Anchor cable opposite-puling type supporting and protecting structure system and construction method thereof

A support structure and construction method technology, applied in the direction of earth drilling, installation of bolts, mining equipment, etc., can solve the problems of inability to effectively ensure the safety of construction and operation, the inability to ensure the safety and stability of tunnel structures, and the inability to effectively control foundation settlement. , to achieve high flexibility and adaptability, improve the stability of the structure itself, and achieve high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

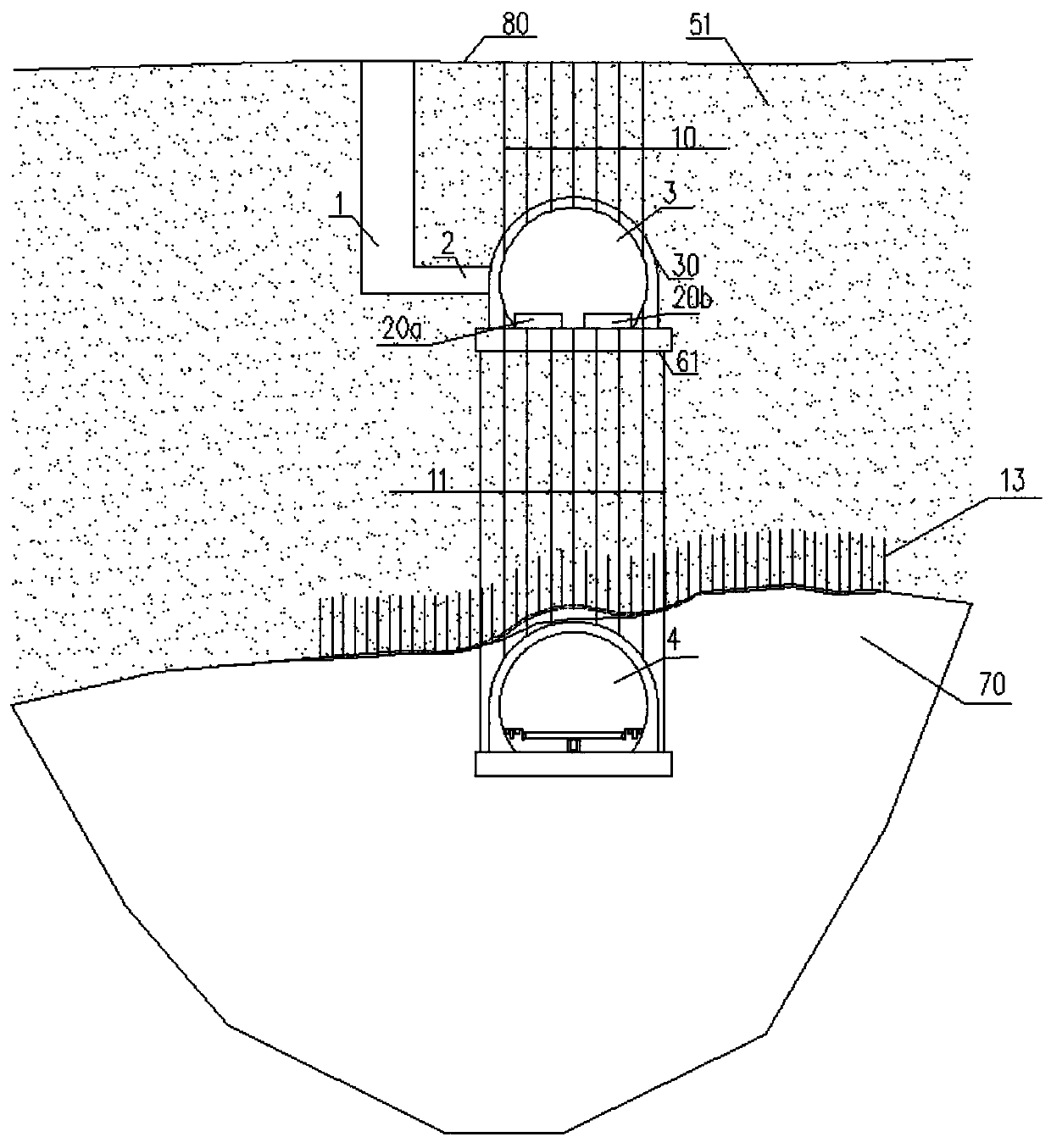

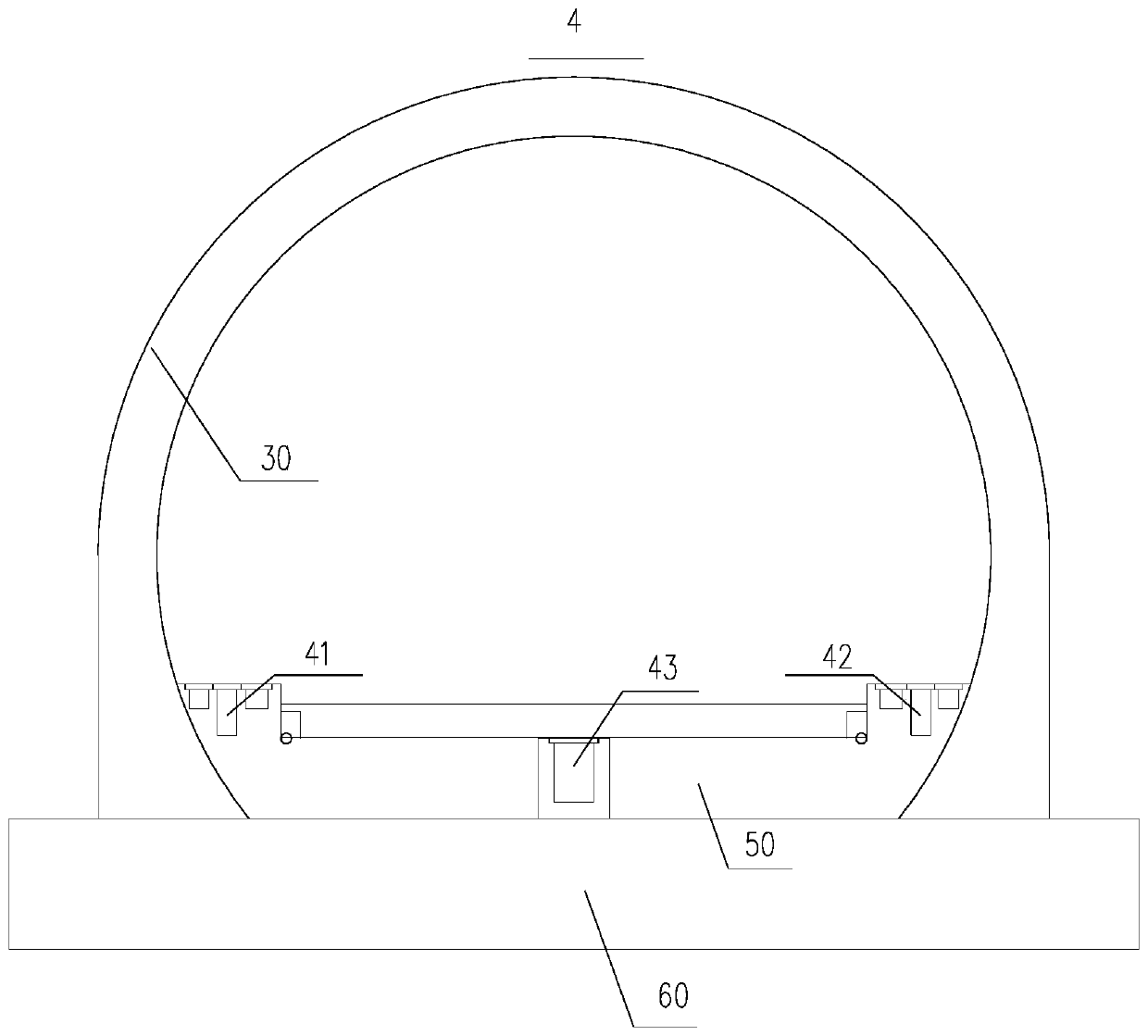

[0050] see Figure 1-Figure 8 . An embodiment of the present invention provides a pair-stayed support structure system of anchor cables, which includes a vertical guide hole 3 , a tunnel main hole 4 , a first pair of anchor cables 10 and a second pair of anchor cables 11 .

