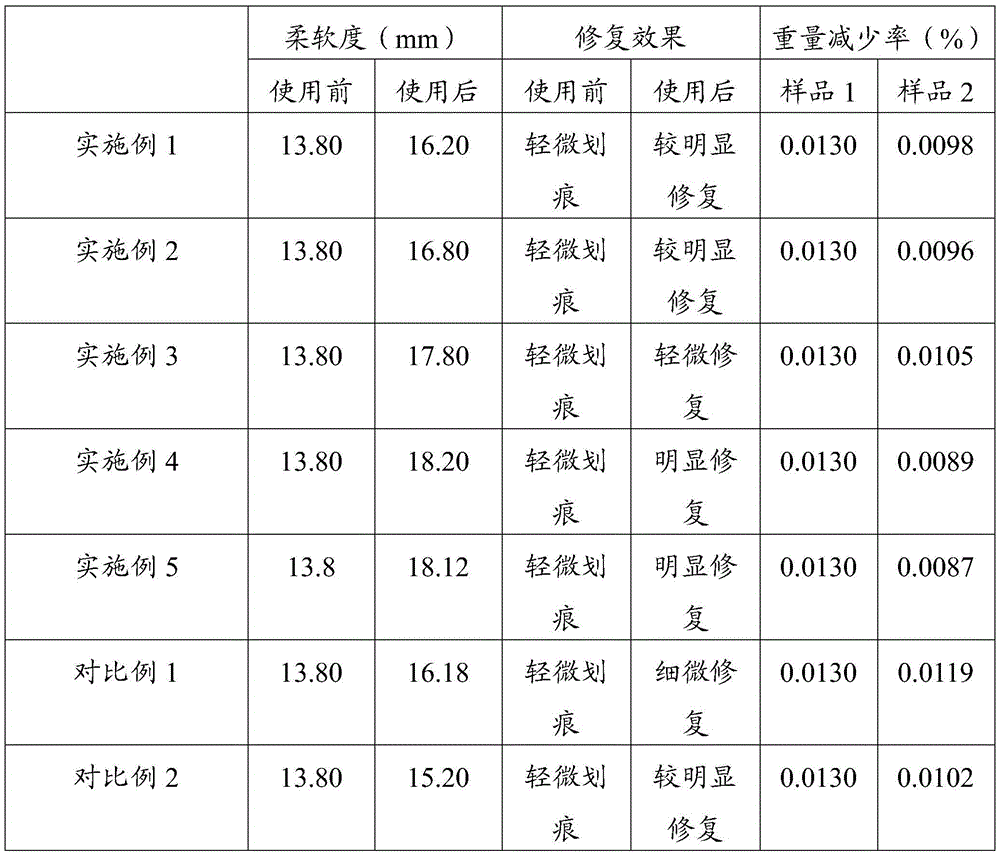

Leather care solution and preparation method thereof

The invention relates to a leather care solution and a preparation method thereof. The leather care solution comprises the following components in parts by mass: 2 to 4 parts of nanoscale water-based wax emulsion, 1 to 3 parts of nano silicon dioxide emulsion, 2.5 to 4 parts of olive oil, 3 to 4 parts of an emulgator, 10 to 15 parts of a seaweed extract, 2 to 4 parts of an aloe extract, 3 to 5 parts of high alcohols and 64.9 to 74.4 parts of deionized water, wherein the solid content of the nanoscale water-based wax emulsion is 20 to 25 wt.%, and the solid content of the nano silicon dioxide emulsion is 20 to 25 wt.%. The leather care solution can effectively moisten and soften leather, prevents the ageing of the leather, and increases the wear-resisting property and the gloss of the leather, thus prolonging the service life of the leather.

