Patents

Literature

107results about How to "Good antibacterial and mildew resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

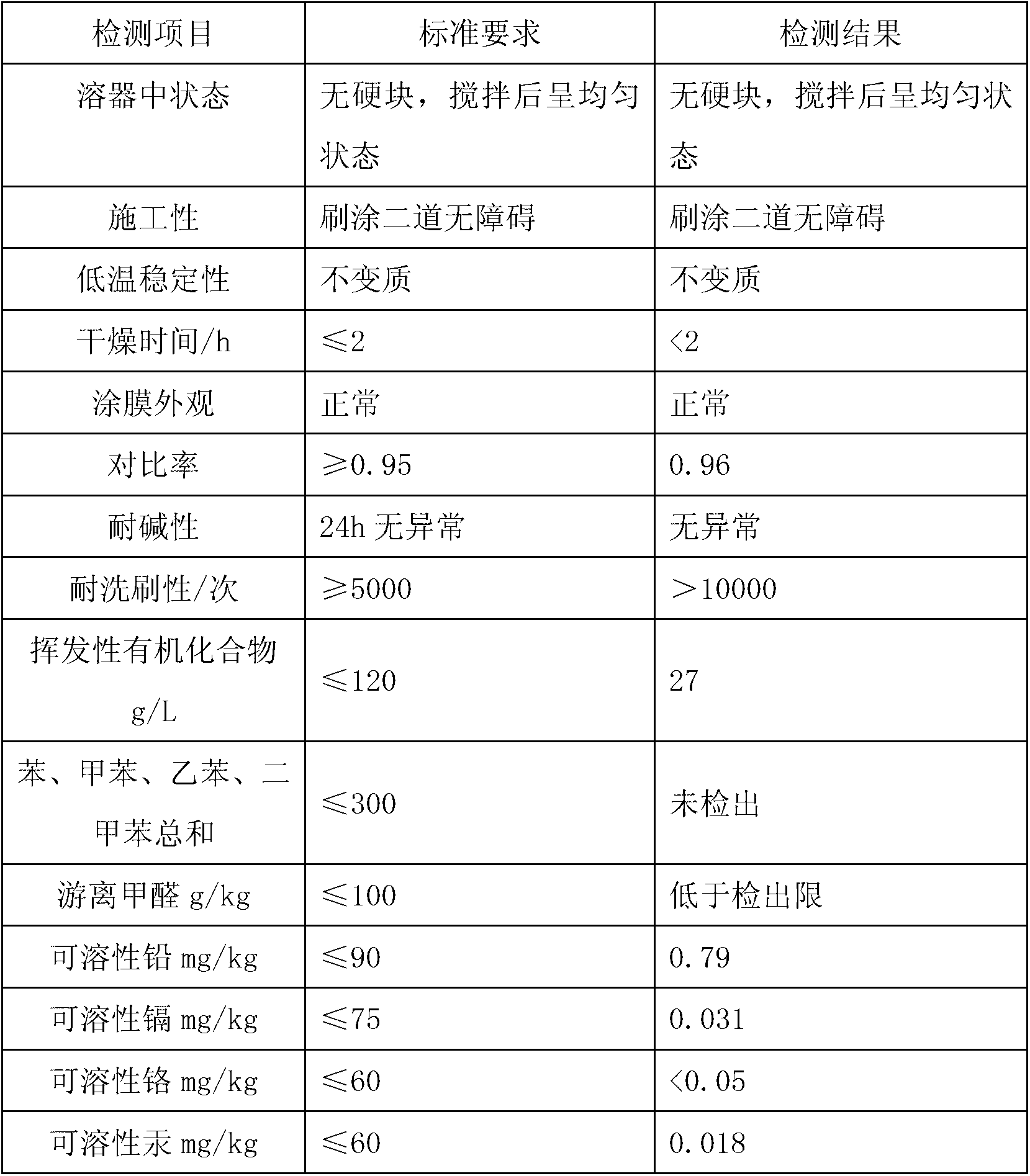

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Antimicrobial mildew-proof ceramic tile and preparation method thereof

The invention discloses an antimicrobial mildew-proof ceramic tile and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 40-50 parts of quartz sand, 20-30 parts of fluorite, 15-25 parts of gravel dust, 10-20 parts of illite, 16-28 parts of loess, 14-22 parts of mullite, 8-16 parts of furnace slag, 4-12 parts of a chalk powder, 24-32 parts of modified clay, 5-15 parts of bone meal, 2-4 parts of zinc silicate, 1-3 parts of copper oxide, and 3-8 parts of silver-loaded zirconium phosphate. Zinc silicate, copper oxide, silver-loaded zirconium phosphate and other inorganic antibacterial agents are added into the ceramic tile, and besides, the modified clay also has the sterilization efficacy, so that the ceramic tile has quite good antibacterial mildew-proof properties, has the sterilizing rate reaching 90% or more, and can effectively inhibit propagation of mildew; and the prepared ceramic tile has the characteristics of being high in strength, low in water absorption rate, good in abrasion resistance, good in weather resistance and durable in use.

Owner:安徽省亚欧陶瓷有限责任公司

Antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof

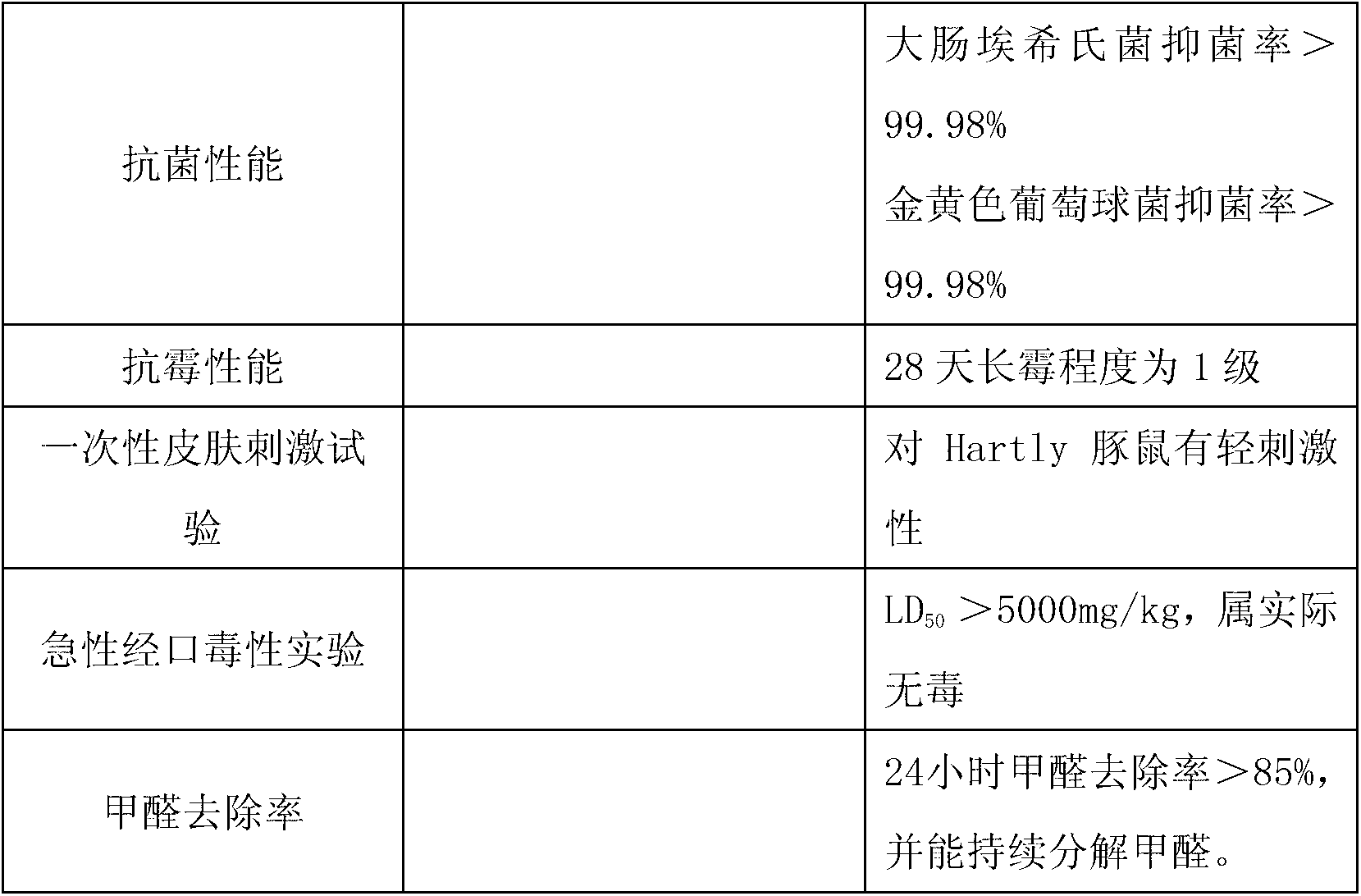

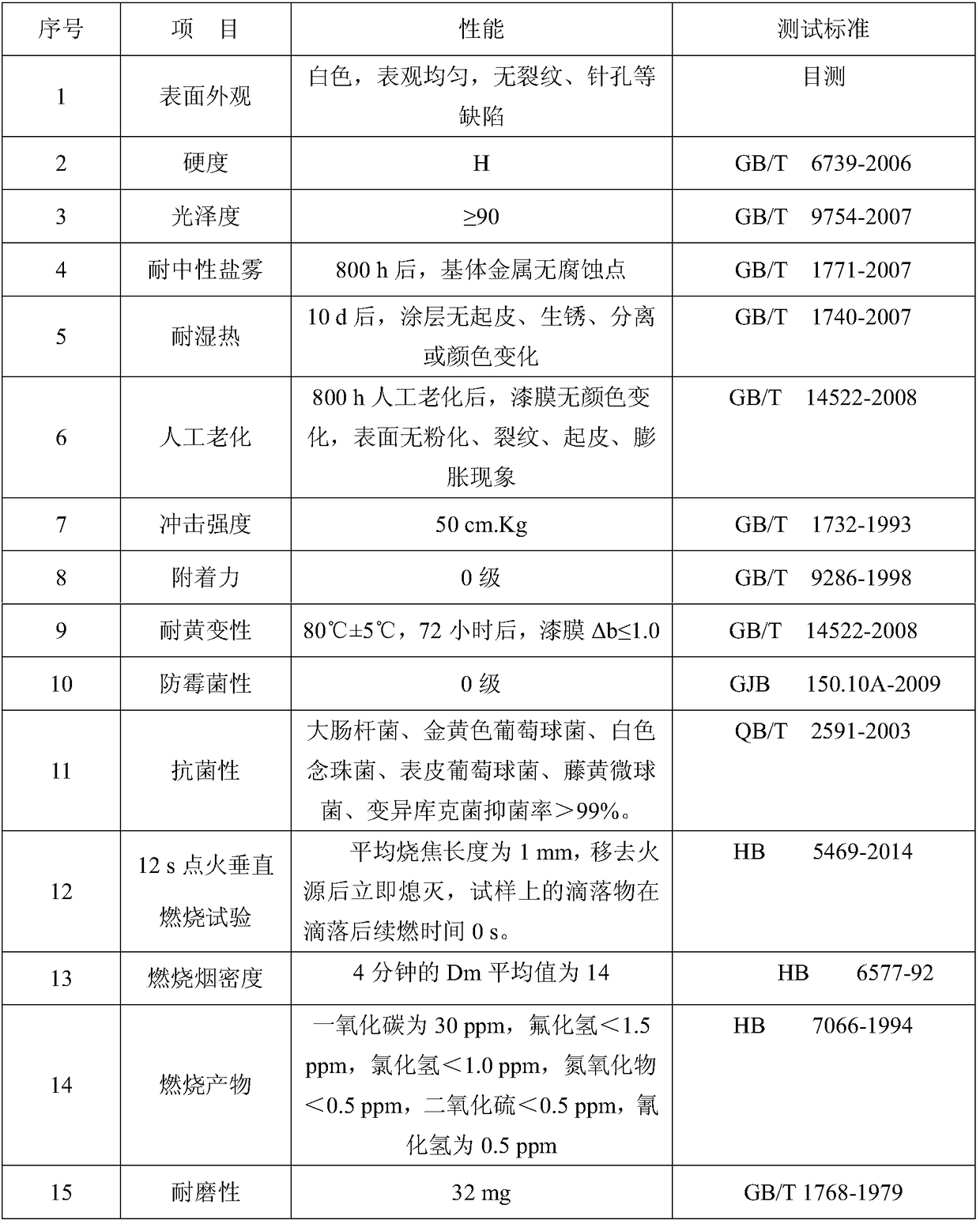

InactiveCN108912945AImprove flame retardant performanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsWear resistantAntiseptic solutions

