Patents

Literature

113results about How to "Reduce fill volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

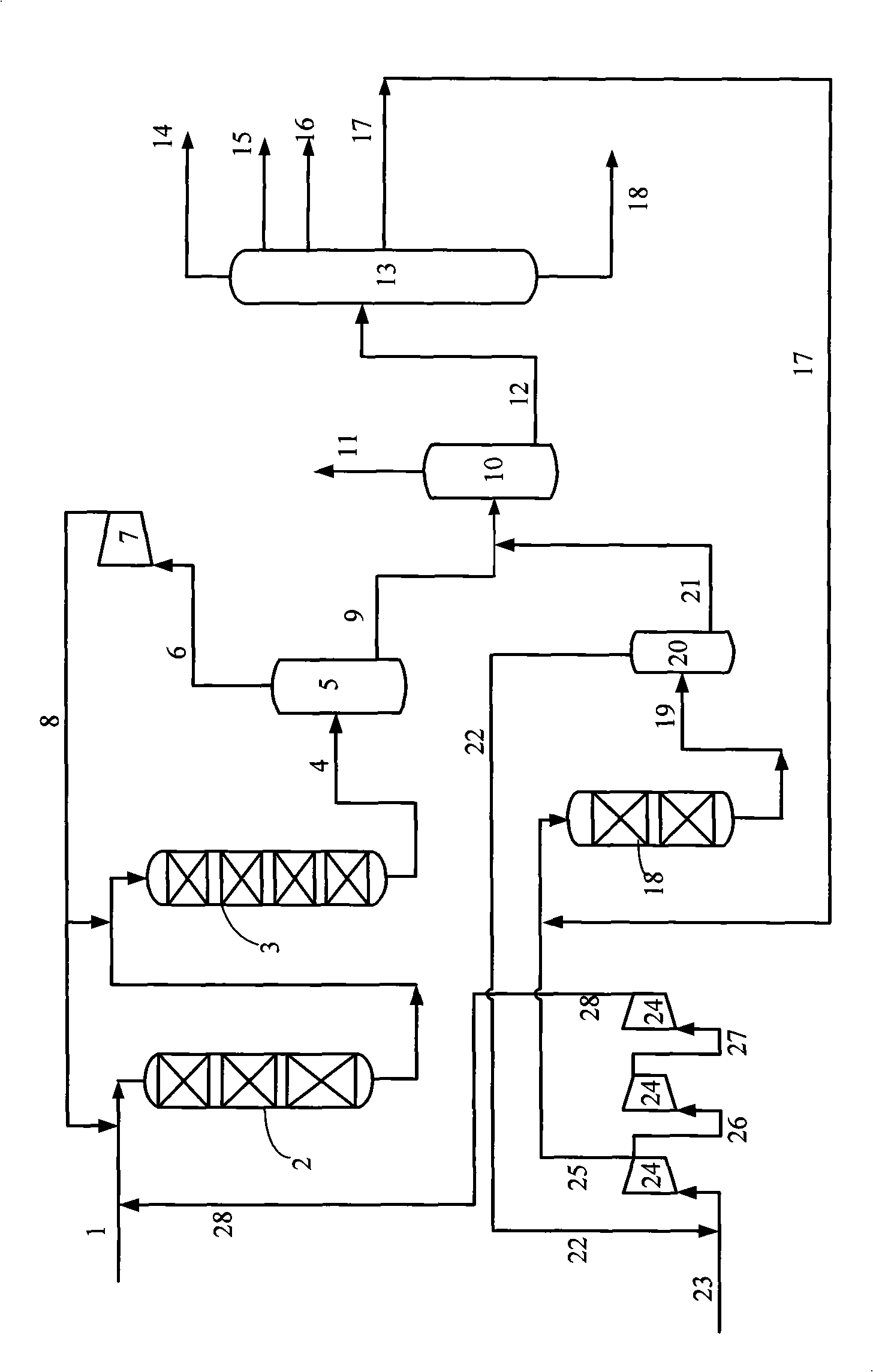

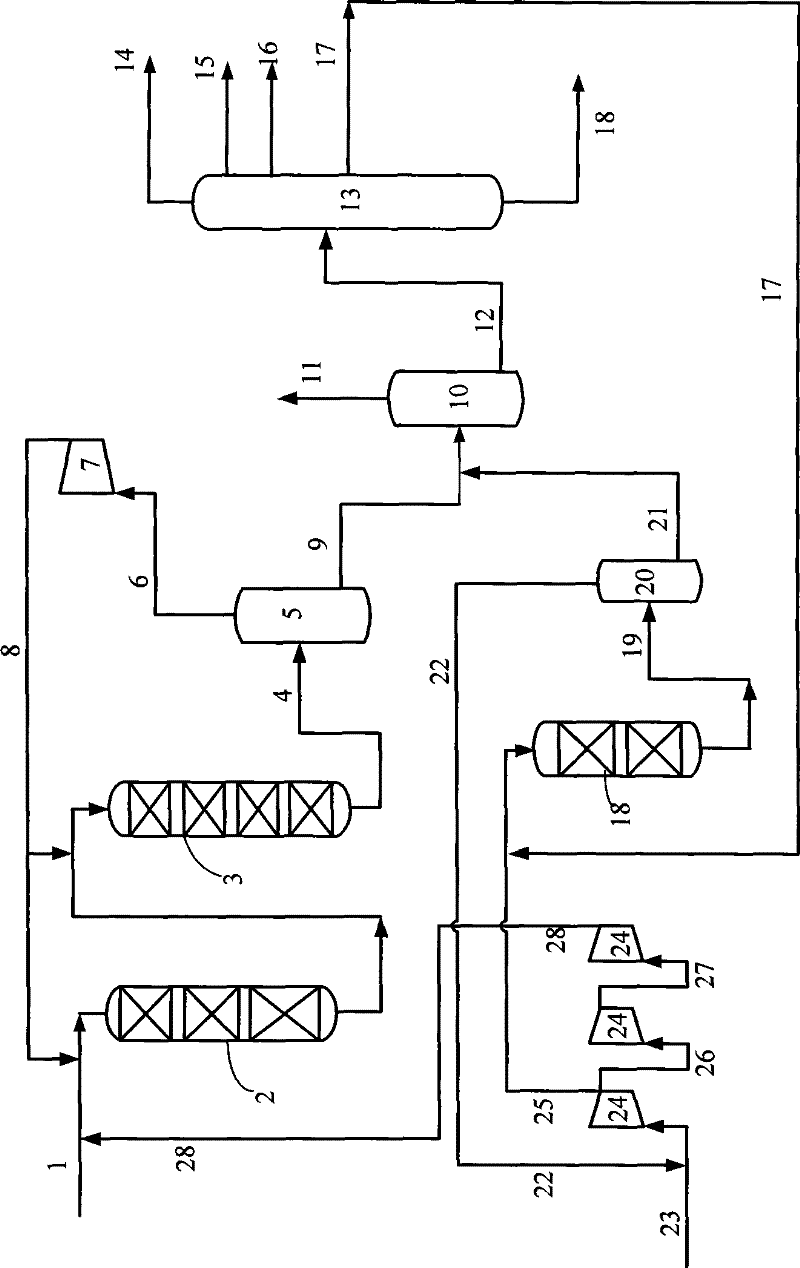

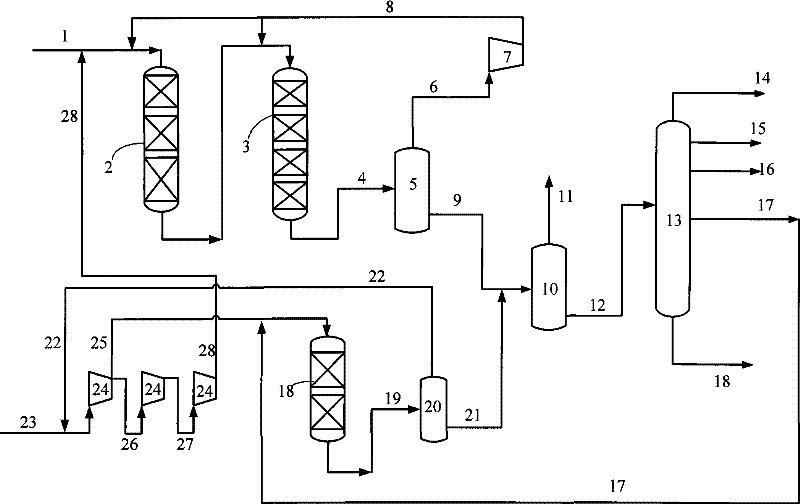

Hydrocracking method for producing chemical materials to maximum with low cost

ActiveCN101684415AReduce hydrogen consumptionLow investment costHydrocarbon oil crackingNaphthaFractionation

The invention relates to a hydrocracking method for producing chemical materials to the maximum with low cost, comprising the following steps: mixing raw oil and hydrogen gas , entering a first reaction area, sequentially contacting with hydrofining catalyst and hydrocracking catalyst, reacting under the pressure of 6.0-16.0 MPa; carrying out oil-gas separation and fractionation on the reaction products thereof to obtain liquefied gas, light naphtha fractions, heavy naphtha fractions, middle fractions and tail oil fractions; mixing the middle fractions and the hydrogen gas and enteringa second reaction area, contacting with the hydrocracking catalyst under the pressure of 1.0-5.5 MPa to react; and carrying out oil-gas separation on the reaction products thereof and entering a fractionation system . By adopting the method, heavy raw materials such as vacuum gas oil, coking gas oil and the like are treated to obtain more than 98 weight percent chemical materials. In the invention, themiddle fractions are wholly converted into the chemical materials in the low pressure condition, and low hydrogen consumption, low investment cost and low operation cost are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