Owner:深圳市艾思生物技术有限公司

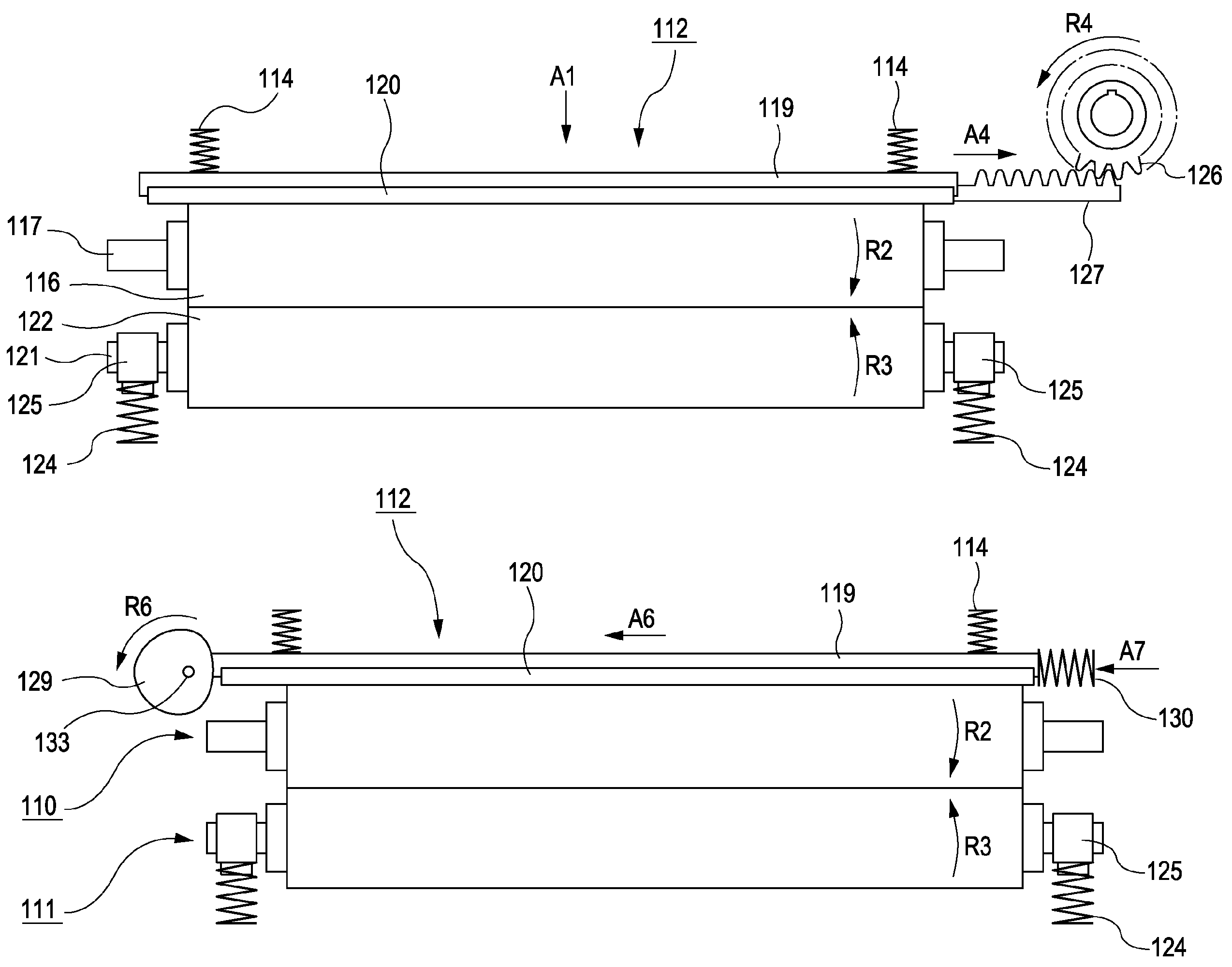

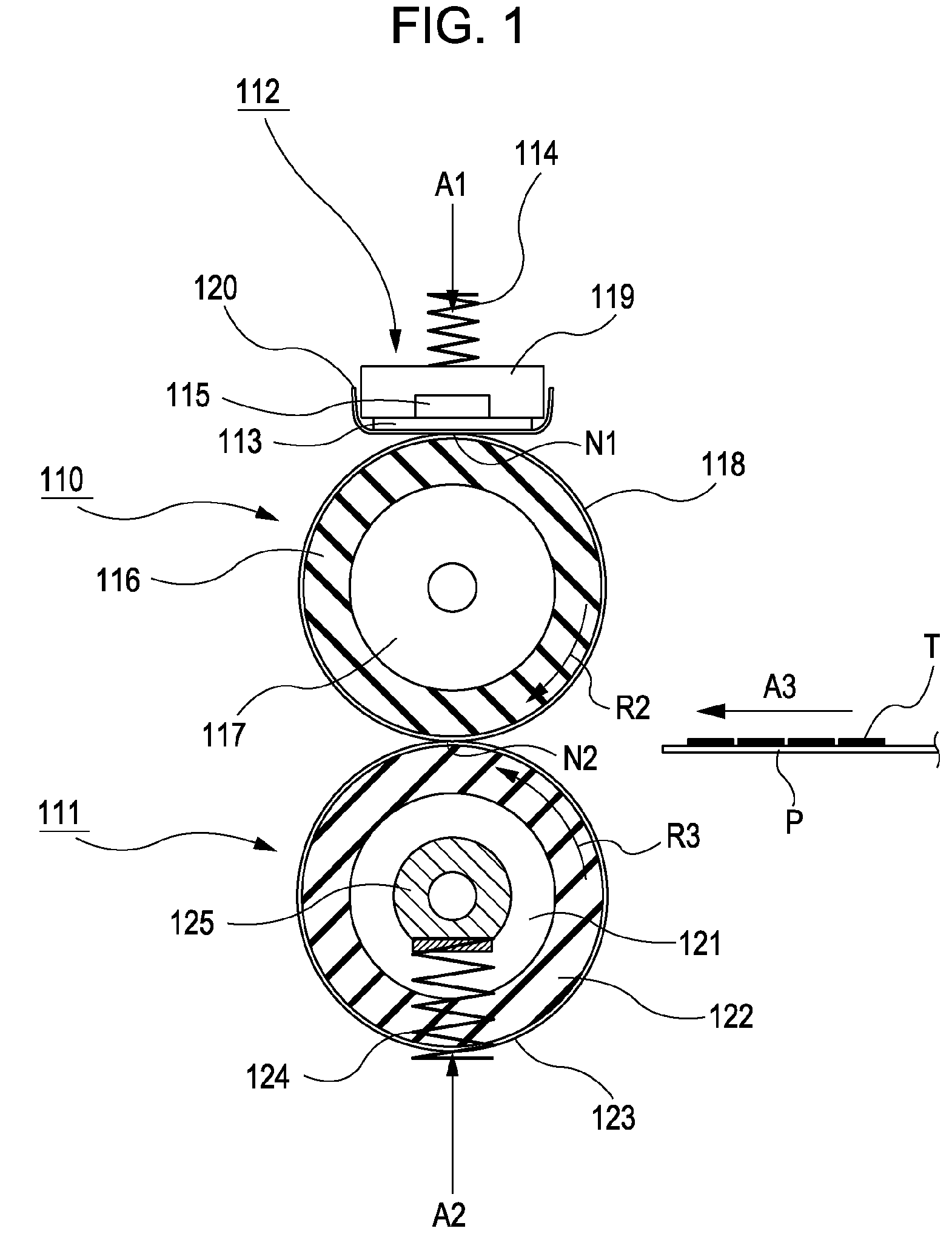

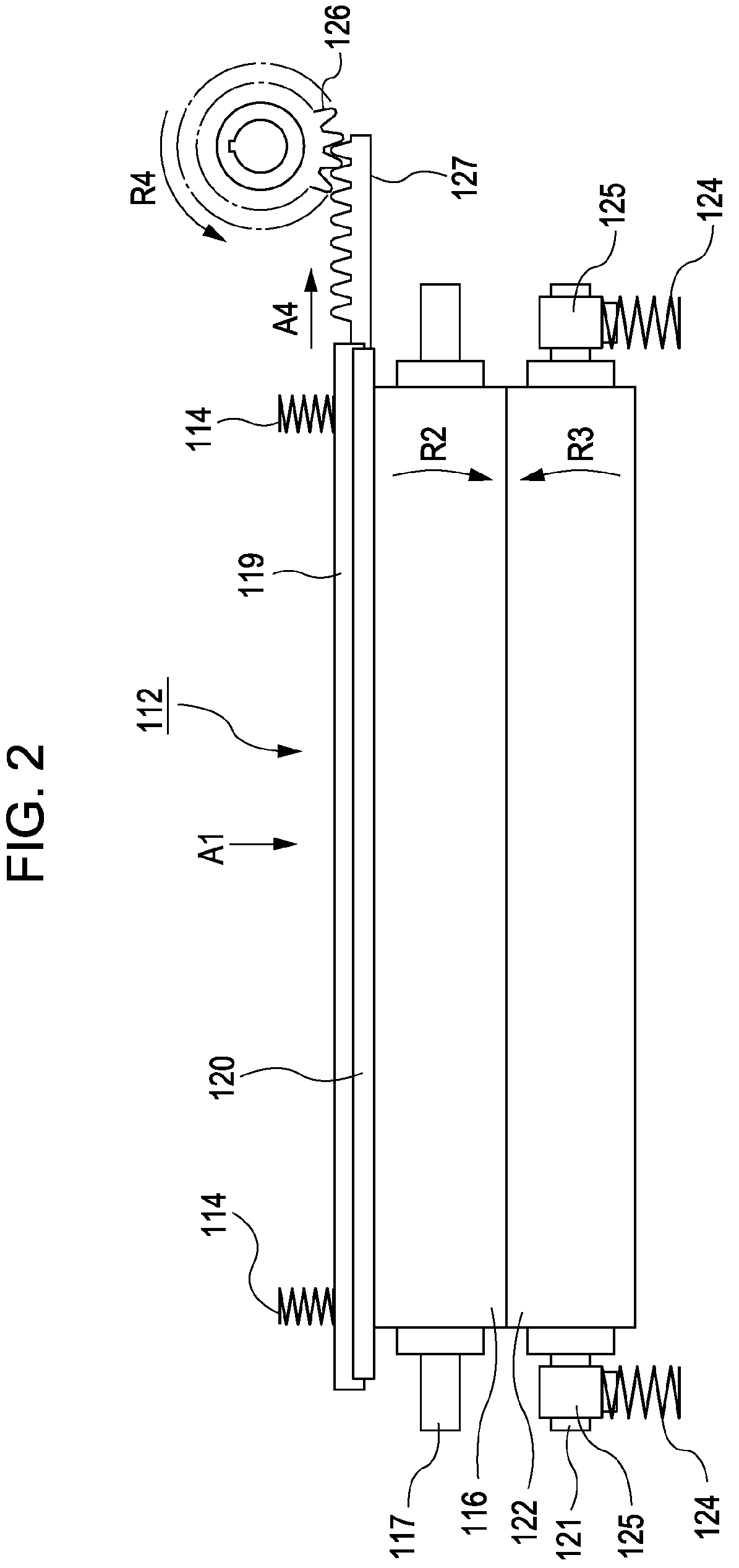

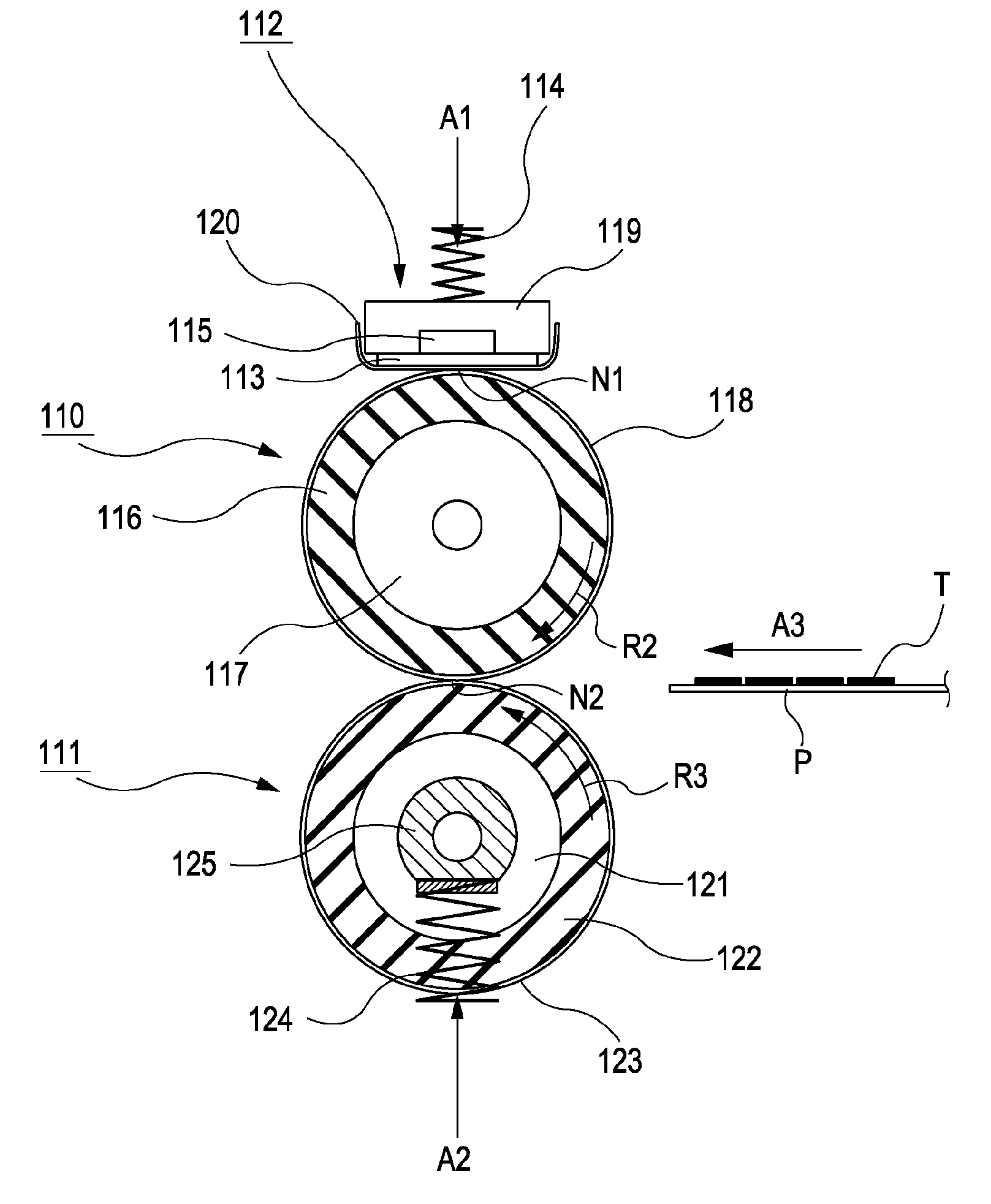

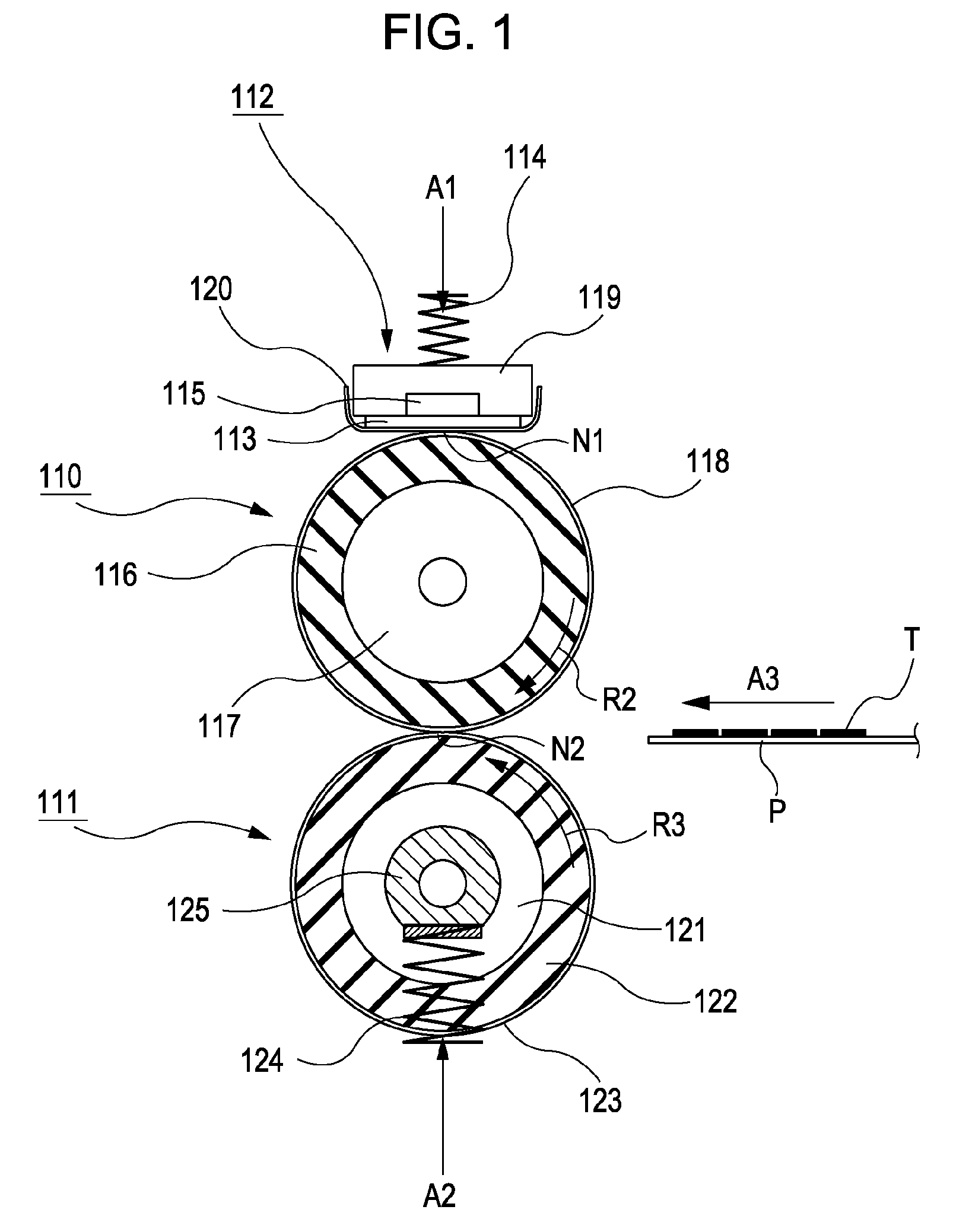

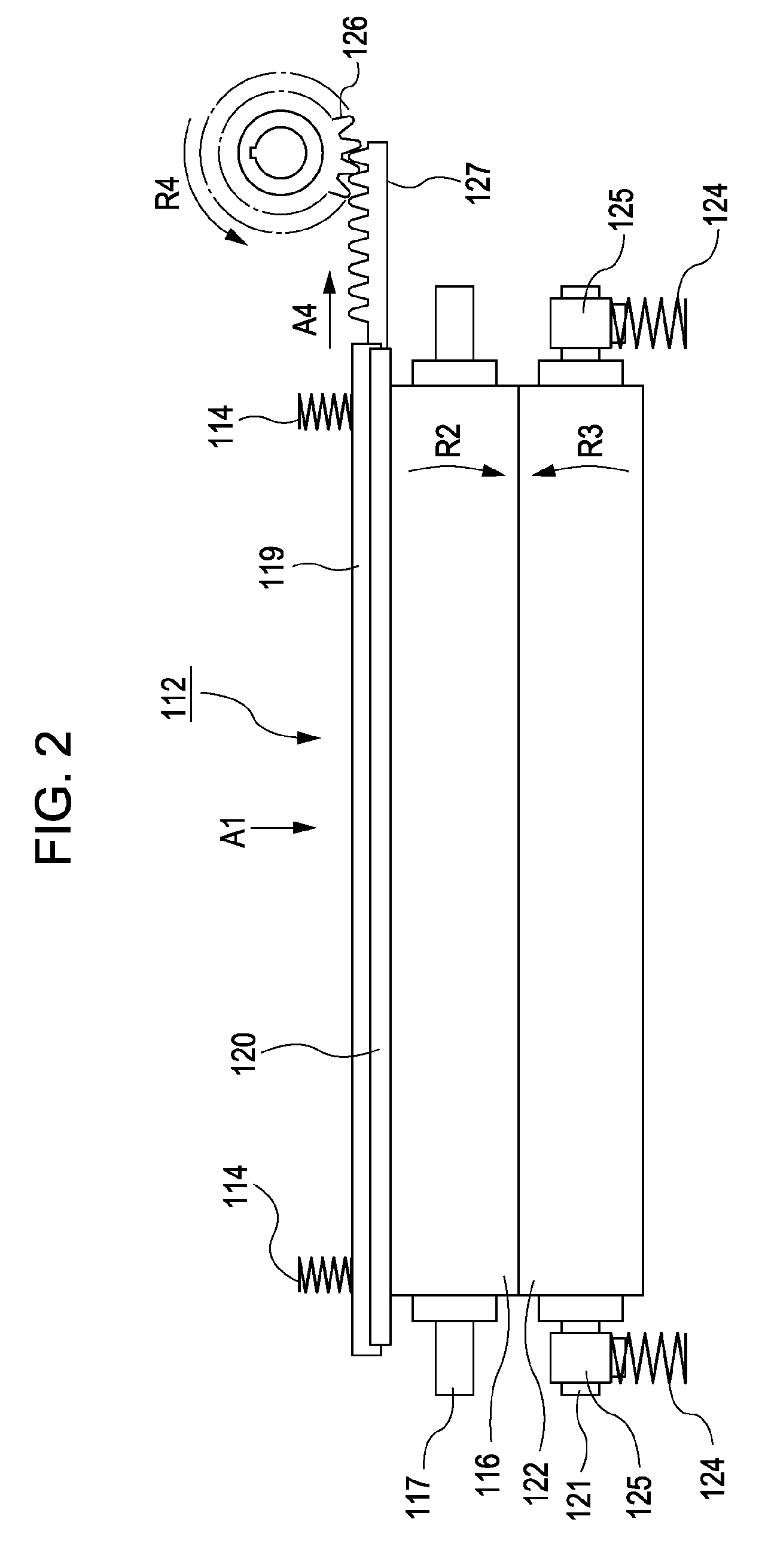

Image heating apparatus and image heating rotational body to be mounted on the image heating apparatus