The invention discloses an antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof. The antibacterialmildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint is mainly composed of a corrosion-resistant flame-resistant epoxy priming paint and an antibacterial mildew-resistant wear-resistant polyurethane finish paint. According to the preparation method, an intumescent flame retardant and graphene are added into the epoxy priming paint as flame retardation auxiliary agents; the paint flame resistance is improved greatly through the cooperative effect of the nanometer material and the intumescent flame retardant; nanometer silver antiseptic and hyperbranched polyethylene imide quaternary ammonium salt nanometer particles are added into the polyurethane finish paint as antibacterial auxiliary agents, and the paint antibacterial mildew-resistant performance isimproved through the cooperative effect of the nanometer silver antiseptic and the hyperbranched polyethylene imide quaternary ammonium salt nanometer particles. The reasonable combination of the priming paint with the finish paint is capable of improving the paint corrosion resistance further. The antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functionalpaint possesses the antibacterial performance, the mildew resistance, the flame resistance, the corrosion resistance, and the wear resistance, is wide in application range, is simple in preparation method, is convenient in operation, and is convenient for large scale applications.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

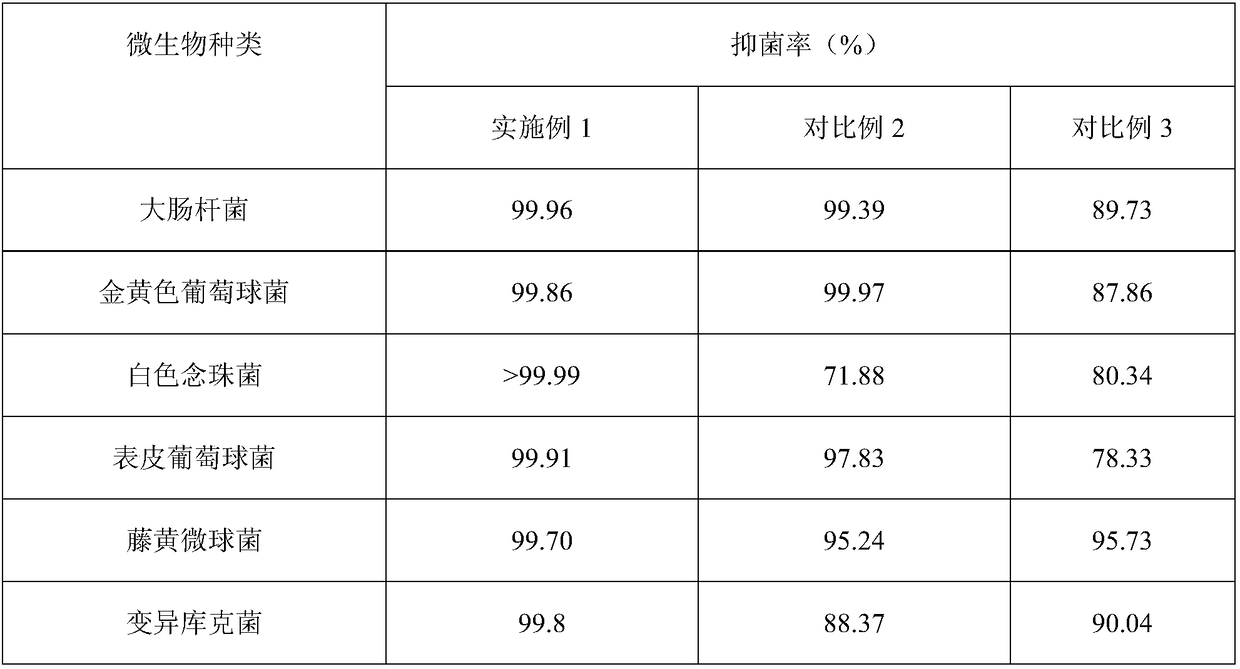

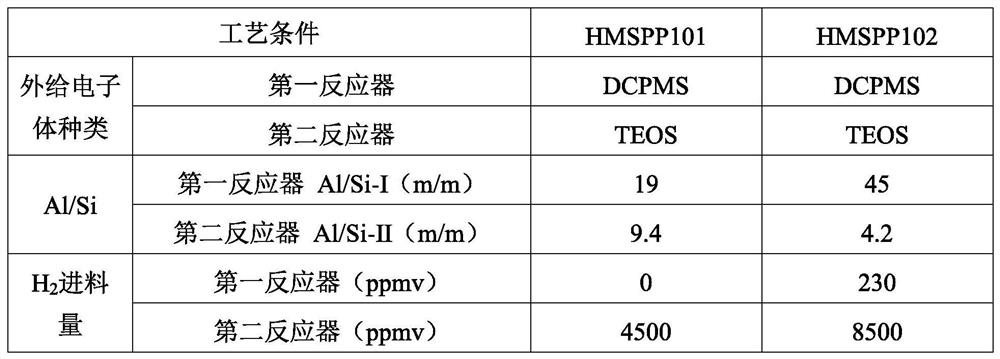

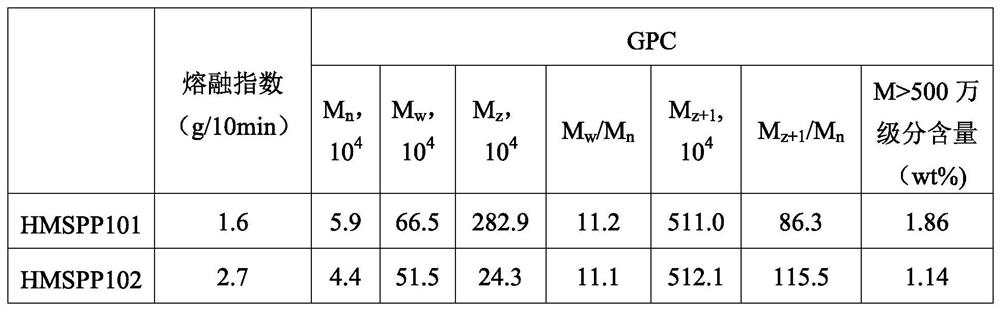

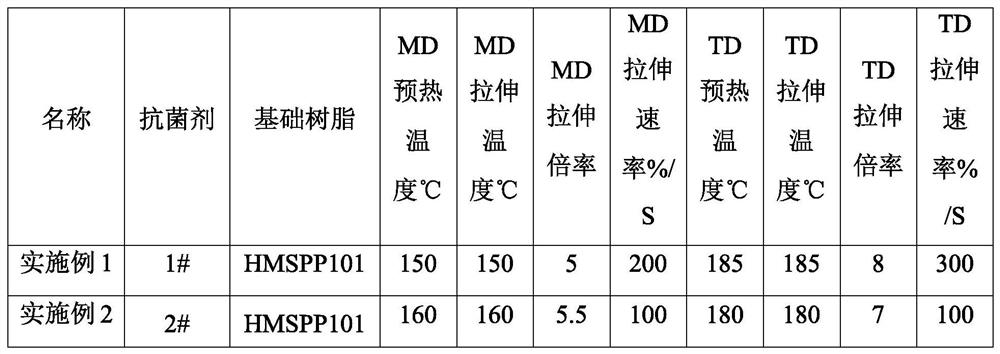

Antibacterial mildew-proof polypropylene composition, polypropylene film and preparation method thereof

The invention belongs to the field of antibacterial materials and products thereof, and relates to an antibacterial mildew-proof polypropylene composition, a polypropylene film and a preparation method of the polypropylene film. The antibacterial mildew-proof polypropylene composition contains high-melt-strength polypropylene base resin, a guanidine salt composite antibacterial agent, a mildewproof agent and an auxiliary agent, wherein the auxiliary agent contains an antioxidant, and based on 100 parts by weight of the high melt strength polypropylene base resin, the content of the guanidine salt composite antibacterial agent is 0.05-2.0 parts by weight, the content of the mildew inhibitor is 0.01-5.0 parts by weight, and the content of the antioxidant is 0.01-10 parts by weight. The antibacterial and mildewproof polypropylene composition has good antibacterial and mildewproof effects, the water resistance is also improved, and a polypropylene film prepared from the antibacterial and mildewproof polypropylene composition has the advantages of low transverse and longitudinal thermal shrinkage rate, excellent antibacterial and mildewproof performance, difficulty in discoloring afterlong-time use and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing anti-bacterial plastic filament

InactiveCN104947224ASimple preparation processImprove antibacterial propertiesMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberEscherichia coli

The invention discloses a method for preparing an anti-bacterial plastic filament. The finished product anti-bacterial plastic filament is obtained through melt extrusion, granulation and spinning with a plastic base body, modified copper powder antibacterial agents and auxiliaries as raw materials. Due to the fact that nanoscale copper powder has very excellent anti-bacterial anti-mold performances, the anti-bacterial rate of the anti-bacterial plastic filament against strains such as escherichia coli and staphylococcus aureus reaches over 99%. A process for preparing the anti-bacterial plastic filament is simple; and the anti-bacterial plastic filament has lasting broad-spectrum anti-bacterial and anti-mold effects, can be widely applied to the fields of tail fibers of intrauterine contraceptive devices, anti-bacterial toothbrushes and makeup brushes and particularly has very high application values in plum rain prone zones in the South of China.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

