Patents

Literature

45results about How to "Distribute the load evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of addition type liquid fluorinated silicone rubber

The invention relates to a preparation method of addition type liquid fluorinated silicone rubber. D3F, ViD4 and MM with the purity larger than 99.5% are adopted as raw materials and evenly mixed according to a certain ratio, and vinyl fluorosilicone oil is obtained; the vinyl fluorosilicone oil is used as base gum, a reinforcement agent, a cross-linking agent and a catalyst are added in the vinyl fluorosilicone oil, kneading, grinding, tabletting and other technologies are performed, and the liquid fluorinated silicone rubber (FSR) is obtained; the insulation performance, hydrophobic property, the high-temperature resistance and the like of the LSR are better than that of liquid silicone rubber (LSR) with the same technology and formula. The preparation method is short in production period, the product has the good heat tear resistance, demolding is convenient, various machining ways of mold pressing, extrusion, injection molding and the like can be achieved, and automatic production materials can be achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

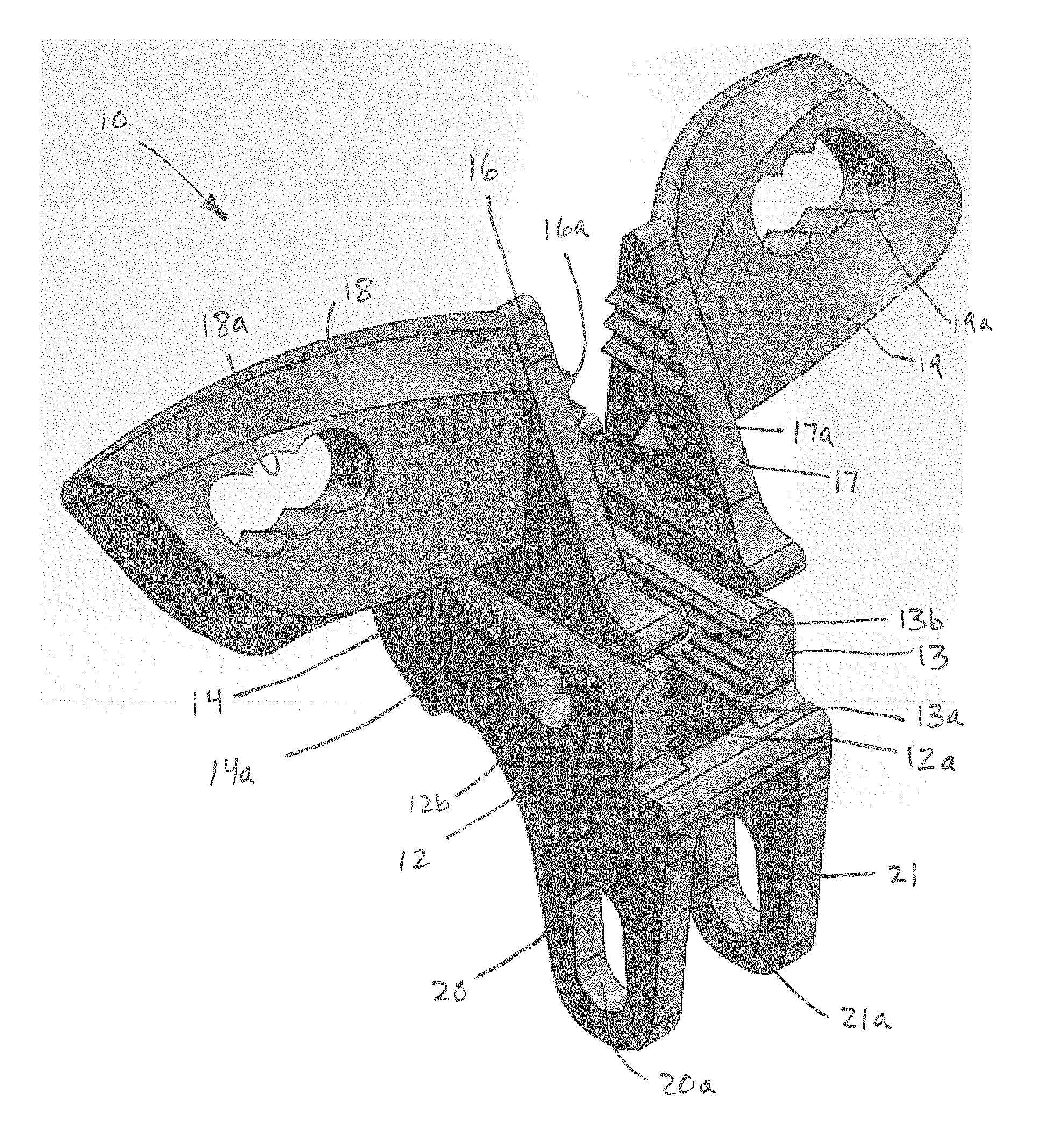

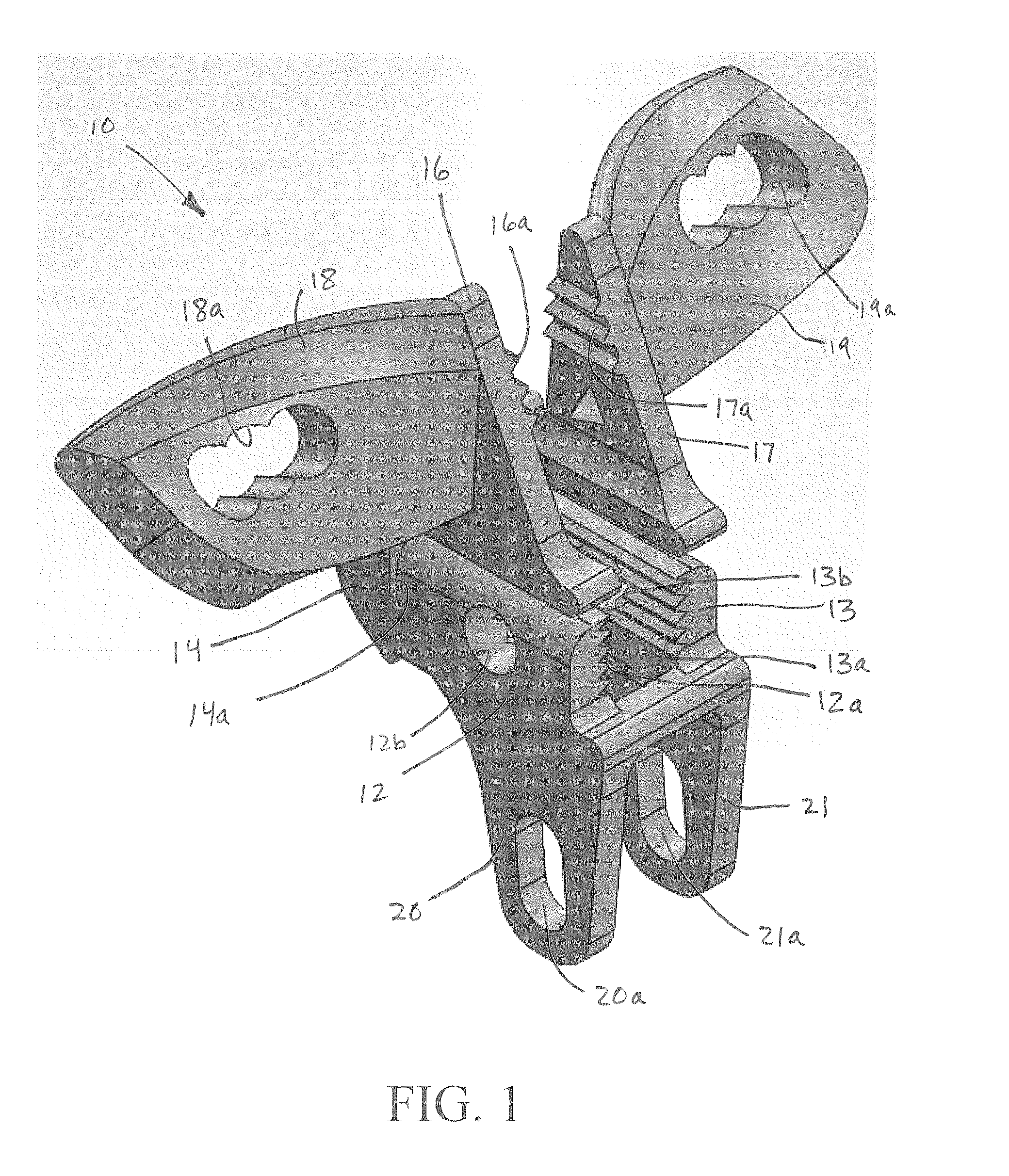

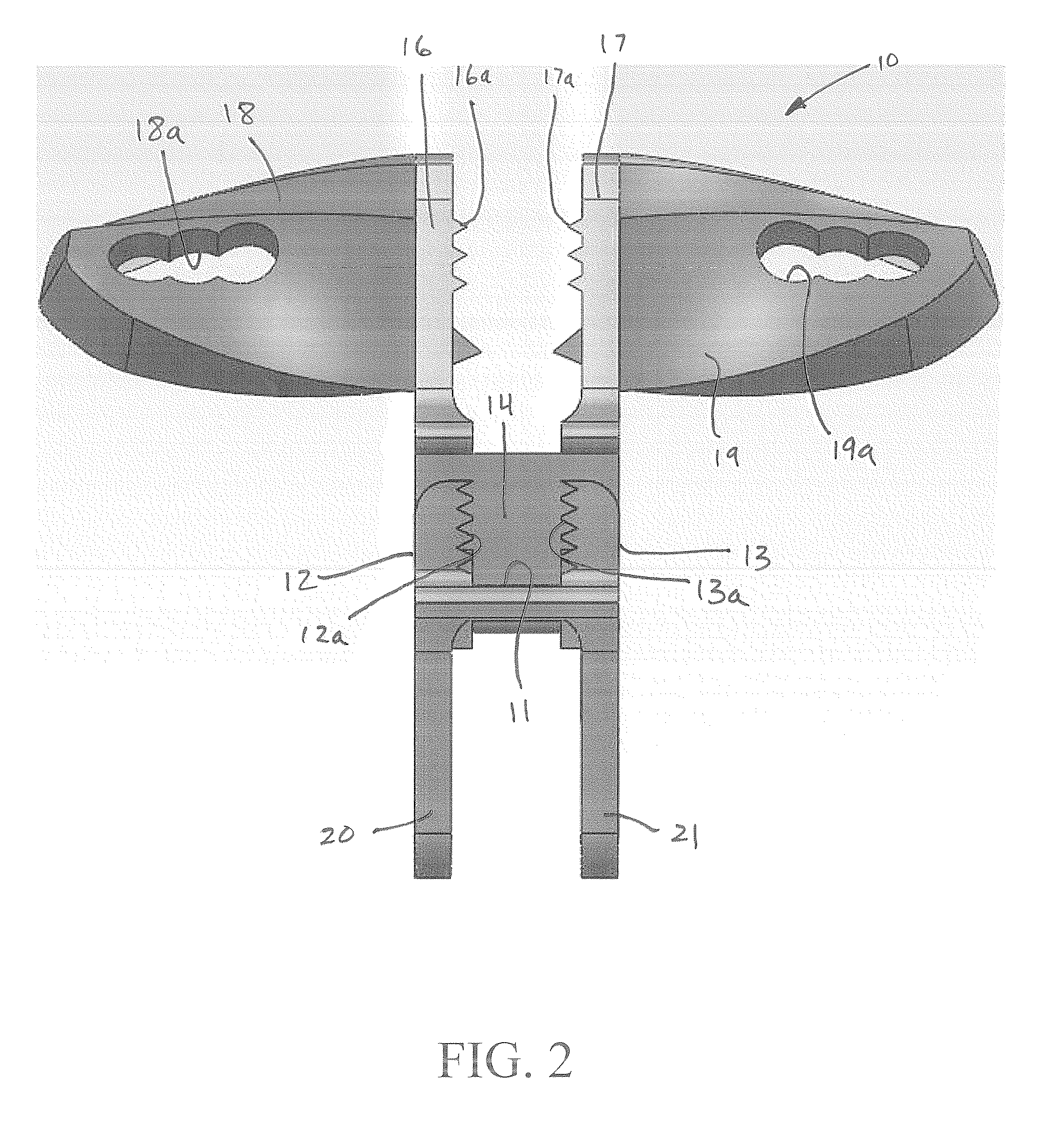

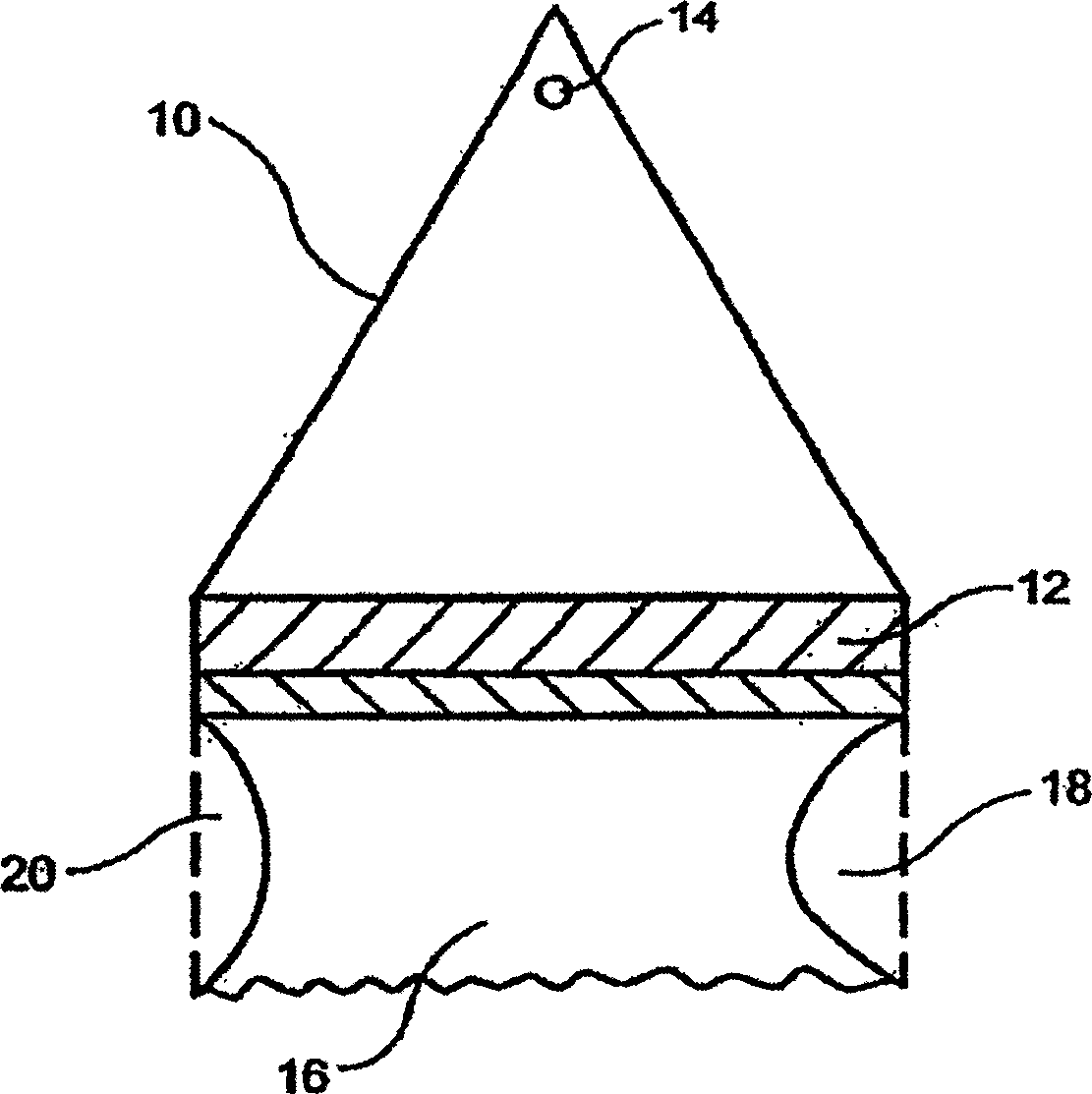

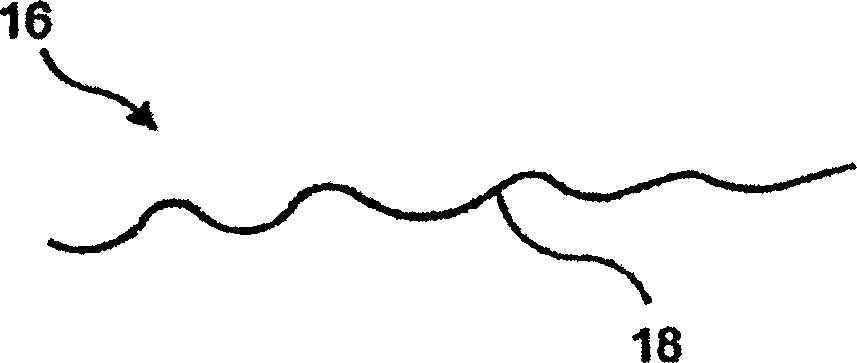

Hybrid Multifunctional Posterior Interspinous Fusion Device

ActiveUS20150012040A1Distribute the load evenlyMaintain continued axial loadingInternal osteosythesisJoint implantsIliac screwSurgery

This invention relates to an improved structure for an interspinous stabilization device that more evenly distributes loads throughout the adjacent vertebrae than known interspinous stabilization devices, and further readily compensates for graft settling so as to maintain continued axial loading of the graft. More specifically, this invention relates to a medical device that helps in performing a spinal fusion procedure by holding the bone graft in place and stabilizing the facet screw by a plate that is attached to it. The invention also performs a dynamic function that compensates for settling of the bone graft over time. This dynamic function may, if desired, be enhanced by a movement-limiting mechanism that allows extension but not flexion such that the bone graft fusion remains in contact and fusion takes place.

