Mite-killing insect-preventing water-based inorganic nano-coating and preparation method thereof

A technology of inorganic nano and inorganic nano-silicon, which is applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of high diatomite price and difficult cost control, and achieve good anti-fouling effect , Antibacterial and anti-mildew long-term effect, excellent anti-mold and anti-bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

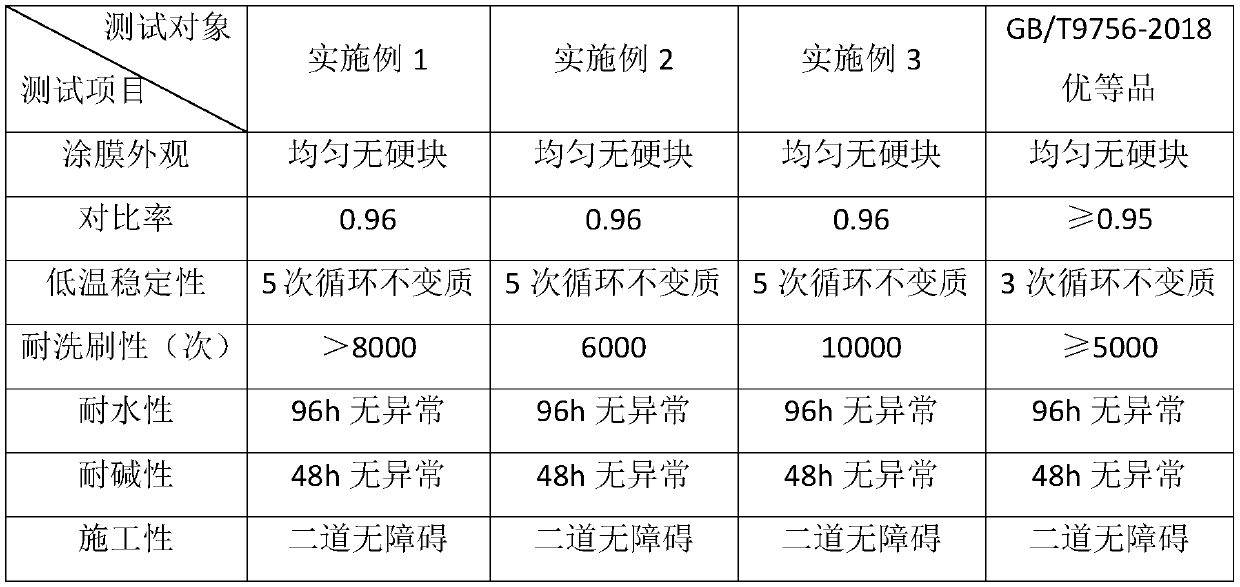

Examples

Embodiment 1~3

[0035] Embodiment 1~3 mite-repellent water-based inorganic nano-coating

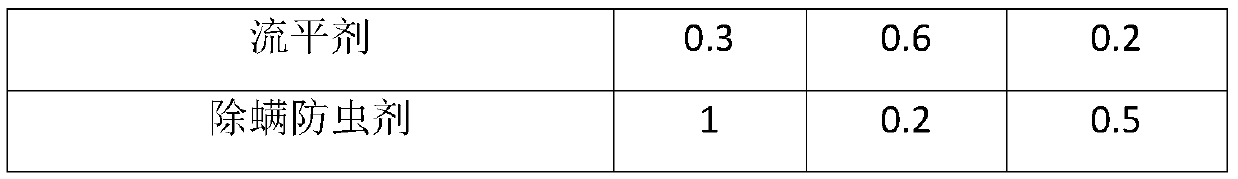

[0036] Embodiments 1~3 The parts by weight of each raw material in the mite-proof and insect-proof water-based inorganic nano-coating are as shown in Table 1:

[0037] Table 1 The parts by weight of the raw materials of the mite-repelling and insect-repelling water-based inorganic nano-coatings in Examples 1-3

[0038]

[0039]

[0040] Note: "-" in the table means not added; Among them, the defoamer NXZ is added in step (2), and the defoamer 334 is added in step (3).

Embodiment 1

[0041] Embodiment 1 The preparation method of removing mite and insect repelling water-based inorganic nano-coating, comprises the following steps:

[0042] (1) According to the parts by weight of the raw materials described in Example 1 in Table 1, water is added to the batching bucket, and at a speed of 700 rpm, hydroxyethyl cellulose is added while stirring, and the mixture is evenly stirred until the hydroxyethyl cellulose Transparent and non-granular liquid;

[0043] (2) According to the parts by weight of raw materials described in Example 1 in Table 1, in the transparent non-granular liquid obtained in step (1), add wetting agent, dispersant and 0.2 parts by weight of antifoaming agent, at 1200 rpm After stirring evenly at different speeds, add pigments and fillers, stir evenly, and then grind and disperse to 50 μm to obtain abrasives;

[0044] (3) According to the parts by weight of the raw materials described in Example 1 in Table 1, the grinding material obtained in...

Embodiment 2

[0046] The preparation method of embodiment 2 mite-repellent water-based inorganic nano-coatings comprises the following steps:

[0047] (1) According to the parts by weight of the raw materials described in Example 2 in Table 1, water is added to the batching bucket, and at a speed of 600 rpm, hydroxyethyl cellulose is added while stirring, and the mixture is evenly stirred until the hydroxyethyl cellulose Transparent and non-granular liquid;

[0048] (2) According to the parts by weight of raw materials described in Example 2 in Table 1, in the transparent and non-granular liquid obtained in step (1), add wetting agent, dispersant and 0.15 parts by weight of defoamer, at 1000 rpm After stirring evenly at different speeds, add pigments and fillers, stir evenly, and then grind and disperse to 60 μm to obtain abrasives;

[0049] (3) According to the parts by weight of the raw materials described in Example 2 in Table 1, the grinding material obtained in step (2) is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com