InactiveUS8699930B2Improve image qualityAvoid scratchesElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

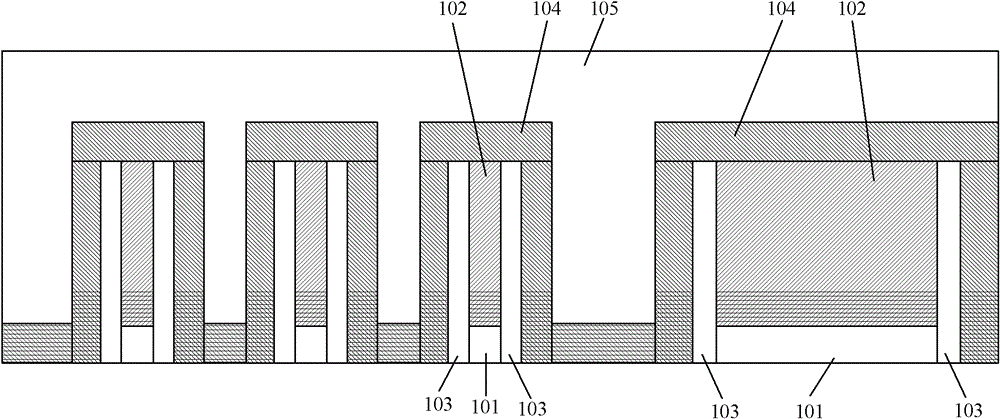

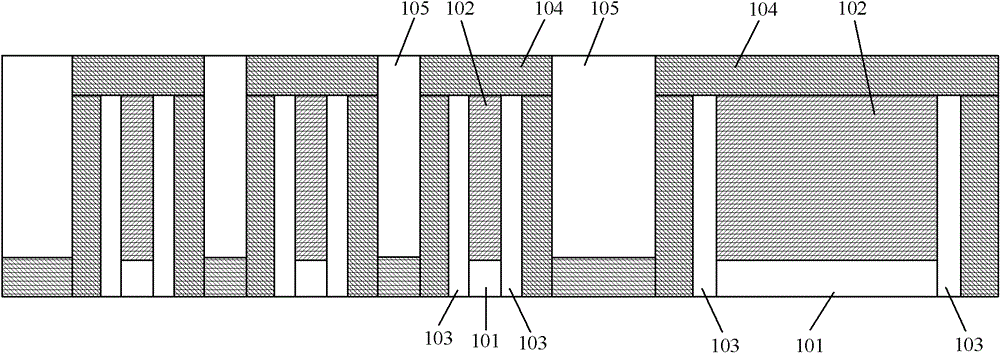

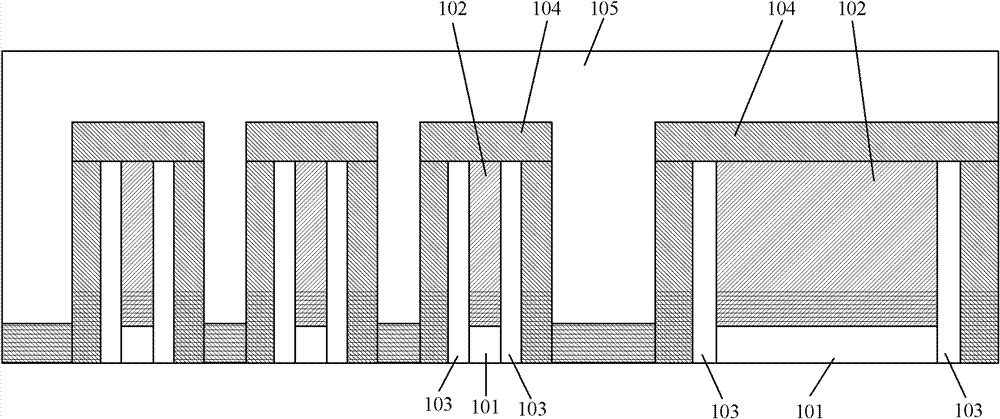

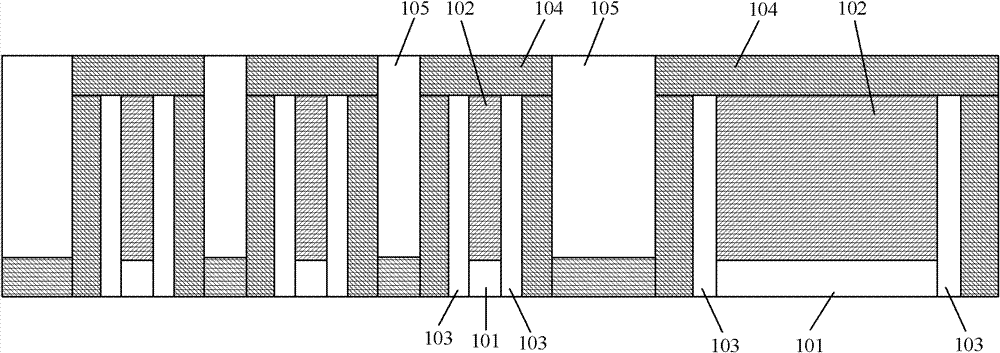

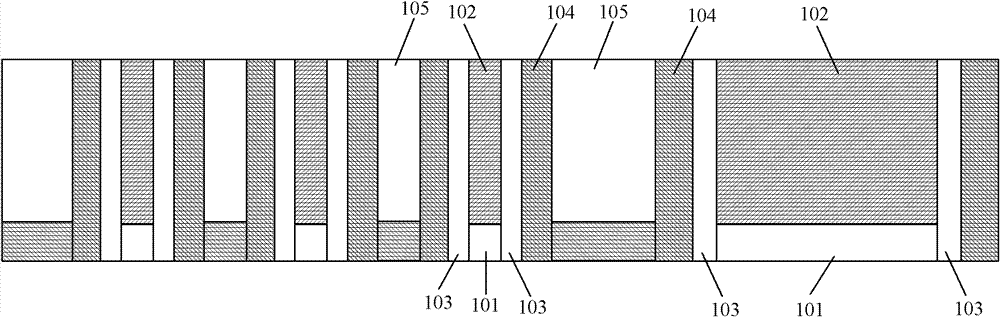

Polishing method and gate forming method

ActiveCN102800580ARepair scratchesEliminate residuePolishing machinesSemiconductor/solid-state device manufacturingGate dielectricDielectric layer

The invention discloses a polishing method and a gate forming method. The gate forming method comprises the following steps of: forming a pseudo-gate structure on a semiconductor substrate, wherein the pseudo-gate structure comprises a sacrificial oxide layer and a polysilicon layer which covers the sacrificial oxide layer; forming a side wall on the periphery of the pseudo-gate structure; forming a silicon nitride layer and a dielectric layer which covers the silicon nitride layer, wherein the silicon nitride layer covers the polysilicon layer, the side wall and the substrate; polishing the dielectric layer until the silicon nitride layer is exposed; polishing the silicon nitride layer and stopping polishing at the polysilicon layer; removing the pseudo-gate structure to form an opening; forming a gate dielectric layer and a metal layer which covers the gate dielectric layer in the opening in sequence; performing first-stage polishing operation on the metal layer until the dielectric layer is exposed to form a metal gate and a residual metal layer; and performing second-stage polishing operation on the metal layer, the dielectric layer and the silicon nitride layer by adopting a non-selective polishing solution to remove the residual metal layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