Owner:UNIVERSITY OF TOLEDO

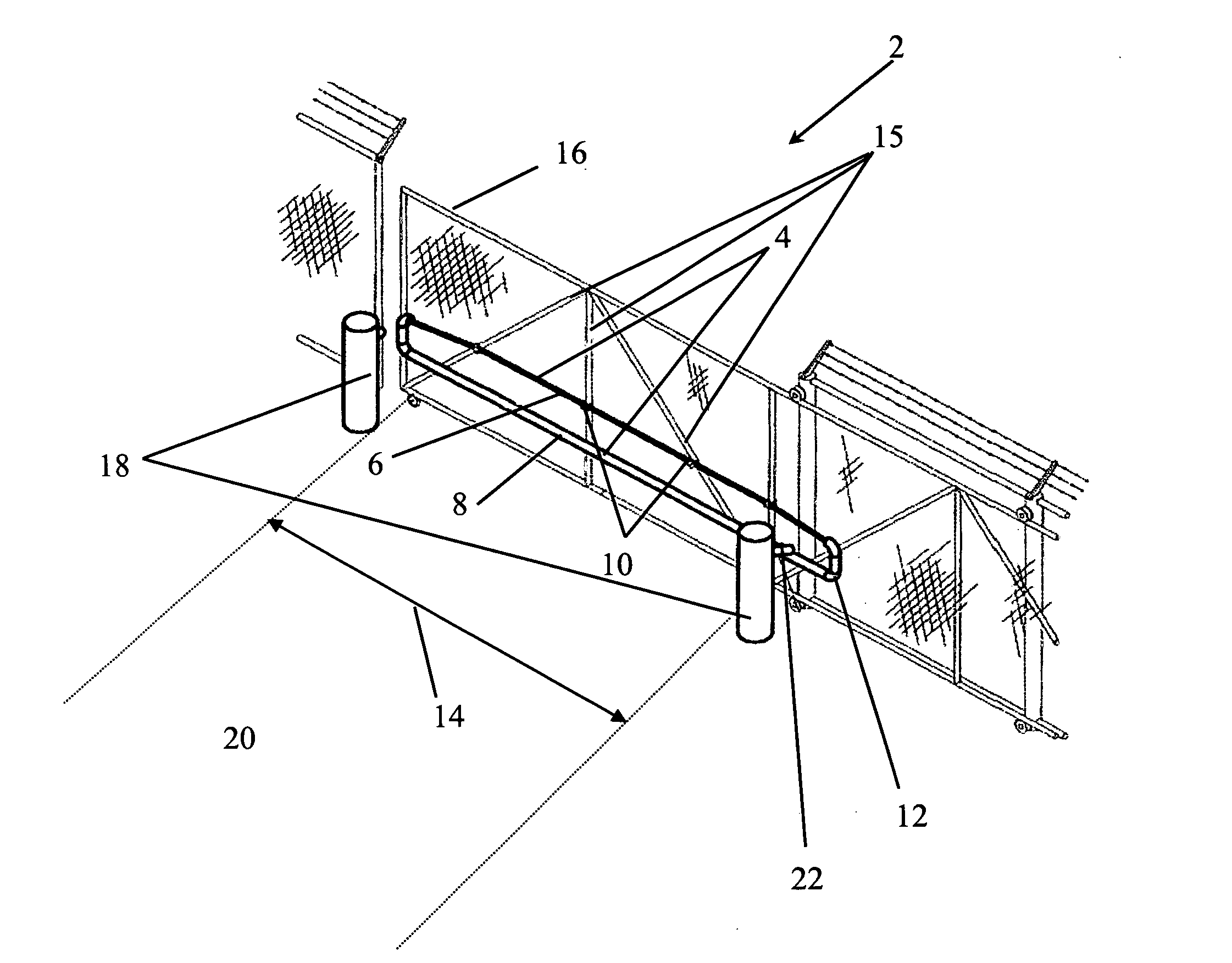

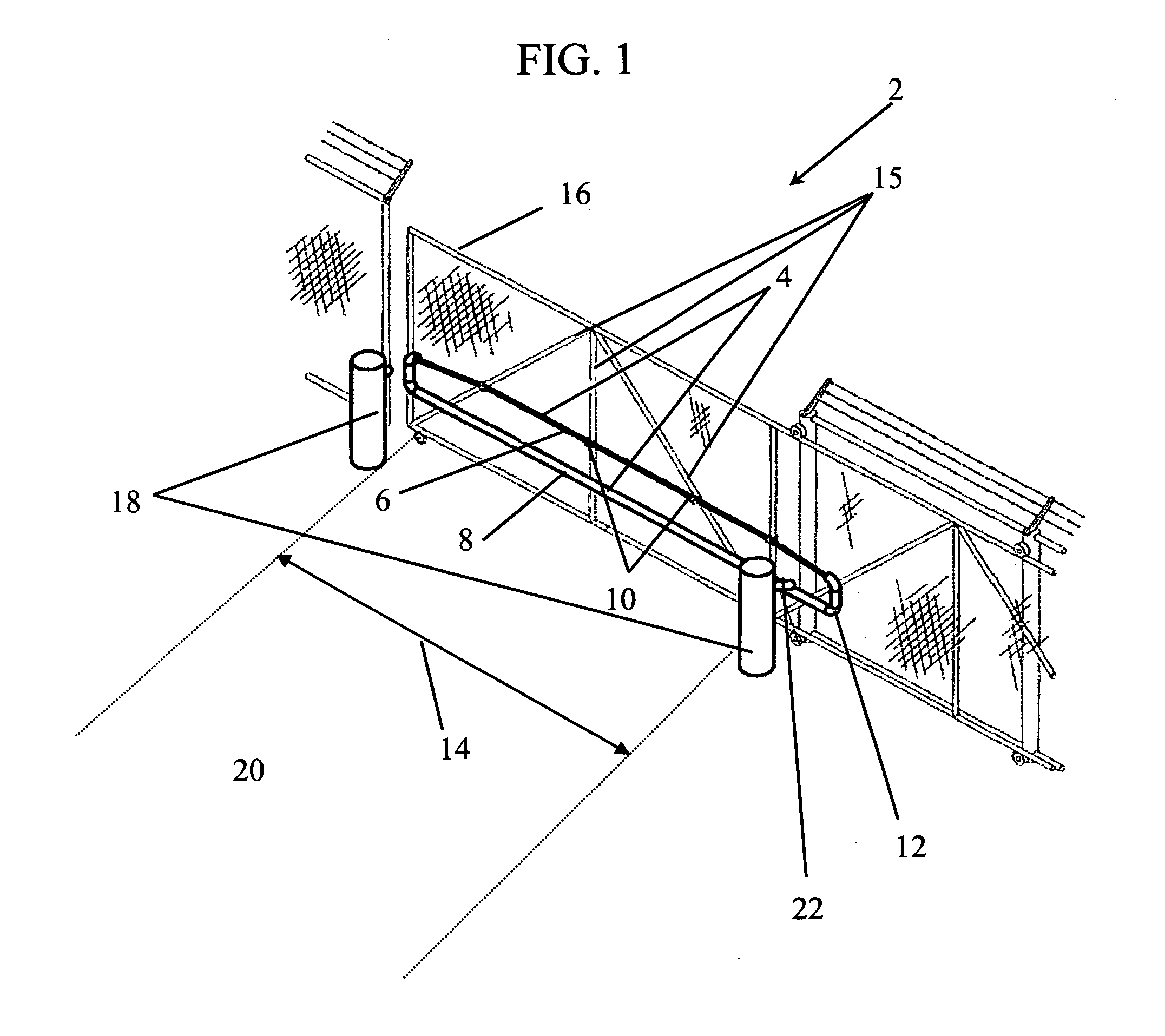

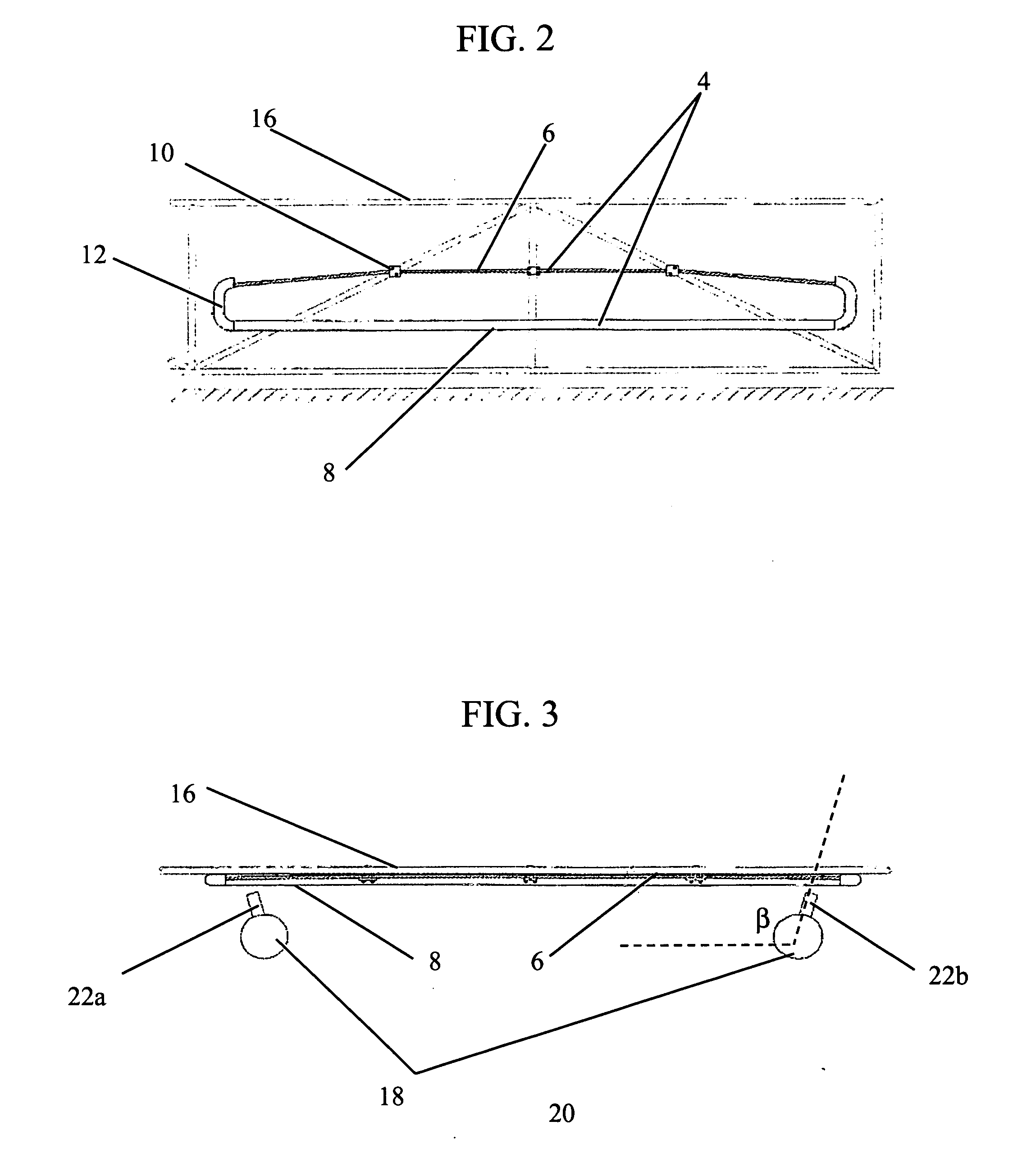

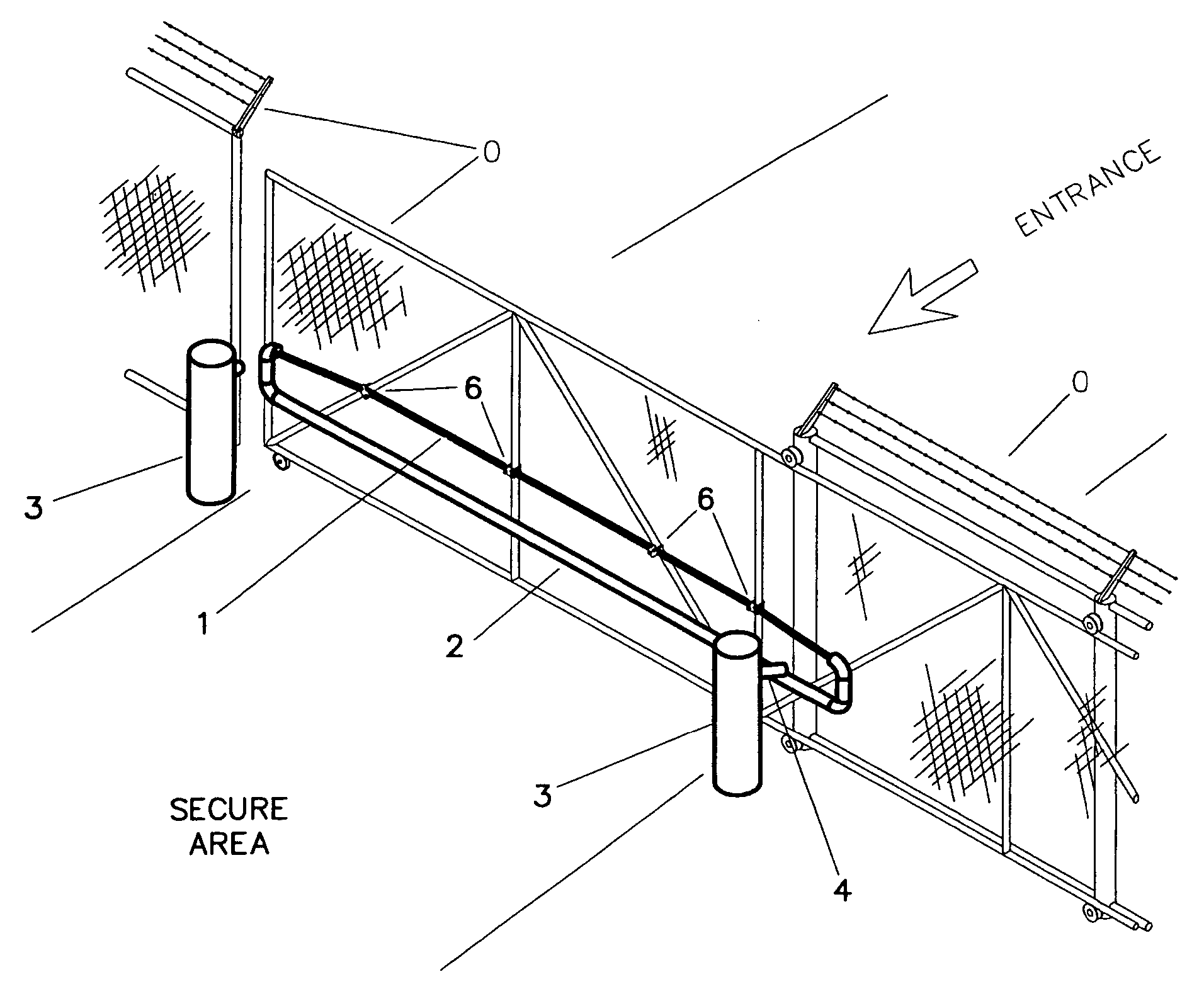

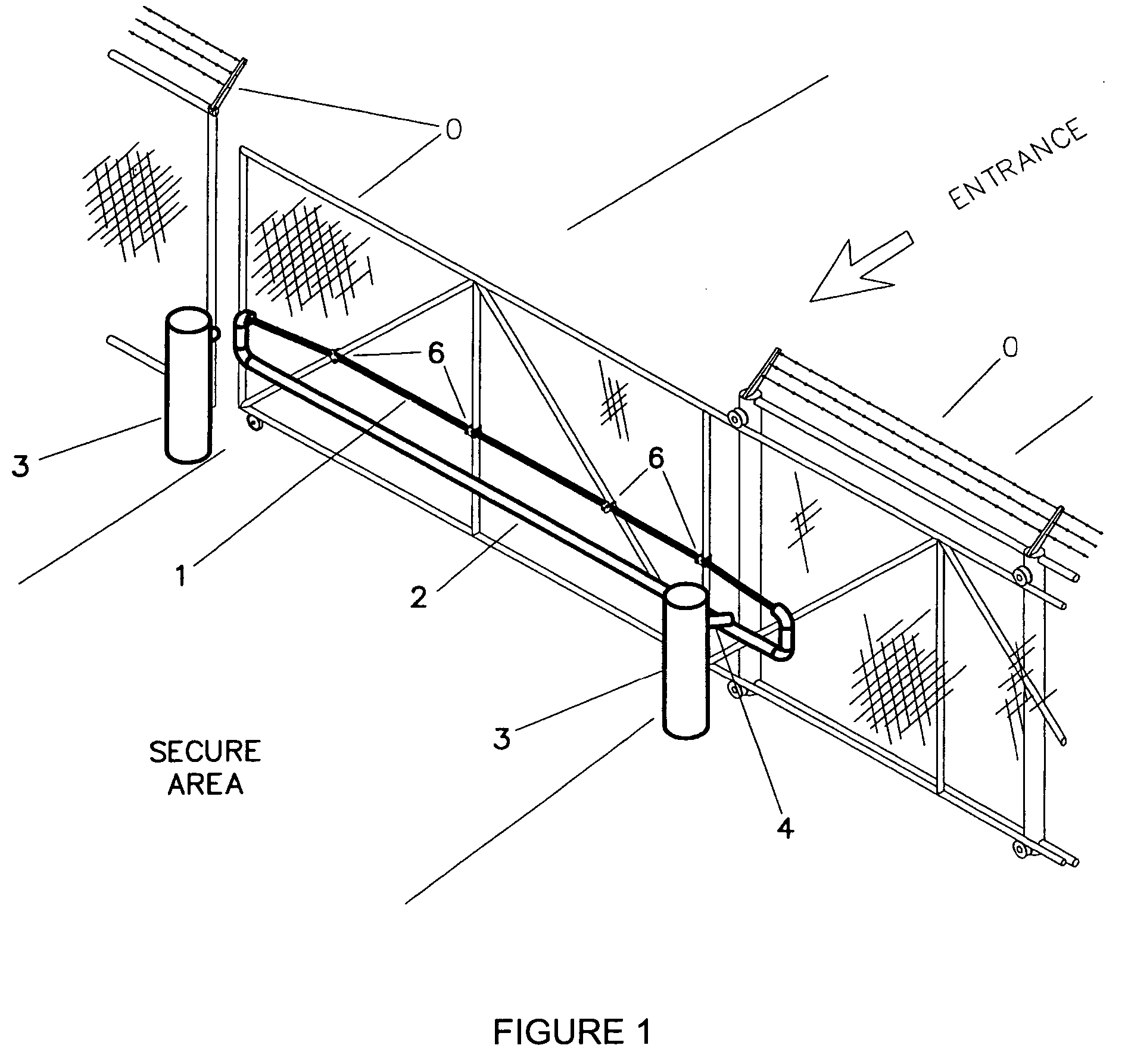

Security barrier system

ActiveUS20070101649A1Distribute the load evenlyReduced wear damageWing arrangementsWing suspension devicesDriver/operatorCombined use

The invention relates to a security barrier apparatus. Some embodiments of the present invention may be used in conjunction with a previously existing security gate or perimeter and other embodiments may be used as stand-alone security barrier gate systems. The various embodiments of the security barrier apparatus comprise a passive security gate apparatus that is capable of withstanding the force of an object, such as a vehicle, of up to 1.1×106 ft-lb / s wherein the driver of the object is attempting to gain entrance through the security gate apparatus.