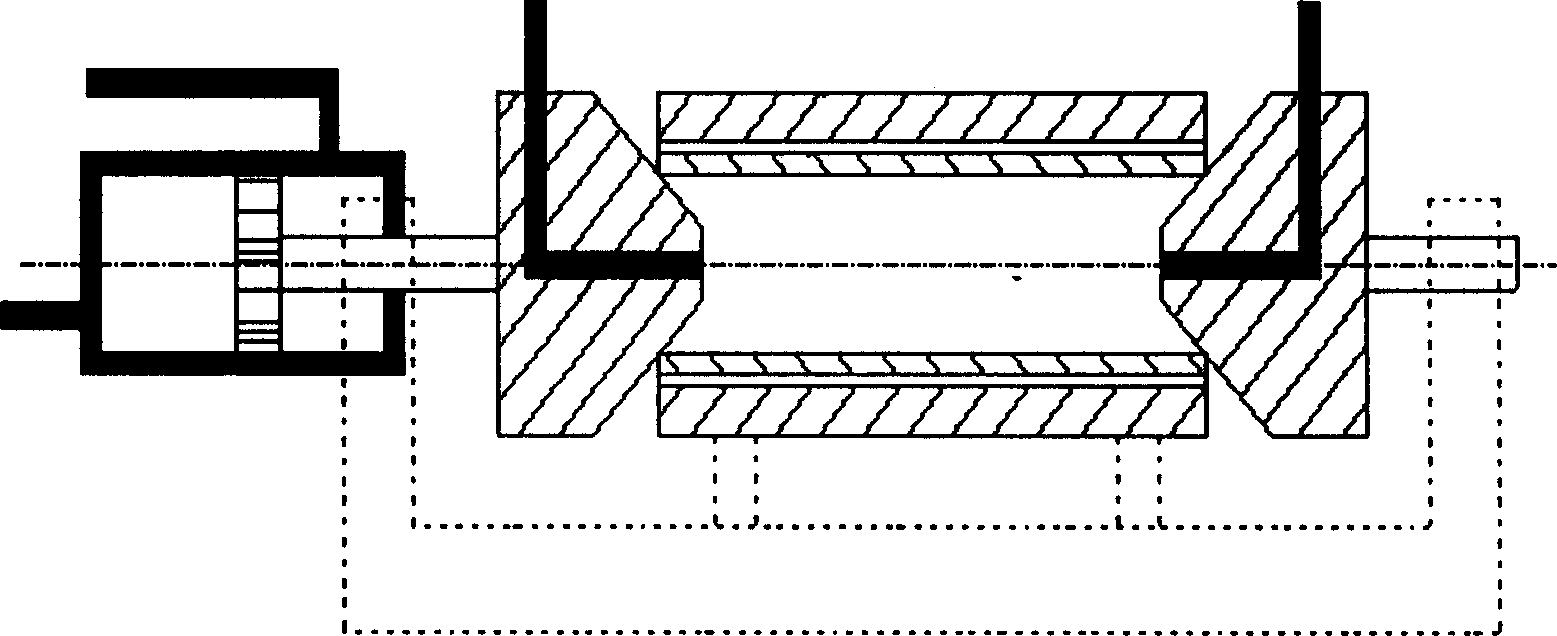

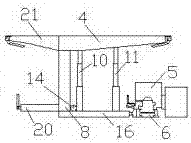

Hydraulic shaping device of stainless steel lined compound pipe and its shaping method

InactiveCN1651163AUniform expansion forceManufacturing quality is easy to guaranteeHydroformingCopper

A hydraulic apparatus for forming a composite pipe with stainless steel liner is composed of core rod, left and right expanding ehads fixed respectively to both ends of said core rod, two self-fastened sealing rings for left and right expanding heads, and the fixers at the ends of said expanding heads. Its forming technology is also disclosed.

Owner:EAST CHINA UNIV OF SCI & TECH

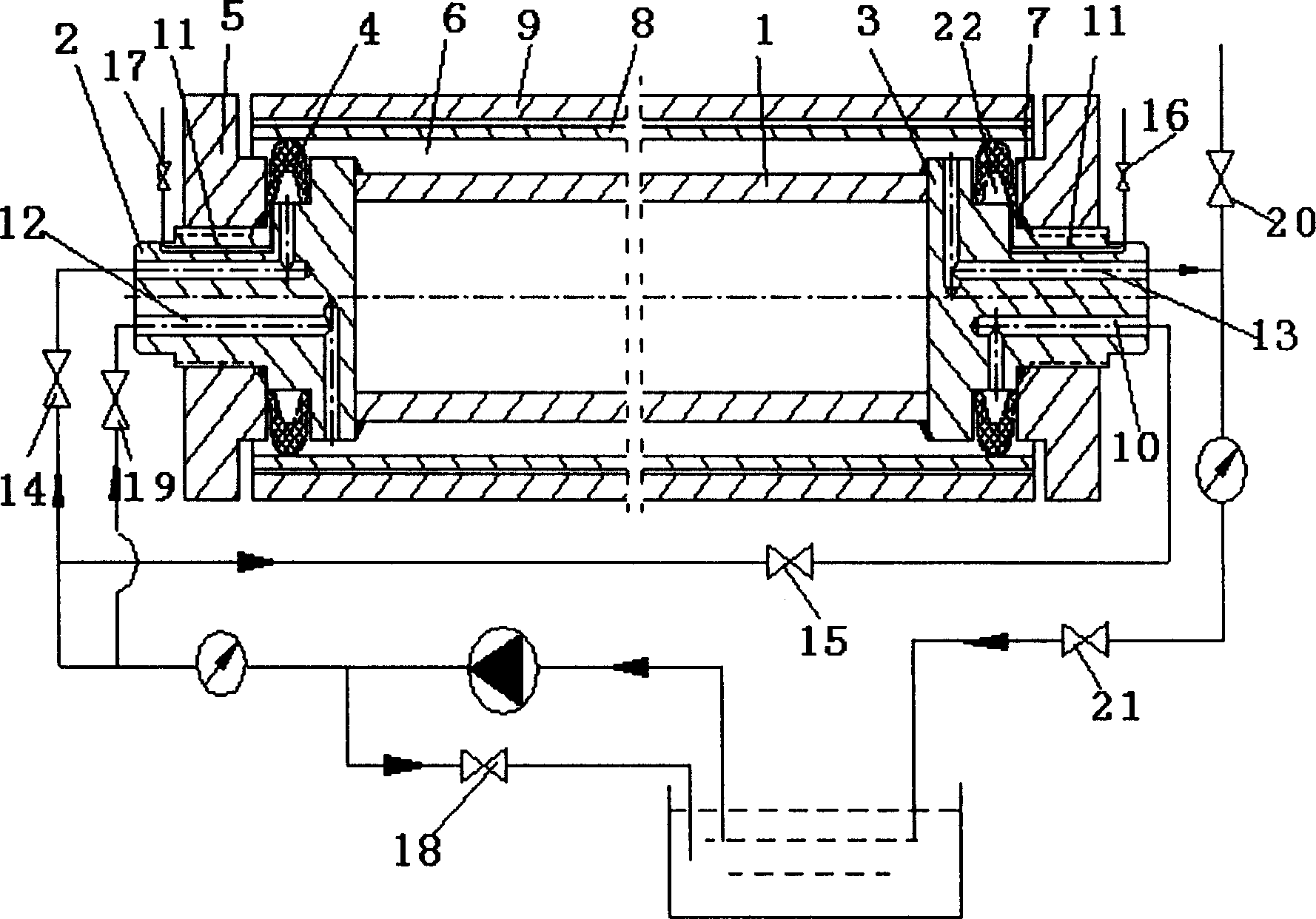

Method for improving filling property of rigid polyurethane foam plastics

InactiveCN101474842ASolve low flow performanceImprove filling performanceDomestic cooling apparatusLighting and heating apparatusChemistryProduct gas

The present invention relates to a method for improving filling property of hard polyurethane foamed plastic. The invention is characterized in that an air induction device is adopted for controlling the inner pressure of cavity of hard polyurethane foamed plastic in the foaming process. The gas which affects the flow of reaction solution is leaded out to cause that the reaction solution easily flows in the whole foaming reaction process. The invention can continuously lead out the gas which affects the generation of reaction solution so that the reaction solution easily flows in the whole reaction process. The problems of low flow property and inferior filling property in the prior forming process of polyurethane are essentially settled. The filling property in the foaming forming process is greatly improved. The filling amount of hard polyurethane foam prepared according to the invention is reduced by 5-20% at the state that the performance is guaranteed compared with the state that the invention is not adopted. The invention can be actualized with the existing foam production device which is little reformed.