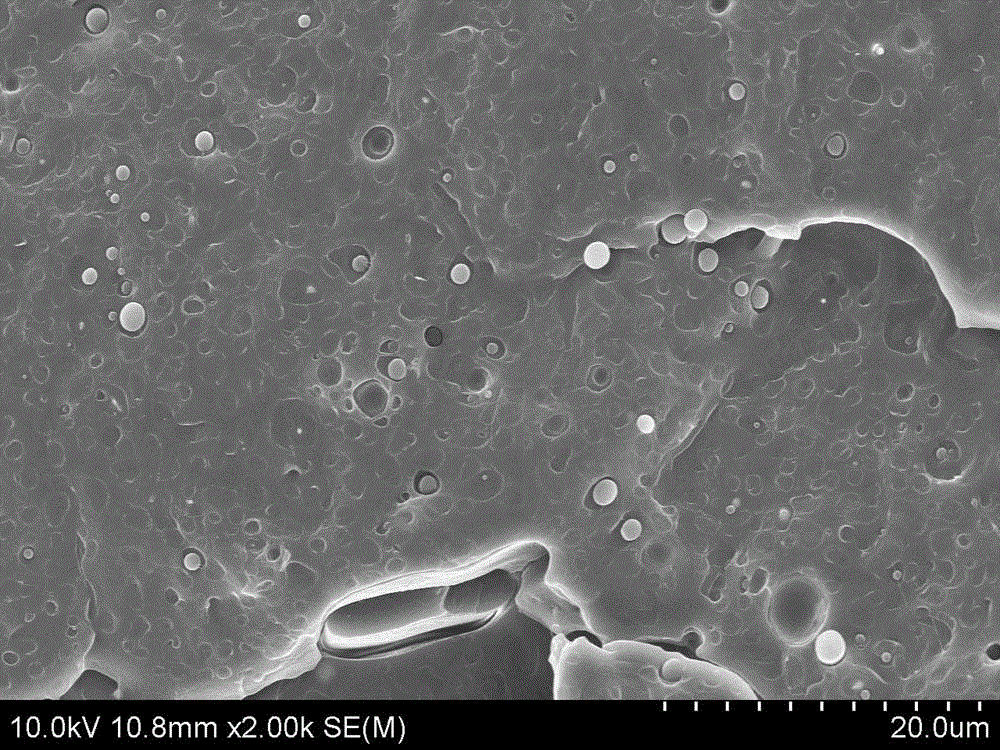

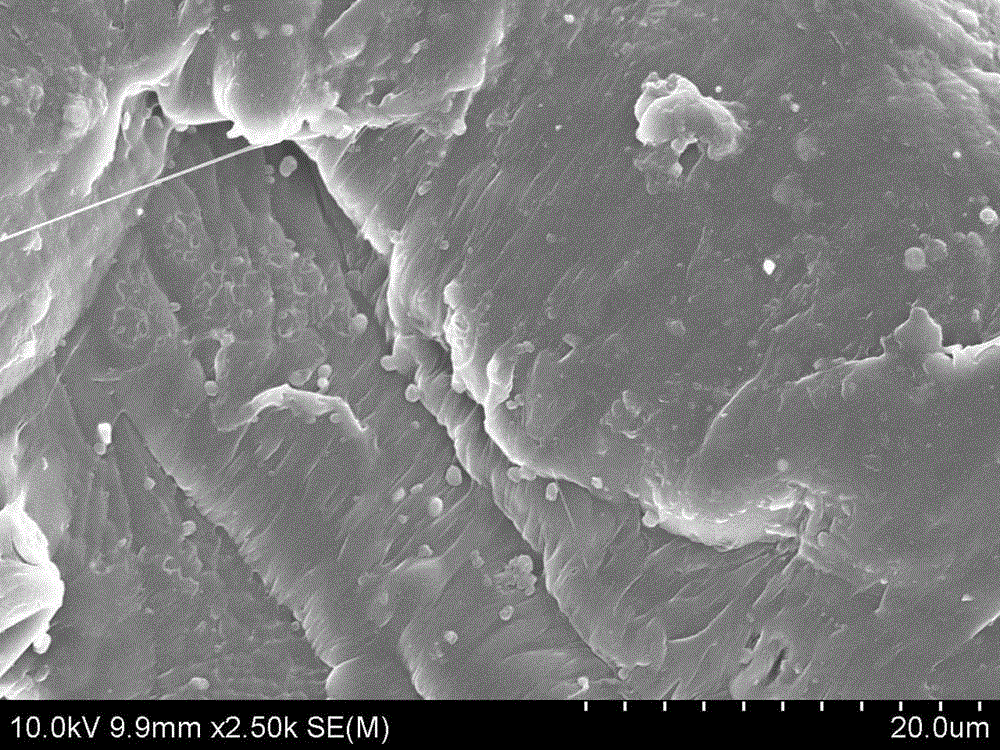

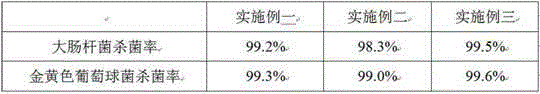

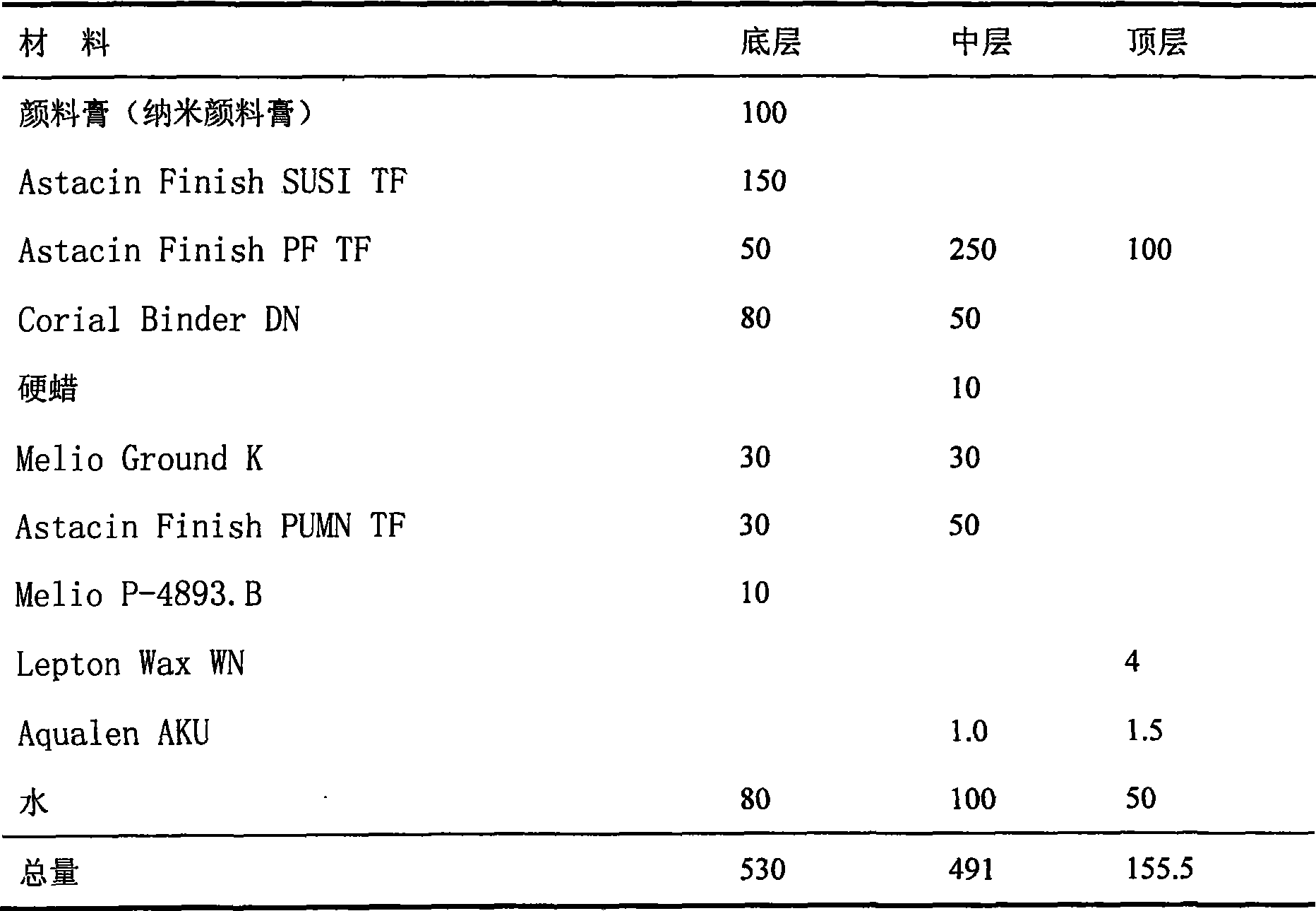

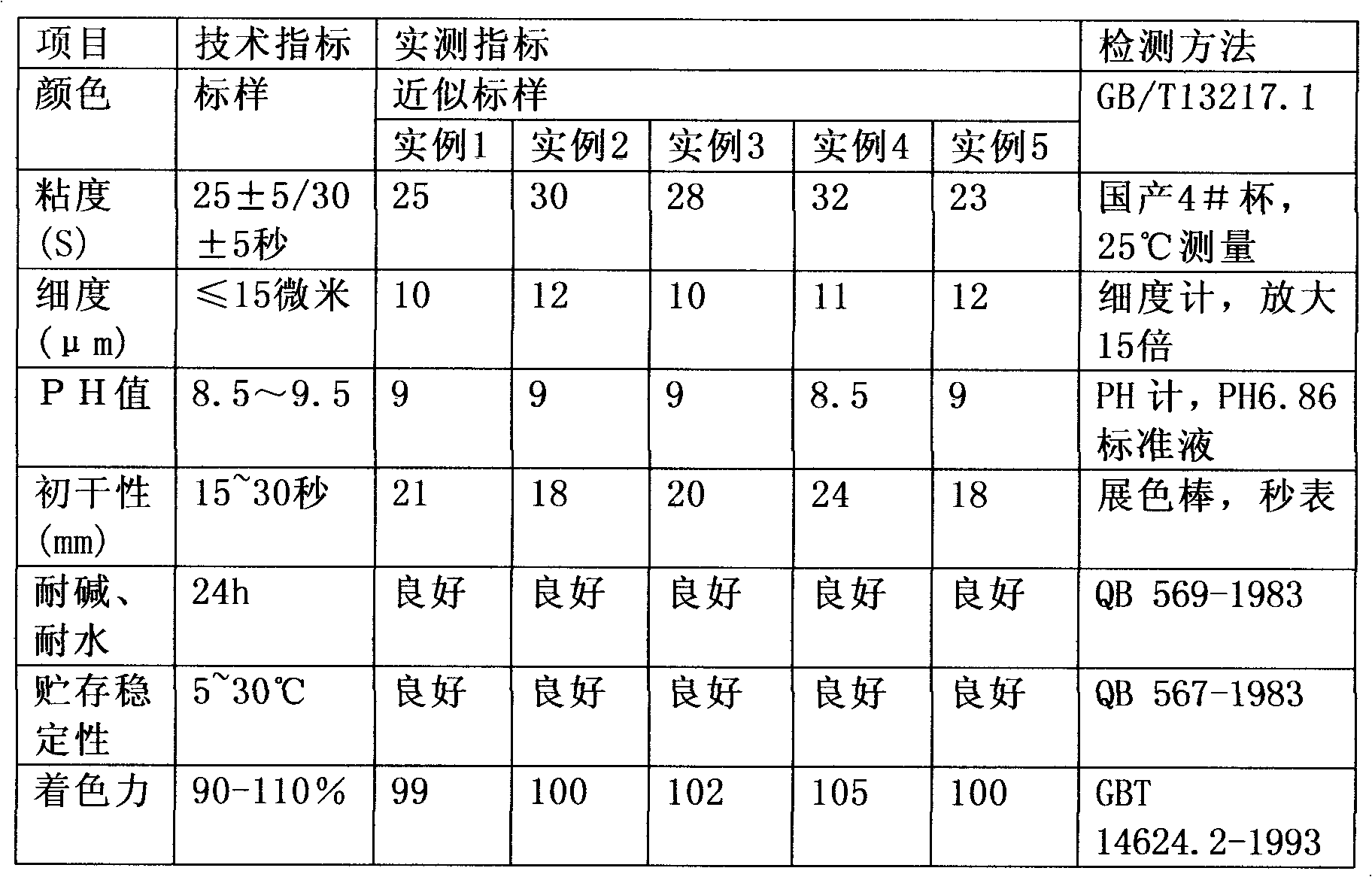

Leather nano pigment paste and preparation thereof

InactiveCN101412869AGood antibacterial and mildew resistanceGood resistance to UV radiationDyeing processPigment pastesDispersion stabilityOxygen

The invention discloses a nanometer pigment plaster for leather, which comprises the following compositions in mass percentage: 5 to 20 percent of inorganic nanometer pigment, 0.05 to 0.5 percent of dispersant, 0.05 to 5 percent of composite stabilizer, 0.05 to 0.5 percent of dispersion stability additive and 74 to 94.85 percent of water. After the pigment plaster is used for coating leather, the diameter of an inhibition ring in an antibacterial mildewproof experiment is between 39 and 45 mm; the chromatism value Delta E before and after ultraviolet accelerated irradiation is between 1.82 and 2.12; and the index of flame retardant oxygen is between 29 and 32 percent. The invention also discloses a method for preparing the nanometer pigment plaster for the leather. The nanometer pigment plaster for the leather has good antibacterial mildewproof performance, ultraviolet irradiation resistant performance, flame retardant performance and the like, has wide use range, can be used in leather coating and can be used in paint and other industries.

