Two-film lubricating oil

A technology of lubricating oil and characteristics, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of low stability and shear strength, increased carbon volume of engine, corrosion and damage of engine parts, etc., to achieve excellent anti-wear Anti-friction performance, good fuel saving effect, effect of prolonging engine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

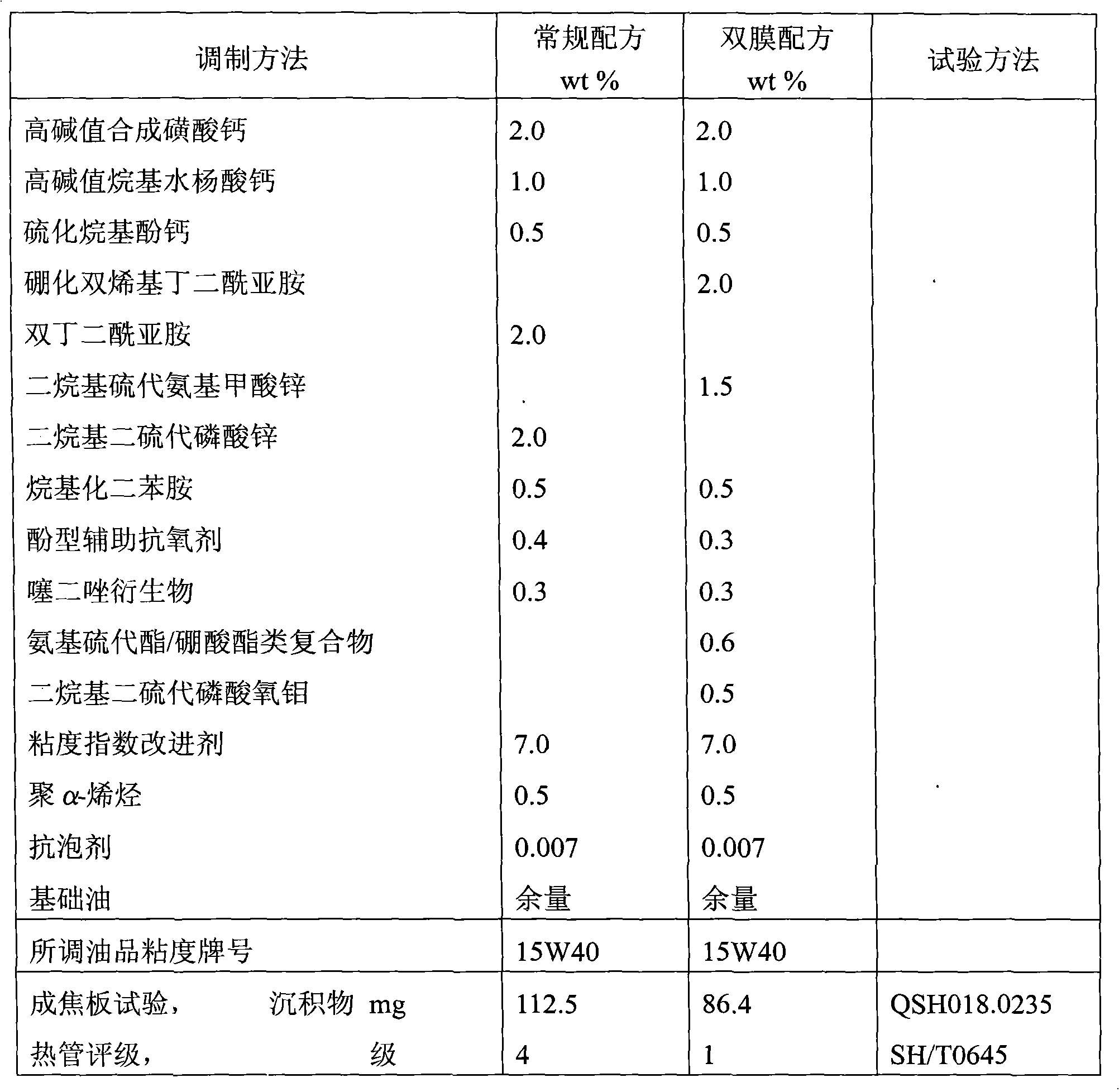

Embodiment 1

[0018] The double-film lubricating oil described in Example 1 of the present invention is made from the raw materials of the following qualities: 0.6 kg of aminothio fat and amino thio fat compound, 0.5 kg of molybdenum dialkylthiophosphate; 1.5kg of zinc dialkylthiocarbamate, 0.5kg of alkylated diphenylamine, 0.3kg of thiadiazole derivatives, and 0.3kg of phenolic auxiliary antioxidants were selected as the oxidizing agent; 1.0kg of high base value alkyl calcium salicylate, 0.5kg of sulfurized alkyl phenate calcium; 2.0kg of borated dienyl succinimide as dispersant; ethylene-propylene copolymer (OPC) and polyvinyl chloride as viscosity indicator 7kg of viscosity index improver compounded with methacrylate (PMA); 0.5kg of polyα-olefin was used as pour point depressant; 0.007kg of methyl silicone oil compounded antifoam agent was used as antifoaming agent, and the balance was base oil.

[0019] During production, weigh the material according to the weight of each component, add...