Owner:HONGBAOLI GRP CO LTD +1

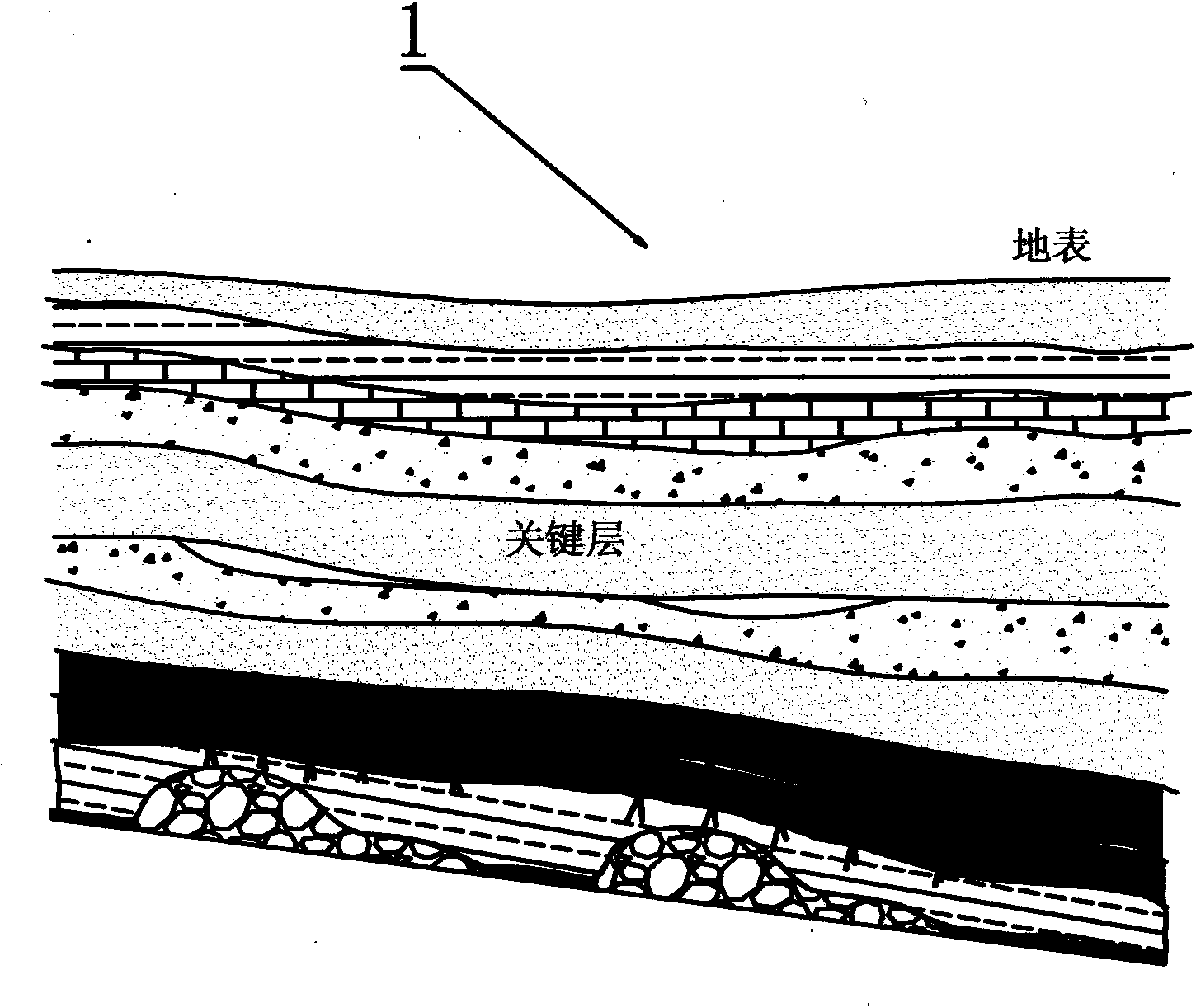

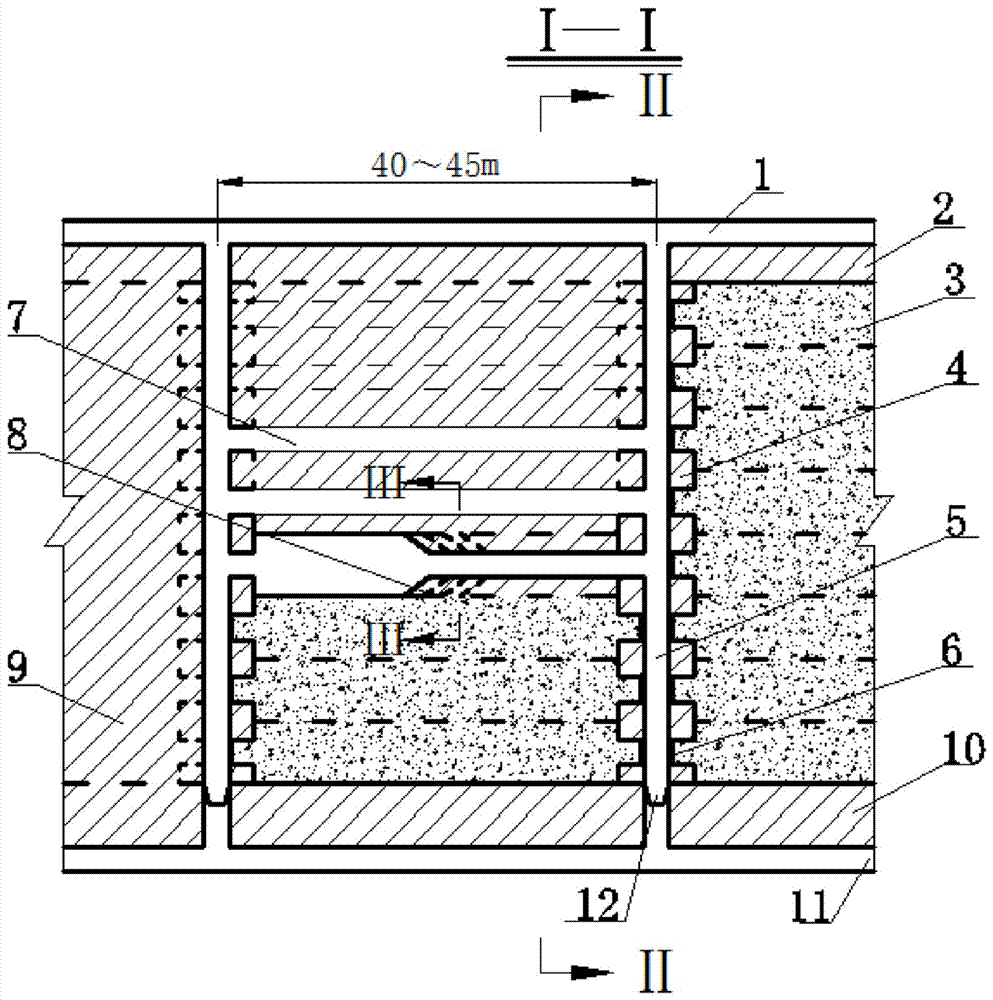

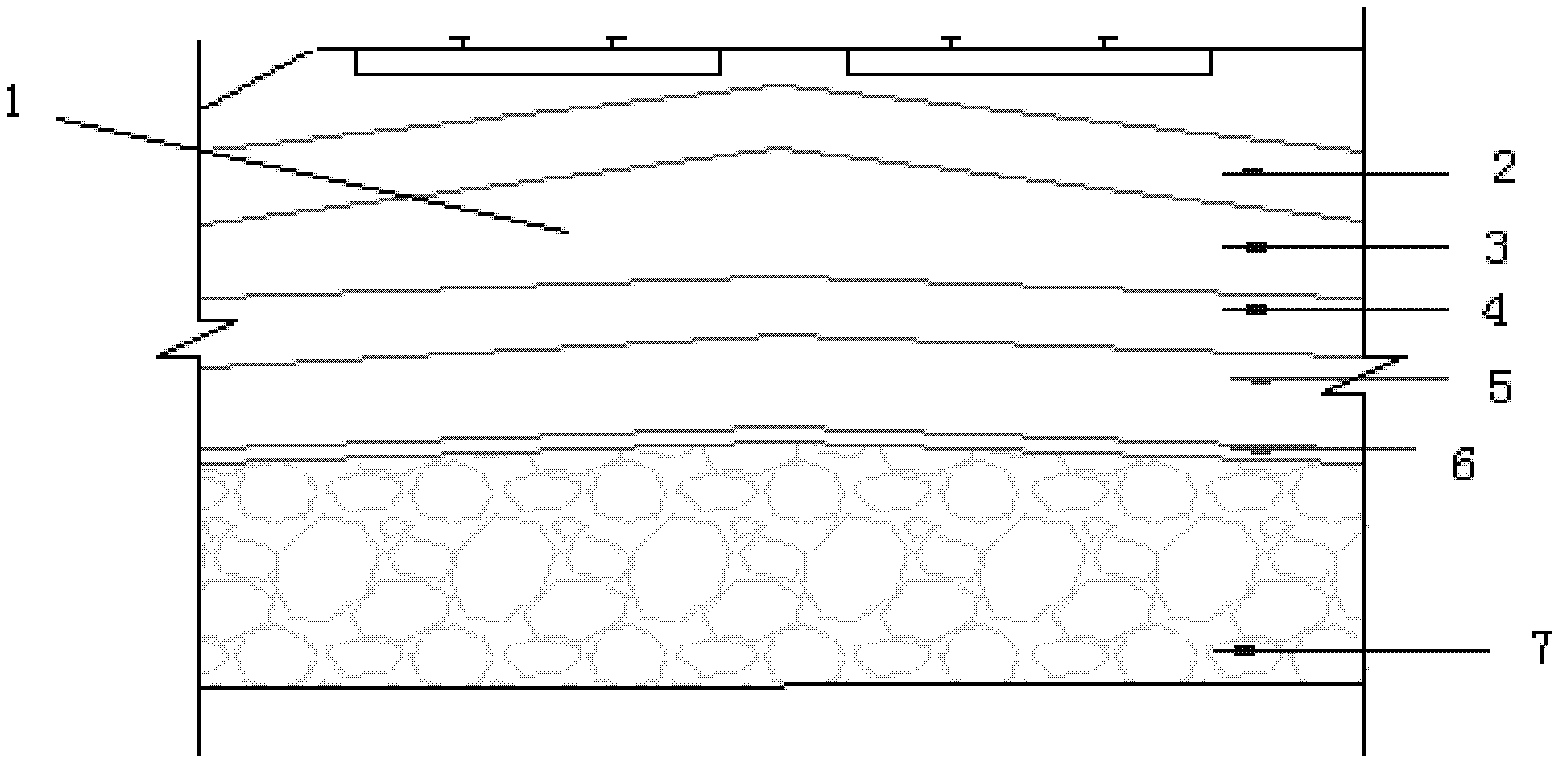

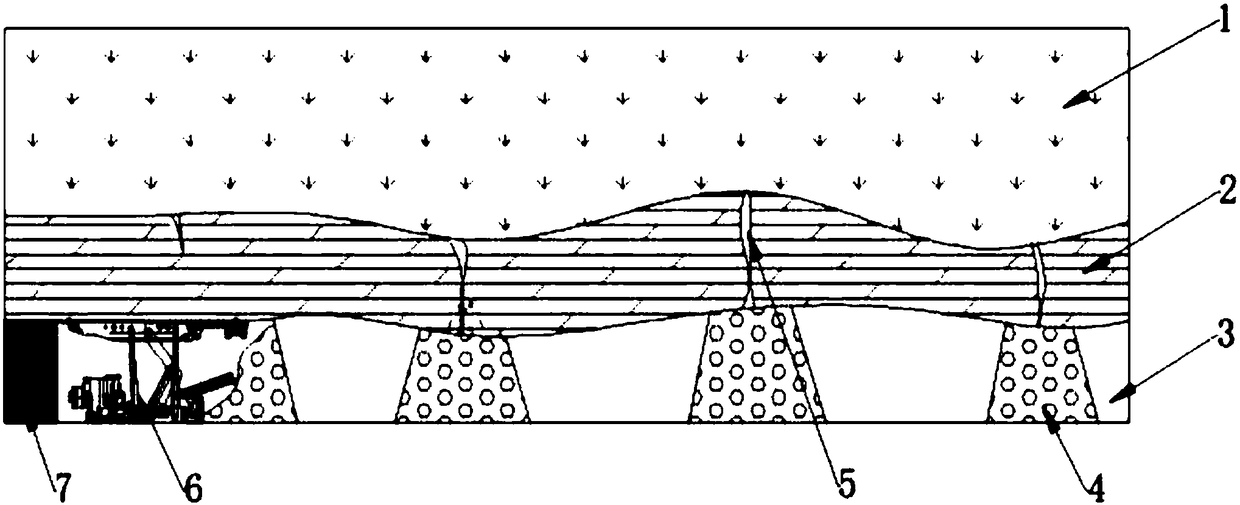

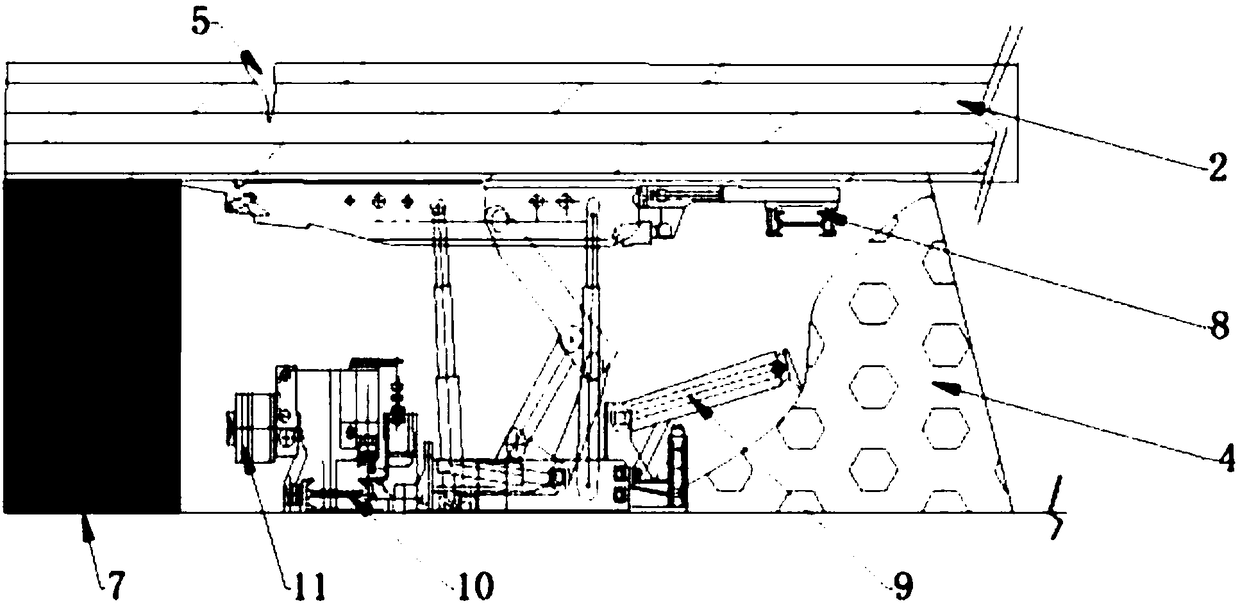

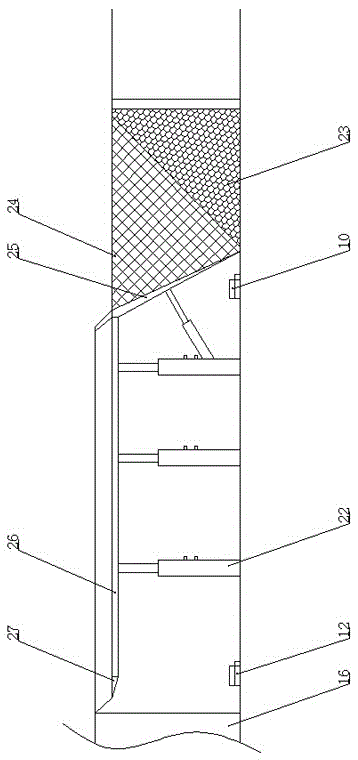

Method of local filling to control surface subsidence in gob

The invention relates to a method of local filling to control surface subsidence in a gob. Metal nets are suspended at intervals from open-off cuts and on top plates behind a hydraulic bracket on a working surface along with coal cutting of a coal cutter and movement of the hydraulic bracket on the working surface, and filling bags are arranged; coal cutting is stopped after cutting is performed once by the coal cutter, and concrete is filled into the filling bags in the metal nets in sequence until a roof; cutting is continuously performed once by the coal cutter, metal nets are continuously suspended on top plates adjacent to the two sides of the filled area, filling is continuously performed to complete a filling cycle, and a row of filled bodies are formed in a gob parallel to the working surface; and coal cutting is continuously performed four to five times by the coal cutter, the following filling cycle is completed continuously, and the procedures are repeated until filling of the whole gob is completed and a plurality of rows of filled bodies are formed in the gob. The method is simple, and the filling cost is low. Since the top plates in the gob are supported uniformly at intervals, the stability of an overburden layer, in particular a key layer, can be improved, and surface subsidence and damage to buildings can be effectively prevented.