Owner:GLOBAL GRAB TECH INC

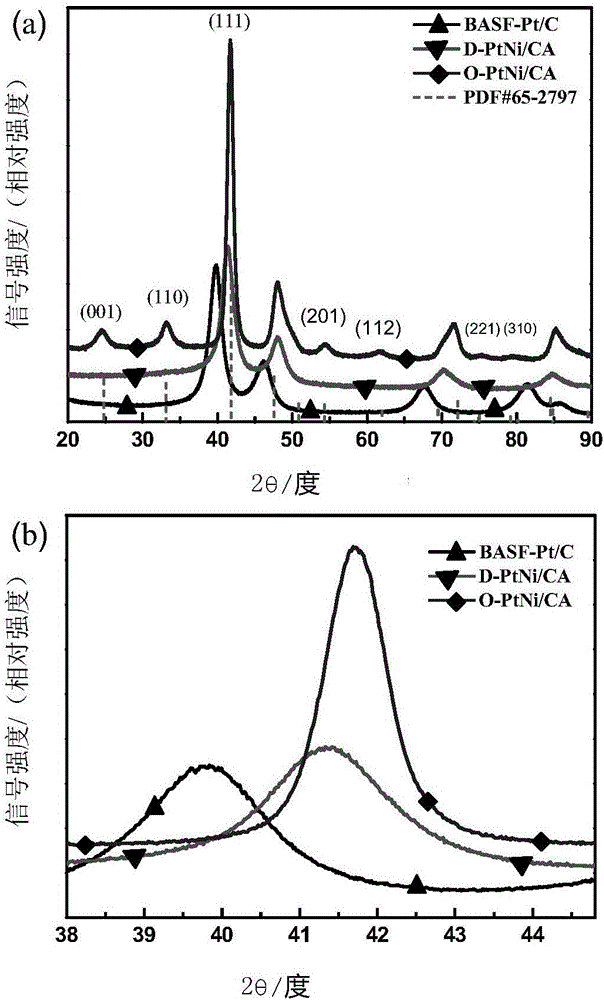

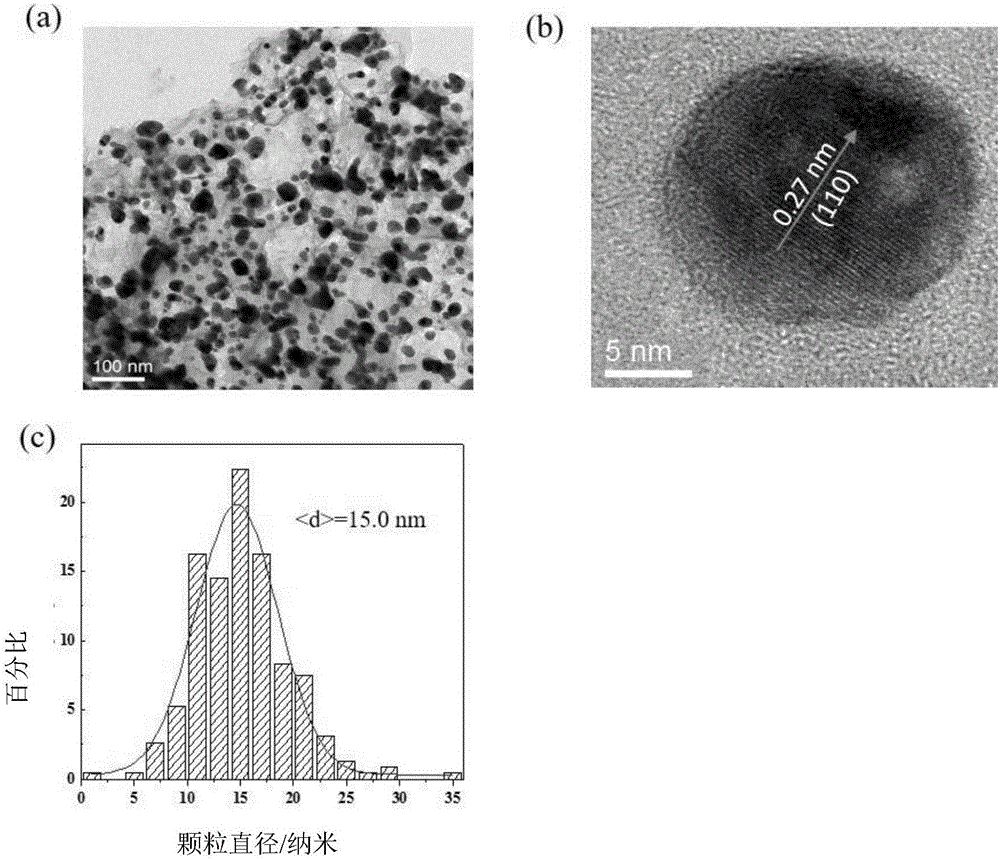

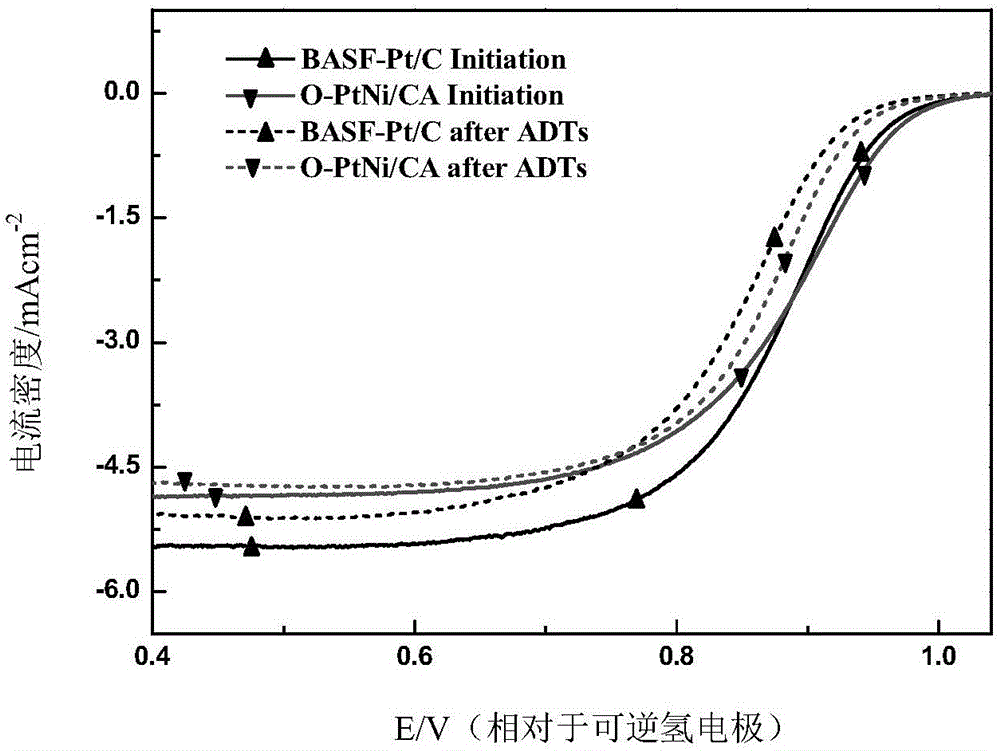

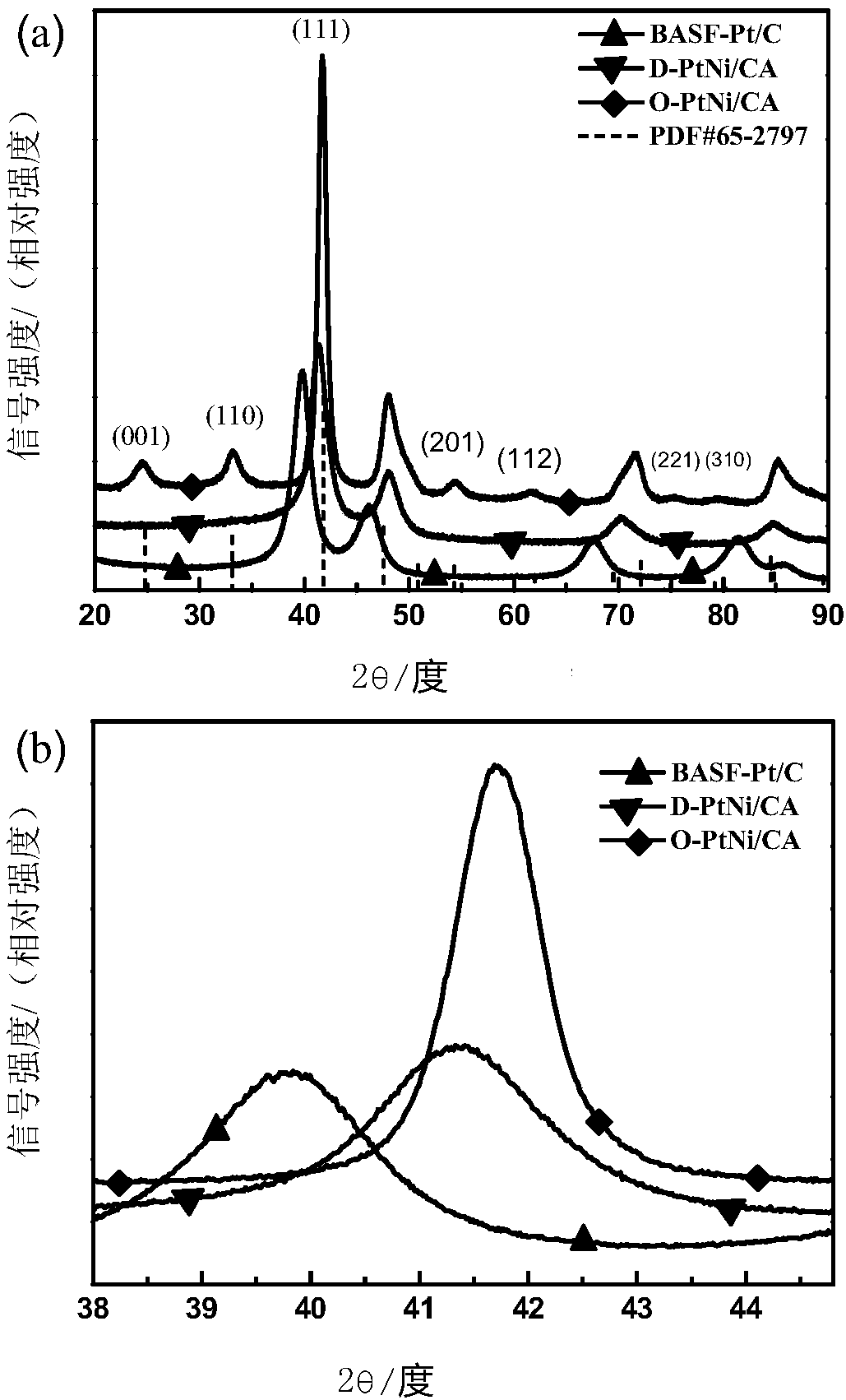

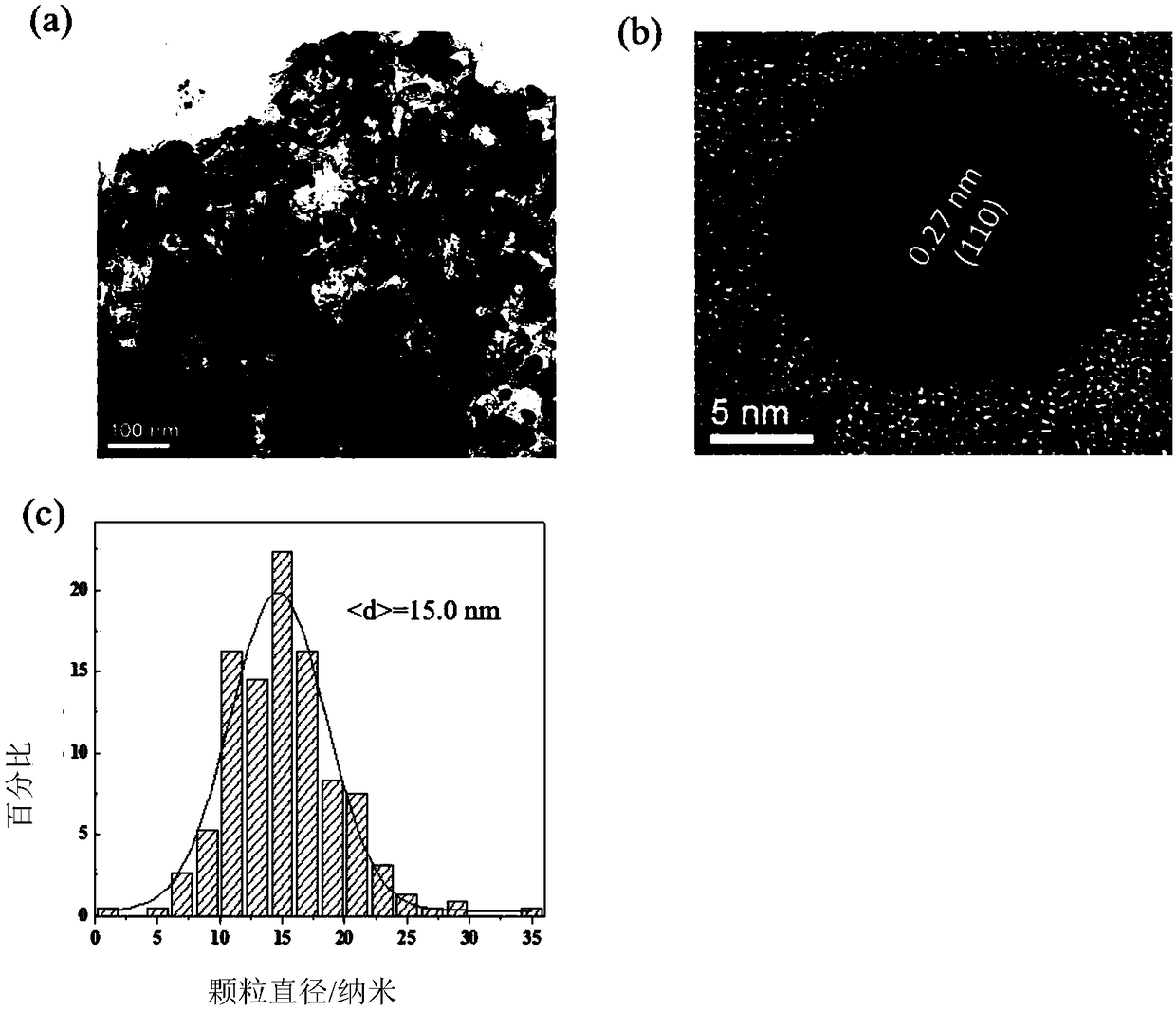

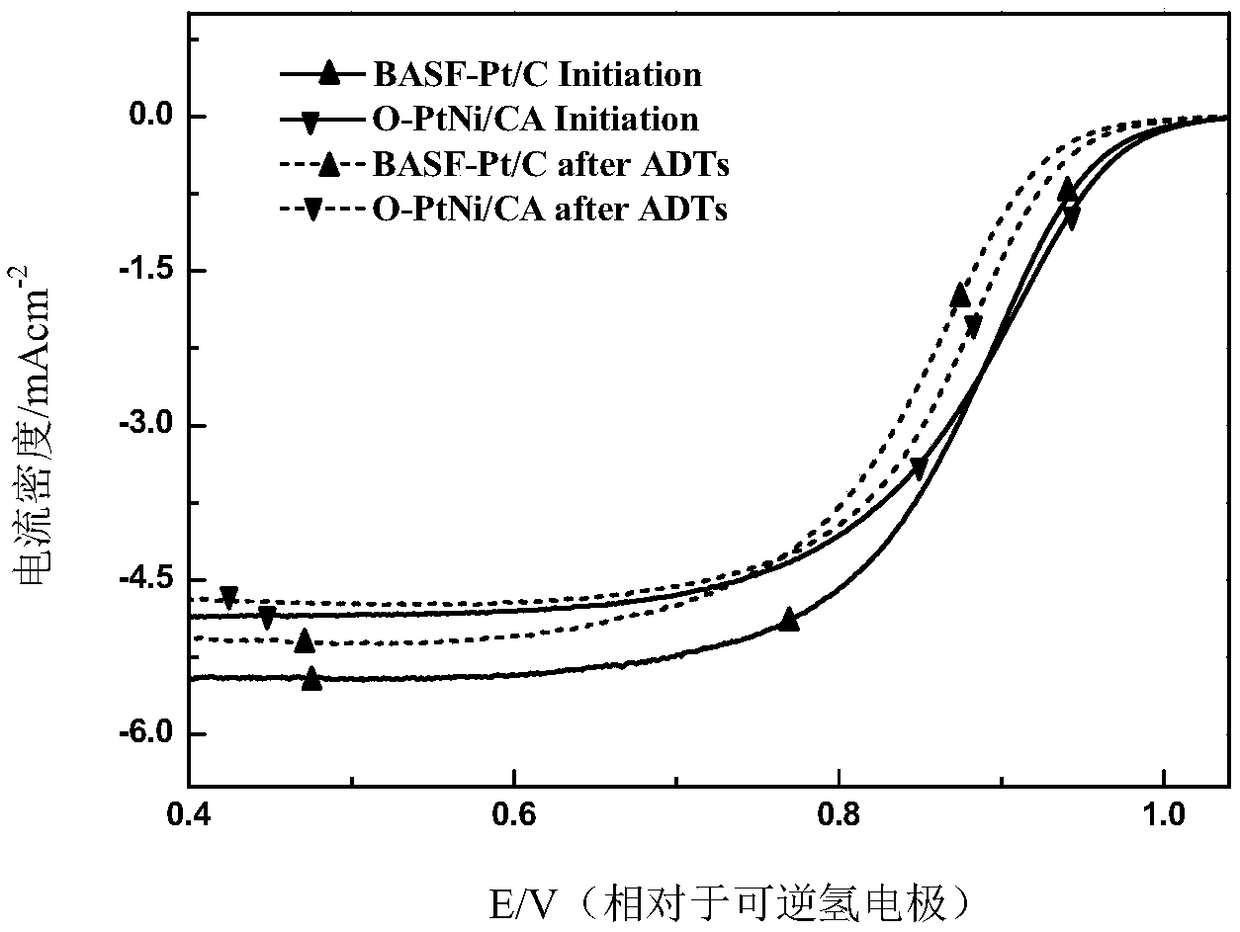

High-load platinum and nickel ordered intermetallic compound as well as preparation method and use thereof

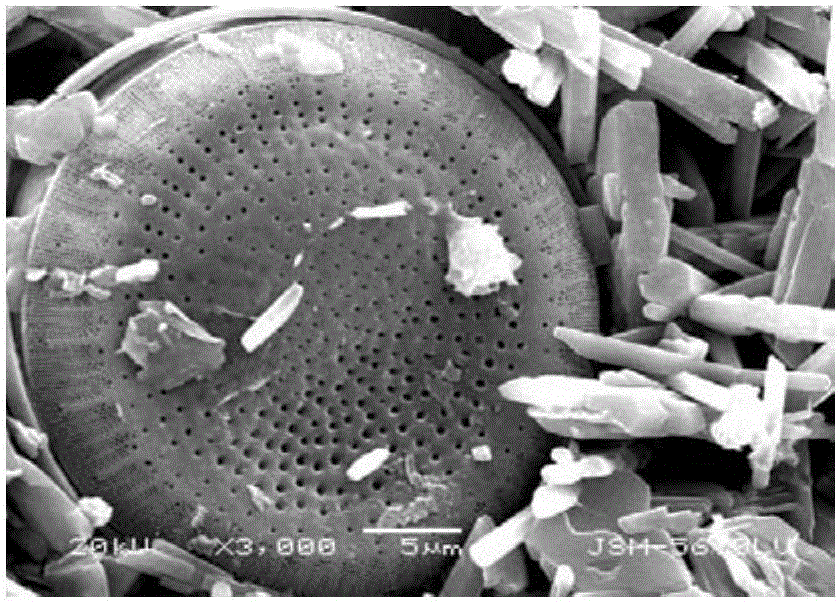

ActiveCN105854897AGood dispersionDistribute the load evenlyMetal/metal-oxides/metal-hydroxide catalystsPorous carbonAlloy

The invention provides a high-load platinum and nickel ordered intermetallic compound. The high-load platinum and nickel ordered intermetallic compound takes three-dimensional porous carbon gel as a carrier, and is prepared by a method comprising the following steps: evenly mixing graphene oxide-containing carbon carrier precursor dispersion liquid, a metal precursor solution containing a Pt precursor and an Ni precursor, a reducing agent and sodium citrate dehydrate; then, carrying out a hydrothermal reaction to generate high-load platinum and nickel disordered alloy evenly loaded in carbon gel; after that, carrying out heat treatment under the reducing atmosphere to form the high-load platinum and nickel ordered intermetallic compound evenly loaded in the carbon gel. Compared with the traditional high-load Pt / C catalyst, the catalyst provided by the invention relatively reduces the consumption of precious metal Pt; the activity of the catalyst is improved by using an intermetallic synergistic effect, the stability of the catalyst is improved by using high dispersion of ordered metal nanoparticles, and the high dispersion characteristic of the catalyst is still maintained after ordered heat treatment is carried out on the catalyst. The invention also discloses the preparation method of the high-load platinum and nickel ordered intermetallic compound. The invention also discloses use of the high-load platinum and nickel ordered intermetallic compound.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

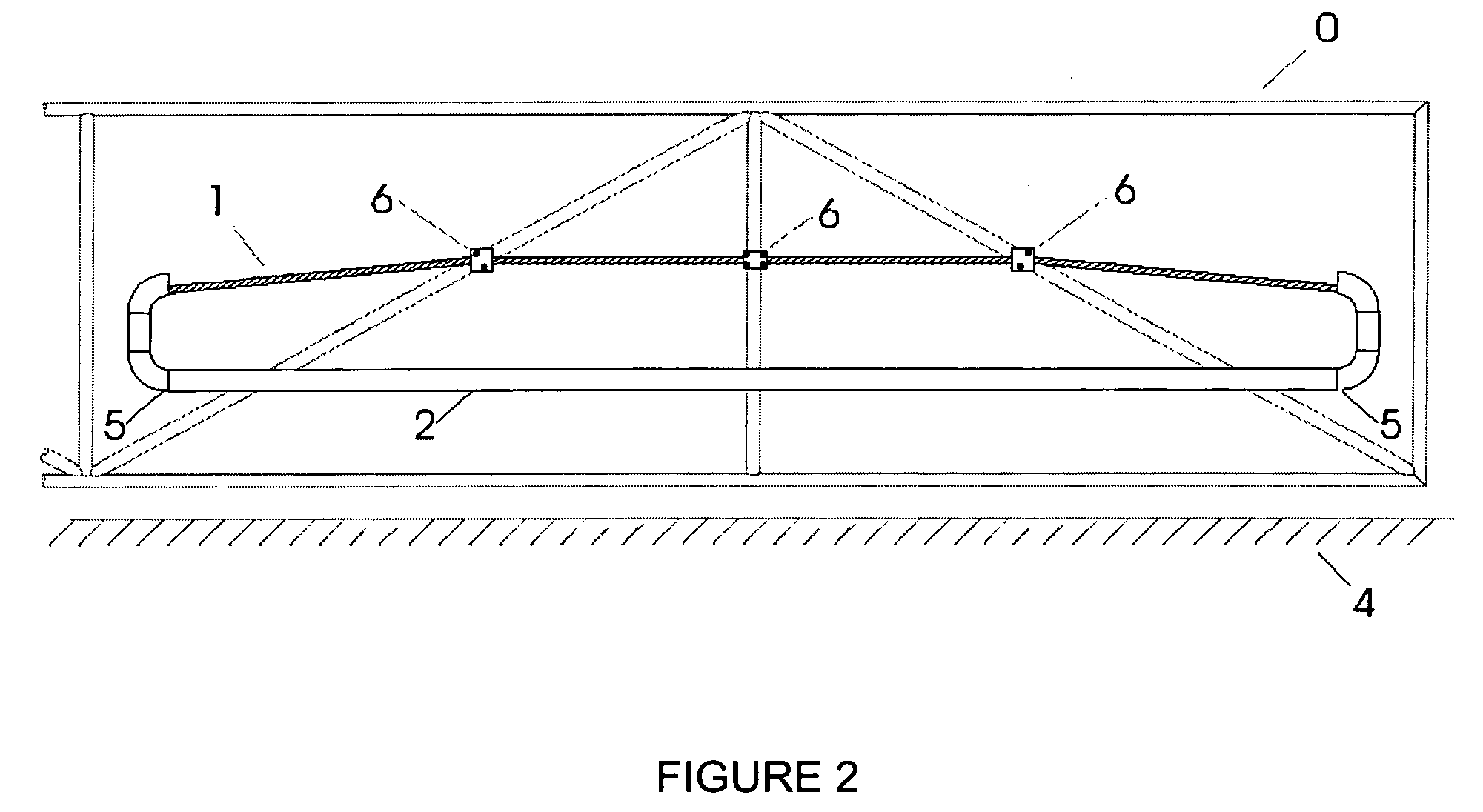

Security barrier reinforcing system

ActiveUS20050178065A1Distribute the load evenlyReduce the potential for damageFencingTraffic restrictionsEngineeringMechanical engineering

An improved system for upgrading new and existing gates or barriers to provide improved crash barrier rating. This system comprises a reinforcing attachment to the gate or barrier and improved reinforced bollards with catch hooks to absorb the energy of impact. The reinforcing attachment is an arrangement of cable and structural members that provide for increased reinforcement by ensuring that the load is distributed on the cable to minimize the risk of breakthrough as a result of cable failure. The bollards have been improved by strengthening the catch hook attachments and adding reinforcement positioning elements to facilitate proper assembly.