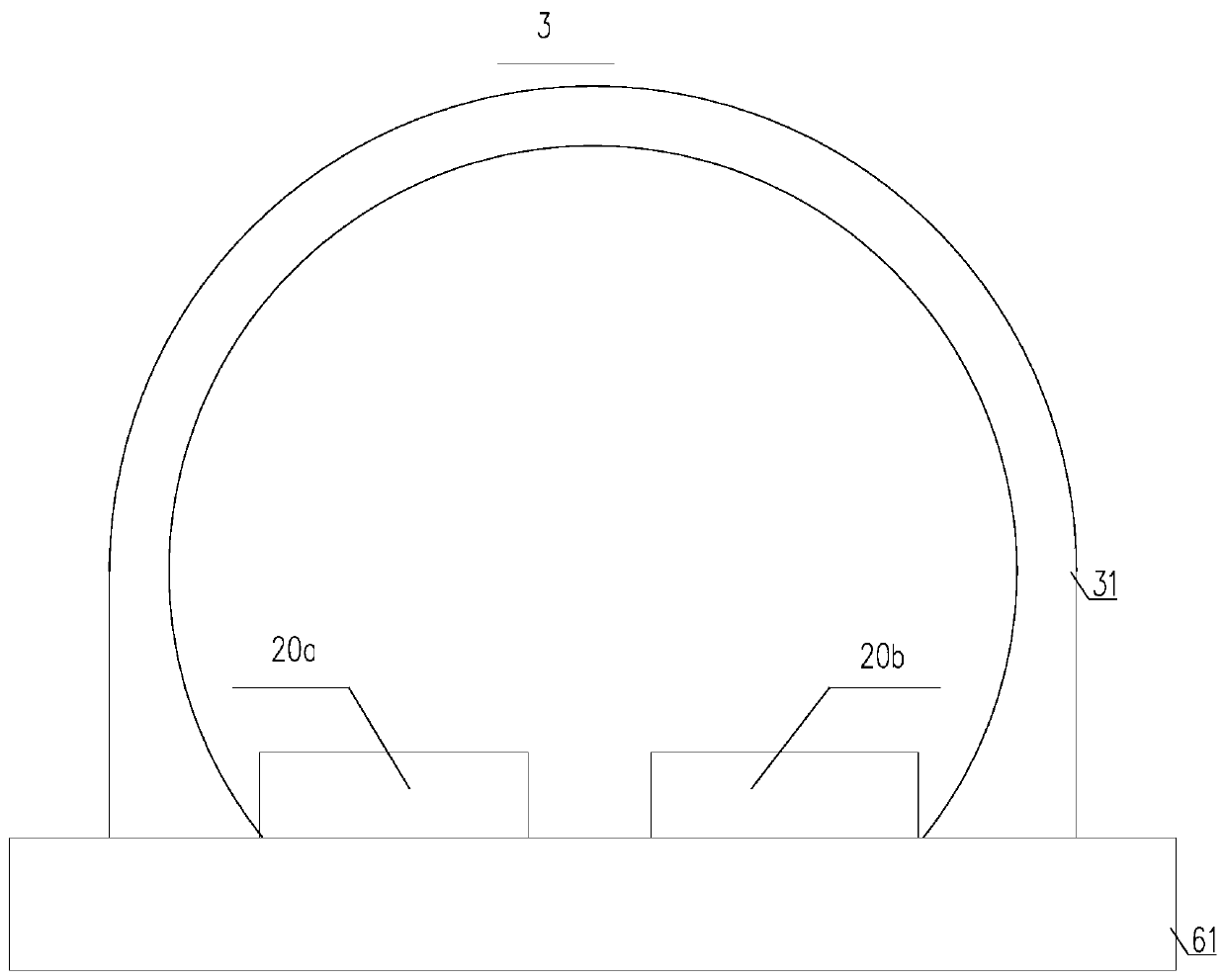

[0051] The vertical guide hole 3 is arranged in the rock mass above the tunnel main hole 4, and the vertical guide hole 3 is arranged in parallel with the tunnel main hole 4. The first pair of anchor cables 10 are arranged from top to bottom, the upper end is fixed to the ground surface, and the lower end is fixed to the vertical guide hole 3 . The second pair of anchor cables 11 are arranged from top to bottom, the upper end is fixed on the vertical guide hole 3 , and the lower end is fixed on the secondary lining 31 structure of the main tunnel 4 in the tunnel main tunnel 4 .

[0052] see figure 2 , the secondary lining 30 of the pilot tunnel, the bottom plate of the pilot tunnel 61 and the ground be...

Embodiment 2

[0083] see Figure 9 , the embodiment of the present invention provides an anchor cable tension support structure system, which differs from the anchor cable tension support structure system in Implementation 1 in that in this embodiment, the number of vertical guide holes 3 For two, connect the two vertical guide holes 3 by setting the third pair of pull anchor cables 12 .

[0084] Aiming at the anchor cable anti-tension support structure system in this embodiment, this embodiment provides a construction method for the anchor cable anti-tension support structure system, which includes the following steps:

[0085] S1. Excavate shaft 1 and cross passage 2 to the designed position;

[0086] Specifically, in step S1, determine the location and scope of the giant karst cave hall 70, and excavate the shaft 1 and the cross passage 2 to the designed location;

[0087] S2. Construction vertical guide hole 3;

[0088] Specifically, step S2 includes the following steps:

[0089] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com