Owner:CHINA UNIV OF MINING & TECH

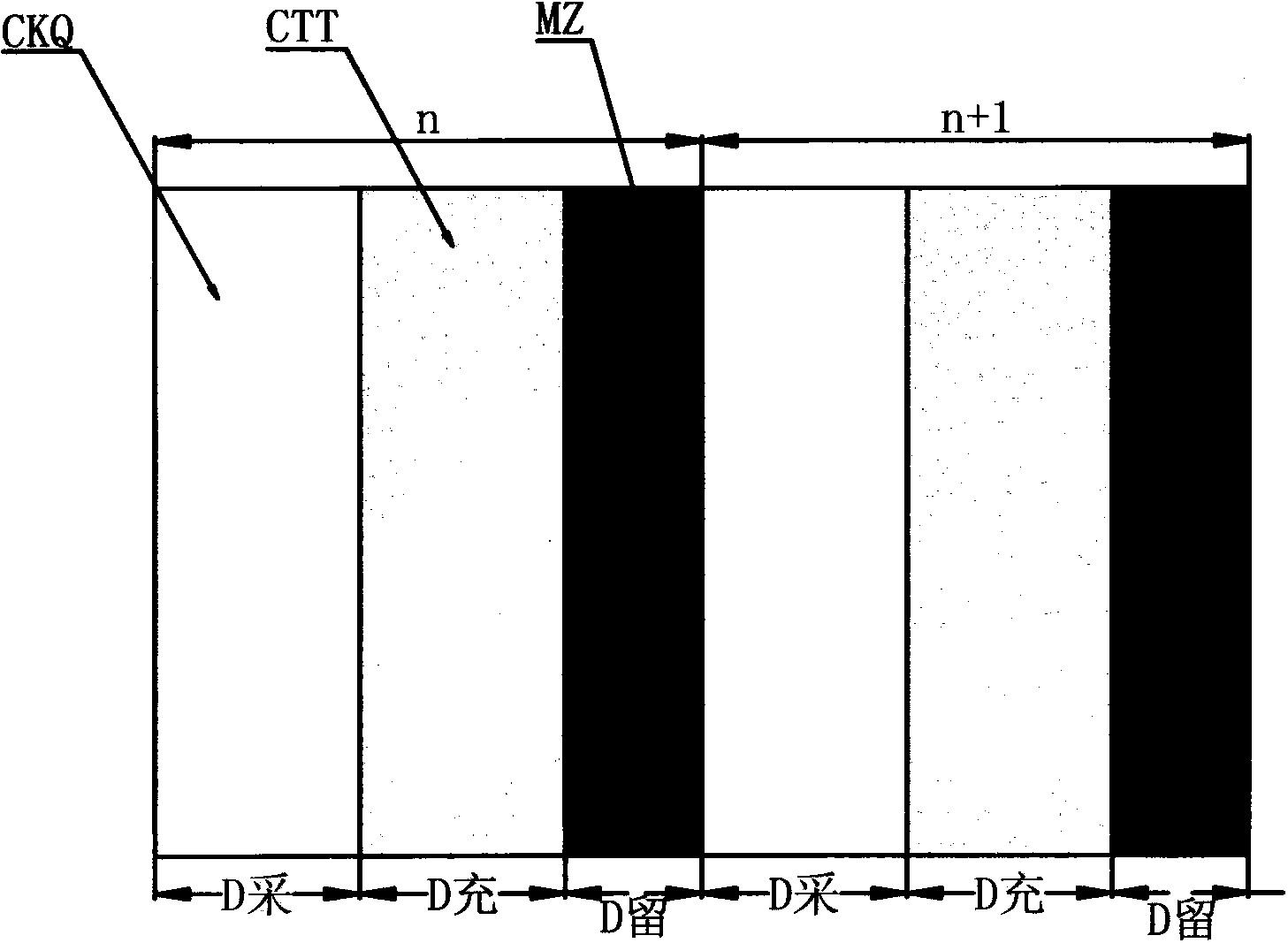

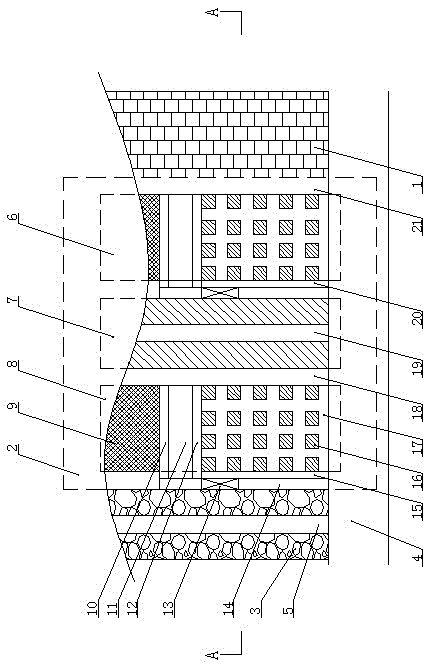

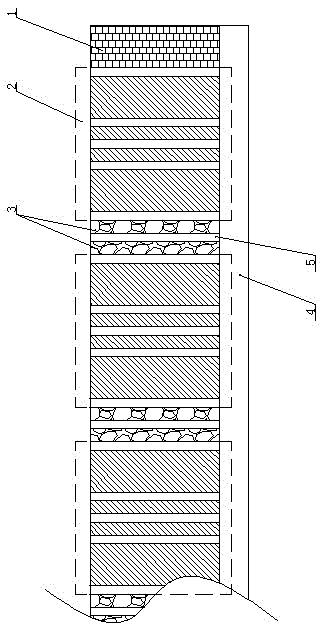

Coal mine rock stratum mobile control mining-filling-preserving coupled coordination mining method

ActiveCN103437765AReduce the degree of movement and deformation of overlying rockControl surface movement deformationUnderground miningSurface miningCoalCoal pillar

The invention discloses a coal mine rock stratum mobile control mining-filling-preserving coupled coordination mining method. Coal pillar preserving-partial filling-partial mining coordination filling mining is implemented, preserved coal pillars are treated as a core, and the preserved coal pillars, a filler and a caving body coordinatively support upside rock to control the mobile deformation value of the rock stratum and the ground surface. A one-side filling mode is characterized in that filling work surfaces and non-filling work surfaces are sequentially arranged at one side of the preserved coal pillars; and a two-side filling mode is characterized in that the filling work surfaces and the non-filling work surfaces are sequentially arranged at two sides of the preserved coal pillars. The filling work surfaces are first mined and then the non-filling work surfaces are recovered, or the filling mining and recovery are simultaneously carried out. The widths of the preserved coal pillars satisfy basic stable requirements; and the widths of the filling work surfaces and the non-filling work surfaces are determined according to extremely-incomplete mining requirements. Compared with strip mining, the method has the advantages of improved coal pillar stress state and increased mining rate because of the coal pillar side filling. Compared with complete mining-complete filling, the method has the advantages of reduced filling amount, enhanced support strengths of the filling body and the coal pillars, improved rock stratum control effect and cost saving.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