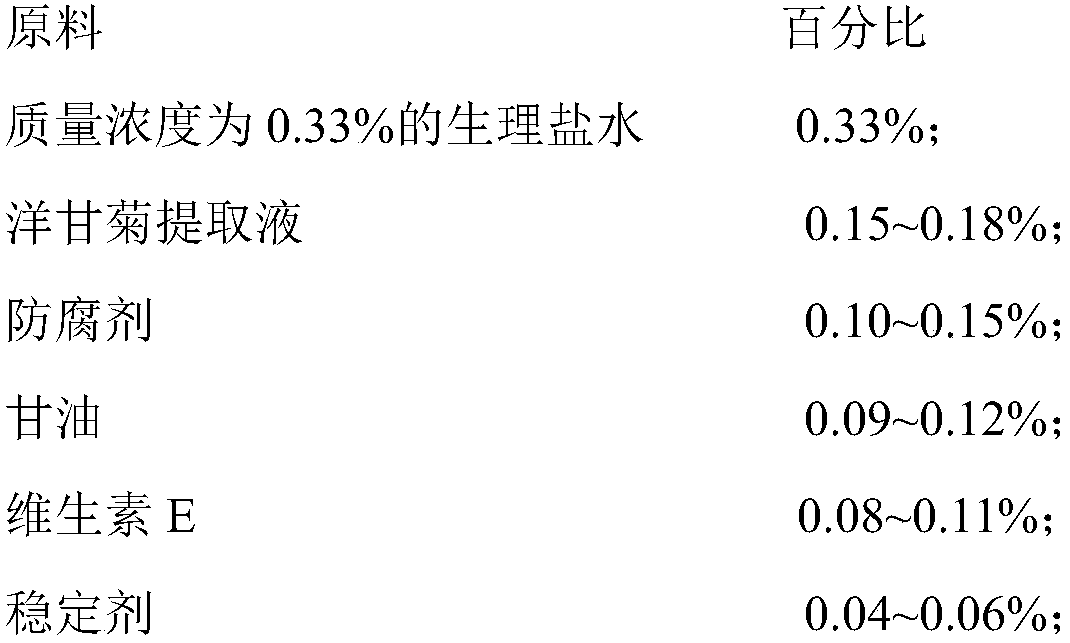

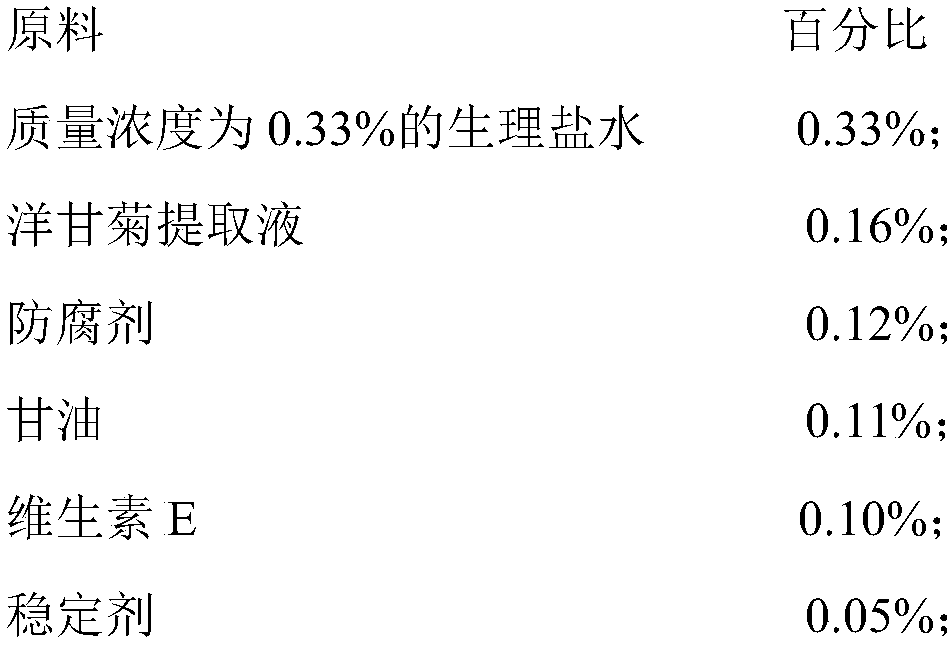

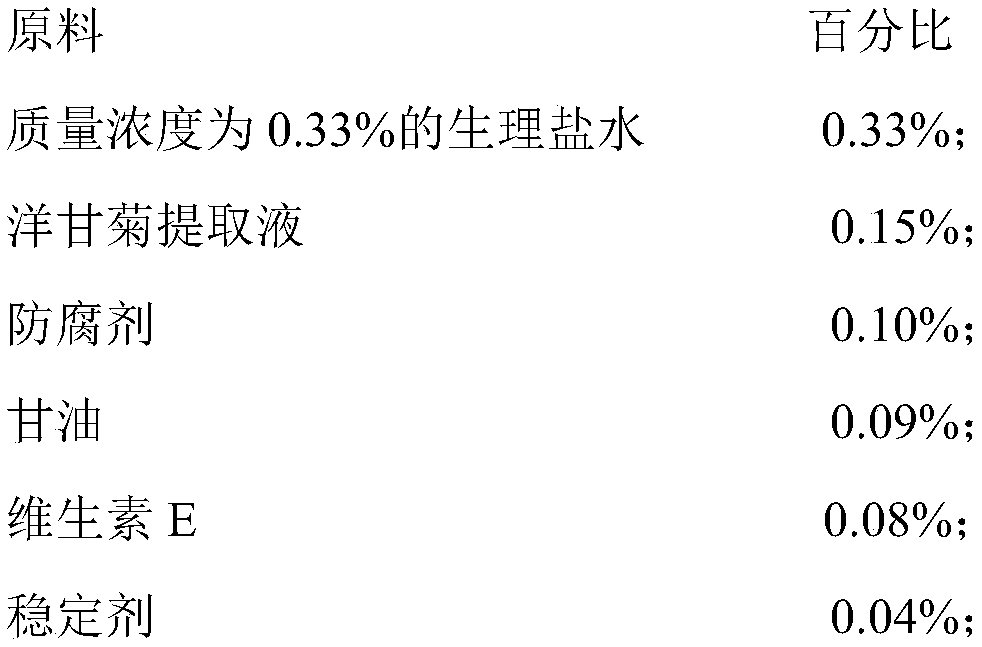

Nose mucus-cleaning soft wet wipes for babies and preparation process thereof

InactiveCN108078839AMild in natureStable in natureCosmetic preparationsToilet preparationsSide effectBronopol

The invention provides nose mucus-cleaning soft wet wipes for babies; an original liquid comprises 0.33% normal saline, a chamomile extract liquid, a preservative, glycerin, vitamin E, a stabilizer, and the balance RO pure water or deionized water, wherein the preservative is at least one of bronopol and polyaminopropyl biguanide; the stabilizer is at least one of EDTA-2Na and EDTA-4Na. The nose mucus-cleaning soft wet wipes for babies provided by the invention have the advantages of mild nature, simple preparation process, no damage to baby skin when in use, disinfection and sterilization effects, and no toxic or side effects.

Owner:福建鼻涕虫护理用品股份有限责任公司

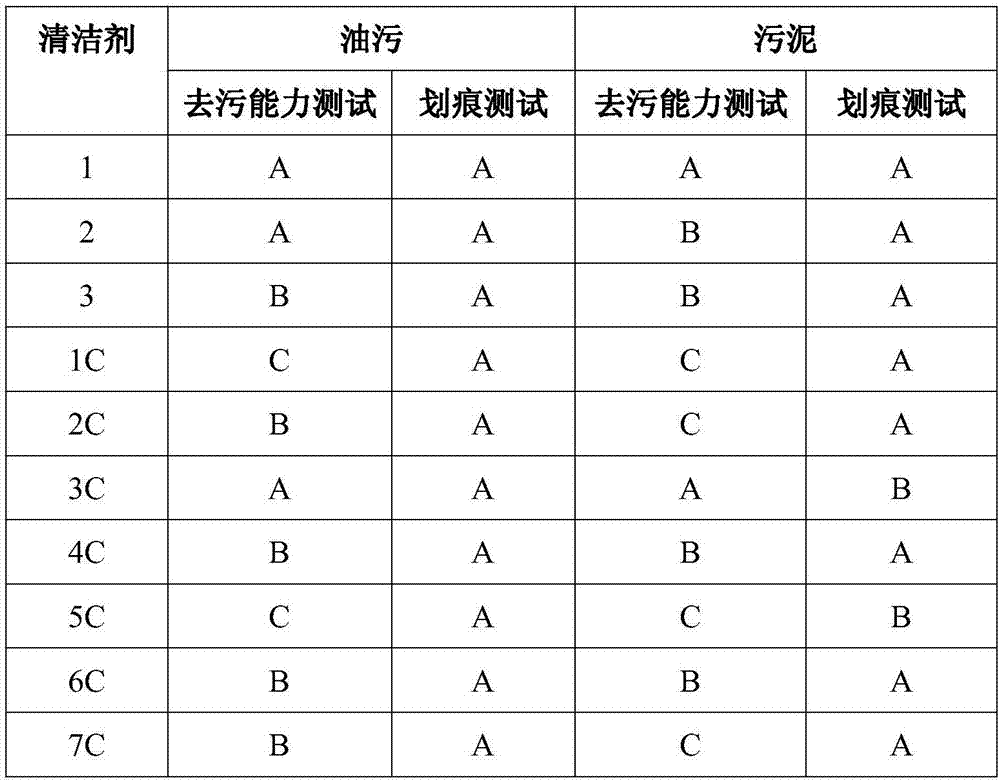

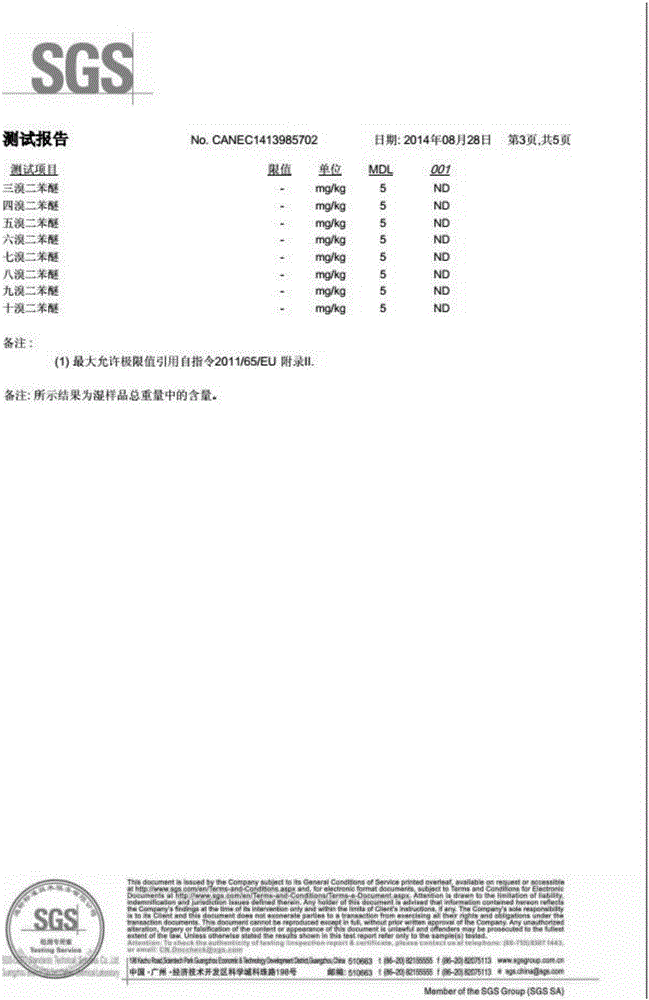

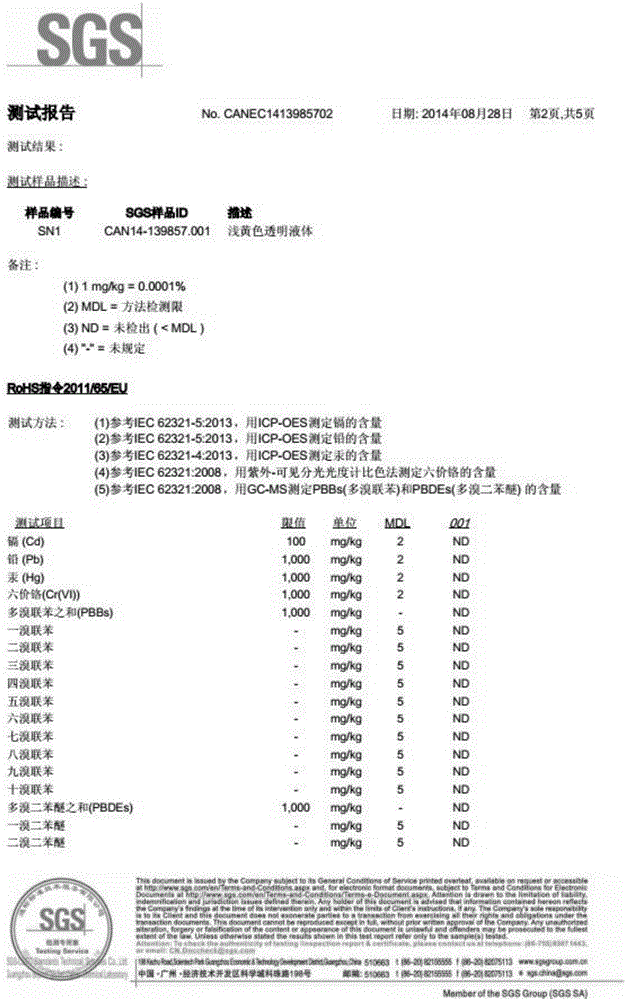

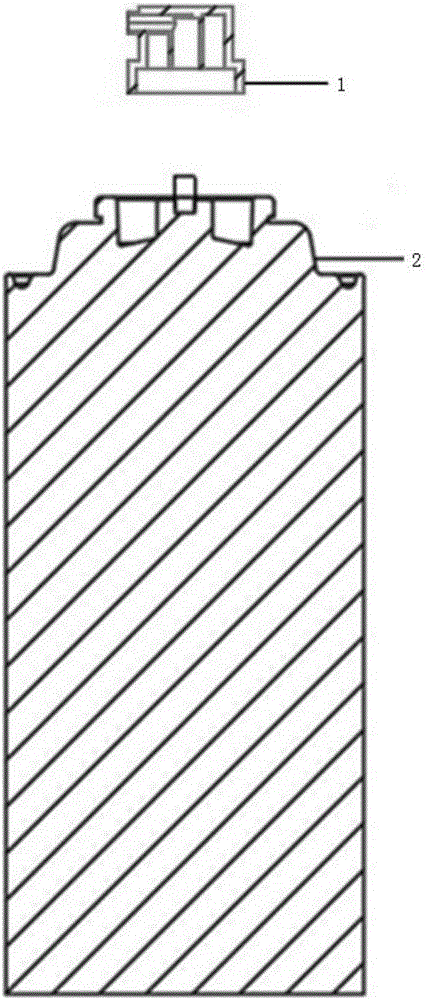

Computer accessory rapid cleaning agent, and preparation method and application method thereof

InactiveCN107189878AStrong decontamination abilityRepair scratchesInorganic/elemental detergent compounding agentsPolymeric surface-active compoundsChemistryCoconut oil

The invention relates to a computer accessory rapid cleaning agent, and a preparation method and an application method thereof. The main active components of the computer accessory rapid cleaning agent comprise, by weight, 1 to 3 parts of a nonionic surfactant, 10 to 18 parts of a ampholytic surfactant, 2.8 to 6.2 parts of a grinding aid, 30 to 80 parts of purified water, and 100 to 800 parts of ethanol; the nonionic surfactant is coconut oil fatty acid diethanolamide phosphate preferable, the ampholytic surfactant is dodecyl ethoxy sulfobetaine preferable, the grinding aid is dispersed nanometer titanium dioxide or dispersed nanometer silicon dioxide, and is obtained via combination of two different particles with a particle size lower than 100nm and a particle size ranging from 200 to 500nm. The computer accessory rapid cleaning agent possesses excellent decontamination capacity, and can be used for removing scratches, and the properties are much better than that of products in the prior art.