Owner:SICHUAN UNIV

Special polyvinyl alcohol thin film for fruit and vegetable packaging

InactiveCN108794954AExtended shelf lifeGood antibacterial and mildew resistanceSilicon dioxideGlutamine transaminase

The invention discloses a special polyvinyl alcohol thin film for fruit and vegetable packaging. The special polyvinyl alcohol thin film comprises the following raw materials in part by weight: 100 parts of polyvinyl alcohol, 10-25 parts of starch, 5-13 parts of gelatin, 2-4.8 parts of montmorillonite, 1-3 parts of activated carbon, 0.5-2 parts of zeolite, 3-5.6 parts of modified alumina, 0.5-2 parts of nanometer silicon dioxide, 0.3-2 parts of chitosan quaternary ammonium salt, 2-8 parts of plant extract, 1-5 parts of spirulina, 0.01-0.09 part of antioxidant, 2-8 parts of retinervus luffae fructus, 2-8 parts of retinervus luffae fructus, 0.3-0.8 part of plant essential oil, 0.2-0.85 part of glutamine transaminase and 0.01-0.1 part of antibacterial peptide . The special polyvinyl alcohol thin film for fruit and vegetable packaging, disclosed by the invention, is excellent in antibacterial property, high in strength, low in moisture permeability and excellent in heat and weather resistance, is used for keeping fruits and vegetables fresh, is good in antibacterial and anti-mildew properties and can prolong the shelf lives of the fruits and the vegetables.

Owner:WUHU JINCHENG AGRI TECH CO LTD

Preparation method of highly-dispersed anti-mold and anti-bacterial coating film

InactiveCN107141937AGuaranteed uniformityFully utilizeAntifouling/underwater paintsPaints with biocidesWater basedAlcohol

The invention discloses a preparation method of a highly-dispersed anti-mold and anti-bacterial coating film. The preparation method comprises the following steps of adding, by weight part, 50-100 parts of anti-mold agent, 20-50 parts of dispersing agent and 2-5 parts of thickener into the bucket of a sand grinder, and starting the sand grinder for grinding for 2-8 h; adding an anti-mold agent suspension with a weight percentage of 1-5% into water-based paint, wherein the water-based paint is composed of propyl alcohol emulsion and surface-modified nano SiO2 dispersing liquid; performing thorough and uniform stirring, coating the mixture onto base materials, baking the coated base materials in a drying oven at 120-150 DEG C for 20-30 min, controlling the film thickness to be 10-28 micrometers. The highly-dispersed anti-mold and anti-bacterial coating film can effectively ensure component uniformity of paint, give full play of effects of the paint, facilitate paint application and meanwhile obtain excellent anti-mold and anti-bacterial performance.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

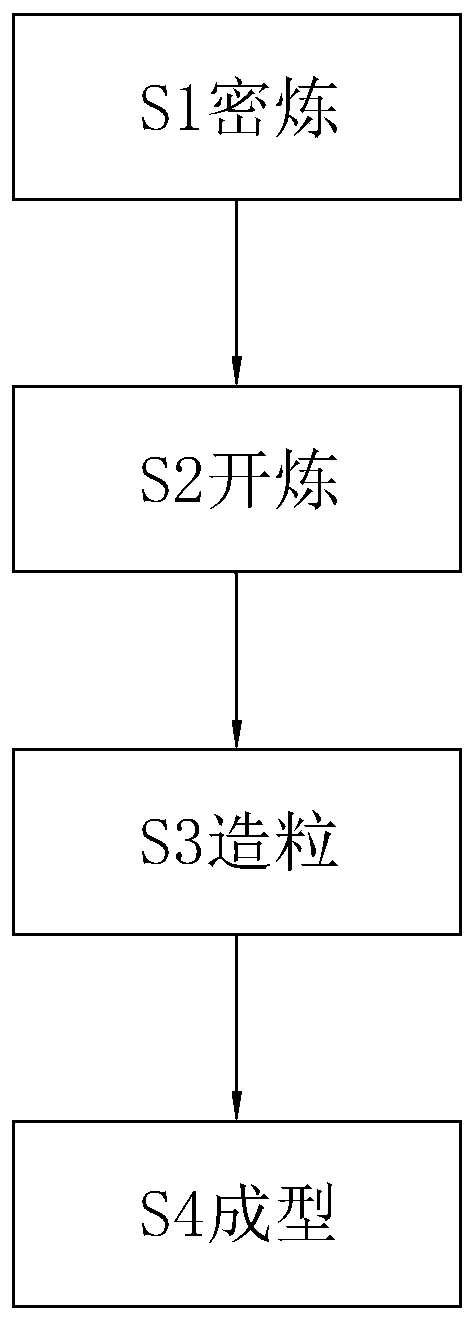

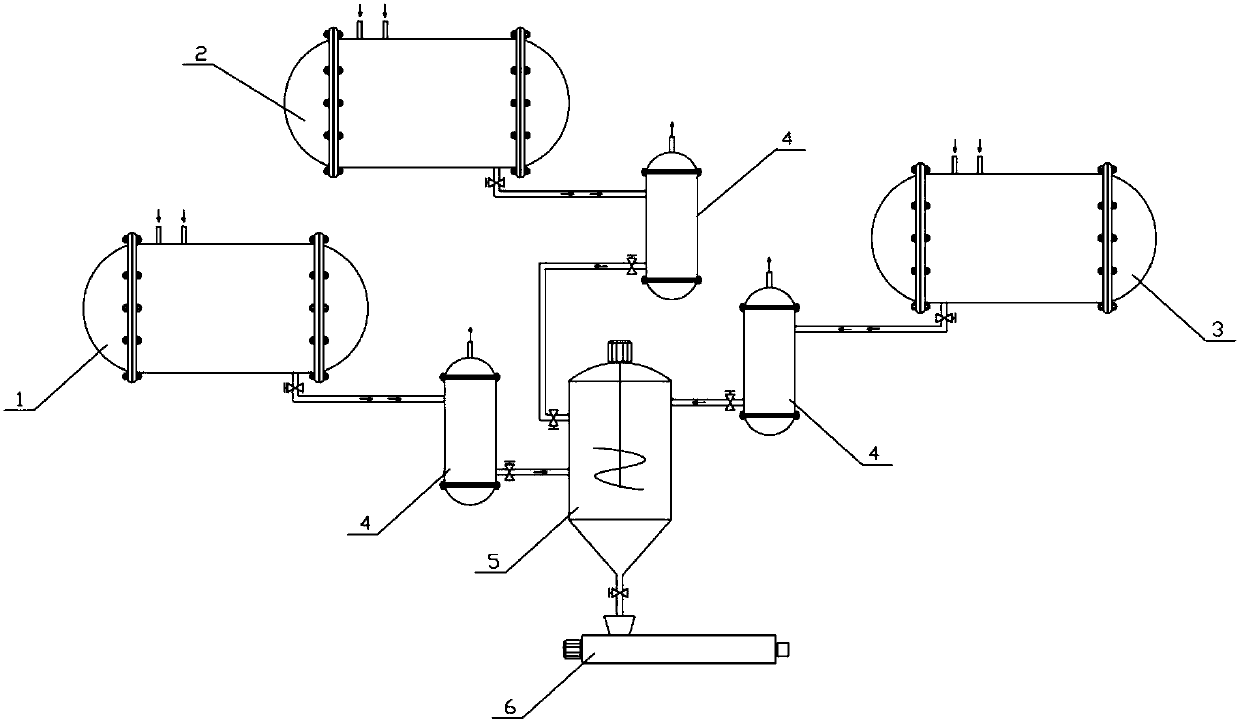

Method for preparing anti-bacterial anti-mildew styrene-butadiene rubber foamed plate

InactiveCN101070405AHigh impact strengthImprove wear resistanceFlat articlesGlyceryl monostearateAntibacterial agent

The present invention relates to a preparation method of antibacterial and antifungal, styrene-butadiene-rubber, foamed sheet. Using 62-70 % SBR as basic material, 14-20% SIS, 0.6-1.2% antibacterial agent, 0.5-1.0% antifungal agent, 5-8% naphthenic oil, 6-10% clay, 1.4-2.2% OBSH, 0.5-1.0% sodium butyl dithiocarbonate, 0.5-1.0% DCP, and 0.6-1.2% glyceryl monostearate are added, after passing through plasticization, twin-roll mixing, first moulding foaming, cooling, second moulding foaming, cooling pitching, and punching shear, the production is formed. The foamed sheet prepared by this method, has low density, high impact resistance, good compression reducibility, wear resistance and slip resistance, good damping effect, no poison and no smell, especially, has excellent antibacterial and antifungal ability, is suitable for the floor board of indoor fitness and exercise sites, and can effectively inhibit pathogenic bacteria and mildew's reproduction and living, thus improves the sanitarian condition of the fitness and exercise sites.

Owner:FUJIAN NORMAL UNIV

Antibacterial and mould-proof shoe material and preparation method of shoe sole

The invention discloses an antibacterial and mould-proof shoe material and a preparation method of a shoe sole. The shoe material is prepared from the following components in parts by weight: 23-27 parts of EVA, 17-21 parts of POE, 6-9 parts of OBC, 4-6 parts of EDPM, 4-6 parts of a filler, 0.3-0.6 part of a vulcanizing agent, 1.2-2 parts of a foaming agent, 0.8-1.2 parts of a foaming assistant, 0.4-0.6 part of a lubricant, 0.2-0.4 part of zinc stearate, and 0.4-0.5 part of a nano antibacterial agent. The preparation process of the nano antibacterial agent is as follows: in parts by weight, 5-7 parts of silver-loaded zeolite are added into 18-20 parts of an absolute ethyl alcohol and water mixed solution with the volume ratio of absolute ethyl alcohol to water being (6 to 8):1, then 1.2-1.5 parts of isobutyltriethoxysilane are added, then heating is conducted to 70-75 DEG C, continuous stirring is conducted for 20-25 min, finally, filtering, drying and grinding are conducted, and the nano antibacterial agent is obtained. The antibacterial and mould-proof shoe material and the preparation method of the shoe sole have the beneficial effects that the silver-loaded zeolite is subjectedto surface modification through the isobutyltriethoxysilane, the surface energy of the shoe material is lowered, agglomeration is not prone to occurring, using demands of the shoe material are met, and after the surface of shoe material is grafted with organosilicon groups, water resistance is improved appropriately.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

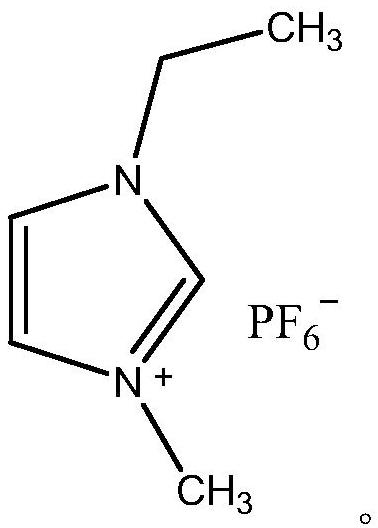

Electromagnetic shielding flame-retardant material for carbon fiber base material as well as preparation method and application thereof