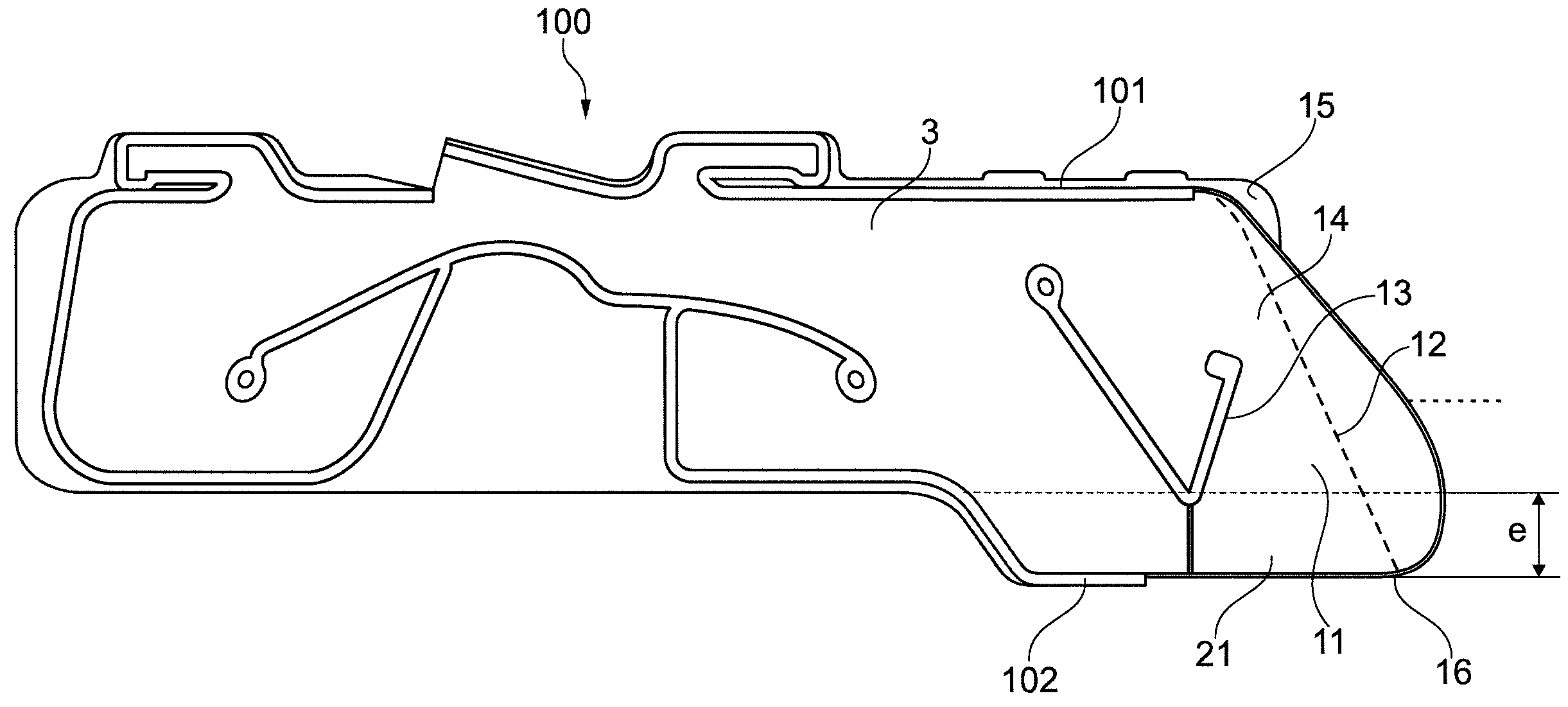

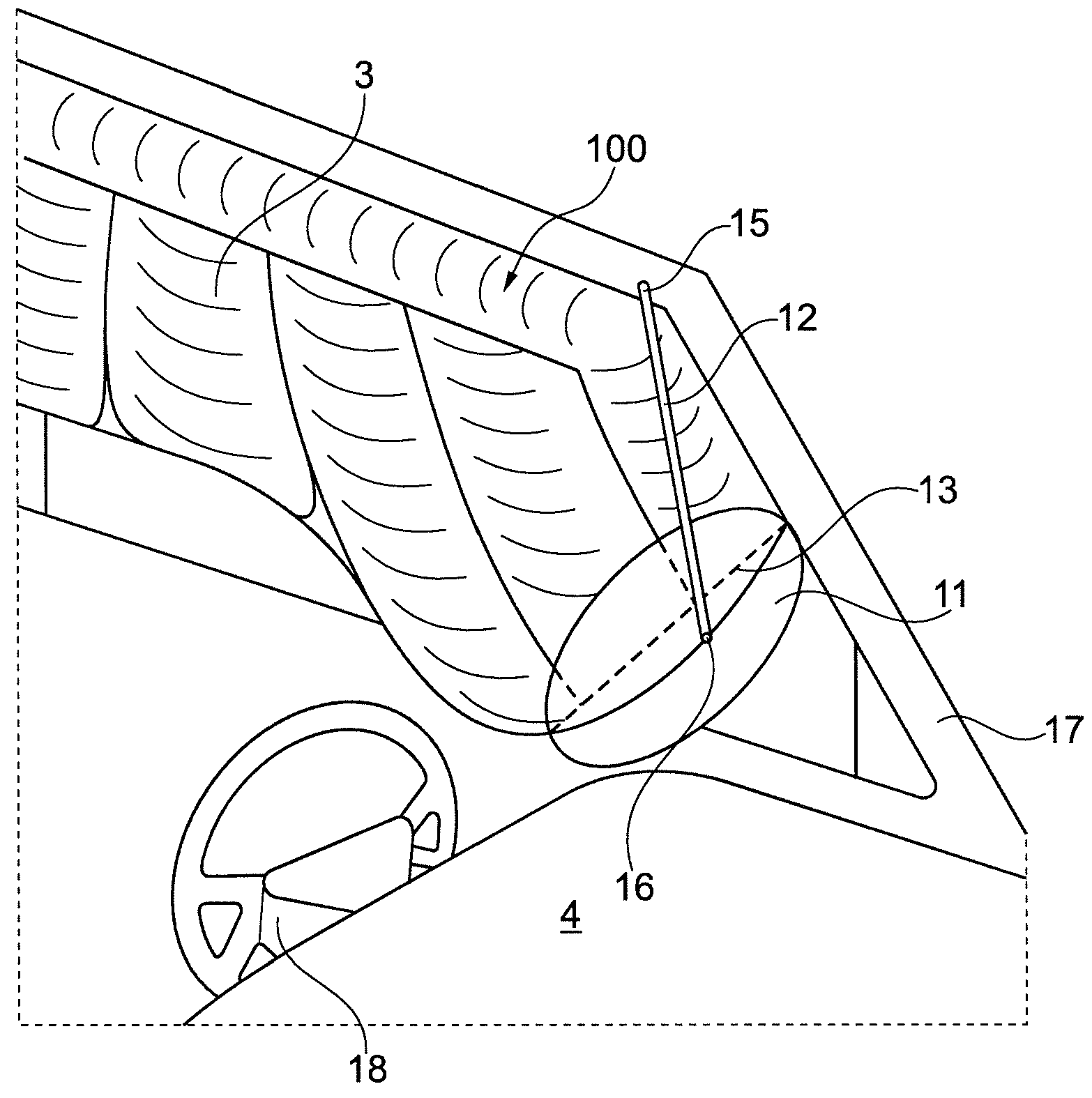

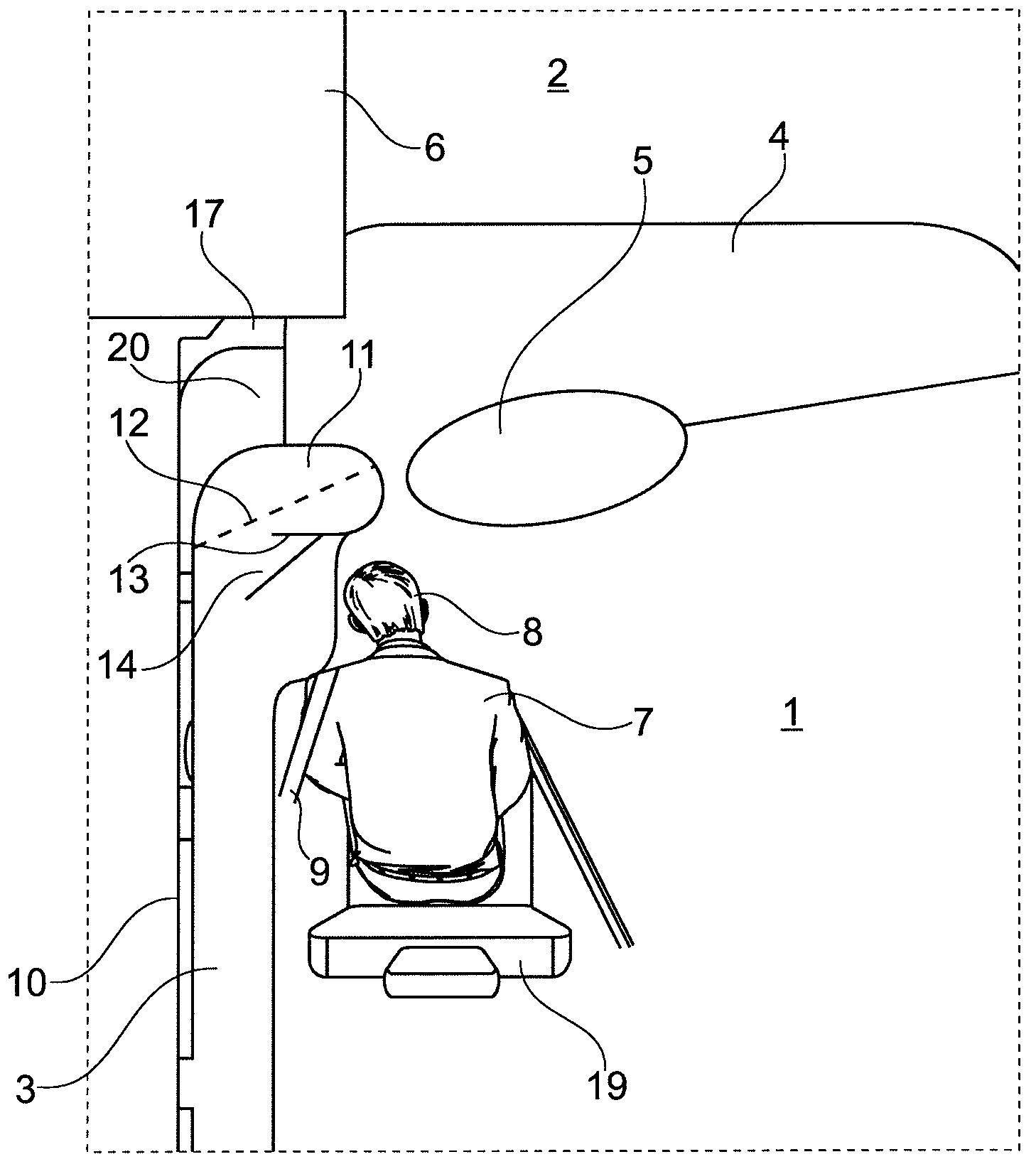

Curtain airbag for a vehicle

ActiveCN103269913AReduce the risk of serious injuryReduce the risk of missing a curtain airbagPedestrian/occupant safety arrangementAirbag

The invention relates to a curtain airbag (100) for a vehicle comprising a main chamber (3) which is shaped in such a way that,in the position being mounted on the vehicle,in the inflated state it covers an inner side structure (10) of the vehicle, wherein the curtain airbag (100) comprises an additional chamber (11) which,in the mounting position,is located on the in driving direction of the vehicle front portion of the main chamber (3), and deploys in the direction of the interior(1)of the vehicle when the curtain airbag is inflated.