Owner:马爱连

Low-energy UV-curing automotive refinishing paint as well as application and usage method thereof

InactiveCN105925169AHigh densityHigh hardnessPolyurea/polyurethane coatingsVehicle servicing/repairingMethacrylateEthyl acetate

The invention provides low-energy UV-curing automotive refinishing paint. The paint comprises the following components in percentages by weight: three-functionality aliphatic polyurethane di-acrylate, ten-functionality aliphatic polyurethane hexaacrylate, trimethylolpropane trimethacrylate, ethoxylated bis phenol A dimethacrylate, 1-hydroxycyclohexyl phenyl ketone, 0-0.5% of 2-hydroxy-2-methylpropiophenone, a polyether siloxane copolymer, ethyl acetate, and 0-10% of xylene; the components are uniformly mixed in order to obtain the low-energy UV-curing automotive refinishing paint, the low-energy UV-curing automotive refinishing paint and liquefied compressed mixed gas are filled into an aerosol tank for uniformly mixing in order to obtain the aerosol low-energy UV-curing automotive refinishing paint. The paint is used for refinishing automobile body paint, repairing car lights, and the like; and the paint is environmentally friendly and nontoxic, heavy metals are not contained, and the paint can be used conveniently.

Owner:HUIZHOU DELAISH TECH CO LTD

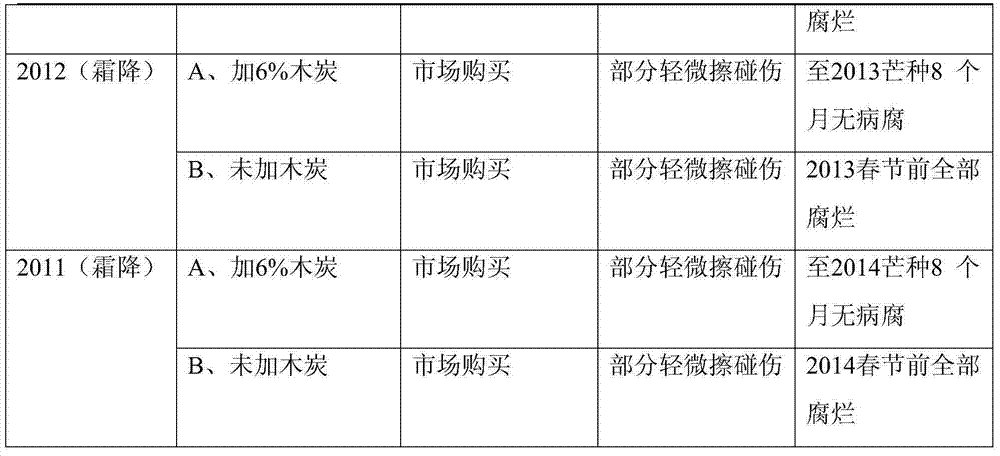

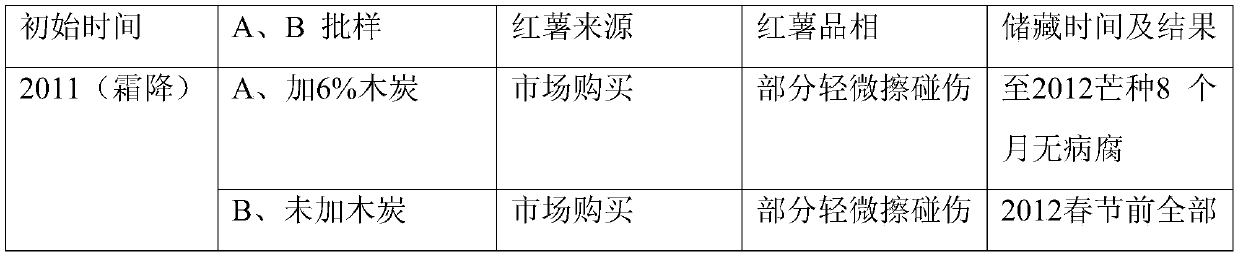

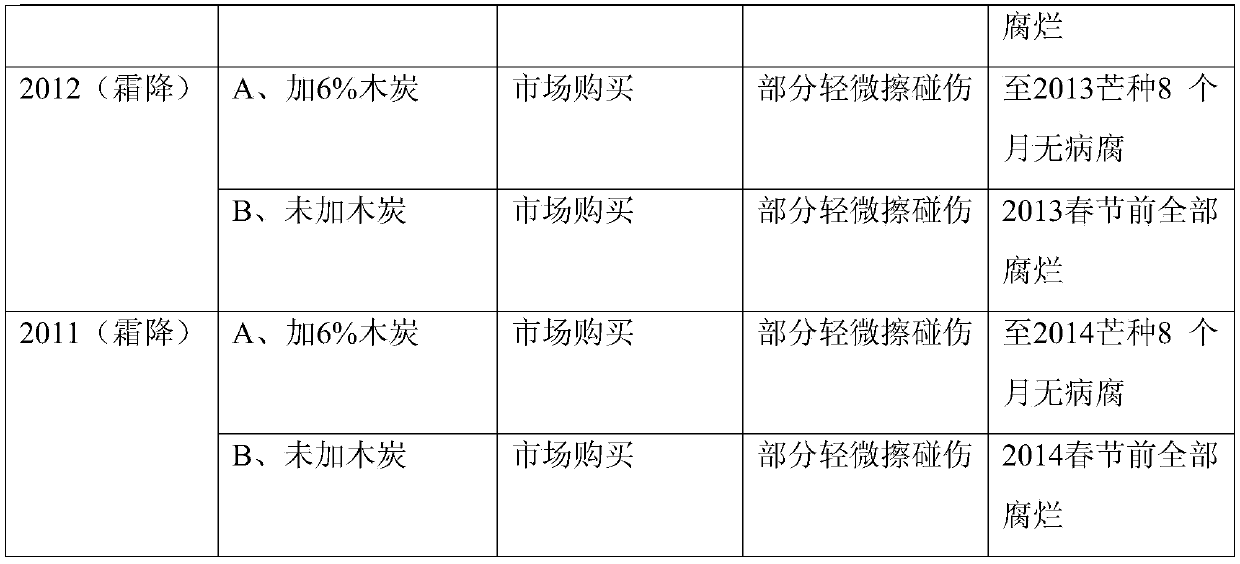

Storage method for sweet potato fresh keeping

InactiveCN107811040AReduce harmHumidity achievedFruits/vegetable preservation by coatingFood ingredient for microbe protectionSocial benefitsDisinfectant

The invention relates to a storage method for sweet potato fresh keeping. The method comprises the steps of sweet potato screening, sweet potato airing, plant ash airing, and mixing and storage of plant ash and sweet potatoes. The storage process of the invention does not need any chemical sterilization disinfectant or preservative, does not need investment of special shed cellars and thermoregulation and humidifying facilities, saves resources, has low costs, is environment-friendly, has no decay phenomenon in storage time, has long sweet potato storage time of up to 12 months or above. The obtained sweet potatoes basically have no difference from fresh sweet potatoes in color, mouth feel and nutrient aspect, and maintain the primary color and original taste of sweet potatoes. The storagemethod has advantages of simple operation, good fresh-keeping effect, long preservation time, low costs, has no harm to the human body, and high edible safety performance. The method can reduce the loss of sweet potato farmers and avoid pollution to environment, can enlarge population who eat sweet potatoes, increase consumption quantity, increase sweet potato value, increase the income of the sweet potato farmers and generate large social benefits, facilitates grain storage for people, and also makes greatly contribution for alleviating potential grain strategy safety in China.

Owner:GUANGXI JIPENG INVESTMENT CO LTD

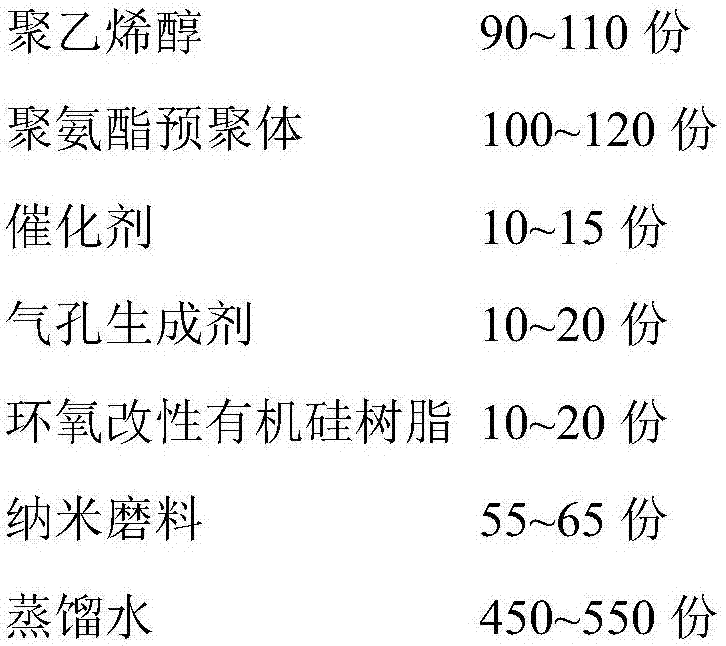

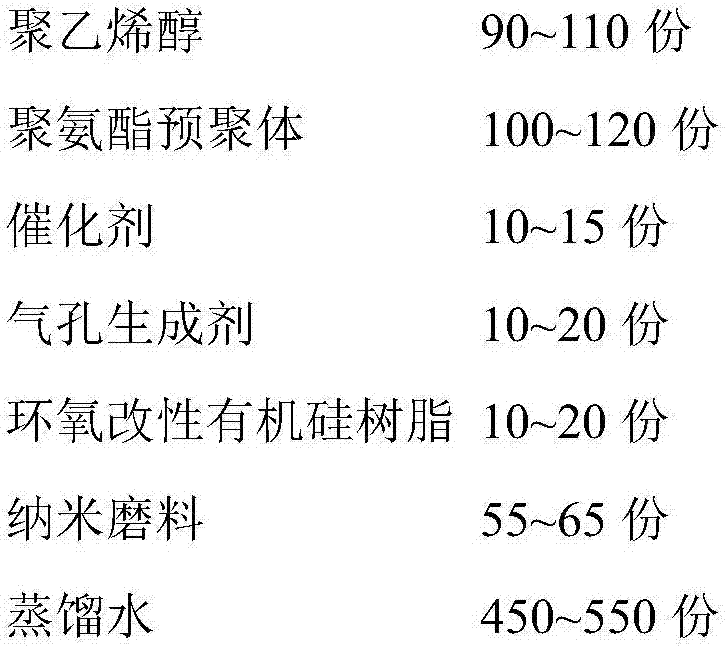

Wet-type fine polishing wheel and preparation method thereof

InactiveCN106891274AStrong sharpnessImprove wear resistanceAbrasion apparatusGrinding devicesEpoxyPolymer science

The invention discloses a wet-type fine polishing wheel which is prepared by the following components, by weight, 90-110 parts of polyvinyl alcohol, 100-120 parts of polyurethane prepolymer, 10-15 parts of catalysts, 10-20 parts of air hole forming agents, 10-20 parts of epoxy-modified silicone resin, 55-65 parts of nano abrasives and 450-550 parts of distilled water; the catalysts comprise stannous octoate and dibutyltin dilaurate; the air hole forming agents comprise one or more of a foaming agent, a foam stabilizer, a foam homogenizing agent and a hole filling agent; and an epoxide number of the epoxy-modified silicone resin is 0.03-0.08. The fine polishing wheel has high resilience and flexibility and super-high sharpness and abrasion resistance, can effectively repair scratches, and has outstanding effects particularly on the grinding and polishing of arcs and uneven surfaces. The invention further discloses a preparation method of the wet-type fine polishing wheel.