ActiveCN111690305AImprove environmental resistanceImprove application performanceFireproof paintsElectrically-conductive paintsAntioxidantFire retardant

The invention discloses an electromagnetic shielding flame-retardant material for a carbon fiber base material as well as a preparation method and application of the electromagnetic shielding flame-retardant material. The material comprises 20-50 parts of a water-based flame-retardant polymer adhesive, 5 to 20 parts of a metal powder conductive filler; 8 to 40 parts of a macromolecular intumescentflame retardant; 4 to 10 parts of an ionic liquid containing phosphorus, nitrogen and halogen; 0.5 to 2.5 parts of a catalytic charring agent, 0.5 to 5.0 parts of a composite antioxidant, 0.5 to 5 parts of an antibacterial mildew inhibitor, 0.5 to 5.0 parts of a flame-retardant cross-linking agent, 0.3 to 3.0 parts of a wetting agent, 0.3 to 3.0 parts of a dispersing agent, 0.3 to 3.0 parts of aleveling agent, 0.2 to 2.0 parts of an antifoaming agent and 0.3 to 3.0 parts of a thickener. The electromagnetic shielding flame-retardant material is applied to a carbon fiber base material; a firmand durable protective layer is formed on the surface; the carbon fiber base material can be protected from being invaded by bacteria and mould, can endure environmental change, has high and low temperature resistance and damp and hot smoke resistance. The electromagnetic shielding flame-retardant material is safe and environment-friendly, a protective layer formed by spraying or coating is low insurface resistance, high in shielding efficiency and good in flame-retardant effect, and when meeting high-temperature flames, the electromagnetic shielding flame-retardant material can rapidly expand into carbon, insulate heat and oxygen and protect a carbon fiber base material from being damaged.

Owner:京准化工技术(上海)有限公司

Formula of environment friendly water-based ink for transfer printing and preparation method thereof

InactiveCN102220048ALow costGood antibacterial and mildew resistanceTransfer printing processInksWater basedAcrylic resin

The invention discloses a formula of transfer printing water-based ink and a preparation method thereof. The ink comprises the following raw materials: 25-50wt% of water-soluble acrylic resin, 10-30wt% of disperse dyestuff, 1-3wt% of auxiliaries and 20-50wt% of water. The invention has the advantage of simple technology, the prepared ink has the advantages of low cost, good antibiotic and anti-mildew property, easiness in storing and excellent printing adaptability, and the printed calicopaper has good waterproofness, no color fading, clear design and strong sense of layering.

Owner:谢亚军 +1

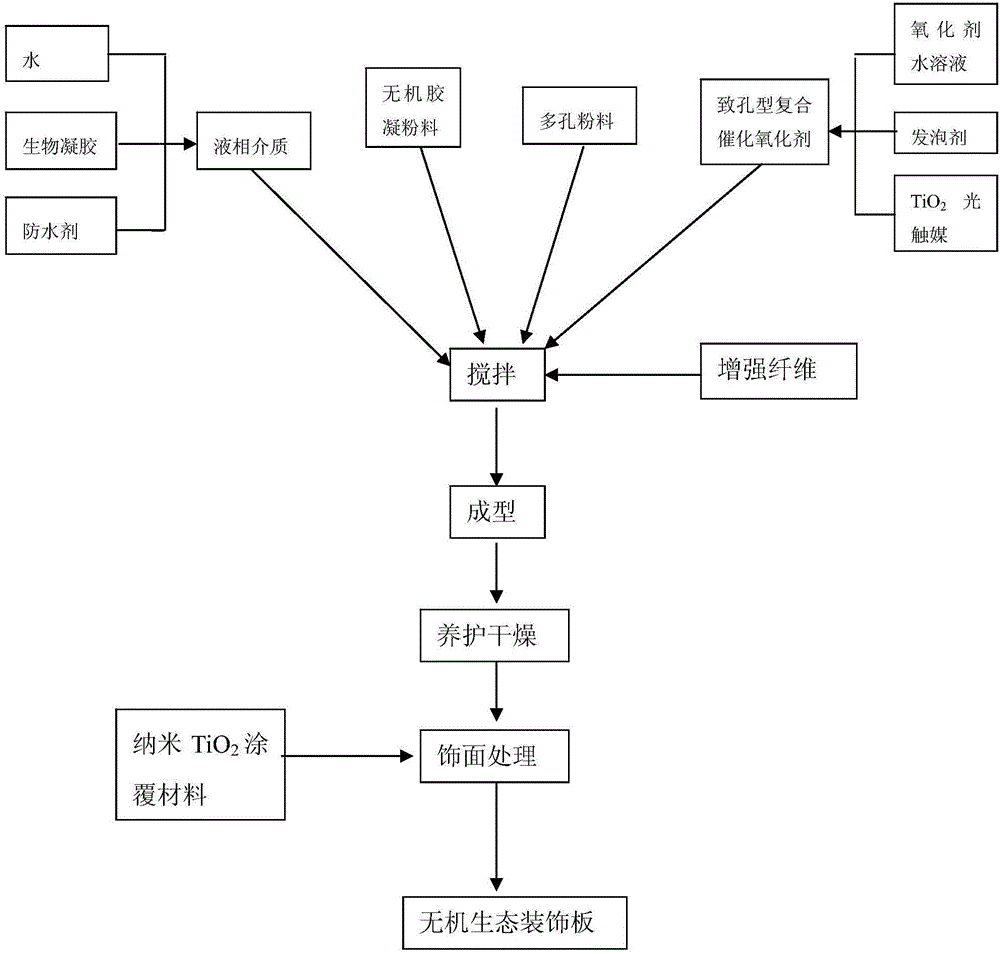

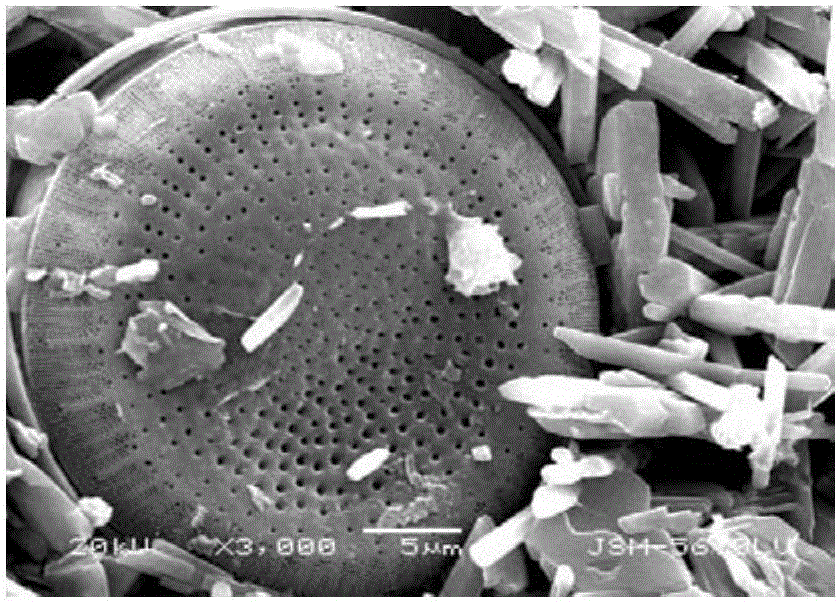

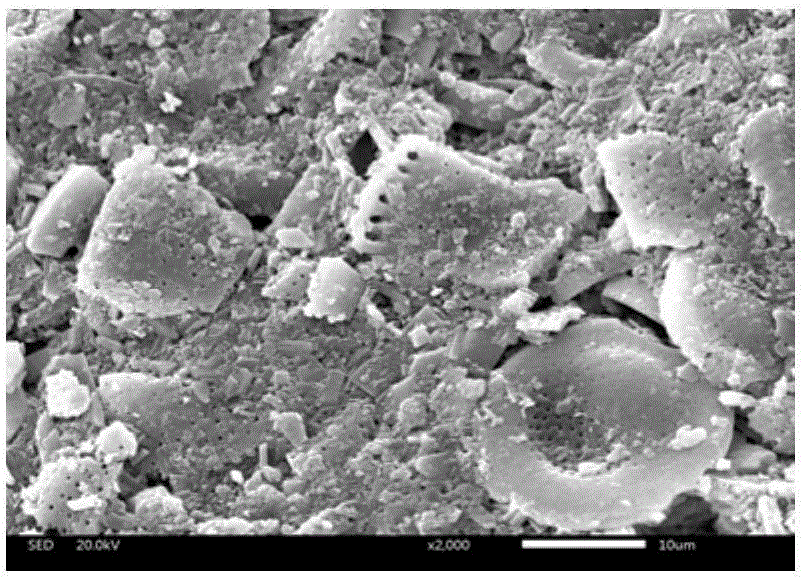

Pore-forming oxidative inorganic ecological decorative board and production method thereof

InactiveCN106518140AAvoid dependence on quality stabilityQuantity collection and distribution richCeramicwareFiberLiquid phase

The invention discloses a pore-forming oxidative inorganic ecological decorative board and a production method thereof. The pore-forming oxidative inorganic ecological decorative board is prepared from, by weight, 100 parts of inorganic gelling powder, 0-22.0 parts of porous powder, 18.5-73.0 parts of liquid-phase medium, 0.05-5.5 parts of pore-forming compound catalytic oxidant, 1.5-20 parts of reinforced fibers and 1.3-4.5 parts of nanometer titania coating materials by stirring, forming, curing, drying and a veneer treatment technology. The pore-forming oxidative inorganic ecological decorative board has the advantages that a catalyst and the oxidant are supported on micropores inside a hydrated condensation matrix of the inorganic gelling material firmly simultaneously, microporous distribution and centralized distribution are enriched, and secondary intensification is achieved with the aid of a nanometer titania coating, so that the inorganic ecological decorative board is endowed with excellent purification performance to efficiently decompose harmful gas continuously and is capable of regulating indoor temperature and humidity effectively, resisting bacteria and preventing mildewing; the problems of contradiction in choosing physical performance and ecological performance of inorganic decorative boards alternatively, proneness to shedding and attenuation of the supported catalyst or oxidant and capability of causing blockage of surface micropores through conventional surface treatment are solved.

Owner:西安藻钙新材料科技有限公司

Antibiotic and mildew-resistant starch adhesive for wallpaper, and preparation method thereof

InactiveCN105623551AGood antibacterial and mildew resistanceResolve failureNon-macromolecular adhesive additivesStarch adhesivesPreservativeResistant starch

An antibiotic and mildew-resistant starch adhesive for wallpaper comprises 100 parts of deionized water, 4-15 parts of rice, 2-10 parts of potato starch, 0.05-1 part of a complexing agent, 0.01-0.5 parts of an in-can preservative, and 0.02-0.8 parts of a dry film bacterium killing mildew inhibitor. The adhesive has a good bonding performance, and especially the adhesive contains 0.01-0.5 parts of an antiseptic and 0.08-0.8 parts of the dry film mildew inhibitor. The adhesive has a good bonding performance, especially the excellent antibacterial property of the adhesive can guarantee the quality of the adhesive in a storage retention range and the long-acting bonding of an adhesive film to the wall paper and avoids moldy degumming of the adhesive.