Owner:AUTOLIV DEV AB

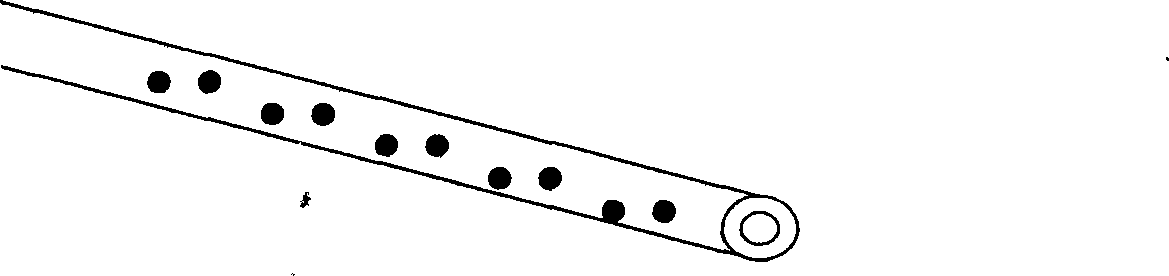

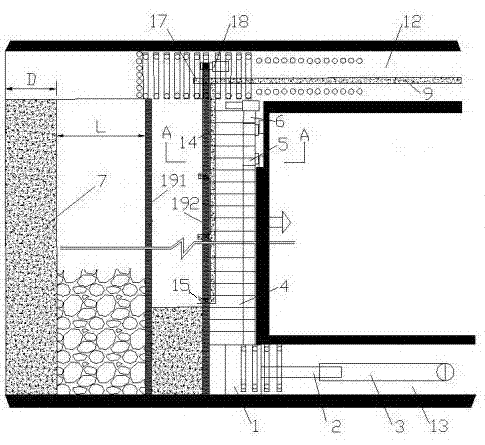

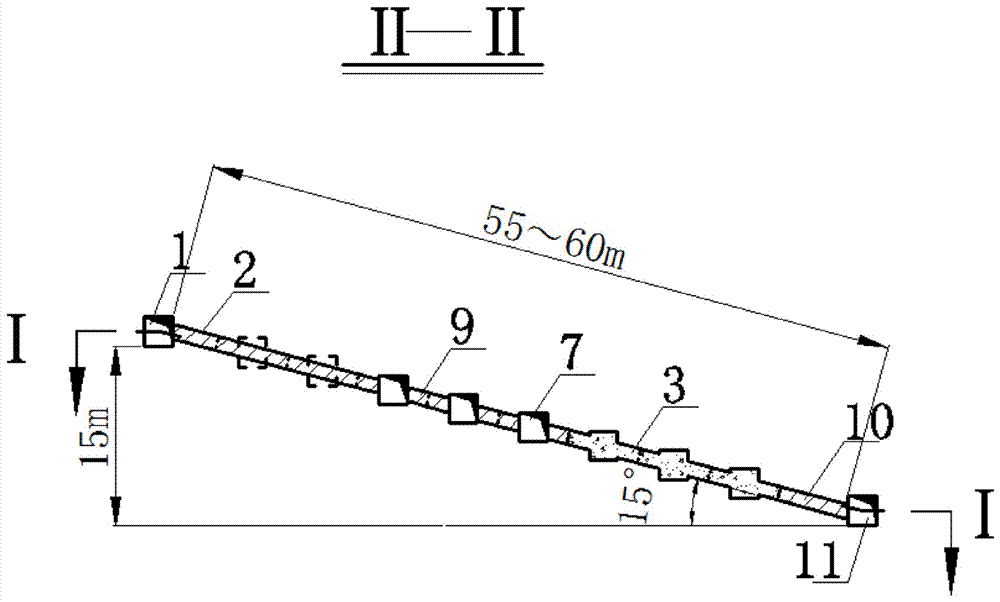

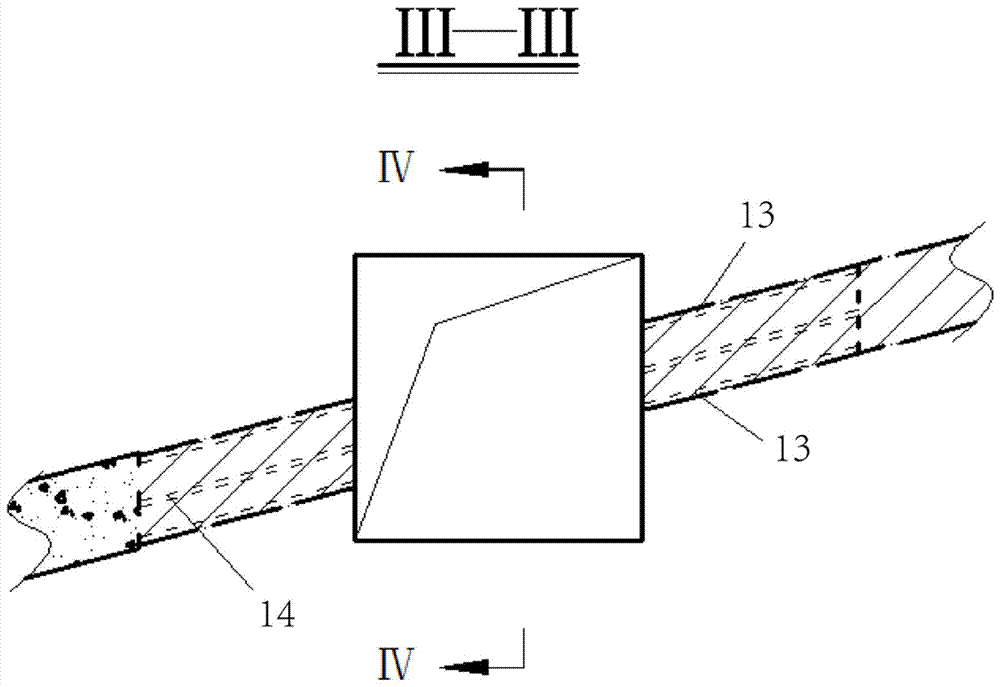

Full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike

InactiveCN106968708ASettlement controlReduce distortionUnderground miningSurface miningLithologyMining engineering

The invention discloses a full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike. According to the principle, the method includes the steps that after a steeply inclined coal seam field is divided into mining areas, a long-wall fully mechanized coal mining face is arranged along the coal seam strike, and after advancing in the coal mining face, a goaf is subjected to sublevel filling along the coal seam strike. According to the rock mechanics principle and the lithology of overlying rock of the coal mining face, the dimensions D and strength of sublevel filling bodies and the limited span L of sublevel filling are determined under the condition that the upper roof of the overlying rock is not broken. A filling-body filling area is divided into inclined sealing filling areas by sublevel small coal pillars and rectangular air bags, and paste filling is conducted in the sealing areas through pipelines. By means of the method, the filling amount can be reduced, the filling cost is lowered, the resource recovery rate is increased, and the safe, environmental-friendly and economical coal mining effects are achieved.