Owner:台山市远鹏研磨科技有限公司

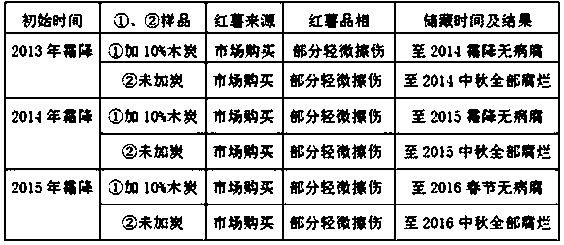

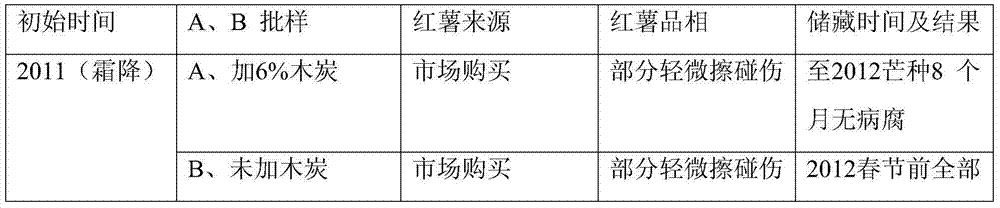

Method for storing sweet potatoes through charcoal functions

ActiveCN104115630AExtended storage timeNo disease and rotAgriculture tools and machinesHarvested fruit hanging devicesDiseaseAgricultural science

The invention belongs to the field of sweet potato storage, and particularly relates to a method for storing sweet potatoes through charcoal functions. The sweet potatoes and wood charcoal / bamboo charcoal are stored mixedly under an air composition environment where the temperature ranges from 1 DEG C to 26 DEG C and the humidity is natural, at least six kilograms of the wood charcoal / bamboo charcoal are allocated to one hundred kilograms of the sweet potatoes, and the distance between the sweet potatoes and the charcoal is smaller than 30 centimeters. The method is used for storing the sweet potatoes, and therefore the sweet potatoes can be stored for more than eight months and have no disease or decay phenomena; in the storage process, neither chemical sterilization disinfectant nor preservative is needed, and special sheds, pits and temperature and humidity regulation facilities are not needed. The wood charcoal for storage can be repeatedly used, storage cost is reduced, and meanwhile the requirement for the environment of sweet potato storage is greatly reduced. The storage process is simplified, the problem that it is difficult to store the sweet potatoes for a long time is solved, and the method is convenient to popularize and makes a great contribution to protection of potential grain strategy safety of our country.

Owner:段甲明

Coating method capable of maintaining original color of aluminum alloy tanker

ActiveCN104070000ARepair scratchesFix blackPolyurea/polyurethane coatingsSpecial surfacesWeather resistanceAlloy substrate

The invention relates to the field of coating of aluminum alloy tankers, in particular to a coating method capable of maintaining an original color of an aluminum alloy tanker. The coating method includes the following steps: step 1, processing before coating; step 2, repairing appearance defect positions of an aluminum alloy substrate; step 3, coating varnish. By the coating method, appearance defects like scratches, blackening and corrosion of the surface of aluminum alloy can be repaired, original unique metal colors of an aluminum alloy tank body and aluminum alloy parts of the aluminum alloy tanker can be maintained, and self-made repair layer painting and self-made painting special for aluminum alloy, which are coated by the coating method have excellent adhesiveness and weatherability; the painting special for the self-made aluminum alloy has high transparency, and the whole surface of an aluminum alloy workpiece is enabled to present high gloss, so that color and glossiness of the whole surface of the aluminum alloy workpiece are enabled to present uniform effect.

Owner:东莞市永强汽车制造有限公司

Car windshield cleaning agent

InactiveCN109762672AGood antibacterial and mildew resistancePlay a role in promoting each otherInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPolyvinyl alcoholSoftened water

The invention relates to the field of car cleaning products, in particular to a car windshield cleaning agent. The car windshield cleaning agent is prepared from the components in percentage by weight: a surfactant, specifically, 2%-6% of a compound of tea saponin and sodium n-decyl diphenyl ether disulfonate; an organic solvent, specifically, 30%-40% of ethanol and glycerin; an antistatic agent,specifically, 0.2%-1% of esteryl quaternary ammonium salt ethylene glycol; an antifogging agent, specifically, 0.1%-0.8% of polyacrylamide and polyvinyl alcohol; a corrosion inhibitor, specifically, 0.1%-2% of a compound of tartaric acid, sodium citrate and sodium silicate; an antifoaming agent, specifically, 1.0%-1.5% of emulsified silicone oil; essence, specifically, 0.01%-5% of mint flavor; andthe balance of softened water.

Owner:FOSHAN DELIAN AUTOMOTIVE ACCESSORIES CO LTD

The method of storing sweet potato by using charcoal function

ActiveCN104115630BExtended storage timeNo disease and rotAgriculture tools and machinesHarvested fruit hanging devicesDiseasePreservative

The invention belongs to the field of sweet potato storage, and particularly relates to a method for storing sweet potatoes through charcoal functions. The sweet potatoes and wood charcoal / bamboo charcoal are stored mixedly under an air composition environment where the temperature ranges from 1 DEG C to 26 DEG C and the humidity is natural, at least six kilograms of the wood charcoal / bamboo charcoal are allocated to one hundred kilograms of the sweet potatoes, and the distance between the sweet potatoes and the charcoal is smaller than 30 centimeters. The method is used for storing the sweet potatoes, and therefore the sweet potatoes can be stored for more than eight months and have no disease or decay phenomena; in the storage process, neither chemical sterilization disinfectant nor preservative is needed, and special sheds, pits and temperature and humidity regulation facilities are not needed. The wood charcoal for storage can be repeatedly used, storage cost is reduced, and meanwhile the requirement for the environment of sweet potato storage is greatly reduced. The storage process is simplified, the problem that it is difficult to store the sweet potatoes for a long time is solved, and the method is convenient to popularize and makes a great contribution to protection of potential grain strategy safety of our country.

Owner:段甲明

Image heating apparatus and image heating rotational body to be mounted on the image heating apparatus

InactiveUS20130251429A1Improve image qualityAvoid scratchesElectrographic process apparatusElectrical and Electronics engineering

Owner:CANON KK

Renewing protective soft film for automobile and furniture

The invention discloses a new protective soft membrane for car and furniture with pH value at 6.2-6.8, which comprises the following parts: 30-40% methyl silicon oil, 30-40% silicon benzenemethyl and 20-30% silicone grease. The invention possesses excellent insulating and flame-proof property, which is fit for broader temperature scale (-50-+150 deg.c).

Owner:吕东江

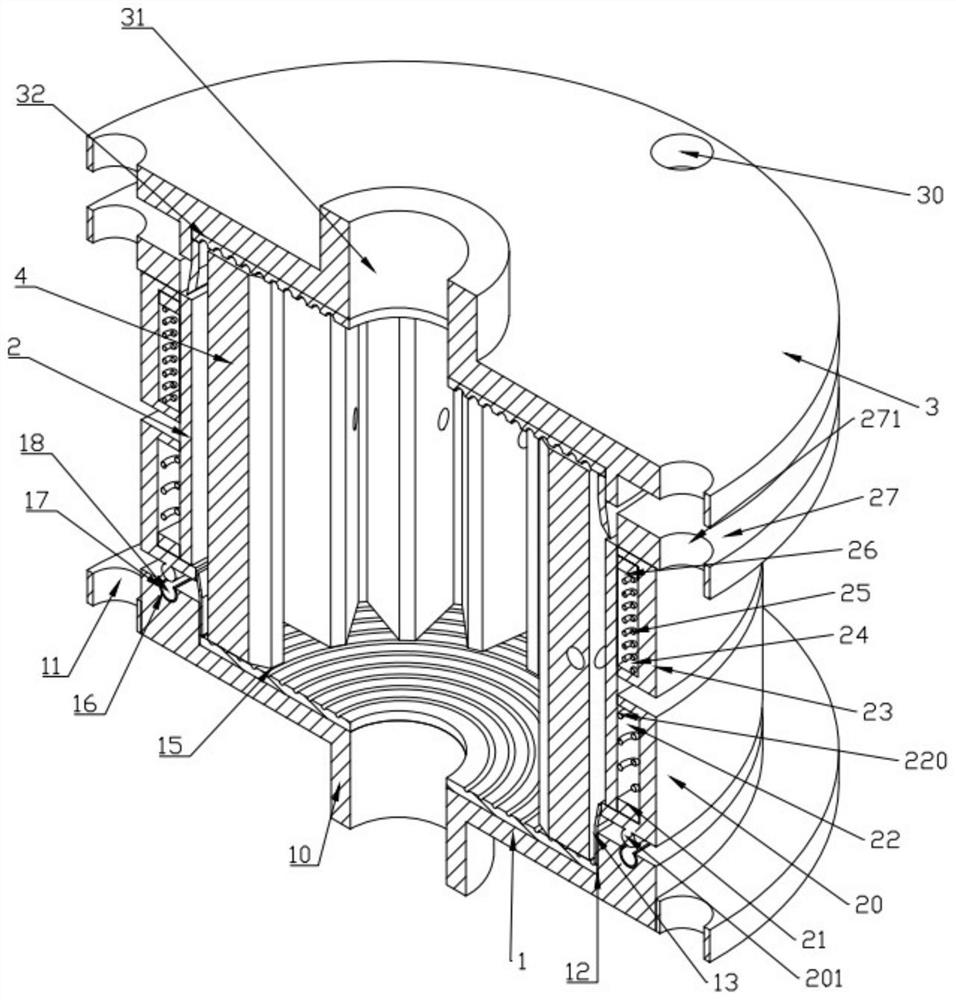

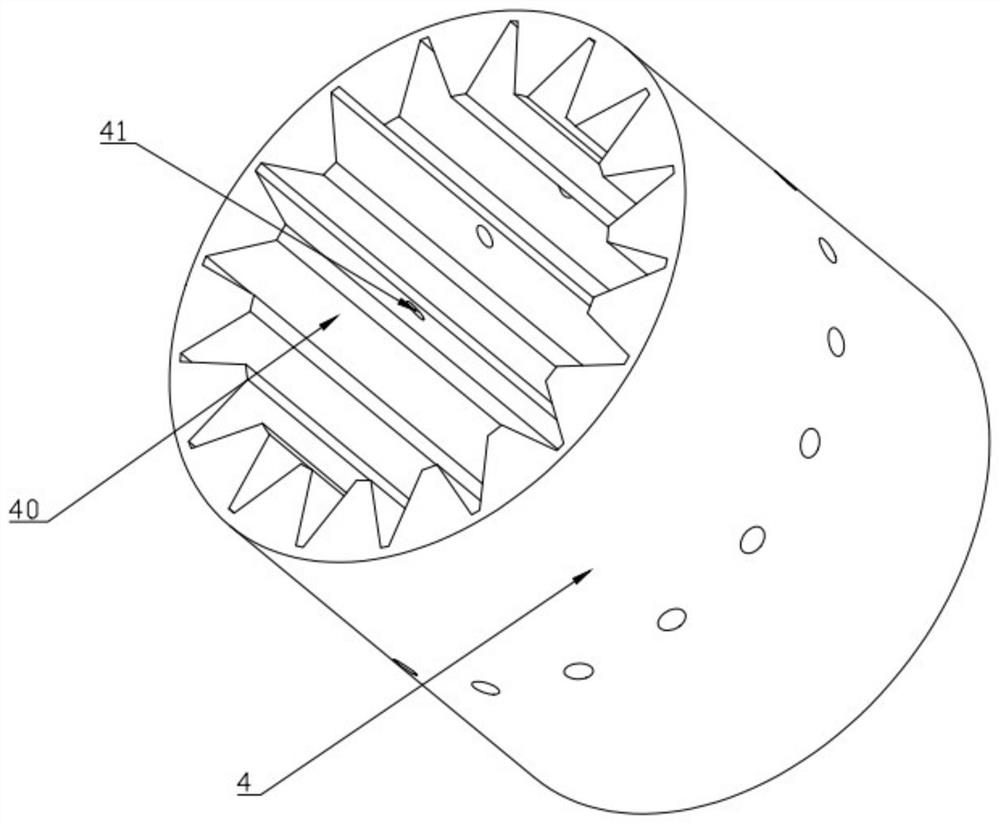

A surface refinement treatment device for internal gears

ActiveCN113524011BImprove removal efficiencyImprove sanding effectEdge grinding machinesGrinding carriagesGear wheelWear particle