Owner:曹燕

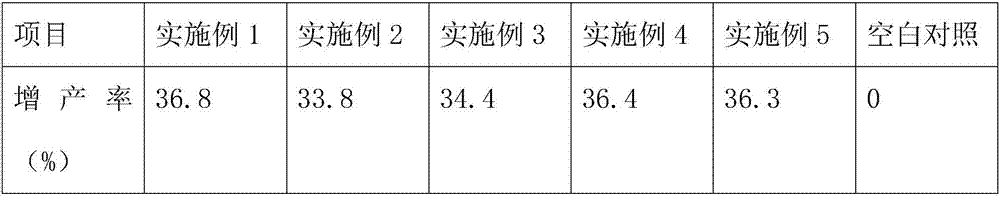

High-slow-release organic compound fertilizer for ulmus pumila

InactiveCN107118017AAvoid infringementGood slow releaseExcrement fertilisersBioloigcal waste fertilisersLivestock manureMonocalcium phosphate

The invention discloses a high-slow-release organic compound fertilizer for ulmus pumila. The high-slow-release organic compound fertilizer comprises raw materials, namely livestock manure, corn stalk, orange peel, rich hull, manioc wastes, turf, rice husk, furfural residues, phosphate solubilizing bacteria, potassium bacteria, nitrogen-fixing bacteria, crude fiber degradation bacteria, compost fermentation bacteria, urea phosphate, ammonium dihydrogen phosphate, humic acid, carbamide, monoammonium phosphate, monopotassium phosphate, potassium sulfate, ammonium sulfate, ferrous sulfate, boric acid, potassium nitrate, calcium nitrate, monocalcium phosphate, sodium glutamate, sodium alginate, a modified slow-release agent, a modified antibacterial anti-molding agent and a soil conditioning agent. The high-slow-release organic compound fertilizer disclosed by the invention is excellent in slow-release property and excellent in anti-molding property, nutrition requirements of the ulmus pumila in the whole growth period can be met, the yield of the ulmus pumila is effectively increased, the quality of the ulmus pumila is effectively improved, the ulmus pumila can be effectively prevented from mold on fertilizers, meanwhile structures of soil in which the ulmus pumila grows can be conditioned, soil caking is avoided, and thus the quality of the ulmus pumila is improved.

Owner:天长市翔净蔬菜种植发展有限公司

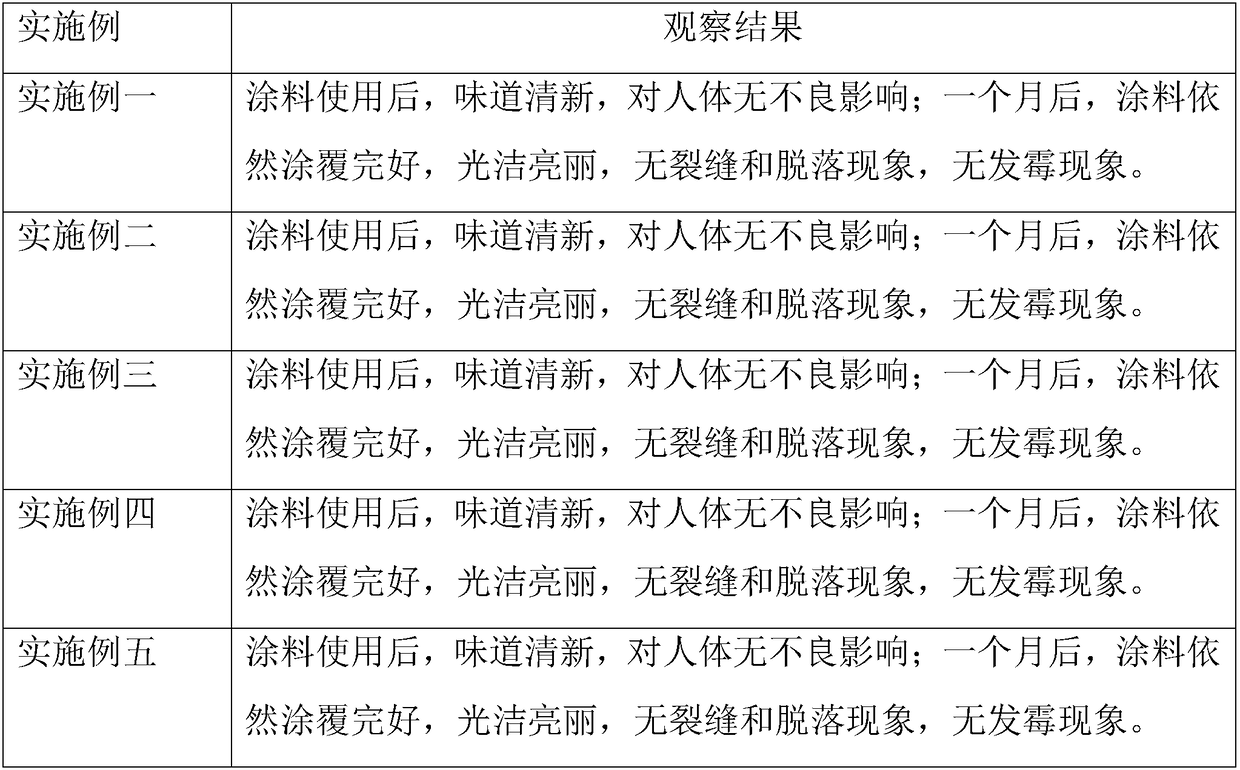

Environmentally-friendly antibacterial internal wall coating

InactiveCN109161240AImprove heat resistanceImprove impact resistanceAntifouling/underwater paintsPaints with biocidesCalcium silicatePhenyl Ethers

The invention discloses an environmentally-friendly antibacterial internal wall coating, which is prepared from the following raw materials: vinyl acetate-acrylic emulsion, organosilicone-modified terpene resin, modified starch, soyabean proteins, nano microporous activated silica, ultra-fine aluminum silicate, nano beta-calcium silicate, kaoline, rutile type titanium dioxide, shell powder, sepiolite, calcium carbonate, calcium sulfate whiskers, water, ethylene glycol tert-butyl ether, 2,2,4-trimethyl-1,3-glutaryl monoisobutyrate, hydrogen-containing silicone oil, a wetting agent, a dispersant, propylene glycol phenyl ether and a thickener. The environmentally-friendly antibacterial internal wall coating provided by the invention can absorb formaldehyde and reduce VOC (volatile organic compounds), and is excellent in antibacterial and anti-mildew properties and long in service life.

Owner:MAANSHAN TIANJINYUN PAINT IND

Moisture absorption and breathable towel fabric

InactiveCN109652890AGood antibacterial and antifungal propertiesImprove wearing comfortBiochemical fibre treatmentHeat resistant fibresWeft yarnEngineering

The invention discloses a moisture absorption and breathable towel fabric which is provided with a three-layer compound fabric. The towel fabric comprises am upper-layer fabric, a lower-layer fabric and a middle-layer fabric, structures of the upper-layer fabric and the lower-layer fabric are consistent, the upper-layer fabric and the lower-layer fabric comprises warp yarns and weft yarns, and thewarp yarns comprise, by weight, 45-50 parts of cotton fibers and 22-26 parts of milk protein fibers. According to the moisture absorption and breathable towel fabric, moisture absorption and breathable finishing liquor is matched and has synergistic facilitation functions, the prepared fabric has excellent antibacterial and anti-mildew performances and moisture absorption and breathable performance, and wearing comfort is improved.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

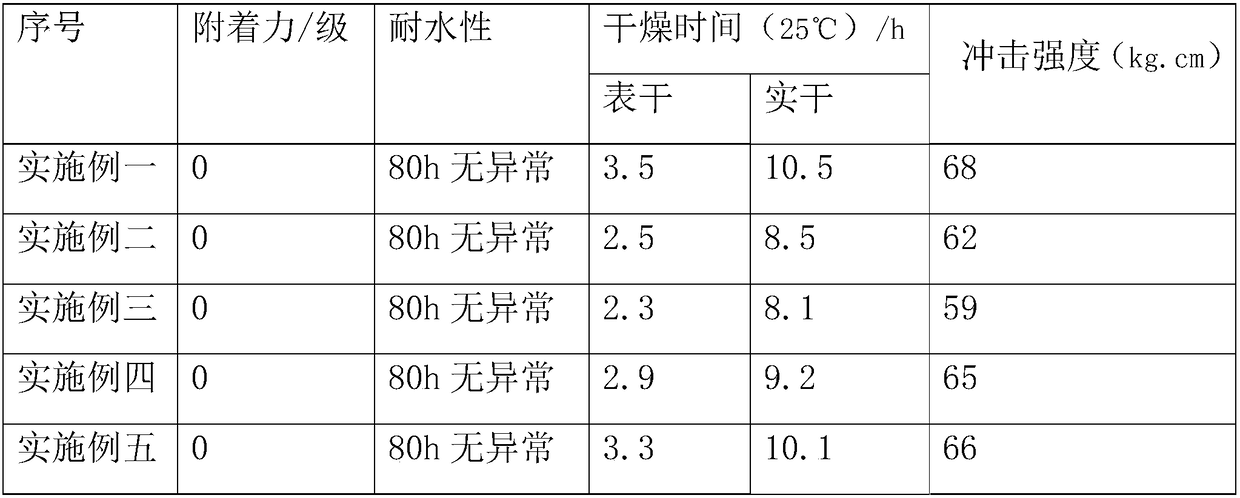

Antibacterial and environment-friendly coating and preparation method thereof

InactiveCN108559343AStrong adhesionGood weather resistanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyvinyl alcohol

The invention provides an antibacterial and environment-friendly coating. The antibacterial and environment-friendly coating comprises the following components as raw materials in parts by weight: 25-32 parts of polyvinyl alcohol, 17-19 parts of a polyacrylate emulsion, 8-10 parts of nanometer attapulgite, 11-13 parts of nanometer kaolin, 12-15 parts of diatomite, 10-12 parts of a shell powder, 5-8 parts of a sepiolite powder, 2.5-3 parts of a Beitou stone powder, 0.5-1 part of nanometer titanium oxide, 1-1.5 parts of polyacrylamide, 6-8 parts of epoxy resin, 0.5-1 part of a mineral oil defoamer, 0.2-0.3 part of an ammonium polyacrylate dispersant, 0.1-0.2 part of carboxymethyl cellulose, 3-5 parts of coconut oil, 3.5-4 parts of a pine needle powder, 2.5-3.5 parts of naringenin, 1.5-2 parts of thyme, 1-2 parts of tamarind shells, 4.5-5.5 parts of callicarpa nudiflora, 3-4.5 parts of holly leaves, 1-2 parts of schizonepeta and 55-65 parts of deionized water.