Owner:GLOBAL GRAB TECH INC

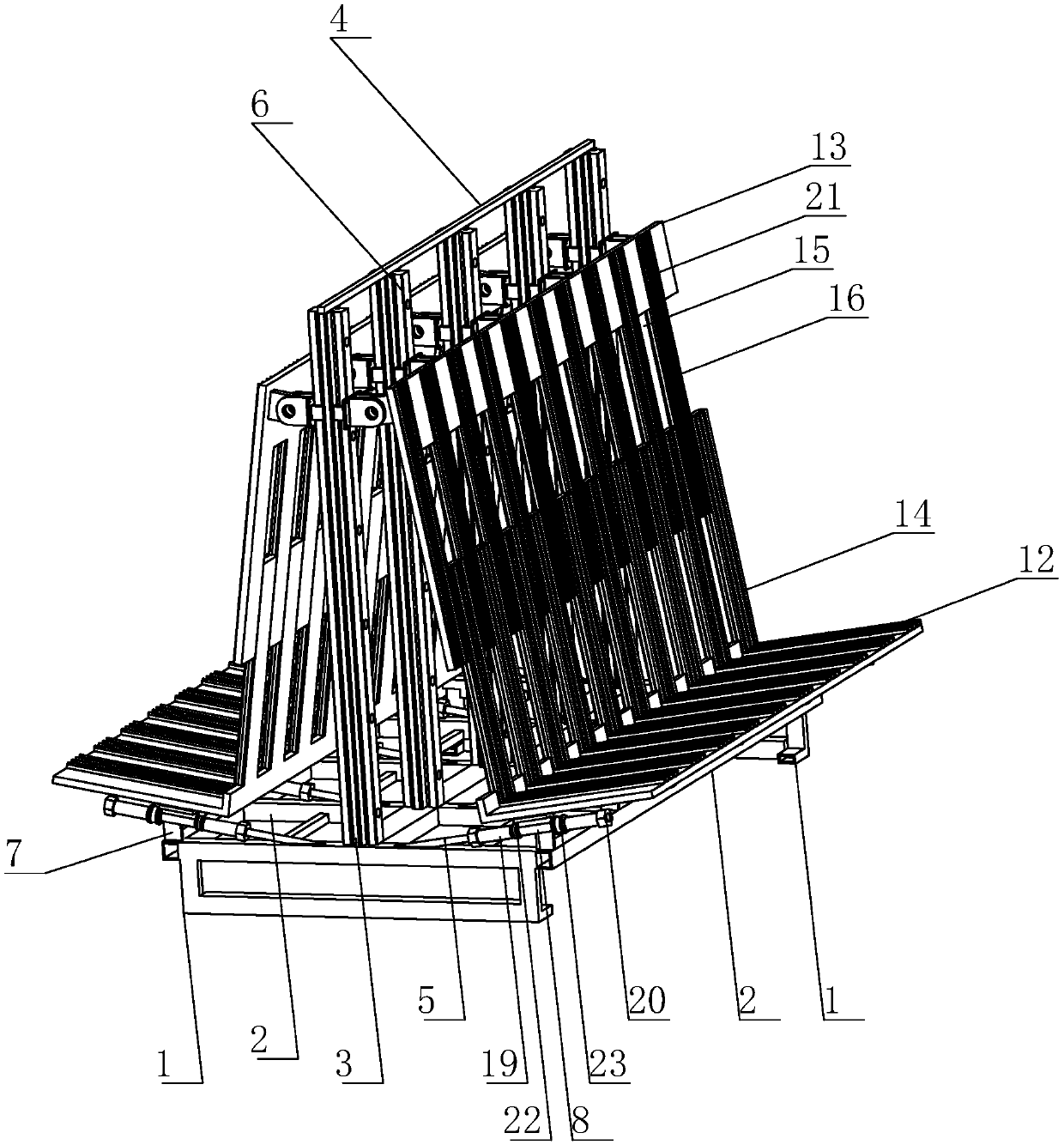

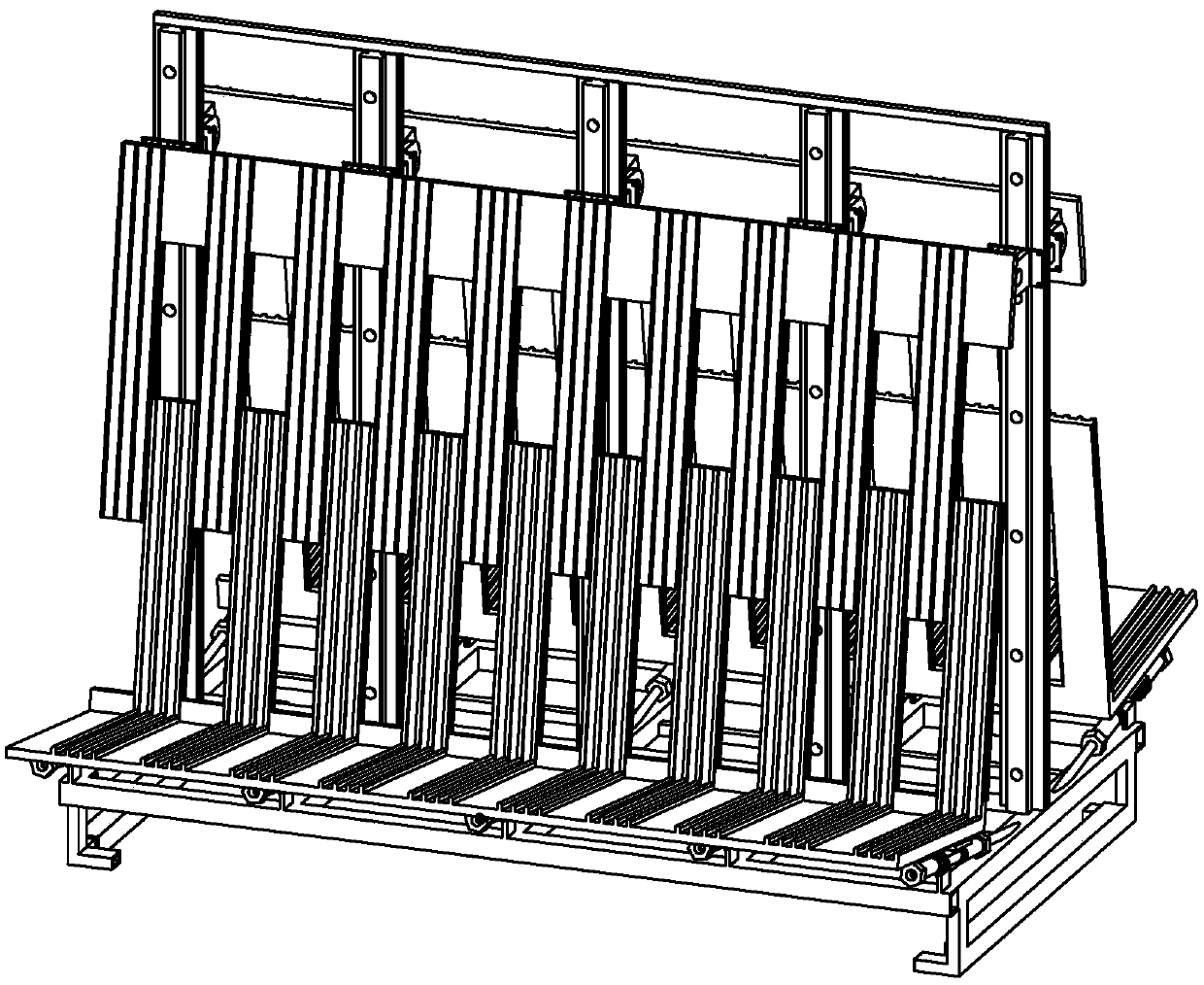

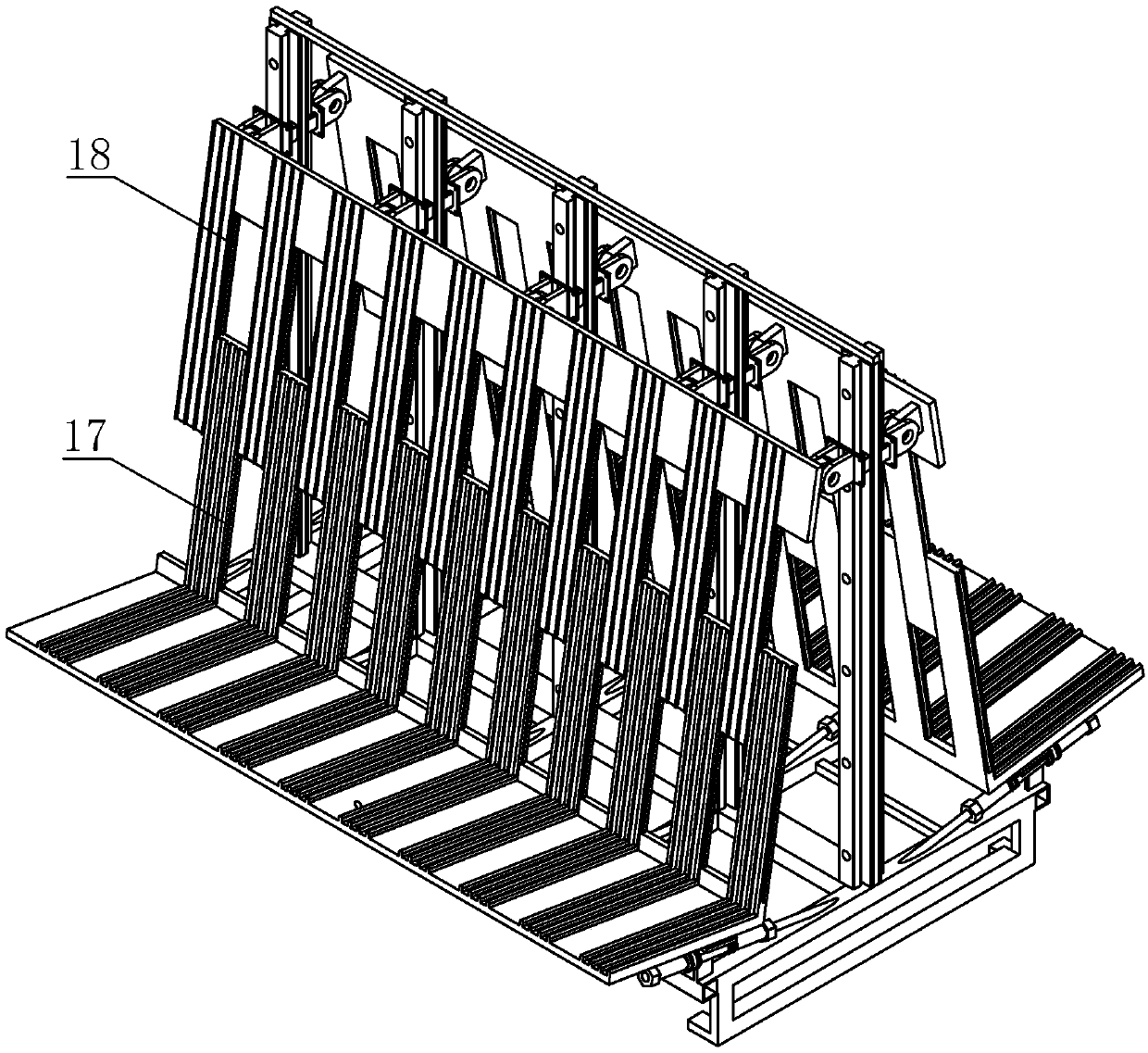

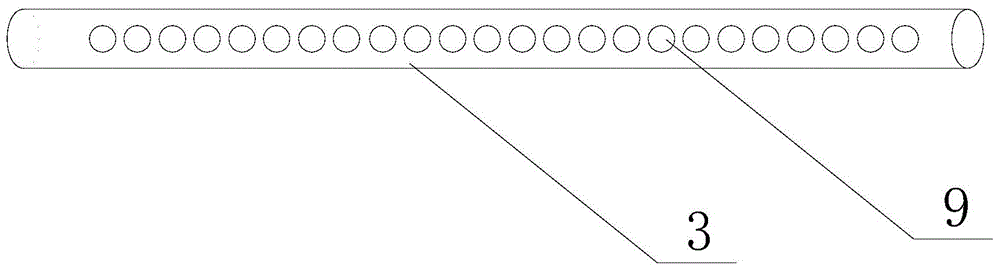

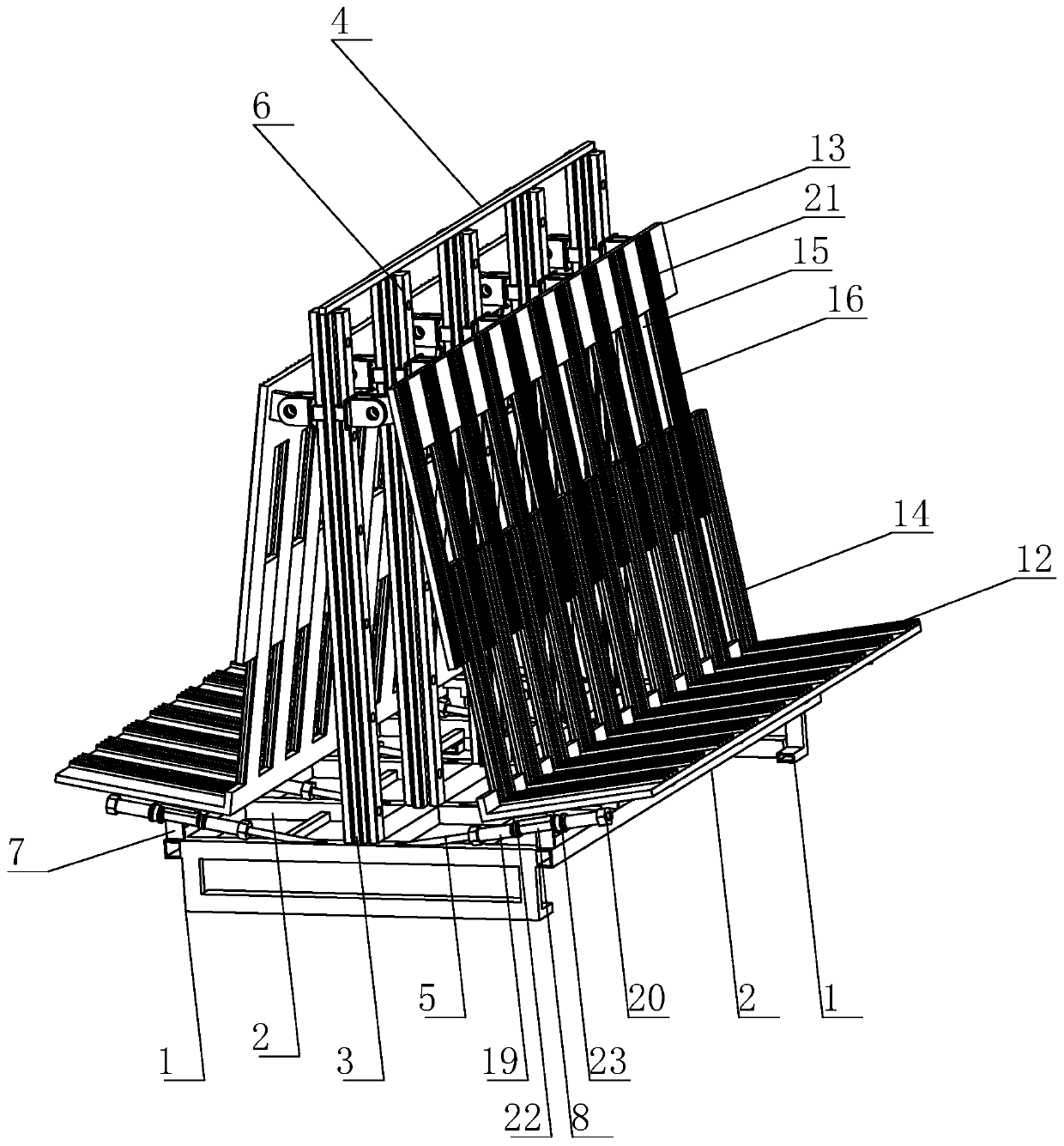

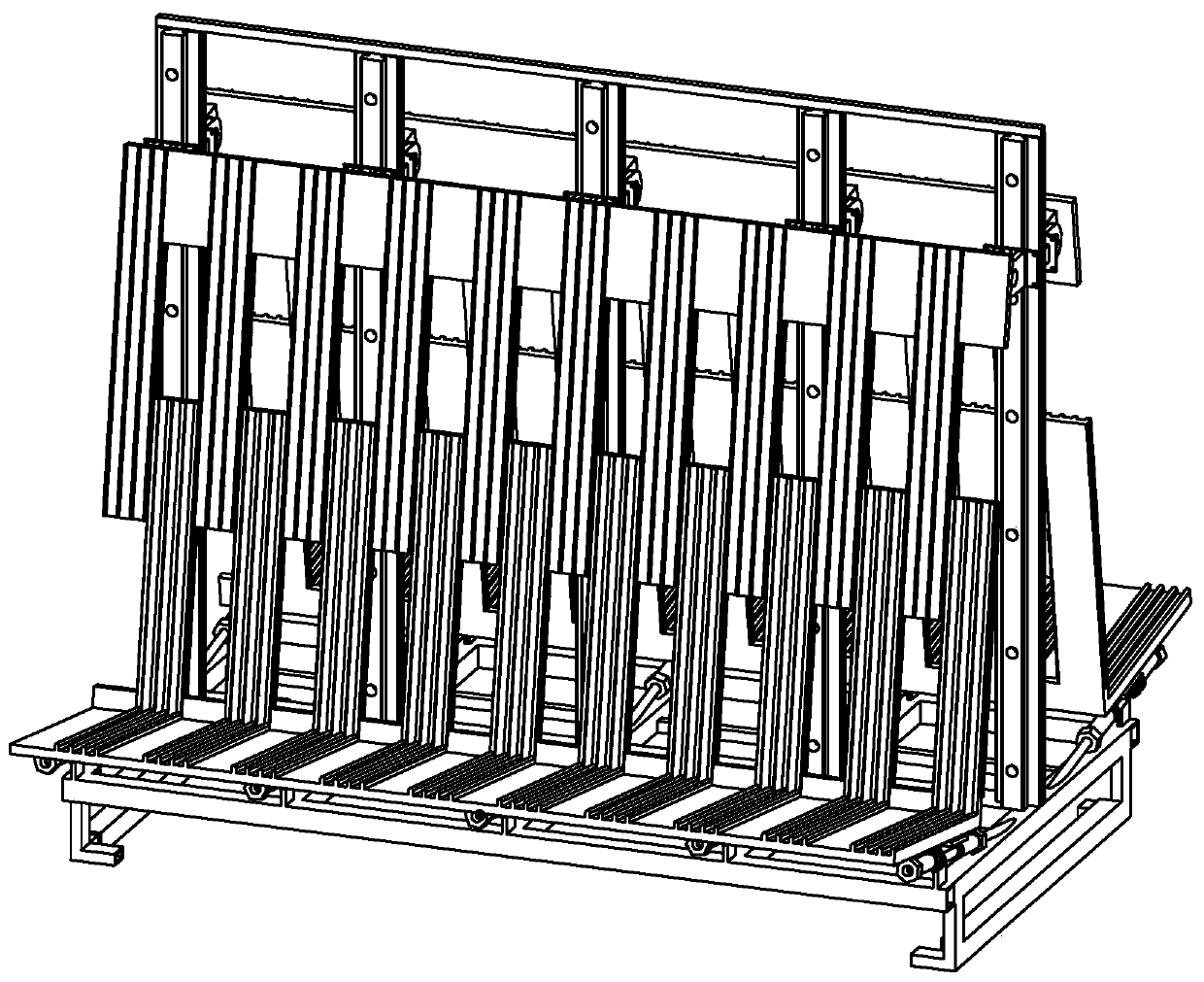

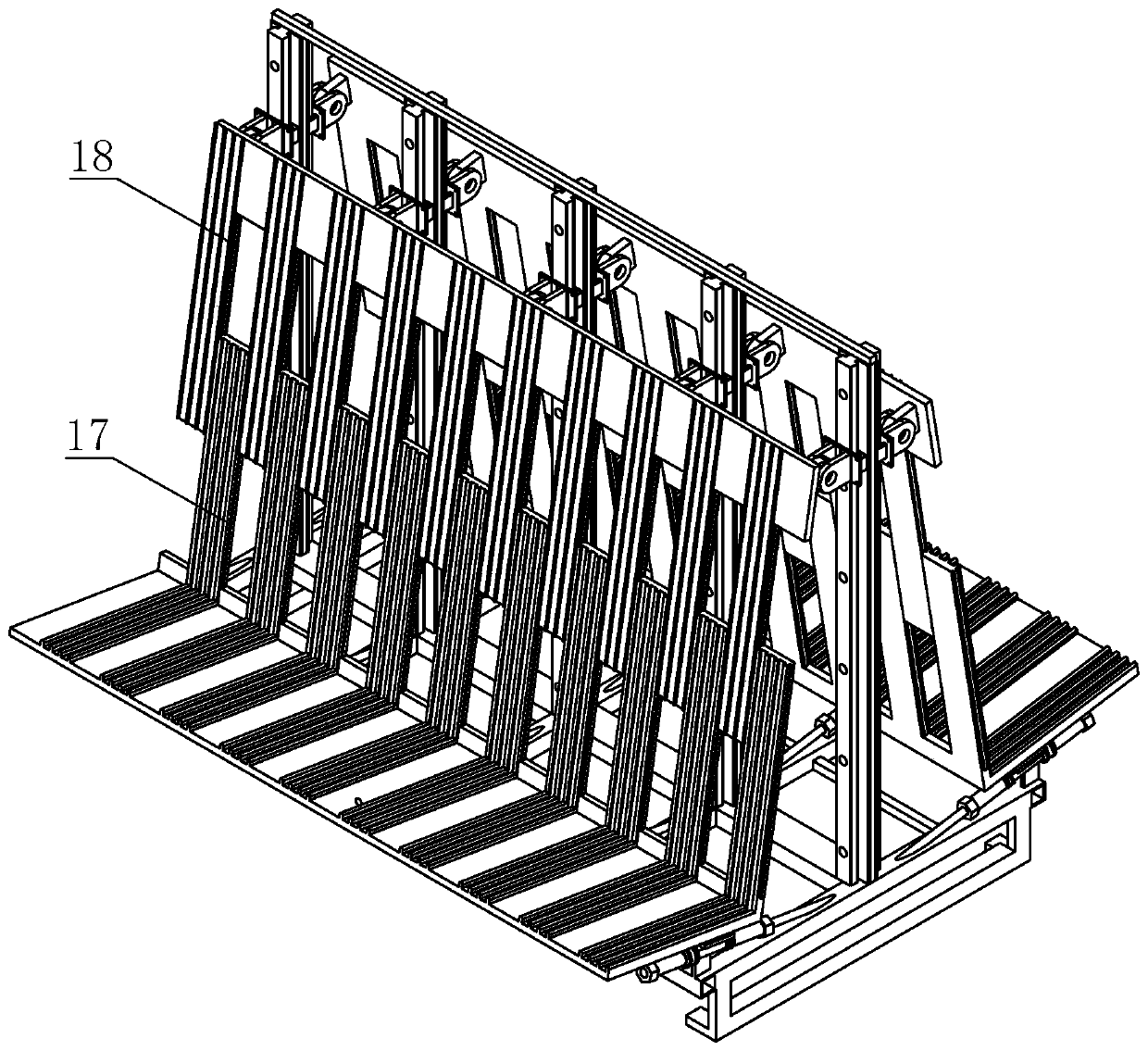

Fixing bracket for glass transportation

ActiveCN108674990AEliminate transportation lossDistribute the load evenlyCharge manipulationConveyor partsEngineeringResource utilization

The invention discloses a fixing bracket for glass transportation, mainly relates to the field of construction equipment transportation. The fixing bracket for glass transportation comprises a main bracket body, a guide rail mechanism, a glass supporting mechanism, a limiting assembly and a buffering piece. The glass supporting mechanism achieves L-shaped extension adjustment by the bidirectionalguide rail mechanism, and achieves fixing and limiting by the limiting assembly; and the buffering piece achieves rigid shock absorption of glass. The fixing bracket has the beneficial effects of being capable of adapting to different conditions on site according to the glass with different sizes and characteristics to fix and transport the glass, significantly lowering transportation losses and improving resource utilization rate.

Owner:王盼

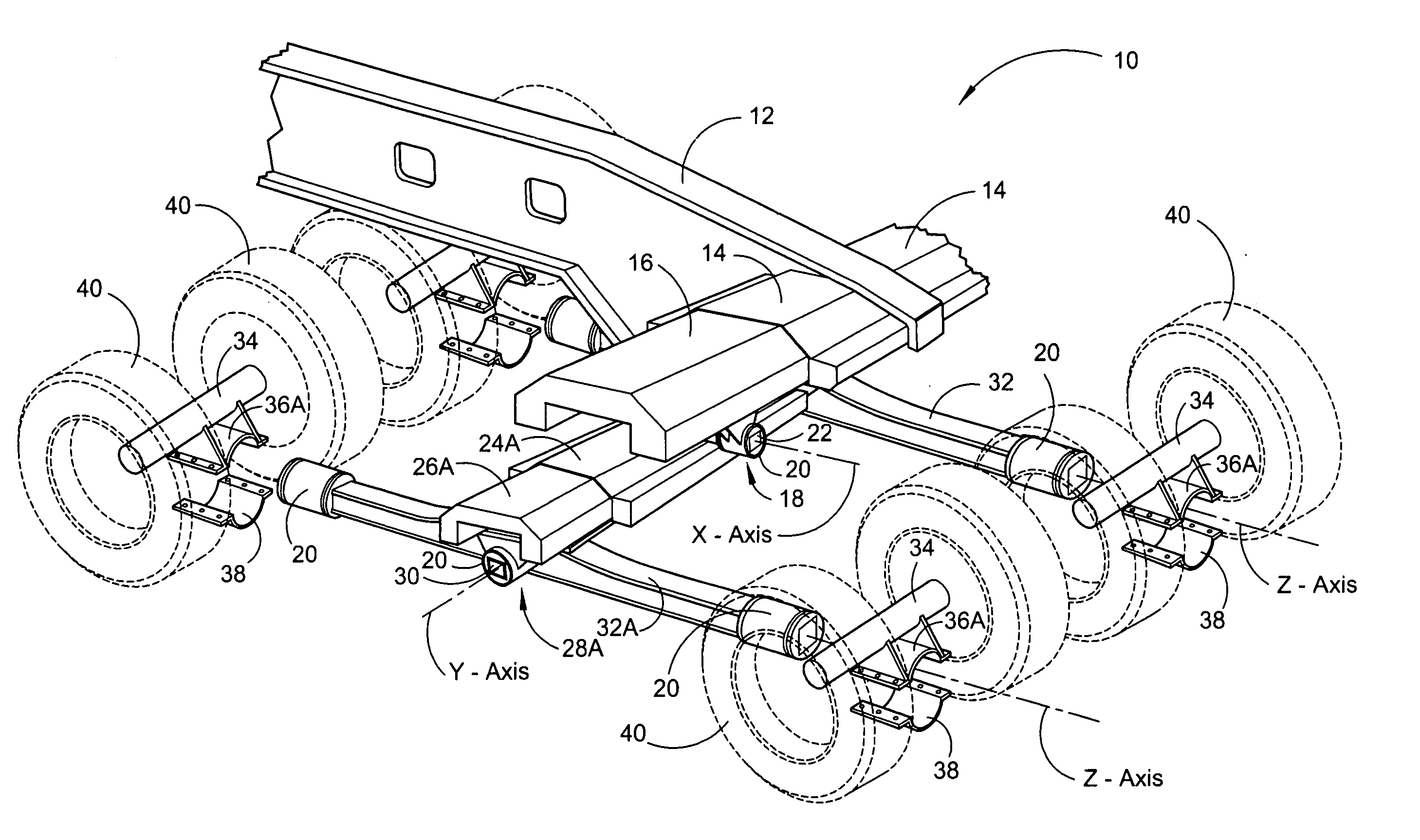

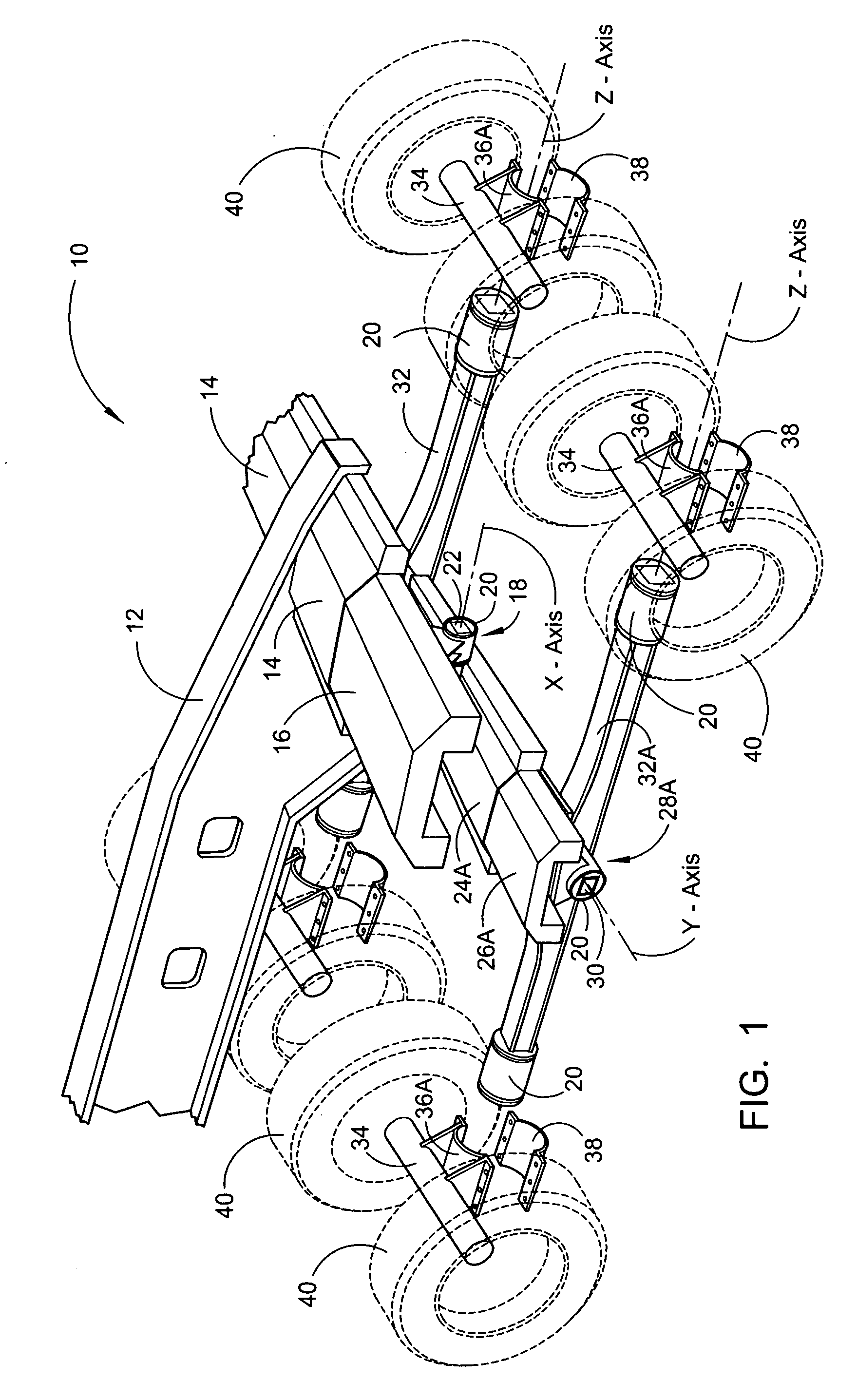

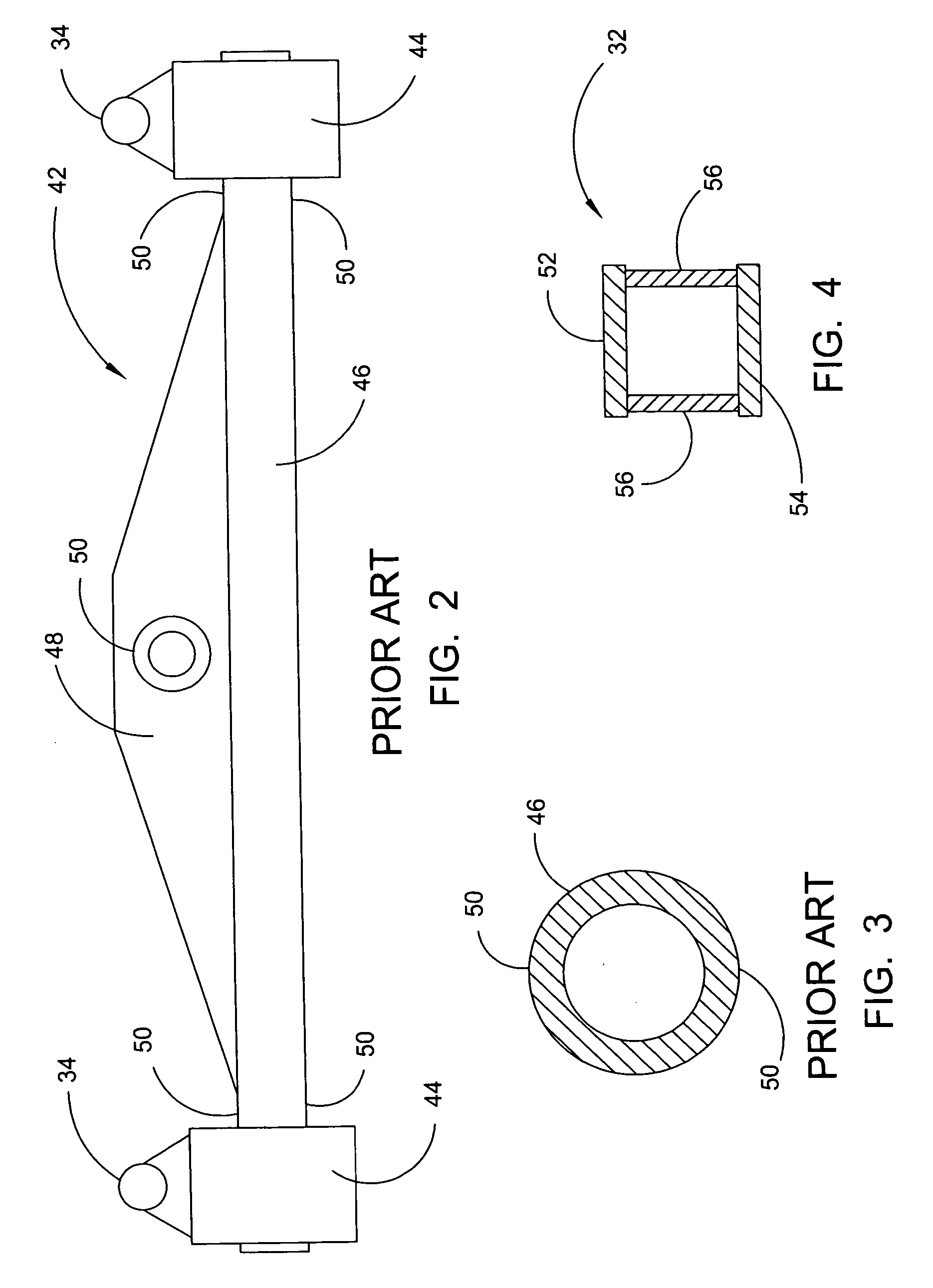

Expanding independent load suspension system

InactiveUS20060208463A1Distribute the load evenlyHeavy loadResilient suspensionsTrailersSurface conditionsAutomotive engineering

An expanding independent load suspension system that incorporates a square walking beam, unique bushings, and multiple expanding sliding units to spread the load bearing tires evenly over the surface instead of grouping them close together. With the weight of the vehicle having the ability to pivot over three separate axes, it maintains an equal pressure on all the tires no matter what the surface conditions. Additional benefits are derived by the separation of the tires with the new design of the square walking beam causing less damage to the roadways. The vehicle has been designed to operate on the highways in the conventional ten-foot width, and then expand to a maximum of twenty feet to move large loads with the permits required.