Owner:JIANGSU AIRSHIP GEAR

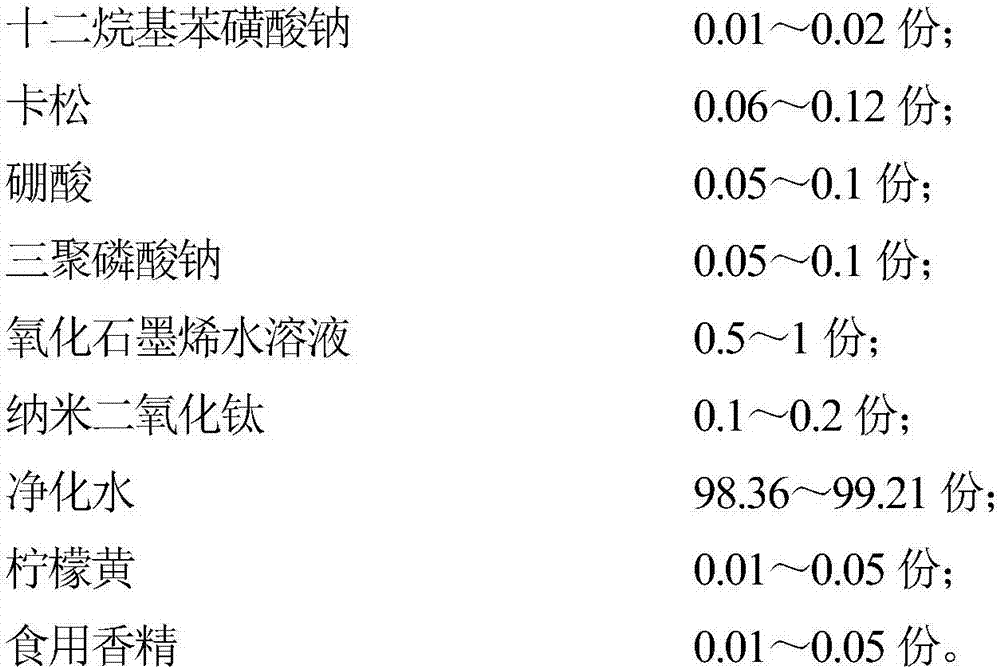

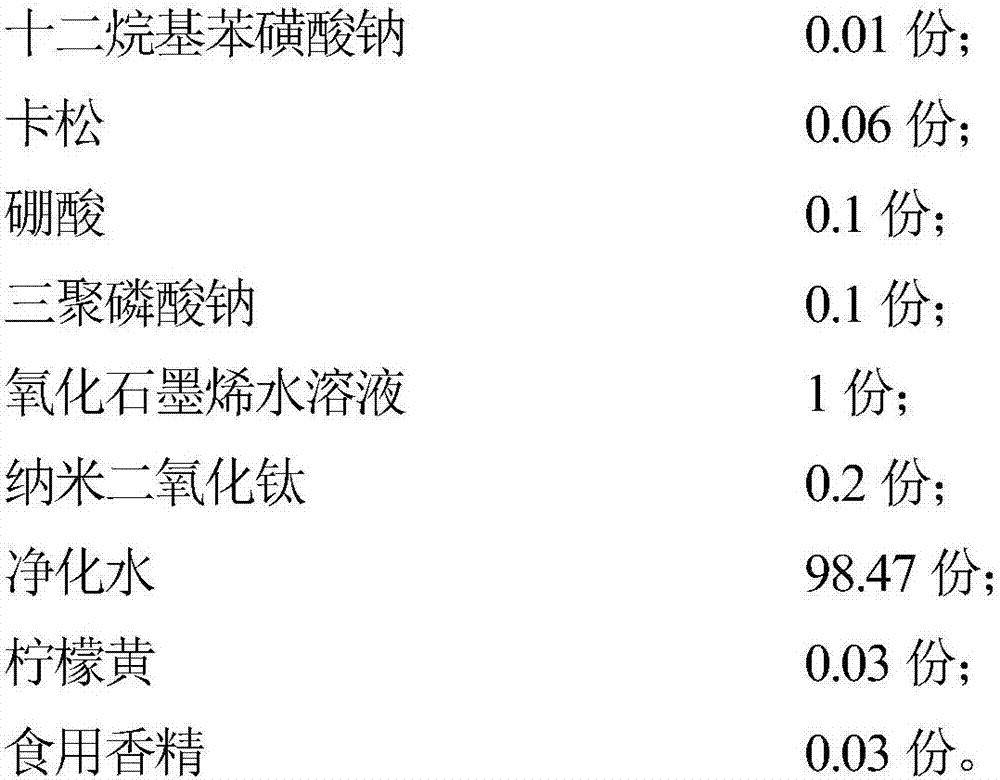

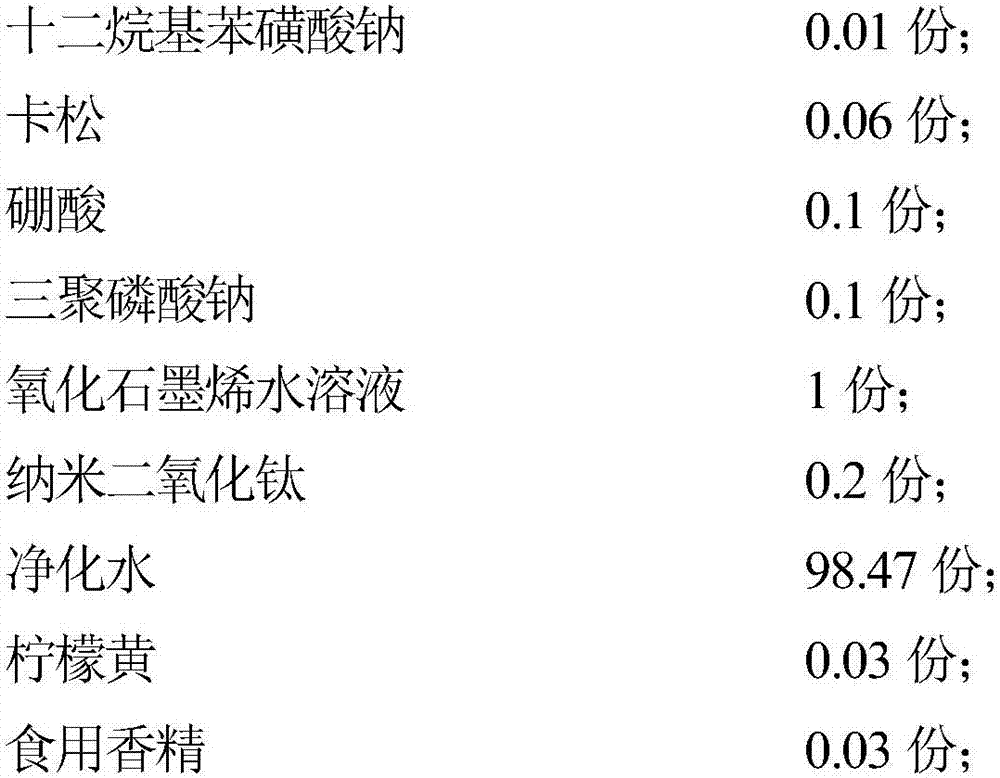

Anti-ultraviolet, antibiosis, self-repairing and water accumulation-elimination environmentally-friendly summer windshield washer fluid

InactiveCN107488522AImprove barrier propertiesRepair scratchesInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsUltravioletBoric acid

The invention relates to the field of windshield washer fluids, and especially relates to an anti-ultraviolet, antibiosis, self-repairing and water accumulation-elimination environmentally-friendly summer windshield washer fluid. The windshield washer fluid is prepared through uniformly mixing, by weight, 0.01-0.02 part of sodium dodecyl benzene sulfonate, 0.06-0.12 part of Kathon, 0.05-0.1 part of boric acid, 0.05-0.1 part of sodium tripolyphosphate, 0.5-1 part of an aqueous solution of graphene oxide, 0.1-0.2 part of nanometer titanium dioxide, 98.36-99.21 parts of purified water, 0.01-0.05 part of lemon yellow and 0.01-0.05 part of an edible essence. The windshield washer fluid has anti-ultraviolet, antibiosis, self-repairing, water accumulation elimination and environment protection functions.

Owner:LIAONING LANJING TECH CO LTD

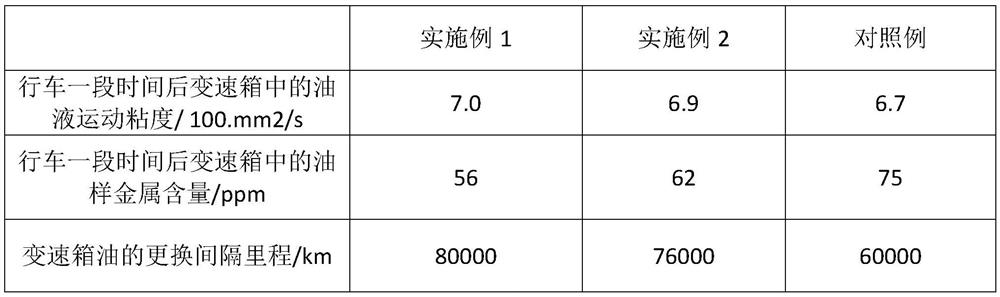

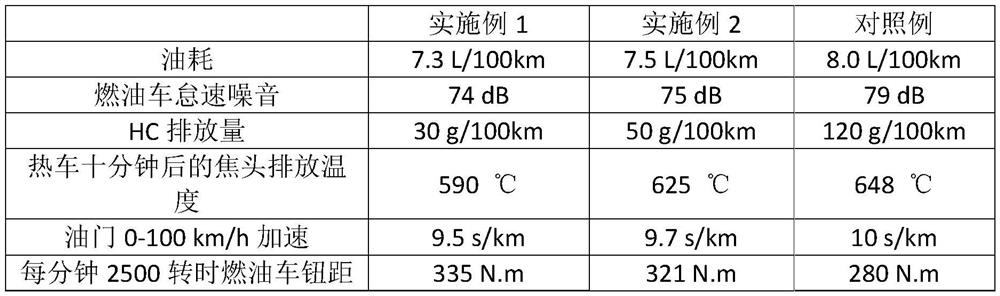

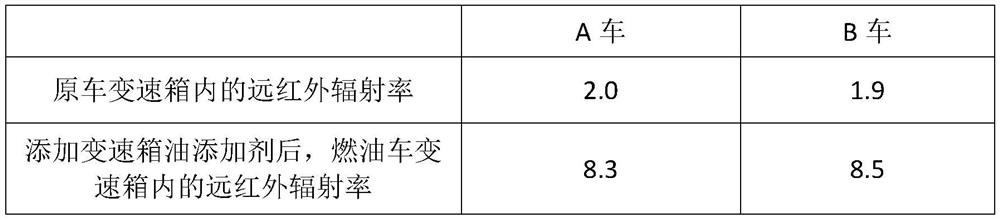

Gearbox oil additive for gearbox of fuel vehicle and preparation method of gearbox oil additive

The invention discloses a gearbox oil additive for a gearbox of a fuel vehicle, which is characterized in that the gearbox oil additive comprises gearbox oil, water-based nano gold and water-based nano platinum. The invention further discloses a preparation method of the gearbox oil additive. By adding the gearbox oil additive into the gearbox of the fuel vehicle and fusing the gearbox oil additive with the gearbox oil in the gearbox, the stability of the gearbox oil can be kept, and the anti-attenuation performance of the gearbox oil can be improved, so that the gearbox is better protected, and the service life of the gearbox is prolonged. Meanwhile, friction is generated under stirring of the gearbox, so that a large amount of far infrared rays are generated, the far infrared rays are guided into the engine in a penetrating mode through the contact parts of the main shaft, the gearbox shell and the engine shell, the engine is indirectly affected, and the combustion efficiency of the engine is improved.