Owner:CHONGQING JIAOTONG UNIVERSITY

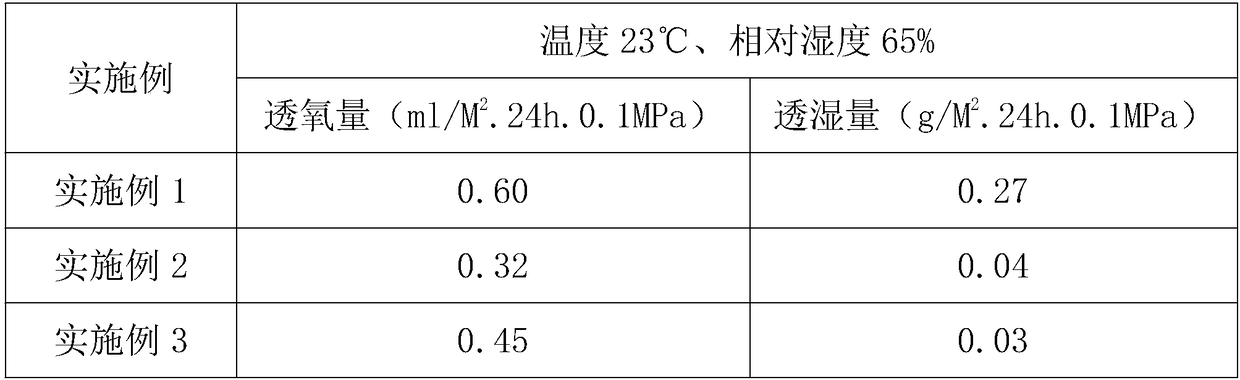

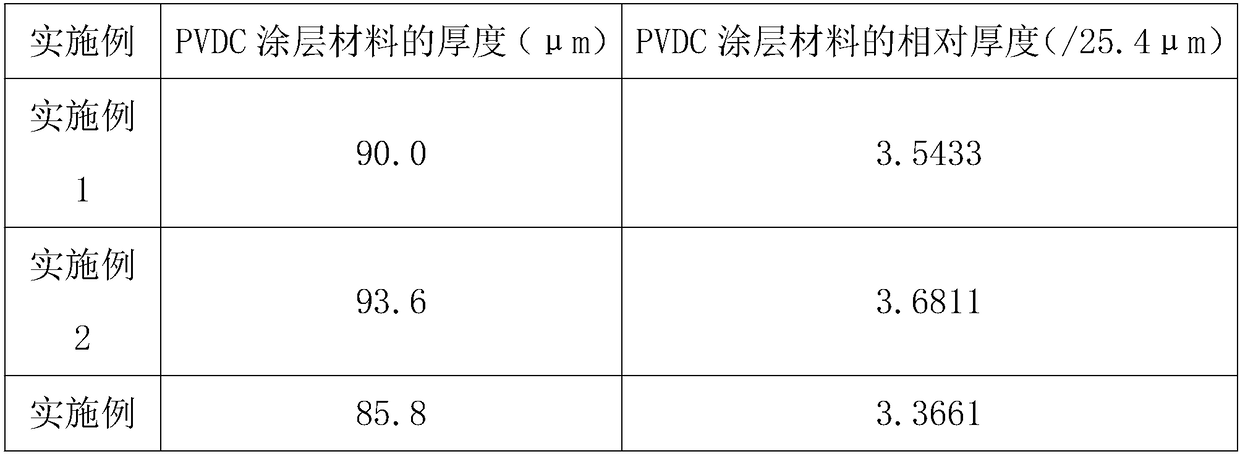

PVDC coating material with high barrier performance and preparation method thereof

InactiveCN108250475AImprove barrier propertiesStrong oxidation abilityAntifouling/underwater paintsPaints with biocidesPolymer scienceDouble bond

The invention discloses a PVDC coating material with high barrier performance. The PVDC coating material comprises a modified PA membrane, wherein the outer side surface of the modified PA membrane iscoated with modified PVDC rubber latex, the inner side surface of the modified PA membrane is coated with modified PVDC nano rubber, the modified PVDC nano rubber is prepared from the following raw materials: ultrapure water, a PH value buffering adjusting agent, vinylidene chloride monomers, methyl acrylate monomers, an initiator, and a dispersion agent, the thickness of the modified PA membraneis 81 to 89 micrometers, the thickness of the modified PVDC rubber latex smeared on the outer side surface of the modified PA membrane is 1.5 to 1.8 micrometers, the oxygen permeation amount of the PVDC coating material at the standard conditions that the temperature is 23 DEG C, the relative humidity is 65 percent and the thickness is 25.4 micrometers is 1.18 to 2.12 ml / M<2>.24h.0.1MPa, and thehumidity permeation amount is 0.1 to 0.96 g / M<2>.24h.0.1MPa. By adopting the PVDC coating material with the high barrier performance, the technical problems that the PVDC rubber latex is poor in heatstability, the dual-bond conjugation easily occurs when the PVDC rubber latex is heated or stored for a long term at a normal temperature, hydrogen chloride is leaked, holes are formed among molecules and the barrier performance is in failure can be solved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Environment-friendly porcelain film coating used for outer wall

InactiveCN109439035AImprove water resistanceGood weather resistanceFireproof paintsAntifouling/underwater paintsUltraviolet lightsAntibacterial property

The invention discloses environment-friendly porcelain film coating used for an outer wall. The environment-friendly porcelain film coating is prepared from the following ingredients by weight percentage: 40-50% of silica sol dispersion, 1-4% of filters, 30-40% of a silane coupling agent, 5-15% of pigment, 0.1-1% of a leveling agent, 1-3% of a weather proofing agent, 1-3% of an antibacterial agent, 0.5-1.5% of an ultraviolet light absorber, 1-3% of poly-dimethyl hydroxyl silicone oil and 0.5-2% of an organic acid catalyst. A preparation method of the coating comprises the following steps: weighing raw materials for standby use; adding the fillers and the pigment into the silica sol dispersion and dispersing the fillers and the pigment; adding the weather proofing agent, the antibacterial agent, the ultraviolet light absorber and the organic acid catalyst and dispersing the weather proofing agent, the antibacterial agent, the ultraviolet light absorber and the organic acid catalyst; adding the silane coupling agent, the leveling agent and the poly-dimethyl hydroxyl silicone oil and uniformly dispersing the silane coupling agent, the leveling agent and the poly-dimethyl hydroxyl silicone oil, so as to obtain a product. The environment-friendly porcelain film coating product used for the outer wall, which is prepared from the matched materials has the advantages of being excellentin water resistance, weather resistance, soiling resistance, antibacterial property and better in effect; in addition, the preparation process is simpler in and is lower in cost.

Owner:常州天瑞新材料科技有限公司

Environment-friendly putty powder and preparation method thereof

InactiveCN111849238ASimple manufacturing methodReduce manufacturing costFilling pastesEpoxyPolymer science

The invention discloses environment-friendly putty powder which is characterized in comprising the following components in parts by weight: 20-30 parts of palygorskite, 10-20 parts of montmorillonite,15-20 parts of white cement, 1-3 parts of lambda-carrageenan modified polyquaternium-10, 2-4 parts of rosin modified cationic guar gum, 1-3 parts of konjac gum, 0.5-1.5 parts of epoxy-terminated hyperbranched polyphosphate and 0.5-1.5 parts of amino-terminated hyperbranched polybenzimidazole. The invention further provides a preparation method of the environment-friendly putty powder. The environment-friendly putty powder disclosed by the invention is good in comprehensive performance, sufficient in strength and adhesive force, high in hardness, good in water resistance, free of phenomena ofhollowing, peeling, cracking and falling off after being wetted by water, and safe and environment-friendly to use.

Owner:刘超

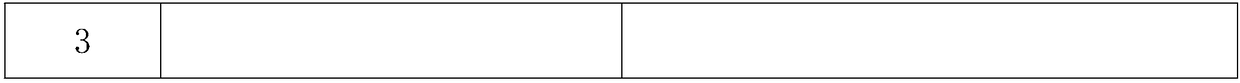

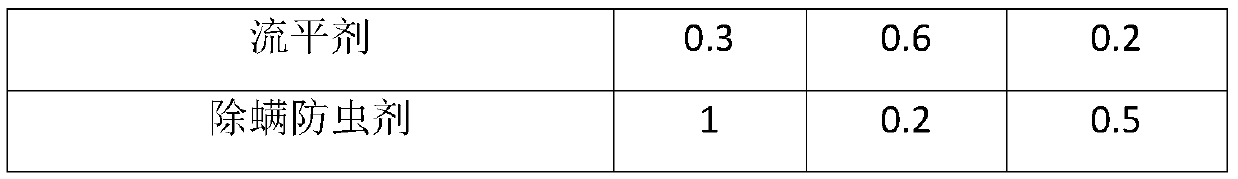

Mite-killing insect-preventing water-based inorganic nano-coating and preparation method thereof

ActiveCN110484030AGrowth inhibitionAvoid problemsAntifouling/underwater paintsPaints with biocidesWater basedHydroxyethyl cellulose

The invention discloses a mite-killing and insect-preventing water-based inorganic nano-coating and a preparation method thereof. The mite-killing and insect-preventing water-based inorganic nano-coating is prepared from a mite-killing and insect-preventing agent, hydroxyethyl cellulose, a wetting agent, a dispersing agent, a defoaming agent, pigment, filler, a coalescing agent, an anti-freezing agent, modified inorganic nano-silicon emulsion, a flatting agent and water. The mite-killing and insect-preventing water-based inorganic nano-coating mainly forms covalent bonds with hydroxyl and amido in the modified inorganic nano-silicon emulsion paint film through the mite-killing and insect-preventing agent, and the mite-killing and insect-preventing effect is achieved by forming a mite-killing and insect-preventing medicine film through a coating film. The invention further discloses the preparation method of the mite-killing insect-preventing water-based inorganic nano coating. The preparation method of the water-based inorganic nano-coating is simple, and the water-based inorganic nano-coating has the characteristics of mite and insect prevention, mildew prevention, antibiosis, stain resistance, high hardness, wear resistance, scratch resistance and the like.

Owner:湖南湘江建筑科技有限公司

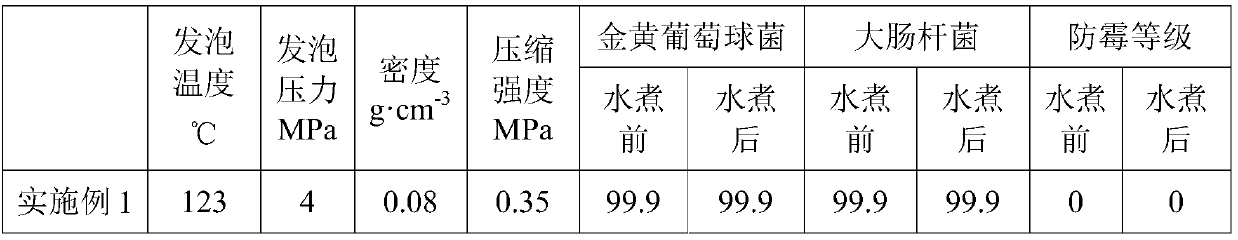

Antibacterial mildew-proof polyethylene composition and foamed beads, preparation method thereof, and molded body

The invention belongs to the field of antibacterial materials and products thereof, and relates to an antibacterial mildew-proof polyethylene composition and foamed beads, a preparation method thereof, and a molded body. The antibacterial and mildewproof polyethylene composition contains polyethylene base resin, a guanidine salt composite antibacterial agent, a mildewproof agent and an auxiliary agent, wherein the auxiliary agent contains a foam nucleating agent and an optional antioxidant; based on 100 parts by weight of the polyethylene base resin, the content of the guanidine salt compositeantibacterial agent is 0.05-2.0 parts by weight, the content of the mildew preventive is 0.01-5.0 parts by weight, the content of the foam nucleating agent is 0.01-10 parts by weight, and the contentof the antioxidant is 0-10 parts by weight. The antibacterial and mildewproof polyethylene composition is good in antibacterial and mildewproof effects, the water resistance is also improved, the foamed beads prepared from the antibacterial and mildewproof polyethylene composition have impact resistance and low molding temperature, and the obtained molded product is excellent in antibacterial andmildewproof performance and high in compression strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antibacterial and anti-ageing coating for bamboo root carvings

InactiveCN109370372AMeet the use requirementsImprove heat resistanceAntifouling/underwater paintsPaints with biocidesTert butyl phenolLanthanum hexaboride

The invention discloses antibacterial and anti-ageing coating for bamboo root carvings. The antibacterial and anti-ageing coating is prepared from the following raw materials in parts by weight: 45 to60 parts of bisphenol A epoxy acrylate, 12 to 22 parts of 3,3'-[oxybismethylene]bis[3-methyl]oxetane, 3 to 9 parts of phenolic epoxy resin, 2 to 9 parts of 1,6-hexanediol diacrylate, 2 to 9 parts ofperfluorohexylethyl acrylate, 8 to 15 parts of tert-butyl phenol glycidyl ether acrylate, 2 to 8 parts of o-cresol glycidyl ether, 2 to 8 parts of a photoinitiator, 3 to 7 parts of modified nano aluminum oxide, 2 to 3 parts of attapulgite, 0.5 to 2 parts of nano titanium dioxide, 0.3 to 1.5 parts of illite, 0.1 to 1 part of lanthanum hexaboride, 3 to 8 parts of a compound antibacterial agent, 2 to5 parts of calcium carbonate whisker and 0.2 to 1.5 parts of an auxiliary agent. The antibacterial and anti-ageing coating for the bamboo root carvings, provided by the invention, has good antibacterial and anti-ageing performance, is used for the bamboo root carvings and can be used for preventing the bamboo root carvings from being mildewed and cracked.