Owner:NEAL ROBERT P +1

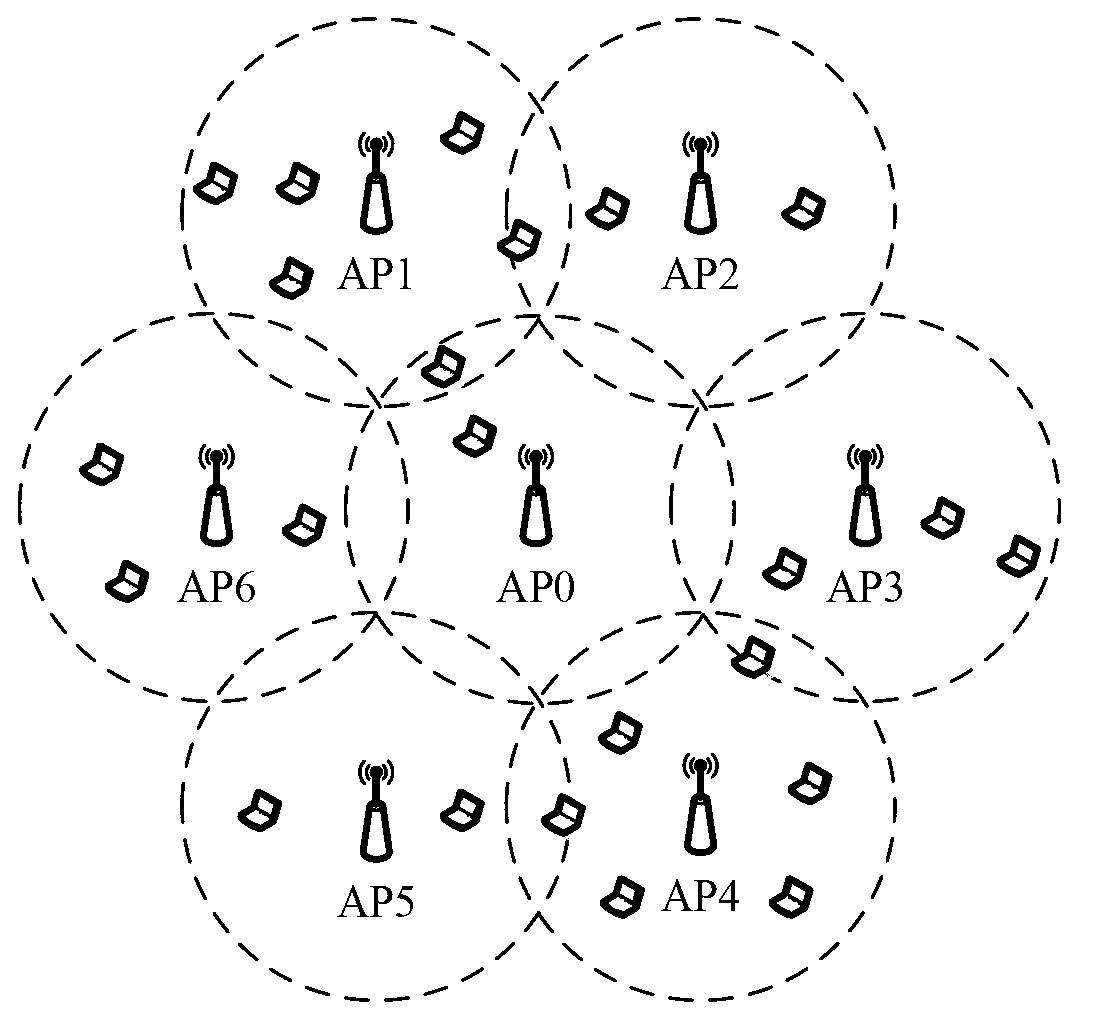

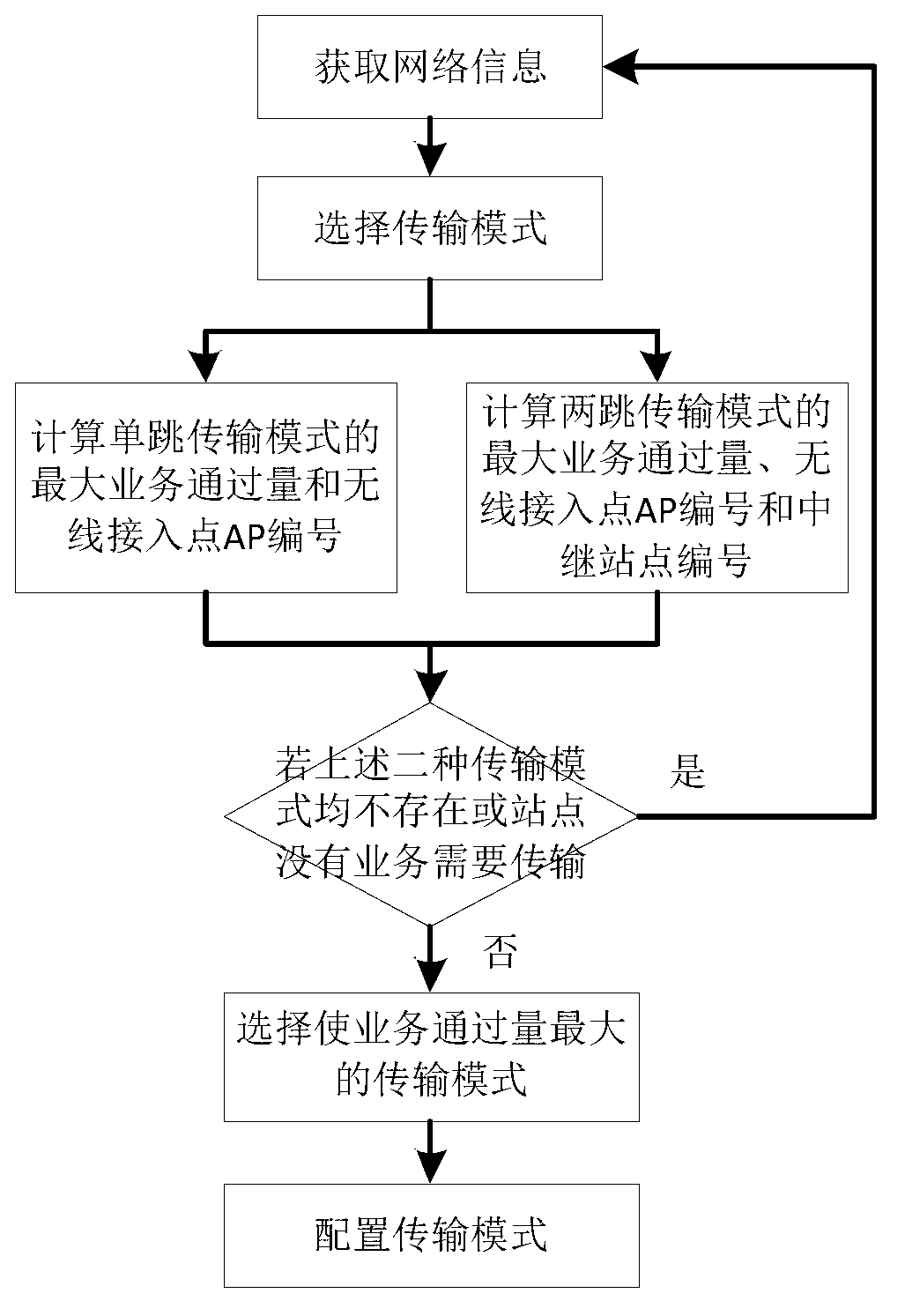

Intensive wireless local area network (WLAN) site transmission mode selecting method

InactiveCN103067948AReduce distractionsHigh communication rateNetwork traffic/resource managementNetwork topologiesTransfer modeLoad distribution

The invention discloses an intensive wireless local area network (WLAN) site transmission mode selecting method, and mainly aims at solving the problems of abnormal rates and uneven load distribution in the prior art. The intensive WLAN site transmission mode selecting method includes several steps, wherein a step one is that each wireless access point (AP) periodically broadcasts network information, and a site receives the network information and gathers two types of wireless AP collections; a step two is that the site calculates the largest traffic throughput of a single-hop transmission mode and a two-hop transmission mode, serial numbers of the wireless APs and a serial number of a relay site according to the acquired network information and the two types of wireless AP collections, and chooses the transmission mode which enables the traffic throughput to be largest; and a step three is that the site carries out corresponding transmission mode configuration according to the selected transmission mode, the wireless AP serial numbers and the serial number of the relay site. According to the WLAN site transmission mode selecting method, resources in the WLAN are fully utilized, the transmission mode of the site is chosen reasonably, interference in the network is reduced, the communication speed and the traffic throughput of AP edge users are improved, and a uniform load distribution is realized.

Owner:XIDIAN UNIV

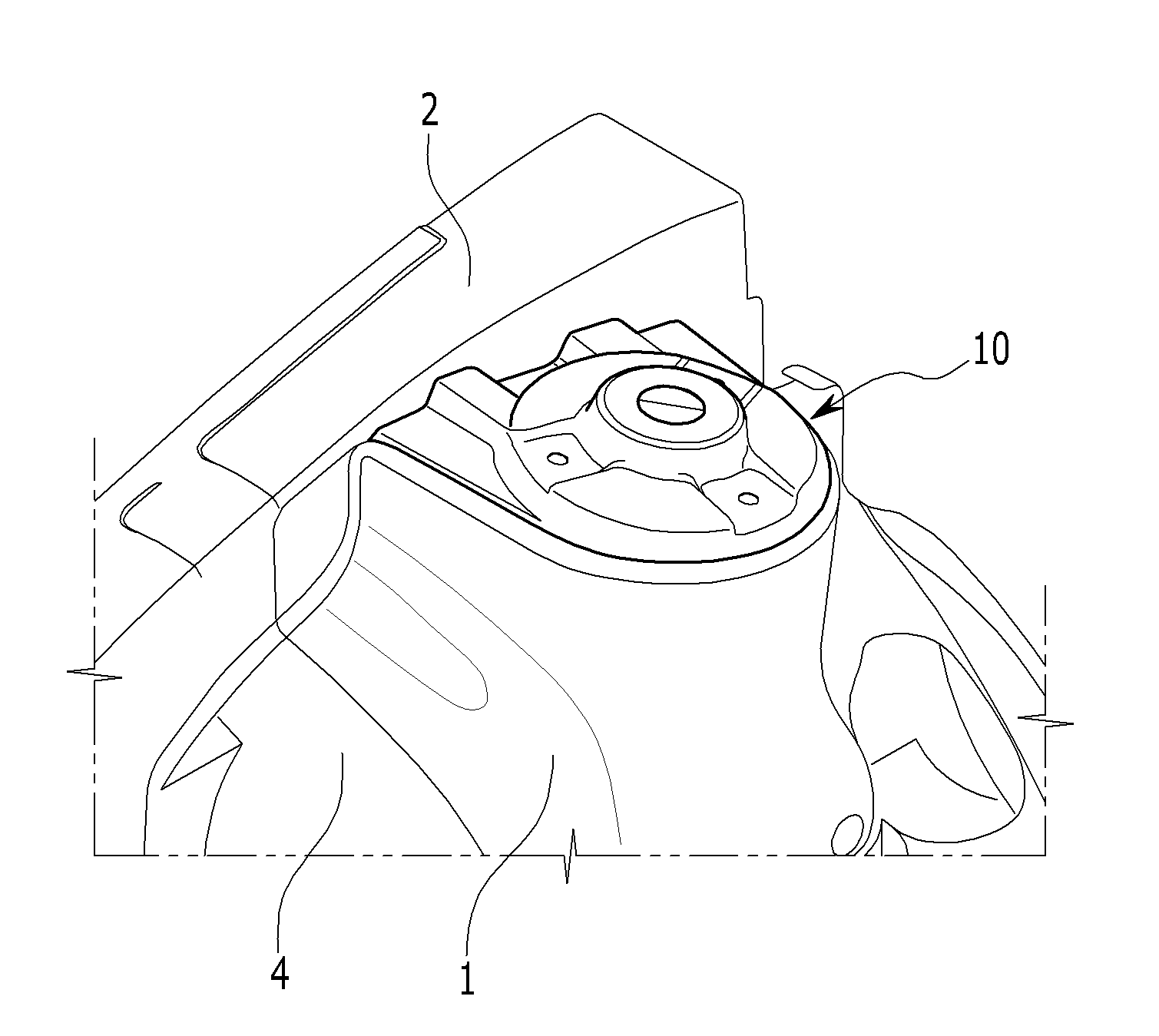

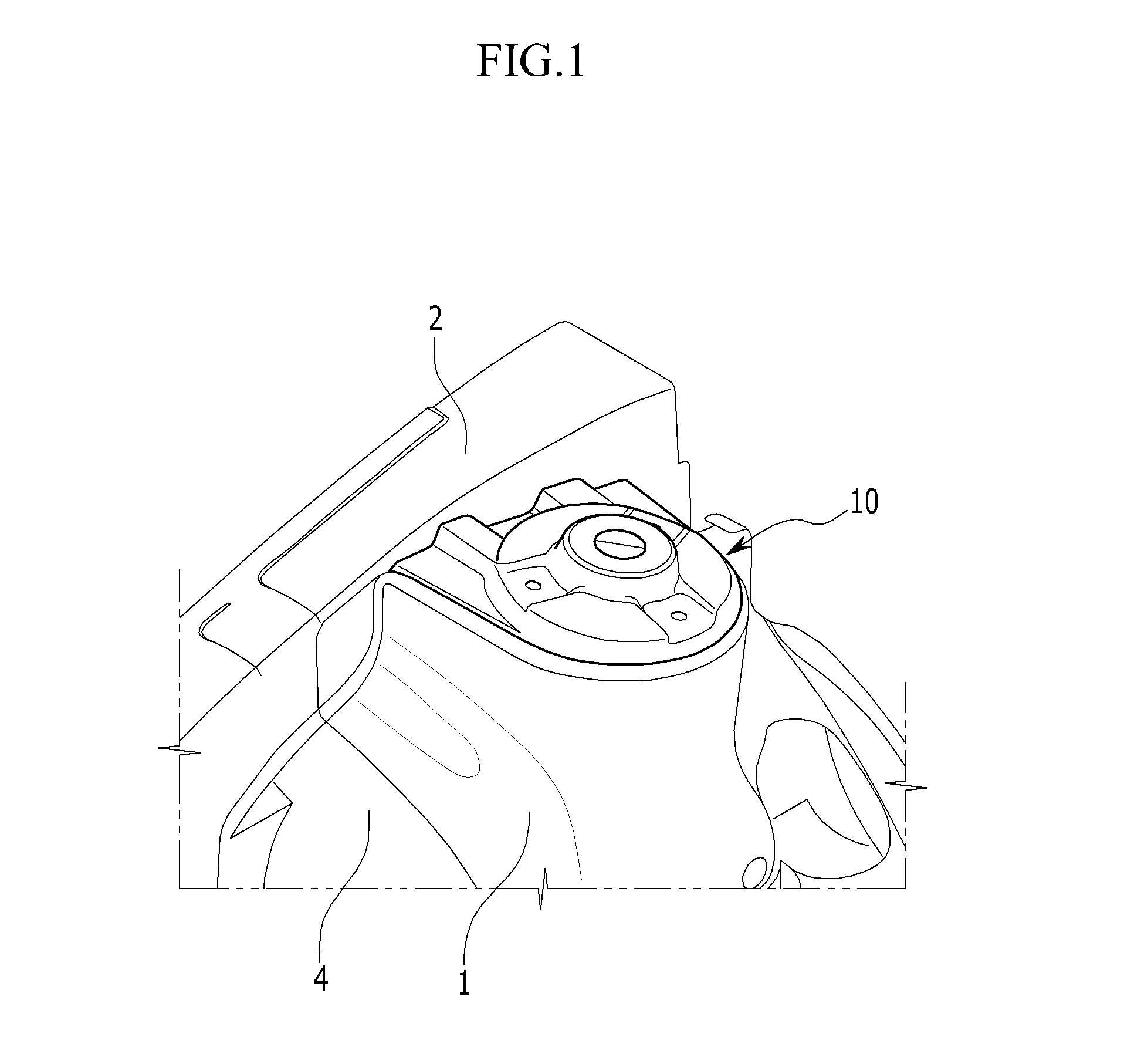

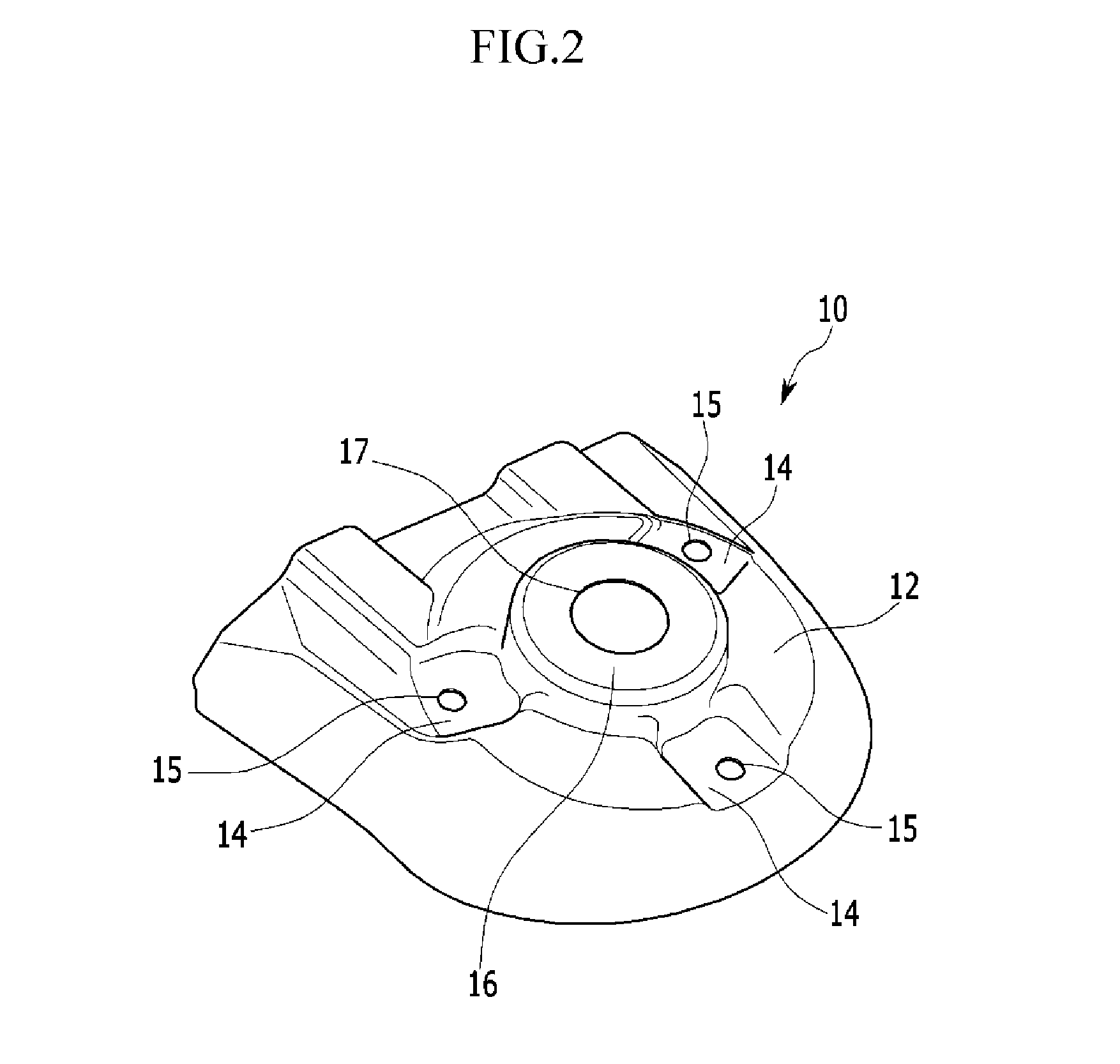

Shock absorber housing for vehicle

A shock absorber housing for a vehicle, which is provided in a vehicle body, encloses a shock absorber, and is coupled to the shock absorber so that the shock absorber is mounted in the vehicle body, may include a housing cap which covers an upper end of the shock absorber housing, and is coupled to an upper end of the shock absorber, wherein the housing cap includes a curved surface portion extending from the upper end and formed in a curved surface shape that is convex upward.

Owner:HYUNDAI MOTOR CO LTD

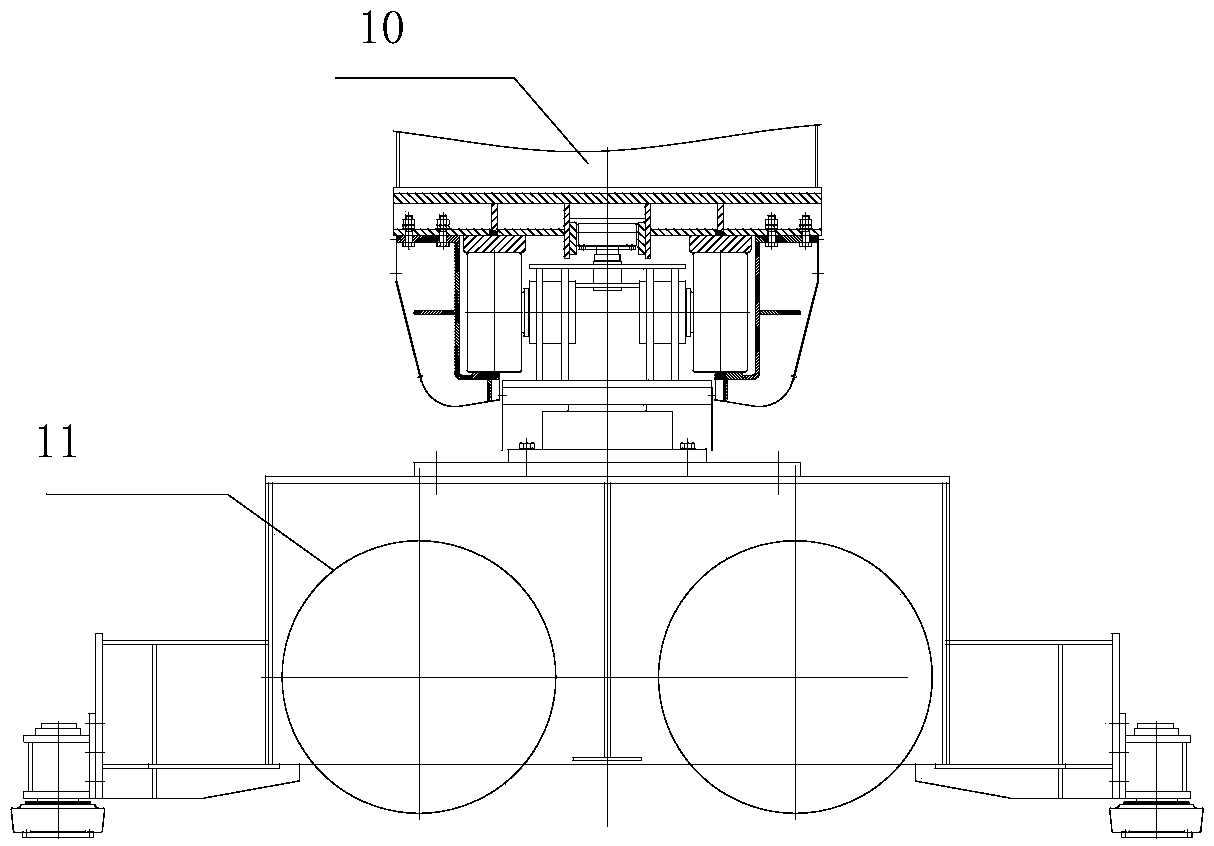

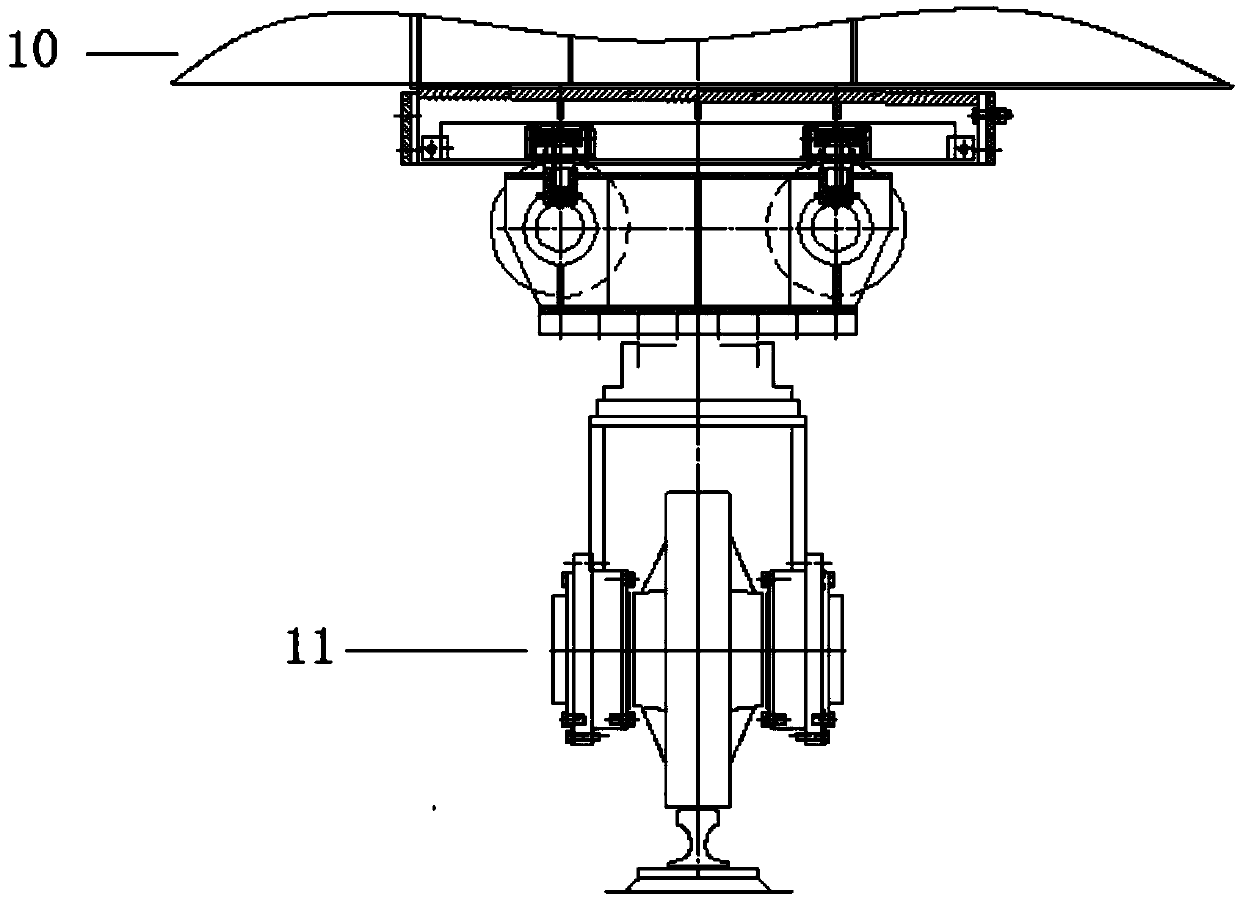

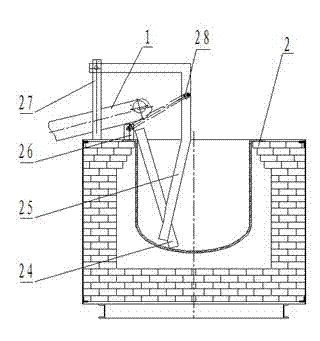

Gantry type circular stockyard material piling and taking machine

ActiveCN105502010APrevent tilt separationAvoid enteringPackagingLoading/unloadingRolling resistanceHigh load

The invention provides a gantry type circular stockyard material piling and taking machine which comprises a circular track, a travel trolley, a gantry, a follow-up device, a top frame and a rolling friction pair. The travel trolley runs along the circular track; one end of the gantry is rotatably connected to the center of the circular track, the other end of the gantry is movably connected with the travel trolley, and the gantry can be driven by the travel trolley to rotate around the center of the circular track; the follow-up device is arranged between the travel trolley and the gantry and comprises a support, and the lower end of the follow-up device is connected onto the travel trolley; the top frame is arranged above the support and is connected onto the gantry; the rolling friction pair is arranged between the support and the top frame, and the movement direction of the rolling friction pair is consistent with the radial direction of the circular track. The gantry type circular stockyard material piling and taking machine has the advantages that the rolling friction pair can bear high load, and deformation of the gantry can be sufficiently relieved.