Embodiment 2

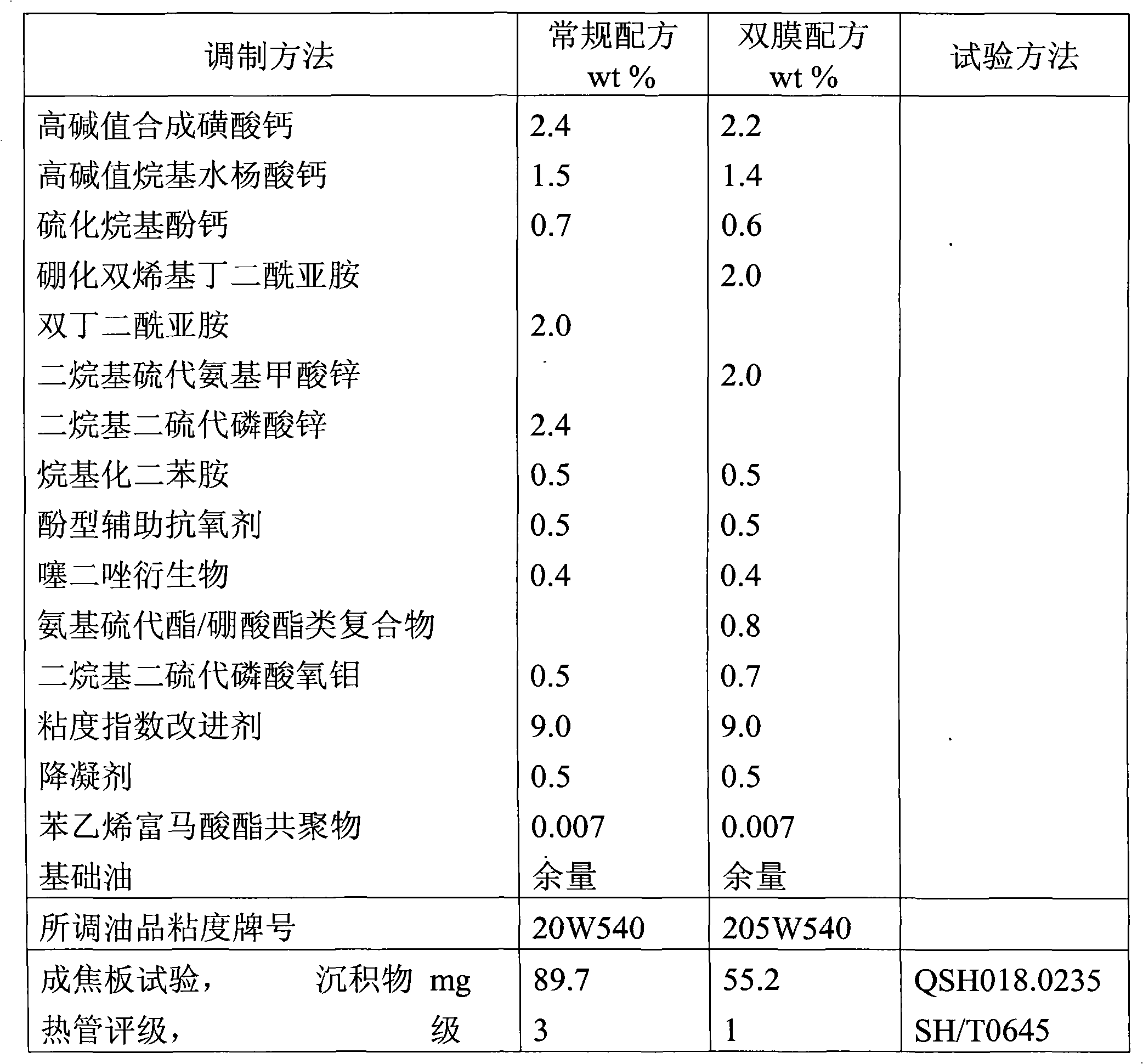

[0026] The double-film lubricating oil described in Example 2 of the present invention is made from the following raw materials: 0.8kg of aminothiofat and aminothiofat compound, 0.7kg of molybdenum dialkylthiophosphate for use as characteristic additives; 2.0kg of zinc dialkylthiocarbamate, 0.5kg of alkylated diphenylamine, 0.4kg of thiadiazole derivatives, 0.5kg of phenolic auxiliary antioxidant were selected as oxidant; High base value alkyl salicylate calcium 1.4kg, sulfurized alkyl phenate calcium 0.6kg; dispersant selected from borated dienyl succinimide 2.0kg; viscosity indicator selected from ethylene-propylene copolymer (OPC) and poly Methacrylate (PMA) composite viscosity index improver 9kg; pour point depressant selected styrene fumarate copolymer 0.5kg; antifoam agent selected methyl silicone oil composite antifoam agent 0.007kg, the balance is base oil.

[0027] During production, weigh the material according to the weight of each component, add the base oil into t...

Embodiment 3

[0037] The double-film lubricating oil described in Example 3 of the present invention is made from the raw materials of the following qualities: 0.6 kg of aminothio fat and amino thio fat compound, 0.6 kg of dialkyl molybdenum thiophosphate; 2.0kg of zinc dialkylthiocarbamate, 0.5kg of alkylated diphenylamine, 0.4kg of thiadiazole derivatives, and 0.4kg of phenolic auxiliary antioxidant were selected as oxidants; Medium alkali value alkyl salicylate calcium 1.0kg, sulfurized alkyl phenate calcium 0.6kg; dispersant selected from borated dienyl succinimide 2.0kg; viscosity indicator selected from ethylene-propylene copolymer (OPC) and poly 7kg of viscosity index improver compounded with methacrylate (PMA); 0.5kg of polyα-olefin was used as pour point depressant; 0.007kg of methyl silicone oil compounded antifoam agent was used as antifoaming agent, and the balance was base oil.

[0038] During production, weigh the material according to the weight of each component, add the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com