Owner:广德竹之韵工艺品厂

PVDC (Polyvinyl Dichloride) coating material with high barrier property and preparation method thereof

InactiveCN108342132AStrong oxidation abilityImprove tensile strength at breakAntifouling/underwater paintsPaints with biocidesAdhesivePolyamide

The invention discloses a PVDC (Polyvinyl Dichloride) coating material with a high barrier property. The PVDC coating material comprises a modified PA (Polyamide) film, wherein the surface of the outer side of the modified PA film is coated with modified PVDC latex; the surface of the inner side of the modified PA film is coated with modified PVDC nano adhesive; the modified PVDC latex is preparedfrom the following raw materials: ultrapure water, a PH value buffer regulator, a vinylidene chloride monomer, a methyl acrylate monomer, an initiator and a dispersant; the thickness of the modifiedPA film is 3.5mu m to 4.0mu m; the thickness of the modified PVDC latex covered on the surface of the outer side of the modified PA film is 2.5mu m to 3.0mu m; the thickness of the modified PVDC nanoadhesive covered on the surface of the inner side of the modified PA film is 1.5mu m to 1.8mu m. The PVDC coating material, within continuous 24h under atmospheric pressure, has the oxygen transmission rate of 0.018ml / mil / 100in<2> to 0.053ml / mil / 100in<2>, and at the temperature of 100 DEG C and under the relative humidity of 90 percent, has the moisture transmission rate of 0.009ml / mil / 100in<2> to0.012ml / mil / 100in<2>, and the PVDC coating material is used for solving the technical problems that PVDC latex is poorer in heat stability, when being heated or put for a longer time at a normal temperature, easily generates double bond conjugation, releases chlorine hydride, enables a cavity to be formed between molecules and is invalid in barrier property.

Owner:席海龙

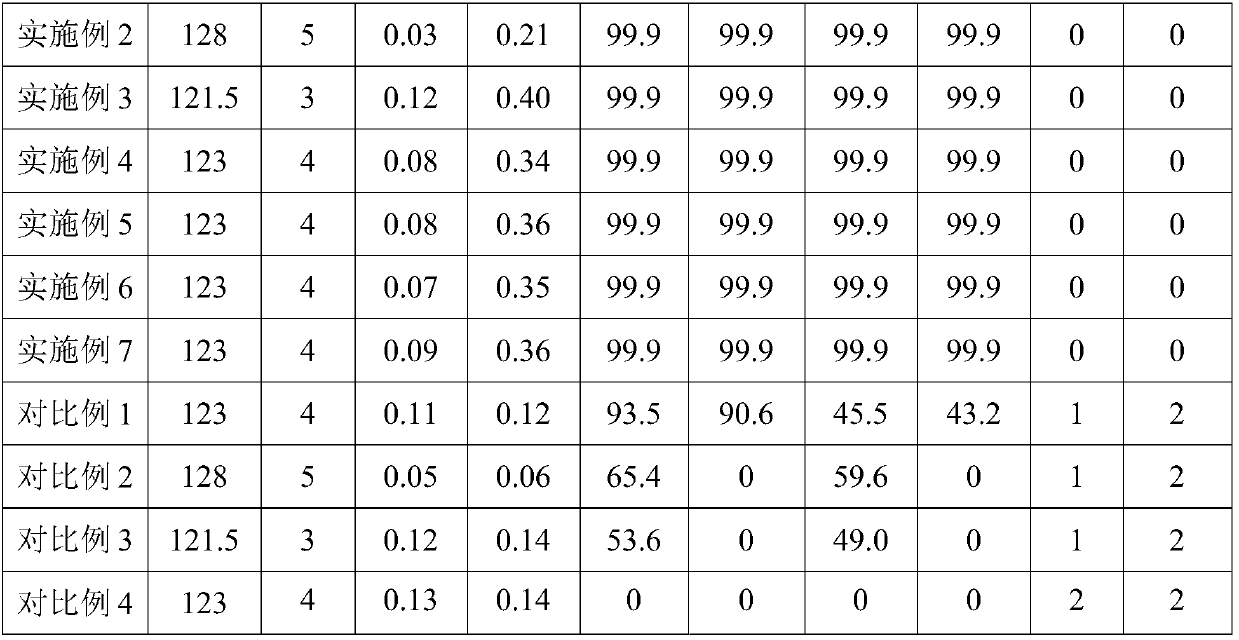

Environmental-friendly hard water resistant cutting fluid and preparation method thereof

InactiveCN103666710AImprove the lubrication effectImprove wear resistanceAdditivesPolyvinyl butyralMorpholine

An environmental-friendly hard water resistant cutting fluid is prepared from the following raw material: by weight, 3-4 parts of hydroxyethylidene-1,1-diphosphonic acid, 1-2 parts of morpholine, 1-2 parts of triethanolamine, 3-4 parts of polyethylene glycol, 3-4 parts of polyvinyl butyral, 1-2 parts of capric acid, 14-17 parts of kerosene, 2-3 parts of octyl phenol polyoxyethylene ether, 6-8 parts of an additive and 200parts of water; the environmental-friendly hard water resistant cutting fluid, by using the hydroxyethylidene-1,1-diphosphonic acid, has good calcium carbonate scale and iron scale prevention property, hard water resistant property, rust resistant property, good lubricity, wear resistance, antistatic property, and excellent antibacterial mouldproof performances, is applicable to a variety of cutting modes and workpiece materials, and is environmental-friendly and less harmful to human body.

Owner:MAANSHAN HENGYI MACHINERY MFG

Mildew-resistant antibacterial braid and preparation method thereof

InactiveCN108035165AGood antibacterial and mildew resistanceAntifouling/underwater paintsPaints with biocidesAntibiosisGlass fiber

The invention discloses a mildew-resistant antibacterial braid and a preparation method thereof. The preparation method comprises the following steps: 1) mixing glass fiber and bamboo fiber to preparea mixture M1; 2) under condition of existence of a solvent, mixing the mixture M1 and bamboo charcoal powder, drying a mixture and grinding the mixture to prepare powder M2; 3) under condition of a pH value being 4-6, mixing the powder M2 and a silane coupling agent to prepare a mixture M3; 4) mixing polyurethane resin, the mixture M3, nano calcium carbonate and graphene to prepare a coating object M4; and 5) coating the surface of the braid with the coating object M4 to prepare the mildew-resistant antibacterial braid. The glass fiber and bamboo fiber are mixed, then a mixture and the bamboocharcoal powder are mixed, then the mixture is dried and ground, the above powder and the silane coupling agent are mixed, polyurethane resin, nano calcium carbonate and graphene are mixed with the above mixture to prepare the coating object, the surface of the braid is coated with the above coating object, and the obtained braid has good antibiosis and mildew-resistant performance.

Owner:WUHU PINDU ELECTRONICS TECH

Special water-borne rust-associated anti-rust coating having antibacterial and antifungal functions and applied to pump valve

InactiveCN105462379AImprove stabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesPetroleumCatechol

The invention discloses a special water-borne rust-associated anti-rust coating having antibacterial and antifungal functions and applied to a pump valve. The special water-borne rust-associated anti-rust coating is prepared from raw materials in parts by weight as follows: 65-70 parts of methyl methacrylate, 60-65 parts of styrene, 0.5-0.6 parts of ammonium persulfate, 4-5 parts of phosphate ester monomers, 20-24 parts of deionized water, 2-3 parts of SDS (sodium dodecyl sulfate), 35-40 parts of glass flakes, 1-1.2 parts of a silane coupling agent KH560, 30-35 parts of an ethanol solution with the concentration of 75wt%, 40-43 parts of a sodium hydroxide solution with the concentration of 10wt%, 2-3 parts of isopropanol, 3-4 parts of catechol, 9-11 parts of nano-zinc oxide, 1-1.2 parts of dimethyl fumarate, 2-3 parts of absolute ethyl alcohol, 3-4 parts of a silver loaded nano-zirconium phosphate antimicrobial agent, 1.5-2 parts of petroleum sodium sulfonate, 19-21 parts of calcium carbonate and proper amount of water. The coating can be directly sprayed to a pump valve material, substrate surface treatment is not needed, and the coating has excellent antibacterial and antifungal performance and is applicable to the pump valve in a humid environment.

Owner:TONGLING SIDE TECH

Antibacterial and mildew-proof processing method for down feathers

InactiveCN107083688AImprove antibacterial and antifungal effectGood antibacterial and antifungal propertiesBiochemical fibre treatmentHygieneChemistry

The invention discloses an antibacterial and mildew-proof processing method for down feathers. The method comprises the following steps: firstly obtaining a silicon dioxide composite sol loading cinnamyl aldehyyde through a sol-gel method, mixing the silicon dioxide composite sol with acetum of chitosan to obtain down feather finishing liquid, padding the down feathers treated after degreasing, dedusting, cleaning, dehydrating and drying into the down feather finishing liquid, and conducting drying treatment. The down feathers obtained after the processing of the invention have excellent antibacterial and mildew-proof properties, are not prone to go bad and produce odor, have a lasting effect and good hygiene, and are beneficial to health of people.

Owner:ANHUI FANSHENG POULTRY IND CO LTD

Mildew-proof polypropylene film

The invention relates to a mildew-proof polypropylene film. The mildew-proof polypropylene film is prepared from the following raw materials in parts by weight: 80 to 90 parts of polypropylene , 0.1 to 0.5 part of antimonous oxide, 0.2 to 0.6 part of aluminum hydroxide, 0.1 to 0.5 part of 2,6-tert-butyl-4-methylphenol, 0.05 to 0.1 part of phosphite, 1 to 4 parts of tourmaline, 3 to 6 parts of nanotitanium dioxide, 1 to 4 parts of silver-loaded zeolite, 0.05 to 0.1 part of horseradish essential oil, 0.1 to 0.5 part of epoxy soybean oil, 0.05 to 0.1 part of tea tree essential oil, 1 to 4 partsof attapulgite, 0.1 to 0.5 part of arginine grafted chitosan, 0.1 to 0.5 part of nanometer bentonite, 2 to 5 parts of bamboo fibers, 1 to 4 parts of activated carbon and 1 to 4 parts of calcium carbonate. The polypropylene film disclosed by the invention has superior comprehensive performance, excellent antibacterial and mildew-proof properties, safety and reliability; in addition, the service life is greatly prolonged and the polypropylene film is especially suitable for food packaging; meanwhile, the polypropylene film has the advantages of wide source of raw materials, economy and applicability.

Owner:ANHUI GUOTAI PACKING PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com