Owner:HUADIAN HEAVY IND CO LTD

Method for preparing polyurethane-modified organosilicon double-component room-curing elastomer adhesive

ActiveCN105018015AEasy to operateShorten the production cycleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerAdhesive

The invention discloses a method for preparing a polyurethane-modified organosilicon double-component room-curing elastomer adhesive, which comprises the following steps: (1) uniformly mixing hydroxypropyl-terminated silicone oil and glycerol, and dehydrating to obtain a hydroxyl-terminated (-OH) component; (2) reacting aromatic polyisocyanate, the hydroxyl-terminated (-OH) component and dibutyltin dilaurate to obtain a component A; (3) adding vapor-phase silica white, carbon black and talcum powder into the container filled with hydroxy silicone oil and dihydroxy polysiloxane, adding a catalyst, adding 3-aminopropyl triethoxy silane, finally adding a defoaming agent, uniformly mixing, and drying to obtain a component B; and (4) uniformly mixing the component A and component B in a mass ratio of 12:(23.5-24), and curing at room temperature for 4-5 hours. The elastomer adhesive prepared by the method has the advantages of favorable tear resistance, excellent high / low temperature resistance and excellent binding property. The preparation method is easy to operate and accessible in raw materials, and lowers the preparation cost.

Owner:道一高分子聚合物(宁波)有限公司

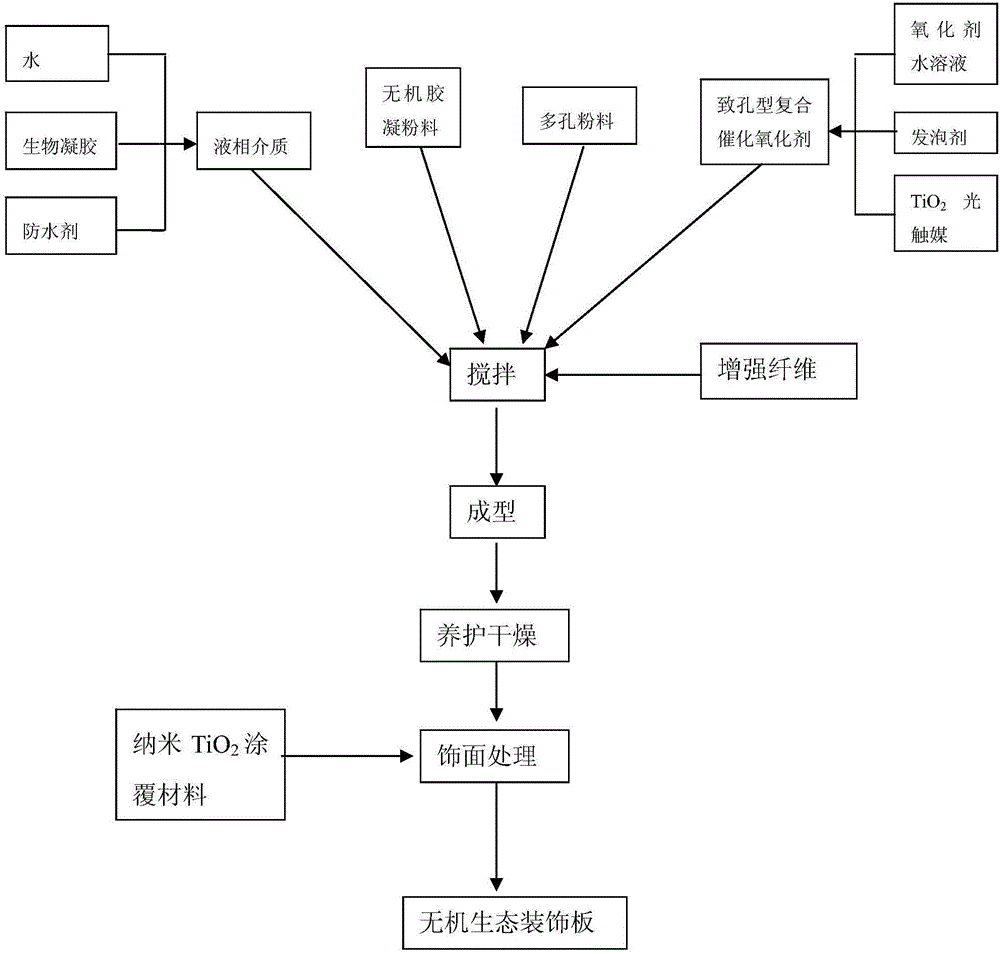

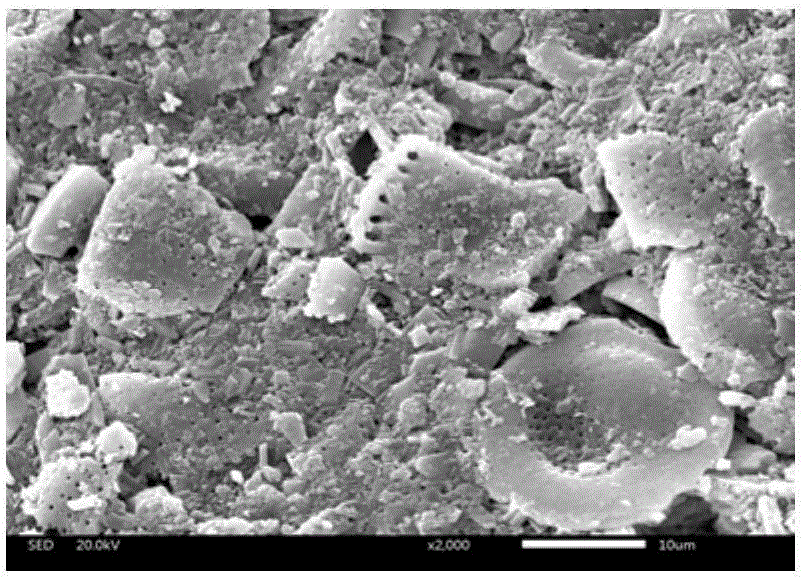

Pore-forming oxidative inorganic ecological decorative board and production method thereof

InactiveCN106518140AAvoid dependence on quality stabilityQuantity collection and distribution richCeramicwareFiberLiquid phase

The invention discloses a pore-forming oxidative inorganic ecological decorative board and a production method thereof. The pore-forming oxidative inorganic ecological decorative board is prepared from, by weight, 100 parts of inorganic gelling powder, 0-22.0 parts of porous powder, 18.5-73.0 parts of liquid-phase medium, 0.05-5.5 parts of pore-forming compound catalytic oxidant, 1.5-20 parts of reinforced fibers and 1.3-4.5 parts of nanometer titania coating materials by stirring, forming, curing, drying and a veneer treatment technology. The pore-forming oxidative inorganic ecological decorative board has the advantages that a catalyst and the oxidant are supported on micropores inside a hydrated condensation matrix of the inorganic gelling material firmly simultaneously, microporous distribution and centralized distribution are enriched, and secondary intensification is achieved with the aid of a nanometer titania coating, so that the inorganic ecological decorative board is endowed with excellent purification performance to efficiently decompose harmful gas continuously and is capable of regulating indoor temperature and humidity effectively, resisting bacteria and preventing mildewing; the problems of contradiction in choosing physical performance and ecological performance of inorganic decorative boards alternatively, proneness to shedding and attenuation of the supported catalyst or oxidant and capability of causing blockage of surface micropores through conventional surface treatment are solved.

Owner:西安藻钙新材料科技有限公司

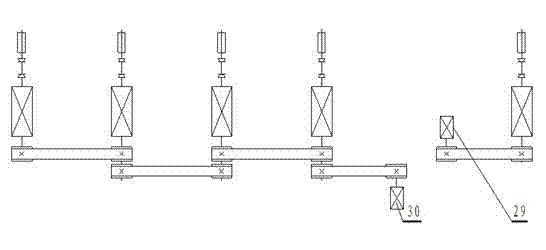

Multi-tier rope harness for installing a fabric into a papermaking machine

InactiveCN1714200ADistribute the load evenlyMachine wet endPaper/cardboardSelf adjustingPaper machine

A multi-layer fabric loading fixture for loading fabric onto a paper machine. The loading fixture includes a first portion (400) with a rigid support member (410) and a plurality of spaced holes (420) across its width, the first portion being connected to an end of the fabric in the cross-machine direction. The first layer (430) is formed of cords which are sequentially threaded through the holes to form a self-adjusting loop. The second rope is sequentially threaded through the loops of the first layer to form the self-adjusting loops of the second layer (440). Pull rings (450) gather the loops of the second layer and are used to draw the fabric to the paper machine.

Owner:ALBANY INT CORP

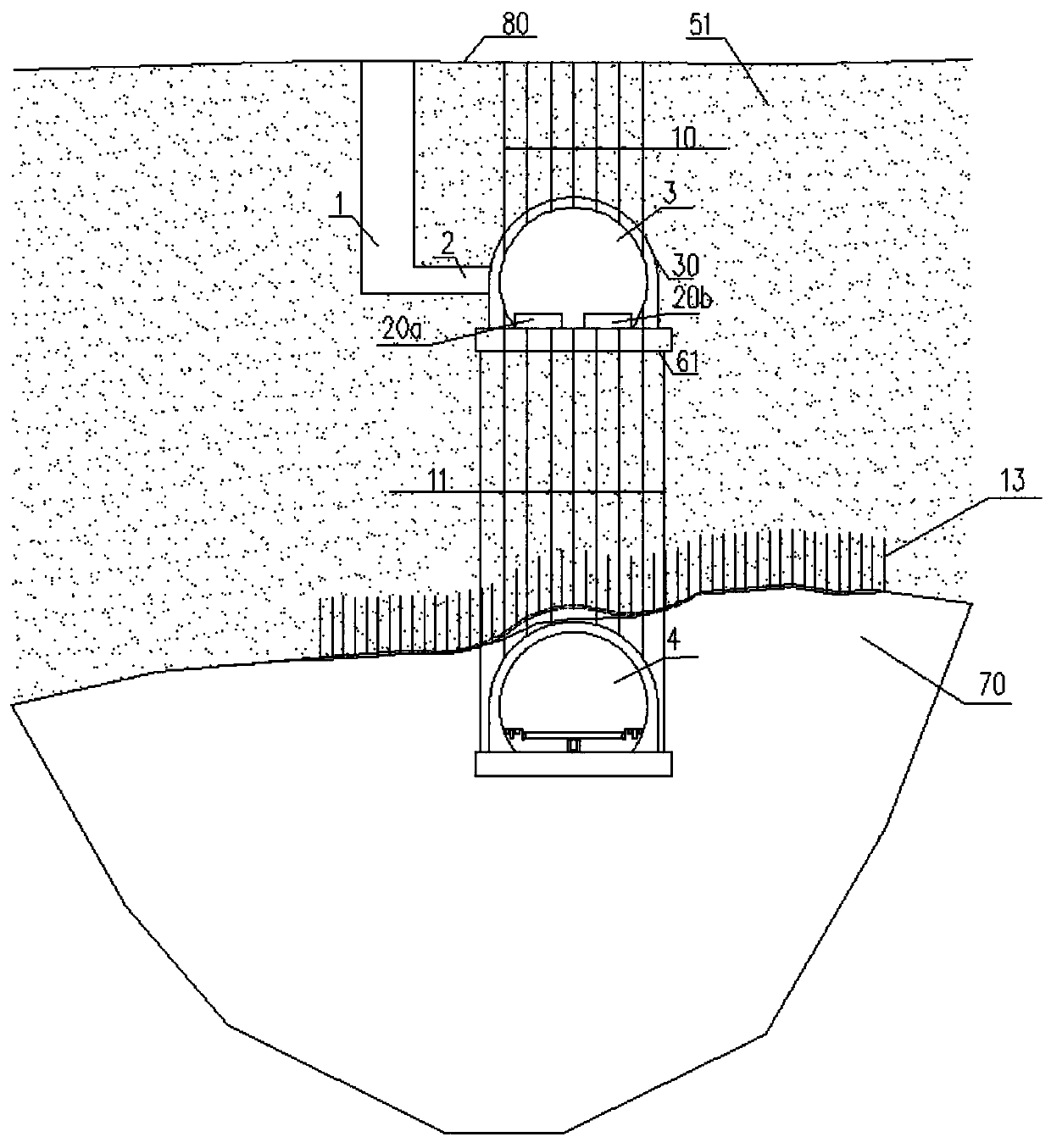

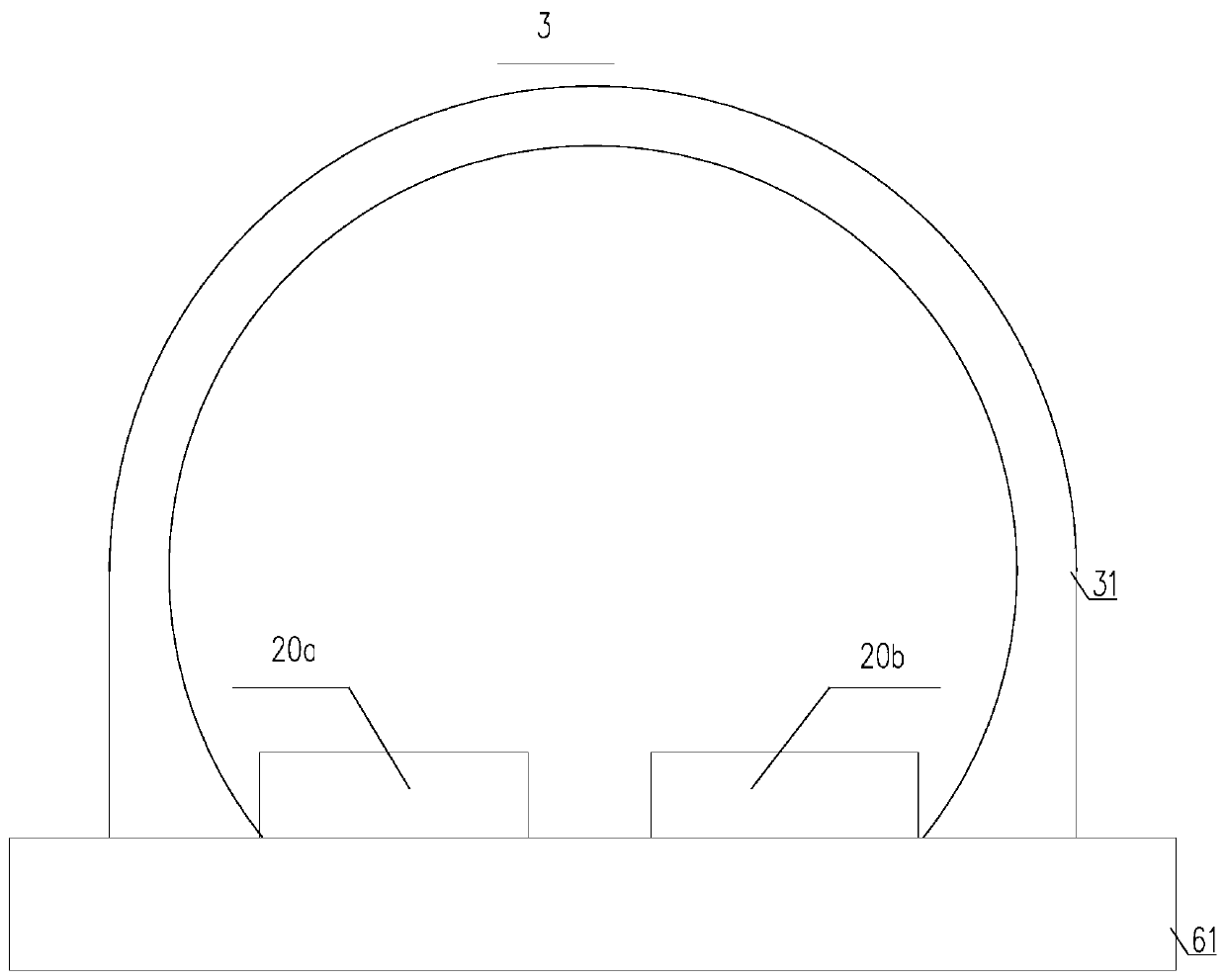

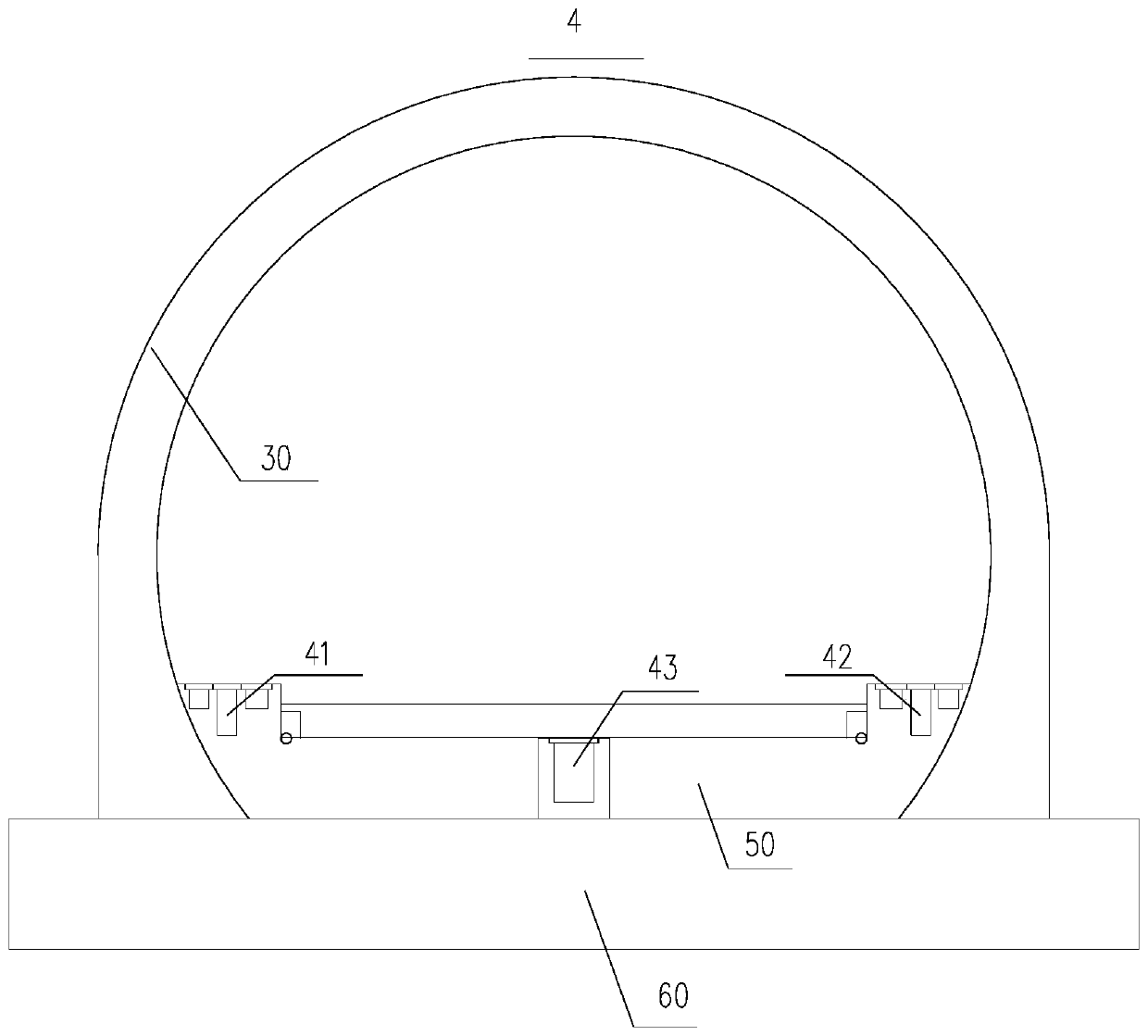

Anchor cable opposite-puling type supporting and protecting structure system and construction method thereof

PendingCN111412002AImprove the force characteristicsSolve problems such as uneven settlement deformationMaterial fill-upAnchoring boltsArchitectural engineeringStructure system

The invention relates to a tunnel supporting and protecting system, in particular to an anchor cable opposite-puling type supporting and protecting structure system and a construction method thereof.The supporting and protecting structure system comprises a vertical guide hole, a main tunnel, a first opposite-pulling anchor cable and a second opposite-pulling anchor cable; the vertical guide holeis arranged in a rock body above the main tunnel and is arranged parallel to the main tunnel; the first opposite-pulling anchor cable is arranged from top to bottom; the upper end of the first opposite-pulling anchor cable is fixed to the ground surface; the lower end of the first opposite-pulling anchor cable is fixed to the vertical guide hole; the second opposite-pulling anchor cable is arranged from the top to the bottom; the upper end of the second opposite-pulling anchor cable is fixed to the vertical guide hole; and the lower end of the second opposite-pulling anchor cable is fixed tothe main tunnel. The construction method is used for constructing the supporting and protecting structure system. The supporting and protecting structure system and the construction method provided bythe invention can effectively control the overall settlement of a tunnel structure, ensure the operating safety, and provide a new idea and a new method for a tunnel penetrating through a giant cavern hall.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

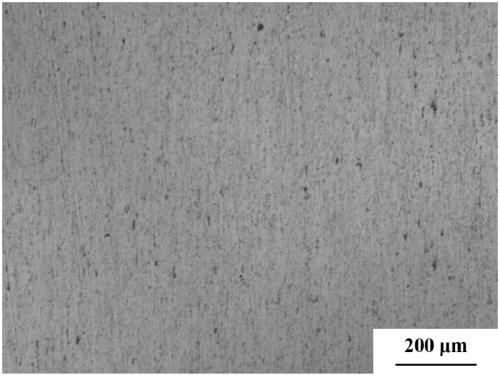

Preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material

The invention discloses a preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material, and relates to the preparation method of graphene reinforced aluminum-based composite material. The preparation method aims to solve a problem that grinding aid is residual in an aluminum alloy matrix, and realize self-repairing of the graphene. The preparation methodcomprises the step 1 of weighing the graphene, the polyethylene glycol and aluminum metal powder; the step 2 of putting the material obtained in the step 1 into a ball milling tank for ball milling;the step 3 of cold pressing; and the step 4 of preparing the composite material after the cold pressing. The grinding aid, polyethylene glycol is subjected to thermal decomposition to generate activeC atoms, and the C atoms can adsorb on the pits of the graphene, so that integrity of the graphene structure is greatly improved, good interface connection is formed, and overall performance of the material is greatly improved; the polyethylene glycol is beneficial to flake formation of the aluminum metal powder, so that a problem of high dispersion difficulty of the single-layer or few-layer graphene in the aluminum-based composite material is solved, and cold welding between the aluminum metal powders is reduced; polyethylene glycol is easy to remove, and the prepared few-layer graphene reinforced aluminum-based composite material is excellent in comprehensive performance. The method is suitable for preparing the graphene reinforced aluminum-based composite material.

