Pore-forming oxidative inorganic ecological decorative board and production method thereof

A decorative panel and hole-forming technology, applied in the field of green ecological environment building materials, can solve problems such as unsuitable for large-scale continuous operation, blockage, and ecological reduction, achieve quantity collection and distribution, improve sound absorption and noise reduction, and avoid Dependent effect on quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of porous oxidation inorganic ecological decorative board-ceiling, comprises 92 parts of hemihydrate gypsum, 8 parts of white portland cement, 58 parts of liquid medium (clear water, seaweed glue, low-alkali high-silicon methyl siliconate potassium waterproofing agent by weight ratio of 100:3.5:3.2), 0.25 parts of porogenous composite photocatalytic oxidizer (nano-TiO2 photocatalyst, K12 foaming agent, 1.2% concentration of hydrogen peroxide in a weight ratio of 8:3:69) Foaming machine), 1.5 parts of 18-22mm glass fiber chopped strands, 1.3 parts of nano-titanium dioxide coating material (nano-titanium dioxide, algal calcium ecological coating compounded at a weight ratio of 0.3:99.7).

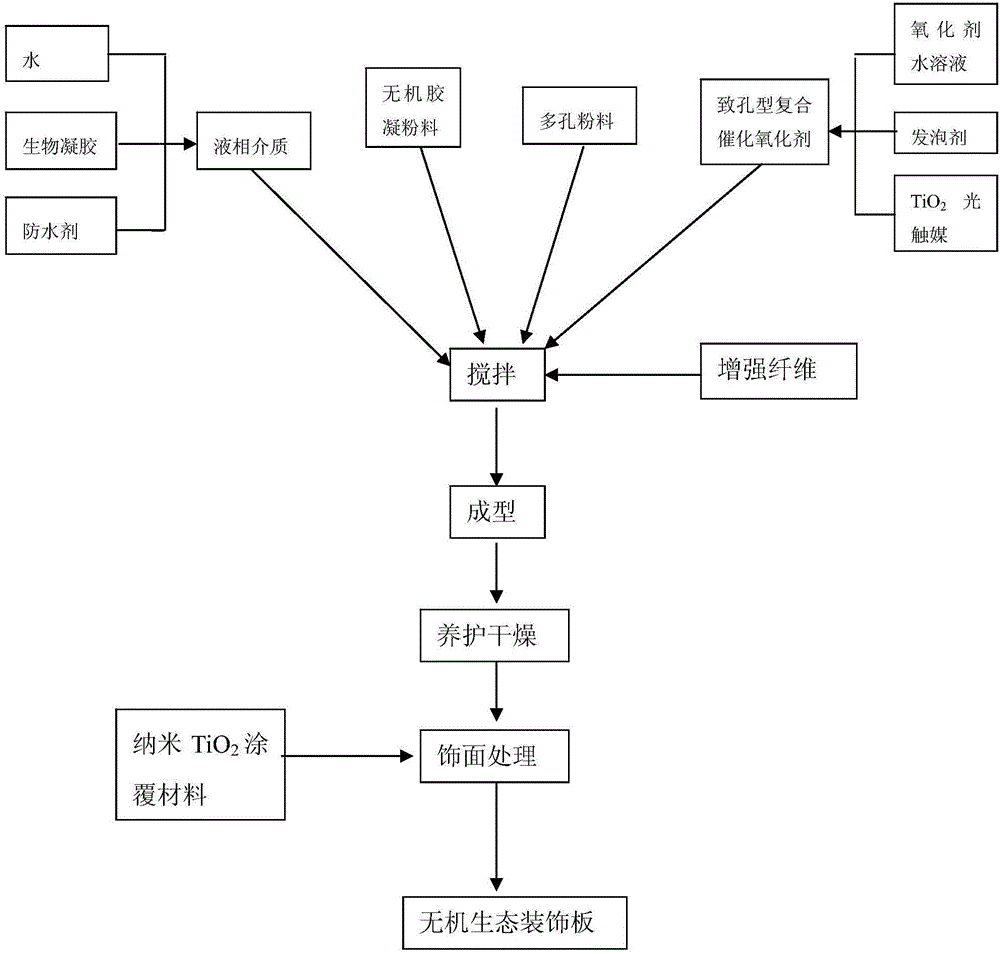

[0040] like figure 1 Shown, the production preparation process by above-mentioned raw material formula is:

[0041] (1) Pretreatment: Measure 92 parts of hemihydrate gypsum and 8 parts of white Portland cement respectively, stir them evenly for use; mix water, alginate, and low-...

Embodiment 2

[0049] A kind of porous oxidation inorganic ecological decoration board-ceiling, comprises 100 parts of hemihydrate gypsum, 8 parts of porous activated carbon powder, 58 parts of liquid medium (clear water, carrageenan, low-alkali high-silicon methyl siliconate potassium waterproofing agent by weight 100 parts : 6.2: 2.8 compound), 018 parts of porogenic composite photocatalytic oxidizer (nano-TiO 2 Photocatalyst, K12 foaming agent, 2.0% potassium permanganate solution compounded by weight ratio 28:3:69 and then foamed with a foaming machine), 6.5 parts of 5×5㎝ glass fiber mesh cloth, 4.5 parts Nano-titanium dioxide coating material (nano-titanium dioxide, algal calcium ecological coating compounded at a weight ratio of 0.5:99.5).

[0050] like figure 1 Shown, the production preparation process by above-mentioned raw material formula is:

[0051] (1) Pretreatment: Measure 100 parts of hemihydrate gypsum and 8 parts of porous activated carbon powder respectively, stir them ev...

Embodiment 3

[0057] A kind of pore-causing oxidation inorganic ecological decorative board-wall panel, comprises 83 parts of hemihydrate gypsum, 7 parts of white cement, 10 parts of mineral powder, 22 parts of porous attapulgite, 28.6 parts of liquid medium (clear water, konjac glue, low alkali high Potassium silicon methyl siliconate waterproofing agent compounded at a weight ratio of 100:8:5.0), 0.5 parts of porogenic composite photocatalytic oxidizer (nano TiO 2 Photocatalyst, K12 foaming agent, 4.0% potassium permanganate solution compounded by weight ratio 15.8:0.5:83.7 and then foamed by foaming machine), 1.5 parts of glass fiber chopped strands, 3.8 parts of nano-titanium dioxide coating Materials (nano-titanium dioxide, algae calcium ecological coating compounded at a weight ratio of 0.5:99.5; nano-titanium dioxide, water-based UV at a weight ratio of 0.3:99.7).

[0058] like figure 1 Shown, the production preparation process by above-mentioned raw material formula is:

[0059] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com