Leather nano pigment paste and preparation thereof

A nano-pigment and pigment paste technology, which is applied in the direction of pigment slurry, dyeing method, textile and paper making, etc., can solve the problems of long preparation cycle, high cost and low efficiency, achieve wide application range, improve film-forming performance, and process mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

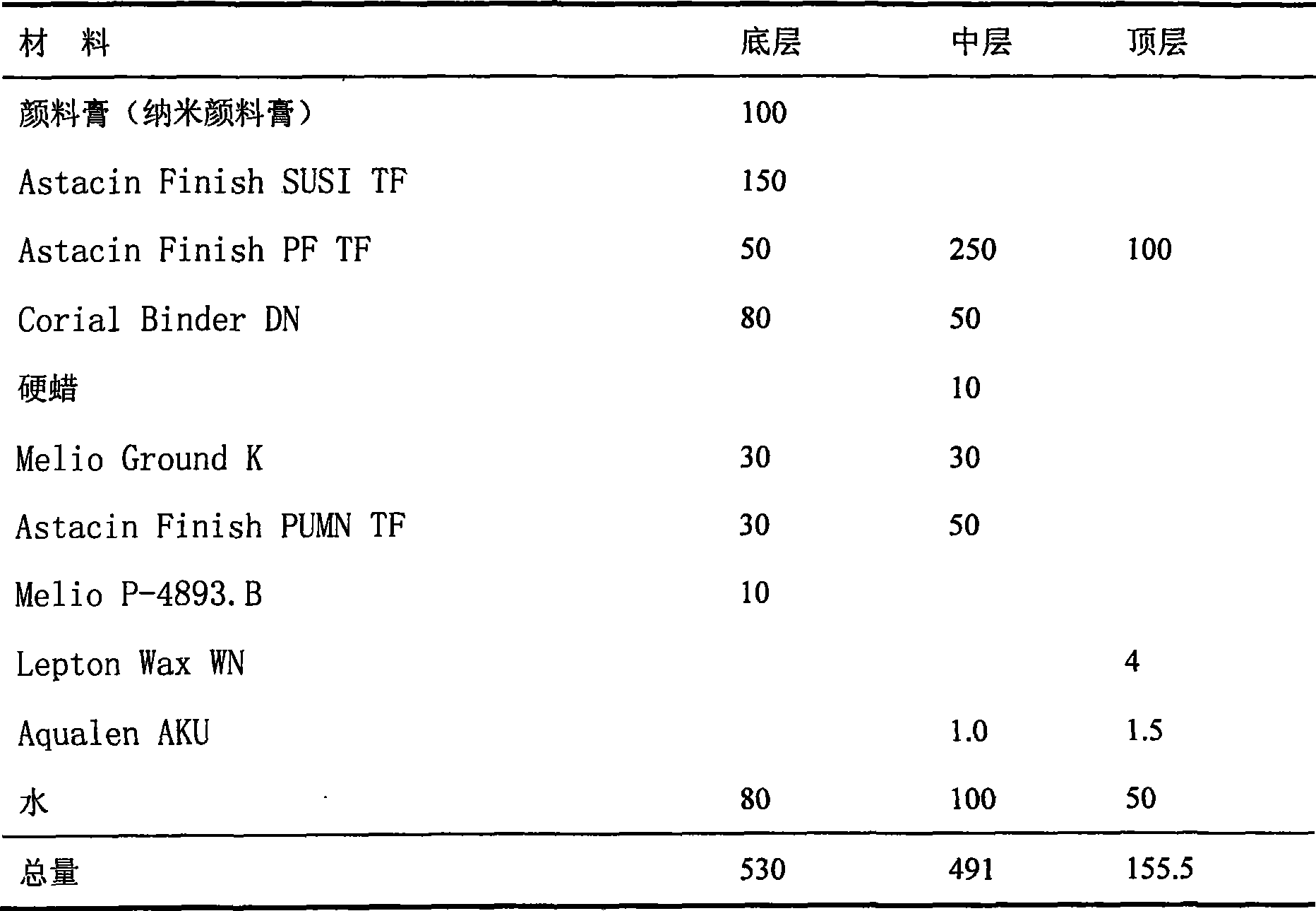

Examples

Embodiment 1

[0034] TiO with a particle size of 50-80nm 2 100g is added into 1897g water, after being uniformly dispersed to form a nano-suspension under a high-shear emulsifier, the pH is adjusted to 7, then 1g of flat plus 0 is added, and the mixture is evenly stirred (the average particle diameter of the suspension detected under a laser particle size instrument is 105.89 nm, Zata potential is 12.68mv); then add 1g of sulfated castor oil, stir evenly, and adjust the pH to 7 again; finally add 1g of compound stabilizer (wherein the content of acrylic resin is 0.2g, and the content of polyurethane is 0.8g), stir Evenly.

Embodiment 2

[0036] TiO with a particle size of 50-80nm 2 300g was added into 1689g of water, after being uniformly dispersed to form a nano-suspension under a high-shear emulsifier, the pH was adjusted to 7.5, then 1g of sodium lauryl sulfate and 2g of sodium hexametaphosphate were added, and stirred evenly (in a laser particle size instrument The average particle diameter of the suspended liquid is 127.38nm, and the Zata potential is 13.55mv); then add 3g of sulfated castor oil, stir evenly, and adjust the pH again to be 7.5; finally add 5g of compound stabilizer (wherein the acrylic resin content is 2g , polyurethane content is 3g), stir well.

Embodiment 3

[0038]Add 100g of ZnO with a particle size of 50-80nm into 1896g of water, disperse evenly under a high-shear emulsifier to form a nano-suspension, adjust the pH to 7, and then add 1g of dodecyltrimethylammonium chloride, Stir evenly (the average particle size of the suspension detected by a laser particle size instrument is 108.09nm, and the Zata potential is 9.32mv); then add 1g of sulfated castor oil and 1g of polyethylene glycol, stir evenly, and adjust the pH to 7 again; finally add 1g of compound stabilizer (wherein the content of acrylic resin is 0.2g, and the content of polyurethane is 0.8g), just stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com