Owner:HARBIN INST OF TECH

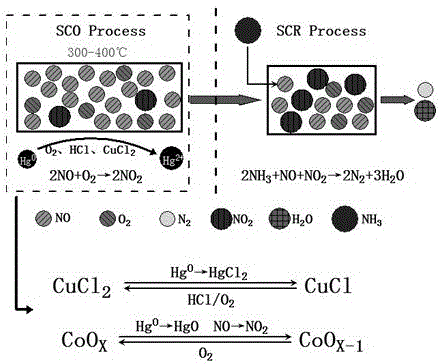

Composite catalyst based on denitration and demercuration reinforcing function of prepositive SCO smoke of coal-fired power plant and preparation method thereof

InactiveCN106311291AImprove performanceEasy to prepareGas treatmentPhysical/chemical process catalystsAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a composite catalyst based on a denitration and demercuration reinforcing function of prepositive SCO smoke of a coal-fired power plant and a preparation method thereof. Main active ingredients of the composite catalyst are Co3O4 and CuCl2, and a carrier ingredient is Ce-doped TiO2. The preparation method includes: adopting a sol-gel method to prepare a Ce-doped TiO2 carrier, adopting an impregnation method to sequentially load Co3O4 and CuCl2. A selective catalytic oxidation unit using the catalyst as a main body is arranged at the front end of an SCR unit, oxidation of Hg0 does not be influenced by the ammonification process of the SCR unit, and high mercury oxidation removing efficiency can be realized in a chlorine-free condition. In addition, the catalyst can convert part of NO into NO2 while efficiently oxidizing Hg0, so that reaction efficiency of subsequent SCR process is improved remarkably. The catalyst is easy-to-get in raw material, simple in preparation method, easy-to-implement in technical process and conducive to industrial application.

Owner:WUHAN UNIV

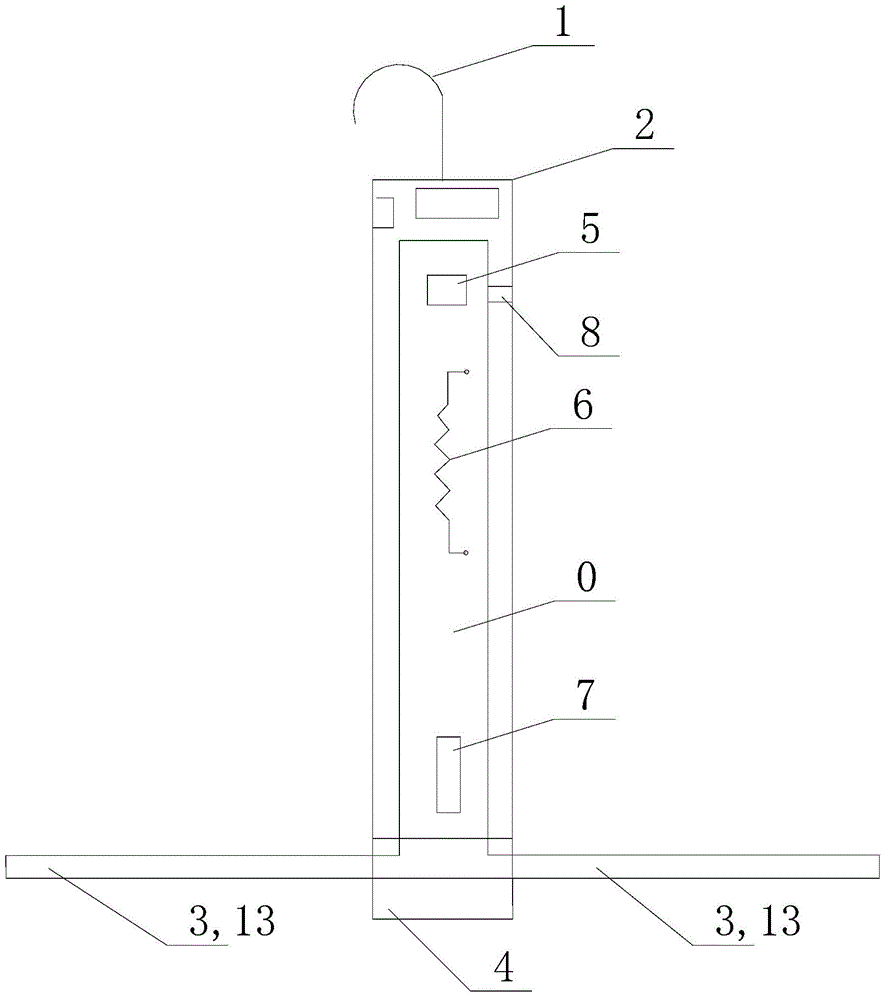

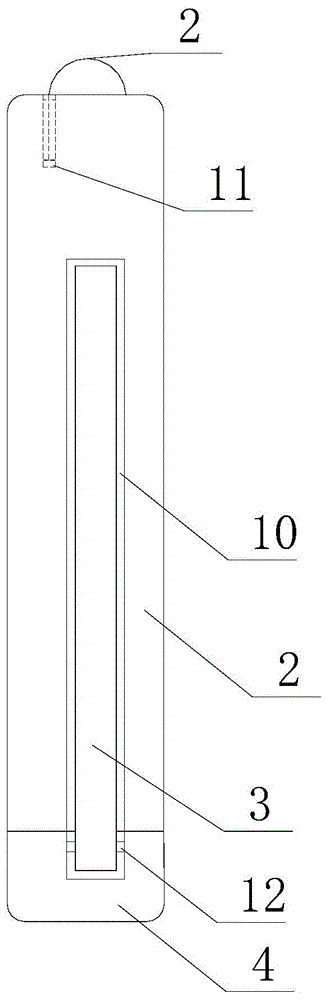

Micro hanging type drying equipment

ActiveCN106283574ATo achieve the purpose of dryingImprove drying rateApparel holdersOther drying apparatusProcess engineeringEngineering

The invention relates to micro hanging type drying equipment in the field of washing and drying. The micro hanging type drying equipment comprises a hanging body, wherein a cavity is formed in the body; heating ventilation equipment capable of forming drying airflow is arranged in the cavity; at least one carrying part on which clothes are placed is arranged on the body; each carrying part is communicated with the cavity; and an air outlet through which the drying airflow blows to the clothes is formed in the carrying part. According to the arrangement, high-temperature drying airflow can be formed in the drying equipment and blows the clothes on the carrying parts through the air outlet, so that the drying airflow is in direct contact with the clothes, and the aim of drying the clothes is achieved. Meanwhile, the equipment disclosed by the invention is simple in structure, obvious in effect and suitable for popularization and application.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Glass Transport Fixtures

ActiveCN108674990BDistribute the load evenlyImprove adaptabilityCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:王盼

A kind of preparation method of addition type liquid fluorosilicone rubber

The invention relates to a preparation method of addition-type liquid fluorosilicone rubber: D3F, ViD4, and MM with a purity greater than 99.5% are used as raw materials, and mixed uniformly in a certain proportion to obtain vinyl fluorosilicone oil; vinyl fluorosilicone oil is used as the base rubber , adding reinforcing agent, cross-linking agent, catalyst, and then kneading, grinding, tableting and other processes to prepare liquid fluorosilicone rubber (FSR); the prepared FSR and liquid silicone rubber ( LSR) performance comparison, FSR is superior to LSR in terms of insulation performance, hydrophobicity, high temperature resistance and other properties. The method has a short production cycle, and the product has good thermal tear performance and is easy to demould, and can realize various processing methods such as molding, extrusion, and injection pressure, and can also realize automatic production of materials.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

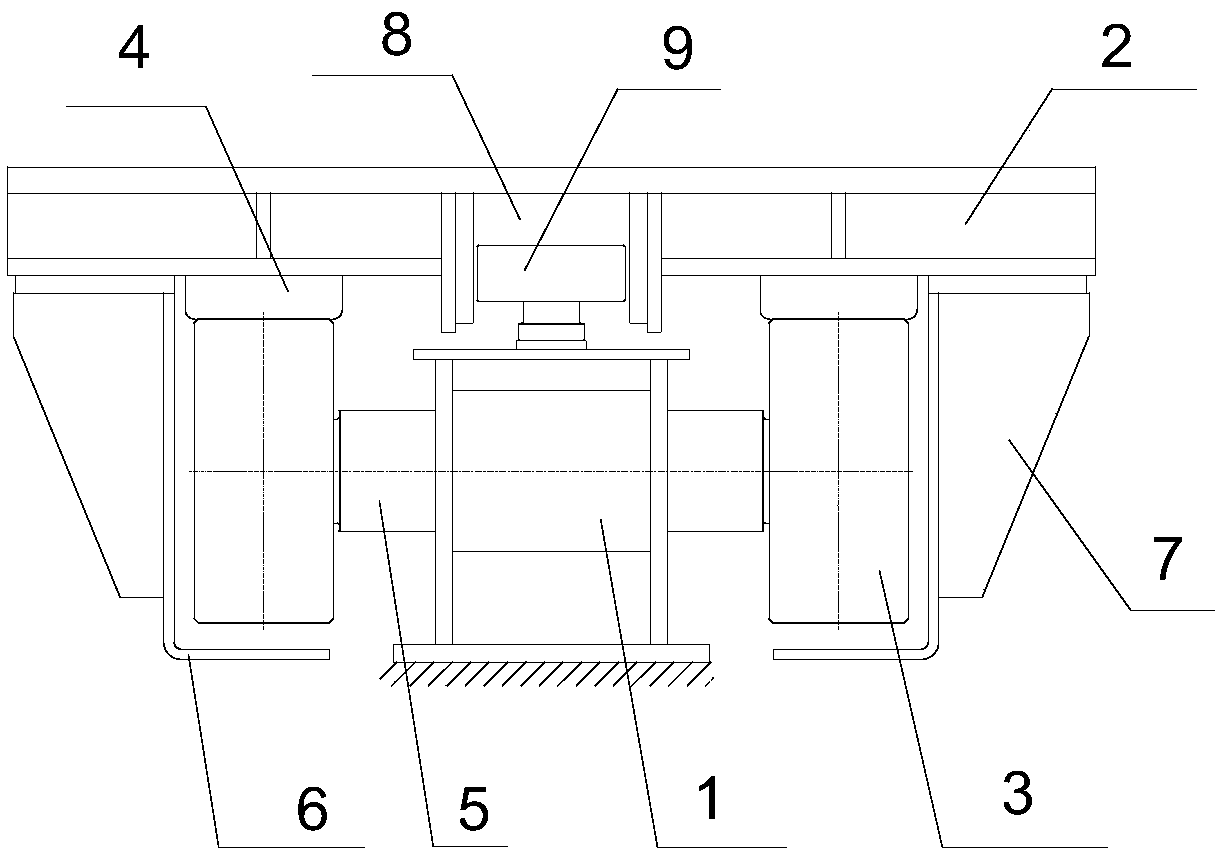

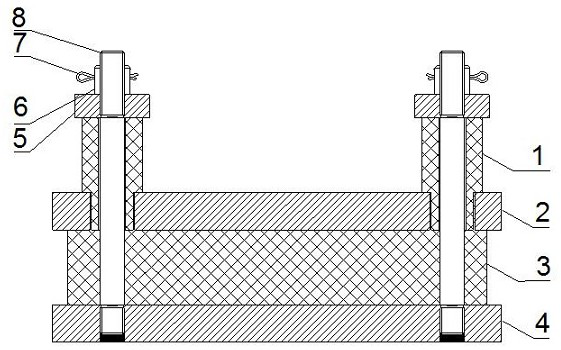

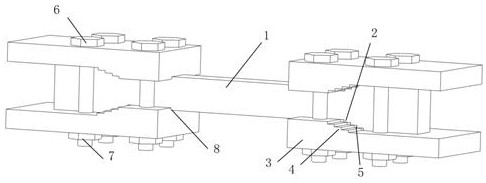

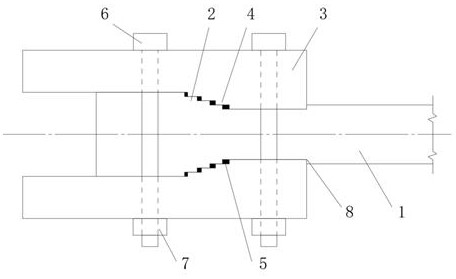

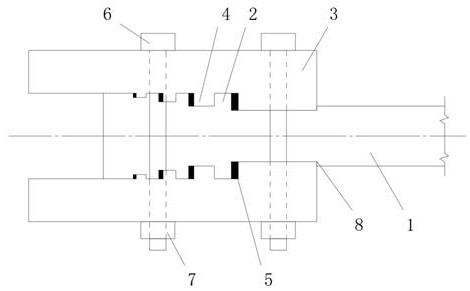

Rubber vibration reduction device for noise reduction of elevator machine room

PendingCN113104707AReduce vibration noiseGood effectNon-rotating vibration suppressionLeaf springsSplit pinClassical mechanics

The invention discloses a rubber vibration reduction device for noise reduction of an elevator machine room. The rubber vibration reduction device comprises an upper supporting plate, a rubber vibration reduction pad and a lower supporting plate, all of which are sequentially arranged from top to bottom. Double-head screws are arranged on the two sides of the top of the upper supporting plate, the two double-head screws sequentially penetrate through the upper supporting plate, the rubber vibration reduction pad and the lower supporting plate from top to bottom, the bottoms of the two double-head screws are in screw joint with the lower supporting plate and are tightly welded to the lower supporting plate, and the upper portions of the two double-head screws are sequentially connected with rubber sound insulation pads and gaskets from bottom to top in a sleeved manner. In the rubber vibration reduction device, the vibration reduction device is connected with embedded iron, I-shaped steel or channel steel of the elevator machine room in a welded manner, vibration can be directly isolated through the vibration reduction pad, loads can be averagely distributed according to different stress loads, a main engine has the advantages of being stable in running, good in vibration reduction performance, resistant to aging, long in service life and the like, a split nut and split pin manner is adopted for connection, and nut falling caused by vibration and buckle moving can be avoided.

Owner:天津兴晟和橡胶制造有限公司

Production process for improving weather resistance of PE solid-wall pipe

InactiveCN110272574AUniform wall thicknessImprove clamping effectTubular articlesMaterials preparationWeather resistance

The invention relates to a production process for improving the weather resistance of a PE solid-wall pipe. The production process comprises the following steps: early-stage preparation, material preparation and material feeding, extrusion molding, sizing sleeve cooling, spray cooling molding, tractor traction, finished product cutting and qualified inspection, wherein material preparation and material feeding include the specific steps: preparing a specific pipe material of the PE solid-wall pipe and a protective layer material, sucking the materials into a material hopper through a material suction device, discharging materials separately from the material hopper into charging barrels of two extruders which are connected with double-layer co-extrusion heads through head connectors, and performing co-extrusion through the double-layer co-extrusion heads. The production process for improving the weather resistance of the PE solid-wall pipe, the process is simple, the production efficiency is high, the wall thickness of the produced PE solid-wall pipe is uniform, and the die spotting effect of the PE solid-wall pipe with the protective layer is better; and no parting lines are needed, good weather resistance is achieved, and a long service life and broad application prospects are achieved.

Owner:南京乐洁新型材料有限公司

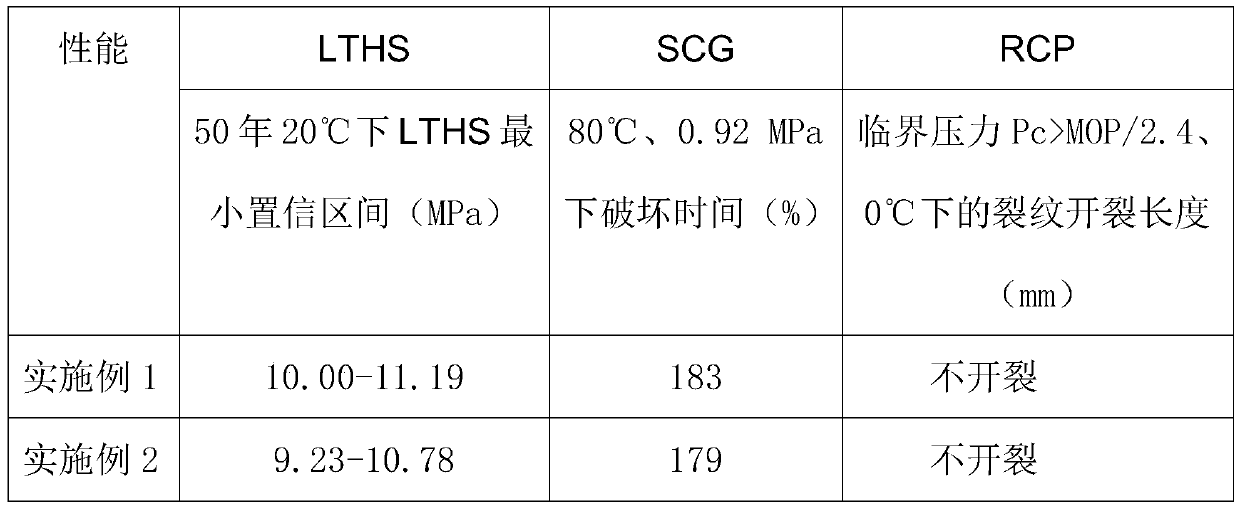

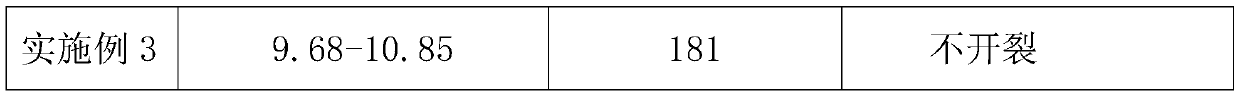

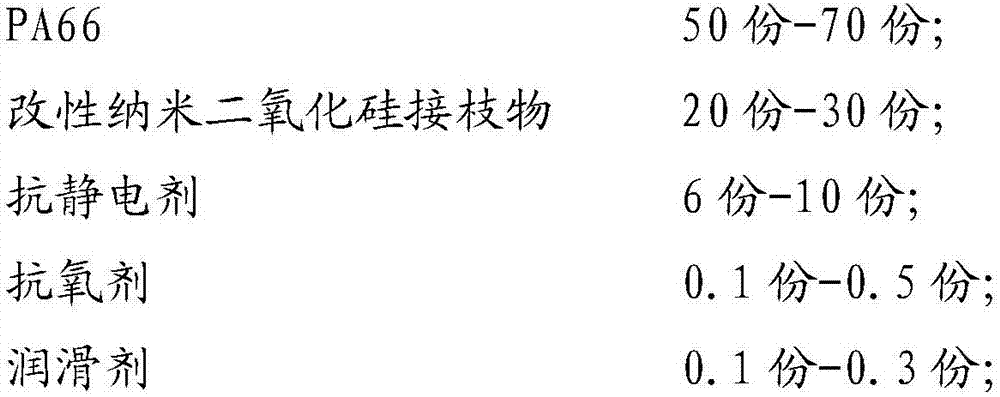

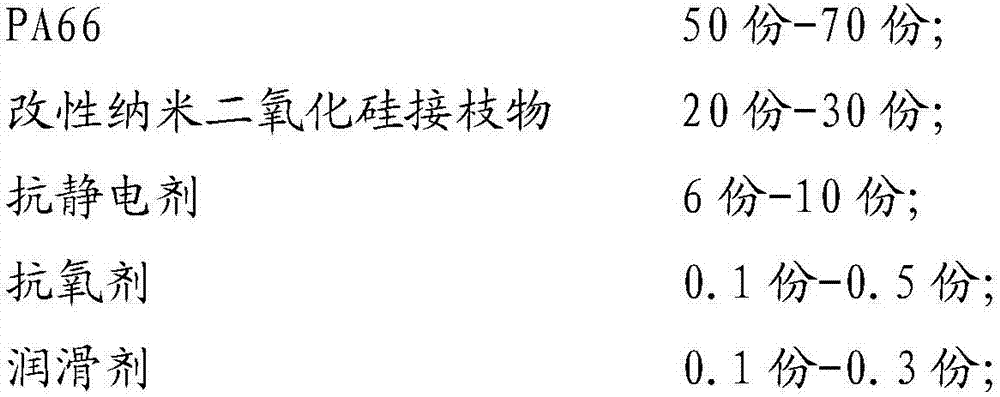

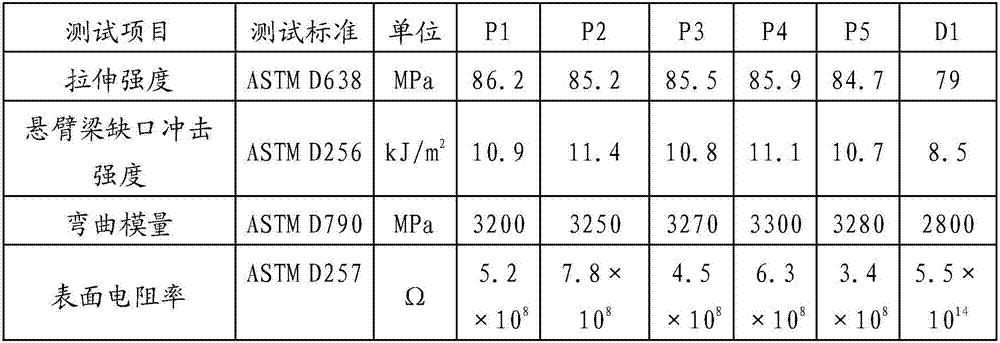

Antistatic and high-performance PA66 composite material and preparation method thereof

The invention relates to an antistatic and high-performance PA66 (polyamide66) composite material and a preparation method thereof. The composite material is composed of the following components in parts by weight: 50-70 parts of PA66; 20-30 parts of a modified nano silicon dioxide graft; 6-10 parts of an antistatic agent; 0.1-0.5 part of an antioxidant; and 0.1-0.3 part of a lubricant. According to the technical scheme, the silane coupling agent and the hydroxyl radicals on the surface of the nano silicon dioxide are subjected to condensation, so that agglomeration of the nano silicon dioxide is prevented, the nano silicon dioxide can be uniformly dispersed in the PA66 matrix, and the mechanical properties of the PA66 composite material are improved. The modified nano silicon dioxide graft is a core-shell type graft which is formed by taking a KH550-g-SiO2 as a core and PS (polystyrene) as a shell body, the graft has better dispersity than that of simple nano silicon dioxide, and the graft has an effect of distributing loads uniformly when the composite material is subjected to external force, so that the mechanical properties of the PA66 composite material are improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