Owner:速马力(广州)环保研究院有限责任公司

Leather care solution and preparation method thereof

The invention relates to a leather care solution and a preparation method thereof. The leather care solution comprises the following components in parts by mass: 2 to 4 parts of nanoscale water-based wax emulsion, 1 to 3 parts of nano silicon dioxide emulsion, 2.5 to 4 parts of olive oil, 3 to 4 parts of an emulgator, 10 to 15 parts of a seaweed extract, 2 to 4 parts of an aloe extract, 3 to 5 parts of high alcohols and 64.9 to 74.4 parts of deionized water, wherein the solid content of the nanoscale water-based wax emulsion is 20 to 25 wt.%, and the solid content of the nano silicon dioxide emulsion is 20 to 25 wt.%. The leather care solution can effectively moisten and soften leather, prevents the ageing of the leather, and increases the wear-resisting property and the gloss of the leather, thus prolonging the service life of the leather.

Owner:深圳市艾思生物技术有限公司

Polishing method and gate forming method

ActiveCN102800580BRepair scratchesEliminate residuePolishing machinesSemiconductor/solid-state device manufacturingGate dielectricDielectric layer

The invention discloses a polishing method and a gate forming method. The gate forming method comprises the following steps of: forming a pseudo-gate structure on a semiconductor substrate, wherein the pseudo-gate structure comprises a sacrificial oxide layer and a polysilicon layer which covers the sacrificial oxide layer; forming a side wall on the periphery of the pseudo-gate structure; forming a silicon nitride layer and a dielectric layer which covers the silicon nitride layer, wherein the silicon nitride layer covers the polysilicon layer, the side wall and the substrate; polishing the dielectric layer until the silicon nitride layer is exposed; polishing the silicon nitride layer and stopping polishing at the polysilicon layer; removing the pseudo-gate structure to form an opening; forming a gate dielectric layer and a metal layer which covers the gate dielectric layer in the opening in sequence; performing first-stage polishing operation on the metal layer until the dielectric layer is exposed to form a metal gate and a residual metal layer; and performing second-stage polishing operation on the metal layer, the dielectric layer and the silicon nitride layer by adopting a non-selective polishing solution to remove the residual metal layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Renewing protective soft film for automobile and furniture

The invention discloses a new protective soft membrane for car and furniture with pH value at 6.2-6.8, which comprises the following parts: 30-40% methyl silicon oil, 30-40% silicon benzenemethyl and 20-30% silicone grease. The invention possesses excellent insulating and flame-proof property, which is fit for broader temperature scale (-50-+150 deg.c).

Owner:吕东江

A kind of conductive polymer microcapsule of reactive liquid core material and preparation method thereof

InactiveCN104028184BEffective control contentEasy to prepareCoatingsMicroballoon preparationMaterials preparationLiquid core

The invention relates to a conductive polymer microcapsule of a reactive liquid core material and a preparation method thereof, belonging to the technical field of preparation of functional materials. The preparation method is as follows: configure an aqueous solution containing surfactant at room temperature, heat it to 30-60°C, add a reactive liquid core material 0.05-0.25 times its mass, and stir at a speed of 200-2000rpm for 10-30min, then Reduce the stirring speed to 50-200rpm and continue for 30-120min. After natural cooling, the product is washed with deionized water to obtain a suspension; add an aqueous solution of an acidic oxidant or an aqueous solution of a heteroaromatic ring monomer that is 1 to 5 times the mass of the core material to the suspension , after reacting for 5 to 20 minutes at room temperature and under mechanical stirring at 100 to 300 rpm, add 5 to 20 times at intervals of 2 to 20 minutes and add heteroaromatic ring monomers whose total amount is equivalent to 1 to 5 times the mass of the core material The aqueous solution or the acidic oxidant aqueous solution is polymerized for 1-12 hours, and finally washed with deionized water and dried, and the aqueous solution added for the first time in this step is not the same substance as the aqueous solution added later. The method of the invention is simple, the raw material is cheap, and the product is easy to collect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A coating method to keep the original color of aluminum alloy tank car

ActiveCN104070000BRepair scratchesUnique metallic colorPolyurea/polyurethane coatingsSpecial surfacesWeather resistanceVarnish

The invention relates to the field of coating of aluminum alloy tank cars, in particular to a coating method for maintaining the original color of aluminum alloy tank cars. The coating method for maintaining the original color of the aluminum alloy tank car comprises the following steps: step 1, pre-painting treatment; step 2, repairing the appearance defects of the aluminum alloy base; and step 3, coating varnish. The coating method for maintaining the original color of the aluminum alloy tank car provided by the invention can not only repair the appearance defects such as scratches, scratches, blackening and corrosion on the surface of the aluminum alloy, but also make the aluminum alloy tank body and the aluminum alloy tank body of the aluminum alloy tank car The parts maintain the original unique metallic color. The self-made repair layer coating and the self-made aluminum alloy special coating applied by this coating method have excellent adhesion and weather resistance; and the self-made aluminum alloy special coating has high transparency, making the whole The surface of the aluminum alloy workpiece exhibits high gloss, so that the color and gloss of the entire aluminum alloy workpiece surface are uniform.

Owner:东莞市永强汽车制造有限公司

Two-film lubricating oil

The invention relates to two-film lubricating oil, which is prepared from the following raw materials in percentage by mass: 0.8 to 2.5 percent of characteristic additive, 1.7 to 3.8 percent of antioxidant, 1.6 to 4.8 percent of detergent, 1.0 to 3.4 percent of dispersing agent, 1.0 to 9.0 percent of viscosity index improver, 0.3 to 0.8 percent of pour point depressant, 0.006 to 0.01 percent of antifoaming agent and the balance of base oil. The invention has the advantages that: the two-film lubricating oil is anticorrosive and antirust, effectively removes carbon deposit and even removes the original rust stain of an engine, has longer service life and lower cost, is environmentally-friendly, and has high antiwear and antifriction performance and a good fuel saving effect, wherein the fuel saving ratio of an automobile per 100 kilometers is 6 to 10 percent, the fuel saving ratio of a large truck per 100 kilometers is 6 to 9 percent, and the fuel saving ratio of a small sedan per 100 kilometers is 8 to 10 percent.

Owner:BEIJING ALLUBE PETROCHEM

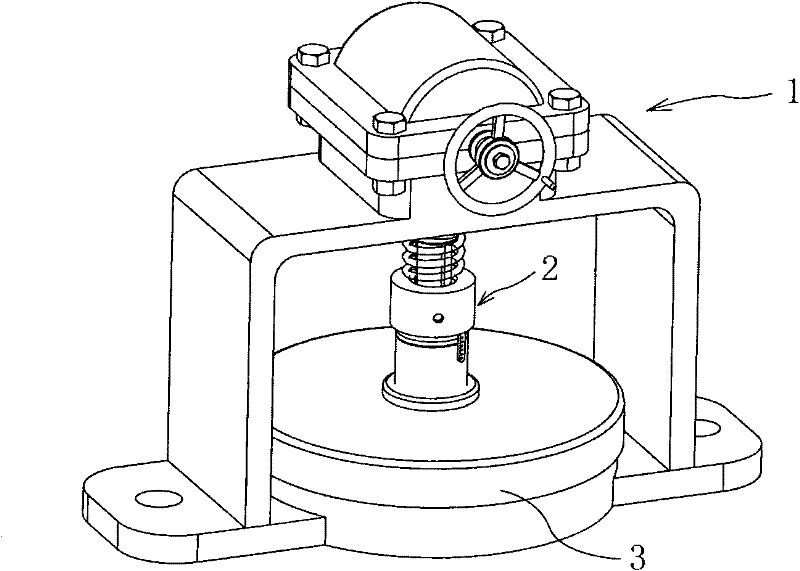

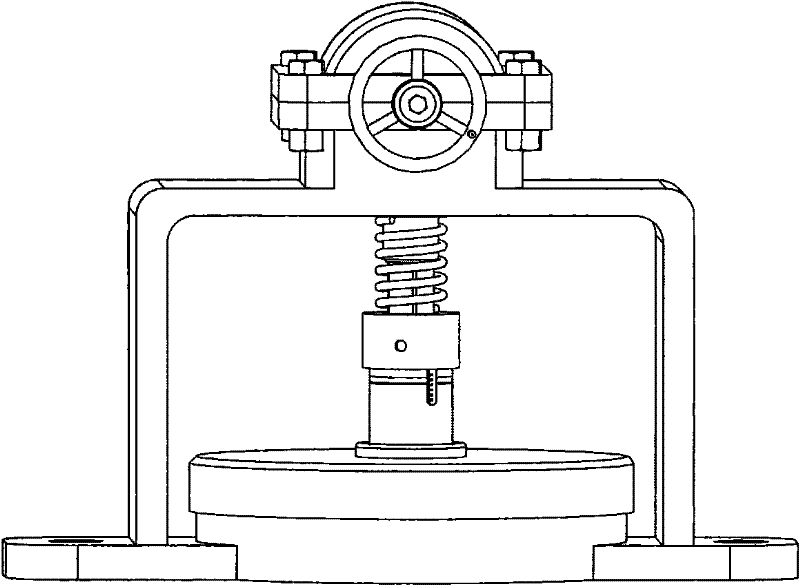

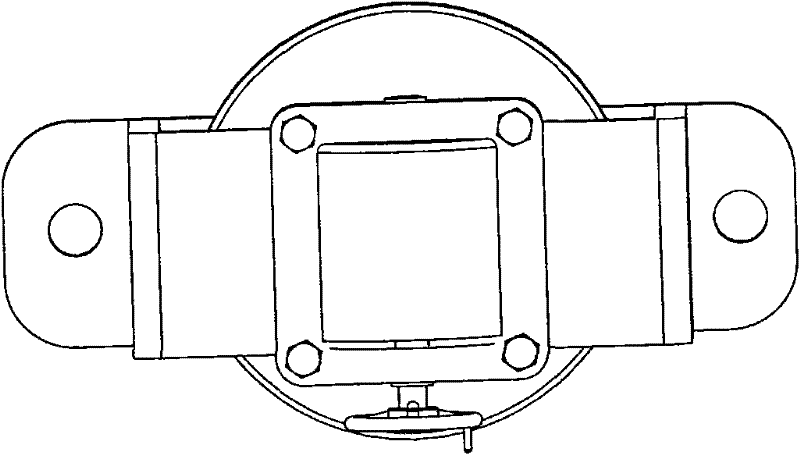

Thrust bearing shoe sharpening machine and repair method

InactiveCN101856798BEasy to useGuaranteed reusePlane surface grinding machinesThrust bearingSharpening

The invention relates to a thrust bearing shoe sharpening machine and a repair method, which mainly aim to overcome the defect of low shoe repair utilization rate in the repair of a conventional thrust bearing shoe. The sharpening machine comprises a shoe positioning mechanism, a sharpener positioning mechanism and a drive mechanism which are used for positioning the shoe and a selected sharpenerrespectively and providing a sharpening driving force. The repair method mainly comprises a shoe positioning step, a sharpened surface selection and positioning step, a sharpening step and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Linseed oil microcapsules capable of rapid film formation and timely repair of scratches and preparation method thereof

InactiveCN103897471BGood lookingUniform and controllable particle sizeCoatingsMicroballoon preparationFreeze-dryingOxygen

The invention relates to linseed oil microcapsules capable of quickly forming films to timely repair scratches and a preparation method thereof. According to the microcapsules, linseed oil is used as capsule cores, gelatin is used as a wall material, the capsules are spherical, the average capsule diameter is 20 microns, the capsule walls are uniform, and the surfaces of the microcapsules are smooth. The preparation method comprises the steps of preparing gelatin emulsion and linseed oil emulsion respectively, dripping the linseed oil emulsion into the gelatin emulsion while stirring, and emulsifying the two phases together; adding glacial acetic acid to adjust the pH value of the solution to 4.8, adding an aqueous solution of anhydrous sodium sulfate, and cooling to 20 DEG C to wrap the capsule walls compactly; dripping formaldehyde while stirring, curing capsule films to obtain a solution, and performing freeze drying on the solution to obtain white linseed oil microcapsule solid powder. The gelatin and the linseed oil are emulsified respectively and then emulsified together, so that the linseed oil microcapsules are good in shape, easy in capsule diameter control and stable in solvents such as water, dimethyl benzene and the like; after the microcapsules are added into a coating, the light scattering is weak, and the appearance of the coating is not affected; the linseed oil flowing out after the microcapsules are broken can quickly form the films in oxygen to timely repair the scratches.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com