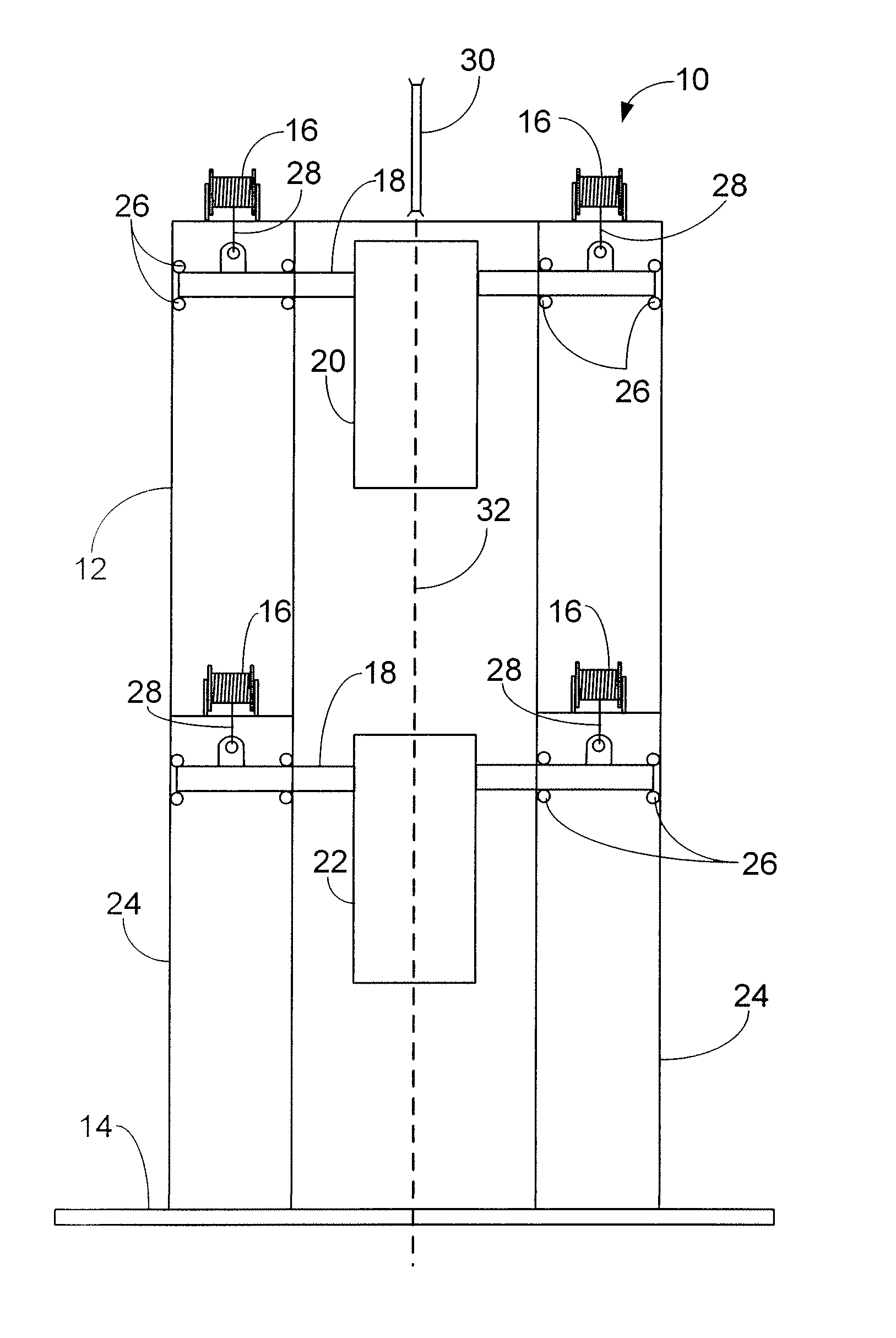

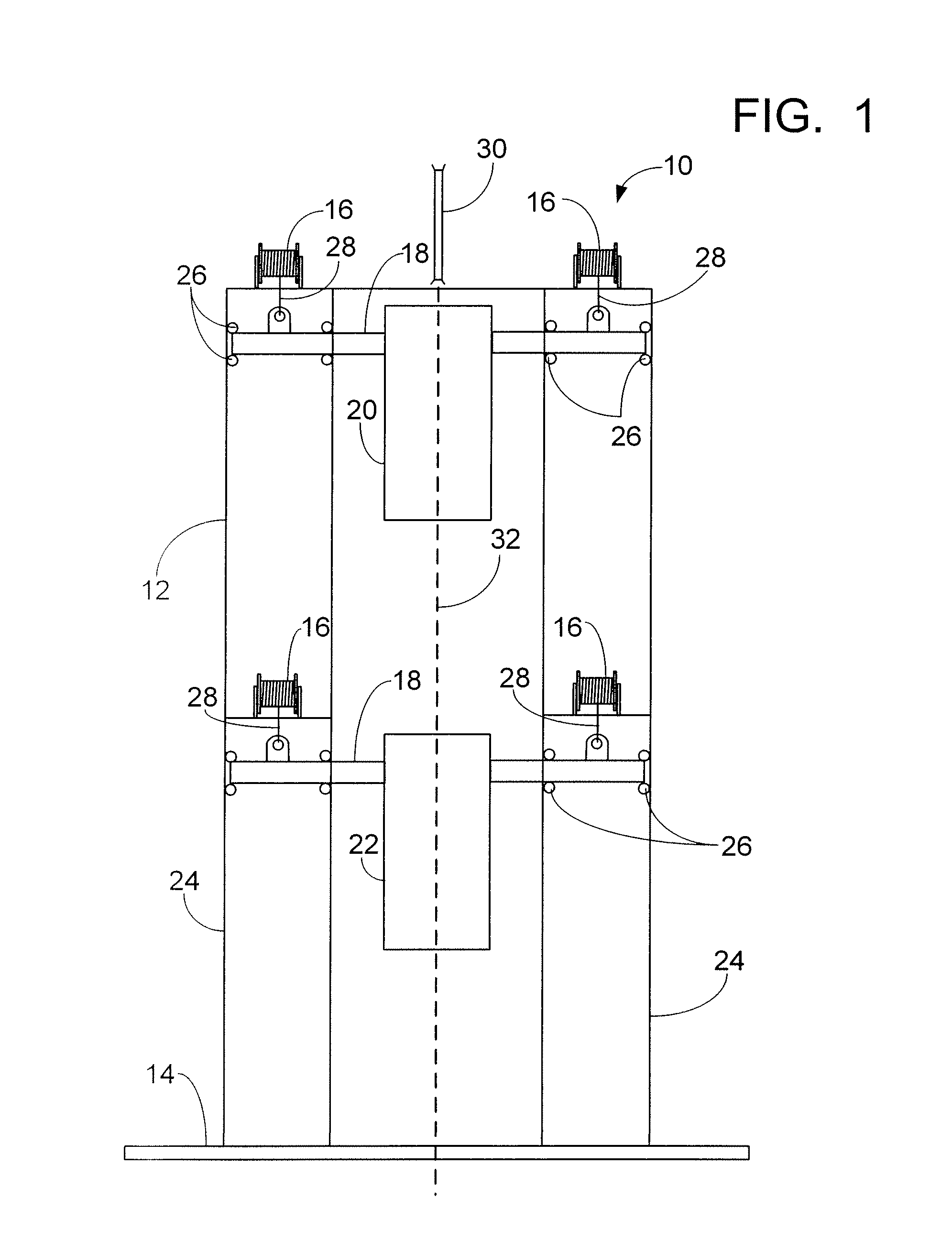

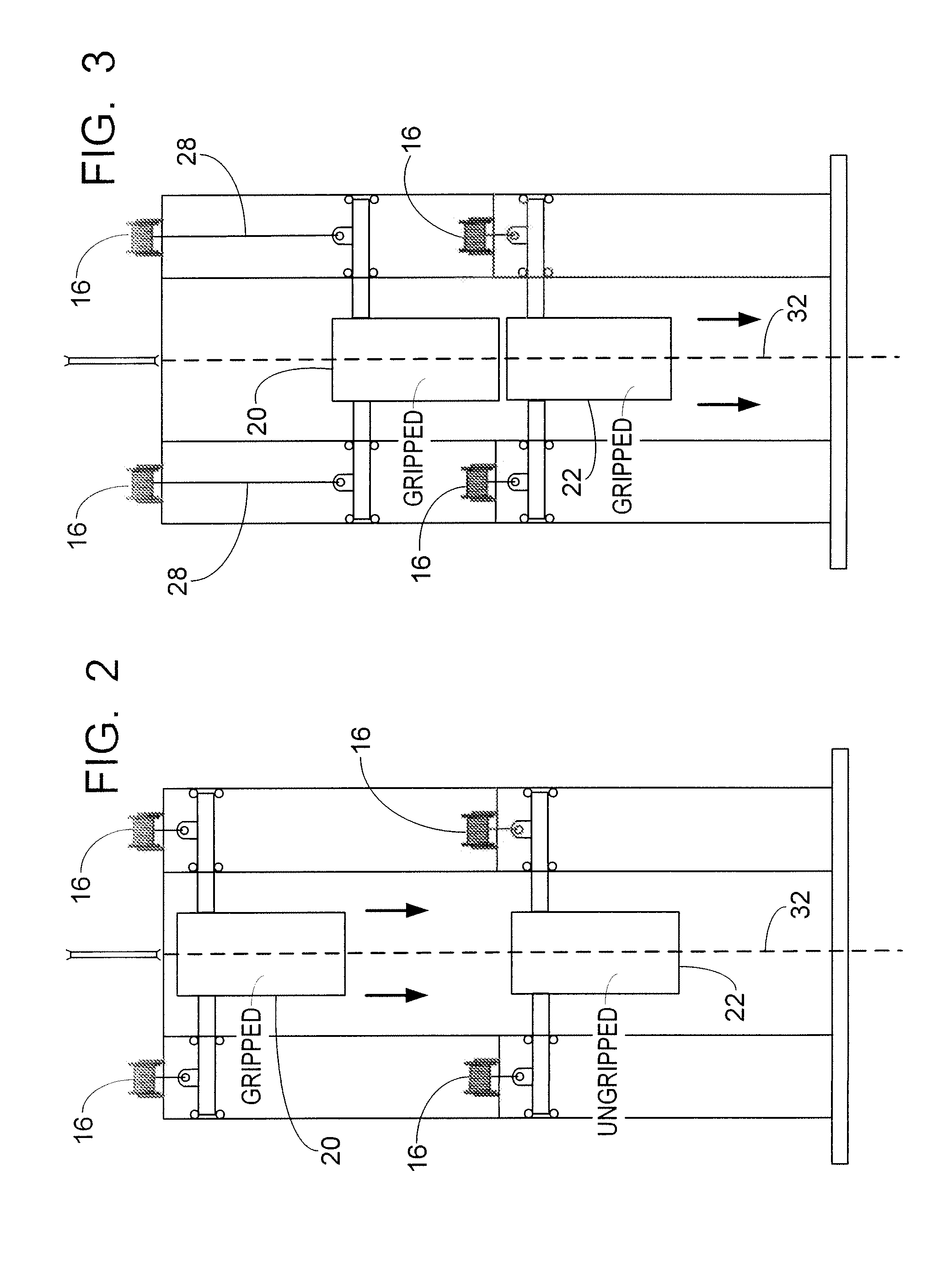

Non-Rigid Product Laying Apparatus

An arrangement for laying non-rigid product offshore that includes a dual long grip length clamp arrangement installed vertically into a tower in a similar manner to a J-lay trolley / clamp system. The invention differs from a J-lay arrangement in that two clamps are used and the clamps are configured for use with non-rigid product, i.e. they have a long grip length in order to spread the load evenly. Each clamp is mounted on a trolley and can travel vertically up or down. The upper clamp is arranged with a distance between it and the lower clamp such that the upper clamp can lower the non-rigid product a suitable distance before the lower clamp grips the non-rigid product so as to create as close as possible continuous movement as practical.

Owner:J RAY MCCDERMOTT SA

Liquid silicone rubber and preparation method thereof

InactiveCN110437621AImproves clarity and tear strengthReduce process and equipment investmentProduction cycleNew materials

The invention belongs to the technical field of chemical engineering novel material, and more specifically relates to a preparation method of liquid silicone rubber. The preparation method comprises following steps: 1, synthesis of a base rubber; 2, reinforcing of the base rubber; 3, crosslinking solidification of liquid silicone rubber; and 4, curing moulding. According to the preparation method,addition solidification is adopted to prepare the liquid silicone rubber. In the processing process, no trimming is needed, precision is high, production period is short, excellent heat tearing performance is achieved, it is convenient for demoulsing, a plurality of processing modes including mould pressing, extrusion, and injection pressing can be adopted, and material automatic production can be realized.

Owner:HUBEI XINHAIHONG CHEM

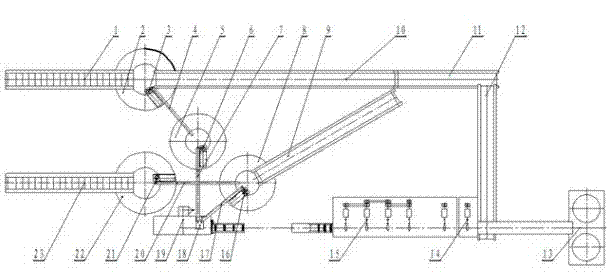

Lead belt production line for anodes and cathodes of storage batteries

InactiveCN102773708AFinal quality impactImprove working conditionsOther manufacturing equipments/toolsLead smeltingMetallurgy

The invention relates to a lead belt production line for anodes and cathodes of storage batteries. The technical scheme is described as follows: a first lead conveying pipe 4 is arranged between furnace mouths of a first lead smelting furnace 2 and a first thermal insulation furnace 5; a second lead conveying pipe 20 is arranged between furnace mouths of a second lead smelting furnace 22 and a second thermal insulation furnace 8; a third lead conveying pipe 7 and a fourth lead conveying pipe 17 are respectively arranged between the furnace mouth of the first thermal insulation furnace 5 and a tank mouth of a continuous casting middle tank 18 as well as between the furnace mouth of the second thermal insulation furnace 8 and the tank mouth of the continuous casting middle tank 18; the continuous casting middle tank 18 is arranged above a continuous casting machine 19; a continuous mill unit 15 is arranged at the downstream of the continuous casting machine 19; a central line of a casting blank is superposed with a rolling central line; a longitudinal shearing and edge scrapping device 14 and a reeling machine 13 are arranged at the downstream of the continuous mill unit 15 in sequence; qualified longitudinally sheared lead alloy belts are reeled by the reeling machine 13; and scrapped slitter edges are conveyed to the first lead smelting furnace 2 (or the first thermal insulation furnace 5) and the second lead smelting furnace 22 (or the second thermal insulation furnace 8) through a belt conveyer. According to the lead belt production line for anodes and cathodes of storage batteries, the work environment can be remarkably improved, and the product quality and the production efficiency also can be remarkably improved.

Owner:WUHAN UNIV OF SCI & TECH

High-bearing composite material parting tooth connecting device based on soft substance

InactiveCN113251037AImprove bearing capacityImprove fracture toughnessMaterial gluingShrinkage connectionsSoft materialsFatigue resistance

The invention discloses a high-bearing composite material parting tooth connecting device based on a soft substance. The device is characterized in that a composite material plate is plate-shaped, and composite material parting teeth are arranged on the upper side surface, or the lower side surface, or the upper surface and the lower side surface of the two ends of the composite material plate; the upper side face and the lower side face of the two ends of the composite material plate are connected with metal plates correspondingly, metal teeth in corresponding forms are arranged on the connecting faces of the metal plates, and after the metal teeth and the composite material parting teeth are attached, a certain gap is reserved between the metal teeth and the composite material parting teeth and filled with soft materials; and a certain pre-tightening force is applied between the composite material plate and the metal plates. Therefore, according to the high-bearing composite material parting tooth connecting device based on the soft substance, metal connecting pieces and a composite material are connected, and a joint has high bearing capacity and good fatigue resistance through application of the soft substance, the parting teeth and pre-tightening force; and the load borne by the teeth in a first path is effectively distributed to the teeth in later paths through application of the soft substance, so that loads on the composite material teeth are evenly distributed, and the problem that the stress of the teeth in the first path is maximum in connection of the composite material teeth is solved.

Owner:李飞 +1

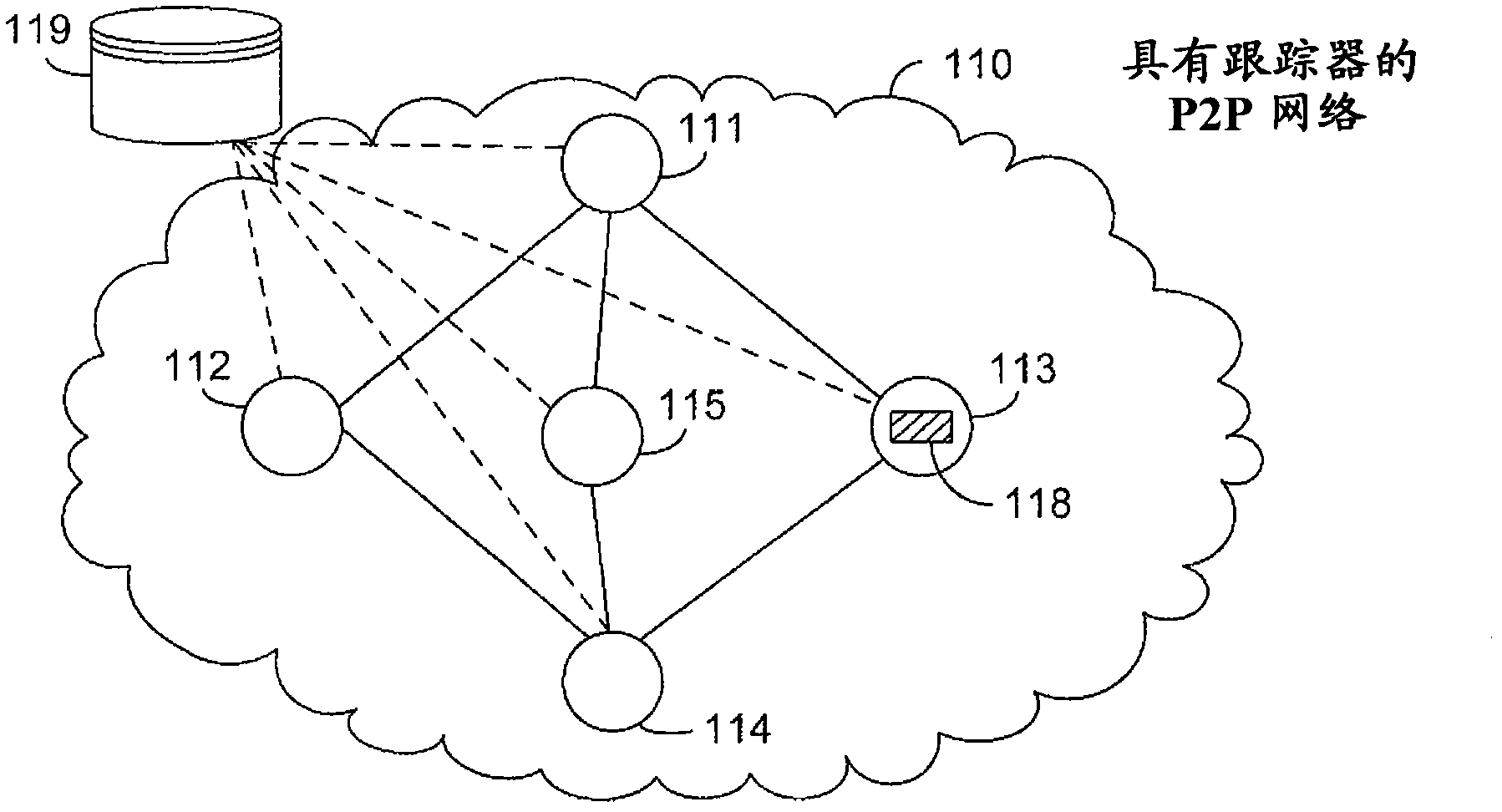

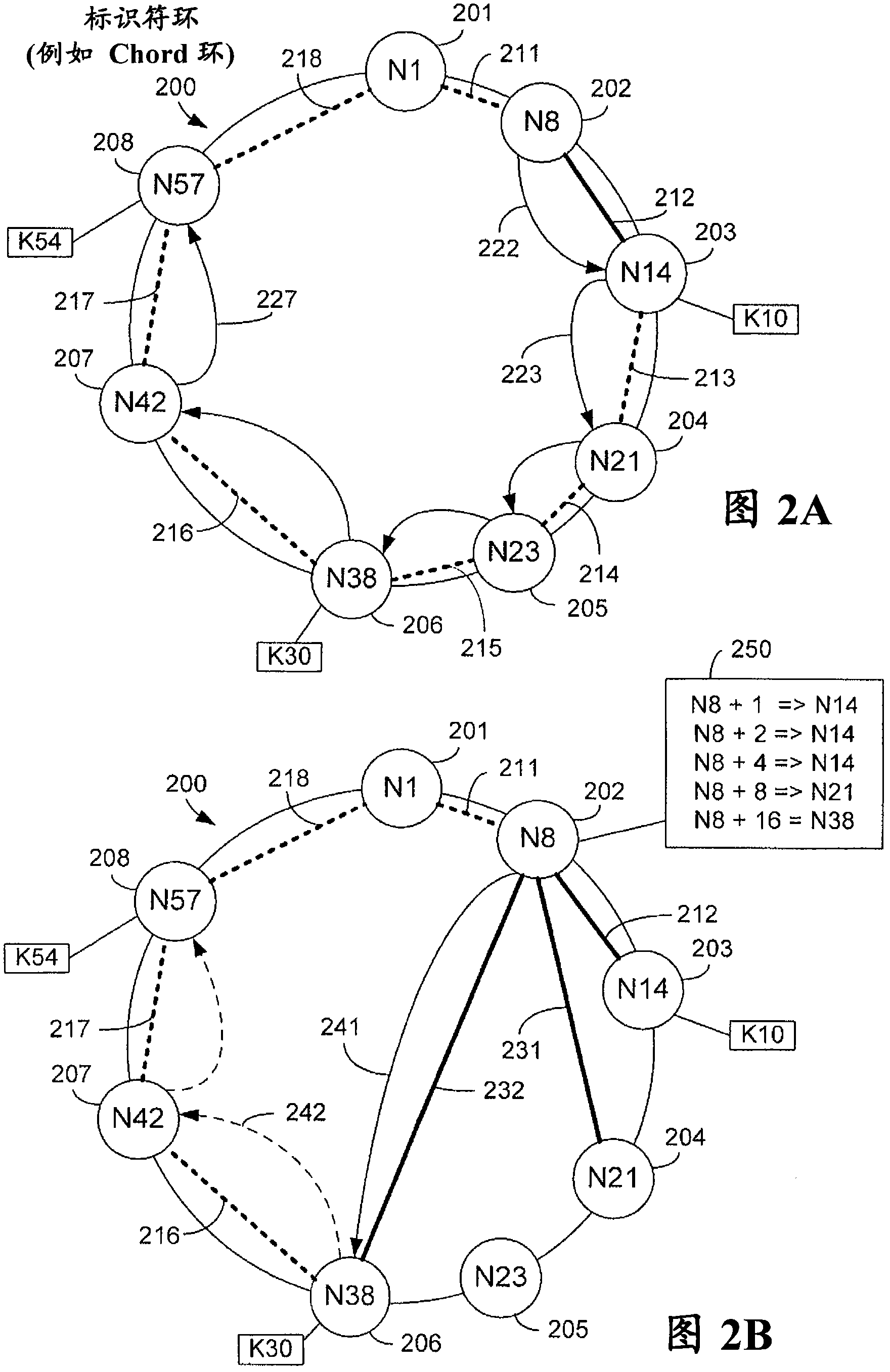

Method and arrangement for locating services in a peer-to-peer network

ActiveCN102668505BAvoid uneven loadDistribute the load evenlyTransmissionDistributed hash tableDistribute hash table

The present invention relates to methods and arrangements for locating services in a structured peer-to-peer distributed hash table, DHT, based, overlay communication network (310). The invention comprises two inter-related methods and nodes. The first method is used by a service node (321) to "advertise" to the overlay network (310) that it is providing a particular service (S1). This is done by distributing instances (351,352,353) of a service object (O1) that are stored in different nodes (331,332,333) in the overlay network (310) and where the instances (351,352,353) comprise an address to the service node (321). The other method is to locate at least one of these instances (351,352,353) with a predetermined probability and with a predetermined number of location request messages (390) from a user node (311) wishing to use the particular service (S1).

Owner:TELEFON AB LM ERICSSON (PUBL)

High-load platinum-nickel ordered intermetallic compound and its preparation method and use

ActiveCN105854897BGood dispersionDistribute the load evenlyMetal/metal-oxides/metal-hydroxide catalystsPorous carbonAlloy

The invention provides a high-loading platinum-nickel ordered intermetallic compound, which uses a three-dimensional porous carbon gel as a carrier and is prepared by the following method: a carbon carrier precursor dispersion containing graphene oxide, a Pt precursor The metal precursor solution of Ni precursor and Ni precursor, reducing agent and sodium citrate dihydrate are uniformly mixed, and then the hydrothermal reaction generates a carbon gel uniformly loaded with a high-loading platinum-nickel disordered alloy, and then heat treated in a reducing atmosphere. The carbon gel is formed to uniformly load high-loading platinum-nickel ordered intermetallic compounds. Compared with traditional high-loading Pt / C catalysts, this catalyst relatively reduces the amount of precious metal Pt, uses the synergy between metals to improve the activity of the catalyst, and uses the high dispersion of ordered metal nanoparticles to improve the stability of the catalyst. properties, the catalyst still maintains a high degree of dispersion characteristics after ordered heat treatment. The invention also discloses a preparation method of the compound. The invention also discloses the use of the compound.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

A kind of high temperature stable coated sand

InactiveCN110586847BGood compatibilityImprove tensile propertiesFoundry mouldsFoundry coresStearic acidNanoparti cles

The invention discloses high-temperature stable precoated sand, and belongs to the field of casting materials. Polylactic acid, lanthanum stearate and the like are used as raw materials, and are combined with subsequent nanoparticle effects for mutual connection to form space netty structures with nanometer microholes so as to improve the forming effect of the precoated sand. Three types of nanoparticles are used as nanomaterials for ultrasonic dispersion and acid mixing effects to improve the dispersion effect; and through adding of nanometer TiO2, a lot of plastic deformation energy can be absorbed when the external pressure effect is suffered, so that the softness of the prepared precoated sand is improved, the shell mold flexibility is improved, and the high-temperature pressure strength is improved. In the mixing process, through coaction between inorganic-organic components, compact air separation layers are formed in the precoated sand, and the influence on the internal of the precoated sand can be reduced when high-temperature effect is suffered. The high-temperature stable precoated sand solves the problems of easy unshelling and agglomeration of traditional precoated sandin the preparation process due to lower high-temperature pressure strength of the traditional precoated sand.

Owner:青铜峡市瑞通支撑剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com