Owner:HUNAN UNIV OF SCI & TECH

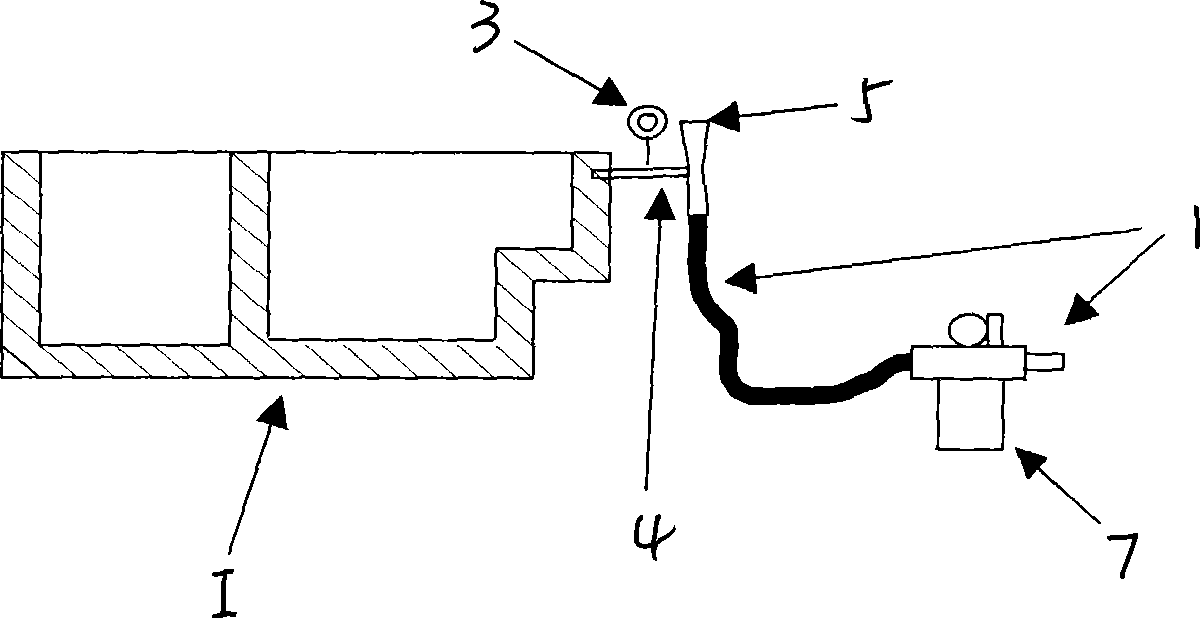

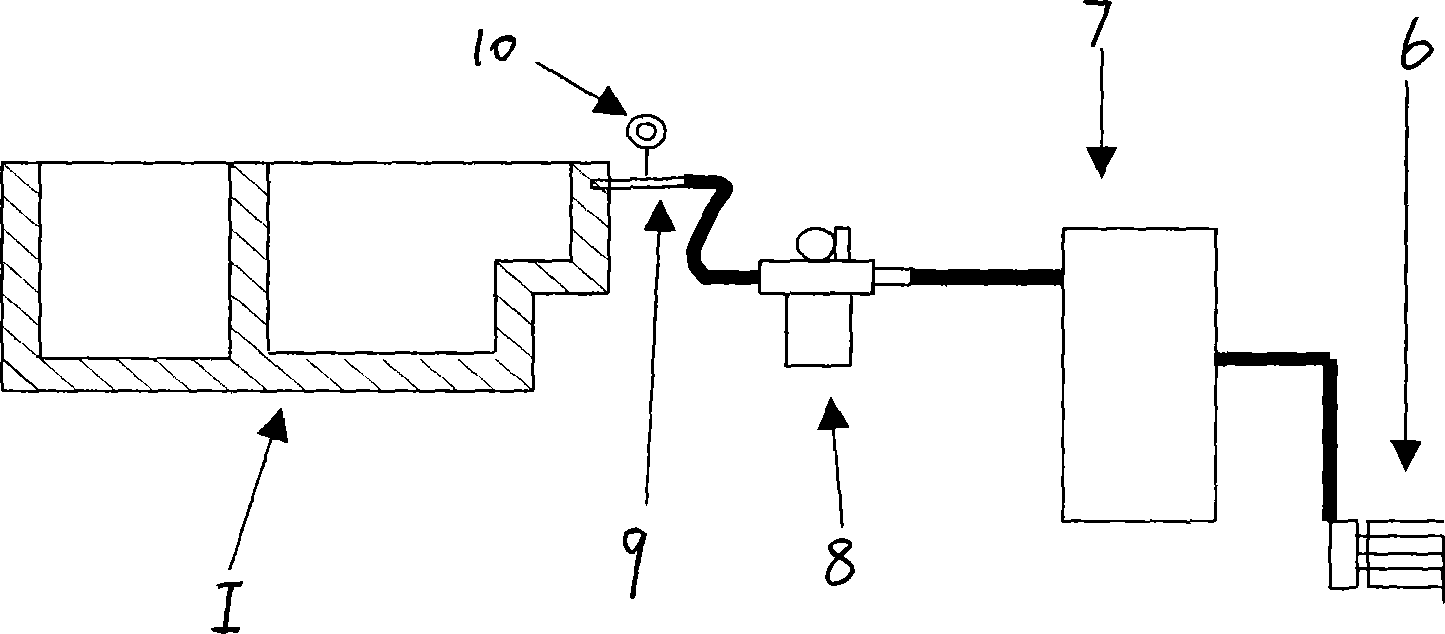

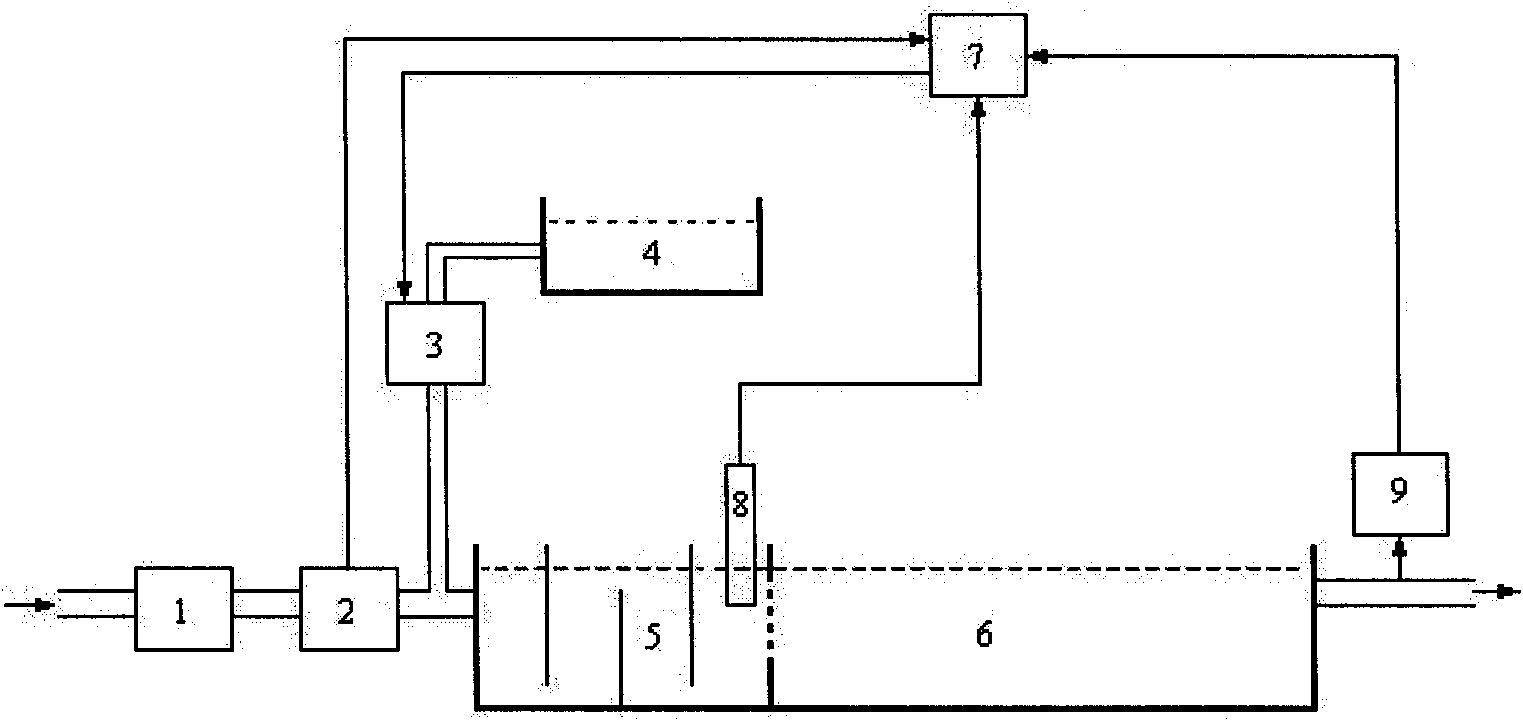

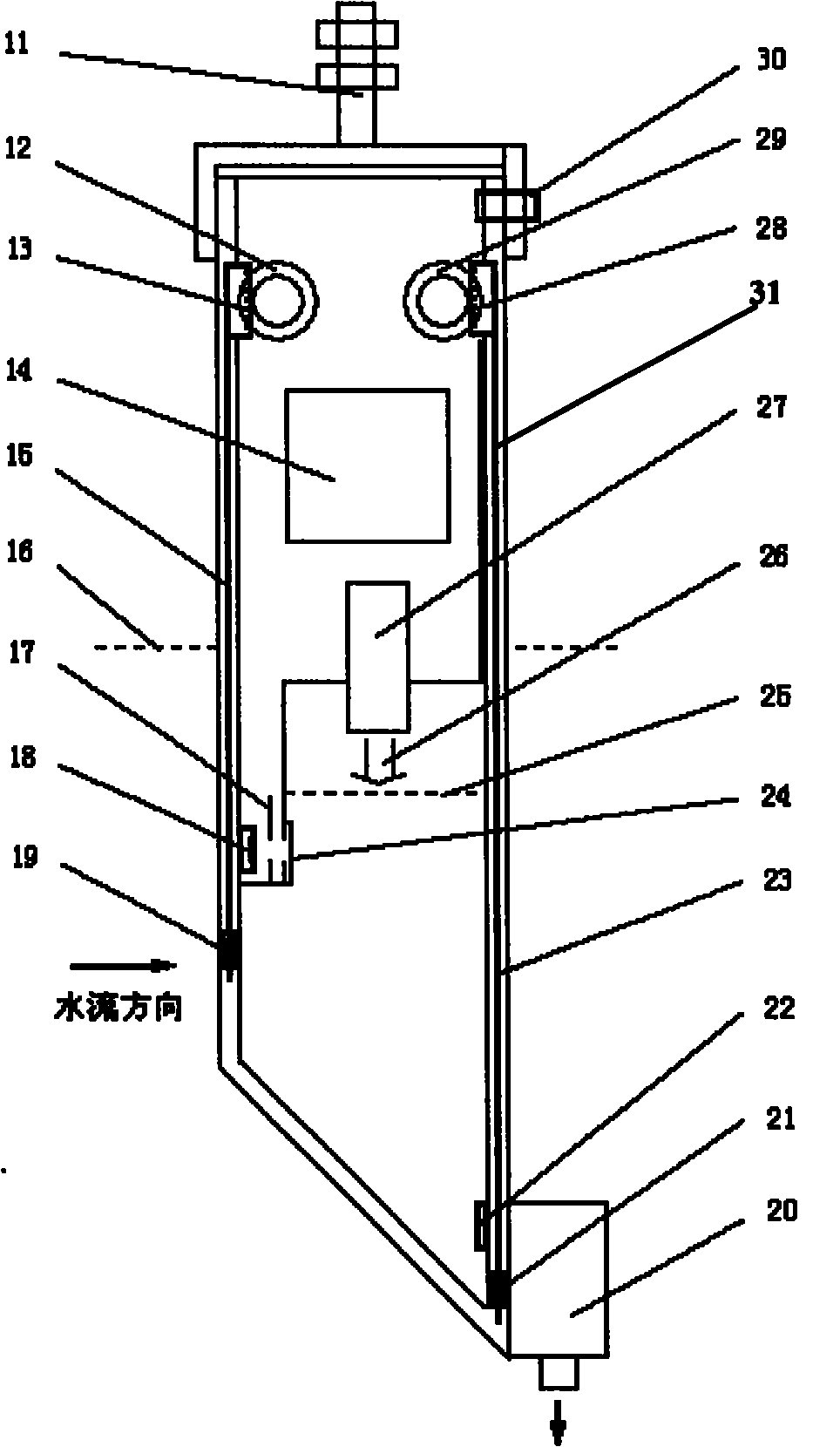

Method and system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation

InactiveCN101805050AReduce purification costsReduce fill volumeWater/sewage treatment by flocculation/precipitationFlocculationTurbidity

The invention relates to a method and a system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation. The method comprises the following steps of: making raw water enter a flocculation tank to mix, react and flocculate with the added coagulant so as to generate a flocculating substance; collecting the flocculation water in real time through a sensor for measuring the turbidity under the water at the tail end of the flocculation tank; sedimenting in the sensor in the given sedimentation time, and measuring the turbidity; comparing the measured value with the set value; and after the difference is subjected to PID operation, obtaining the needed dosing ratio, and multiplying the dosing ratio with the water inlet flow to obtain the dosing, converting the dosing into a standard current output signal to control the dosing of a dosing pump, and dosing the coagulant on line. The system consists of the flocculation tank, a sedimentation tank, the dosing pump, a coagulation tank, a microprocessor and a sensor 5 which is specially designed for measuring the turbidity. Due to adoption of the sensor for measuring the turbidity, the turbidity after flocculation water sedimentation can be accurately measured on line without being disturbed by other factors. Therefore, the on-line coagulant dosing can be accurately controlled, the coagulant dosing is reduced, the water purification quality is improved, and the water purification cost is lowered.

Owner:SHANGHAI UNIV

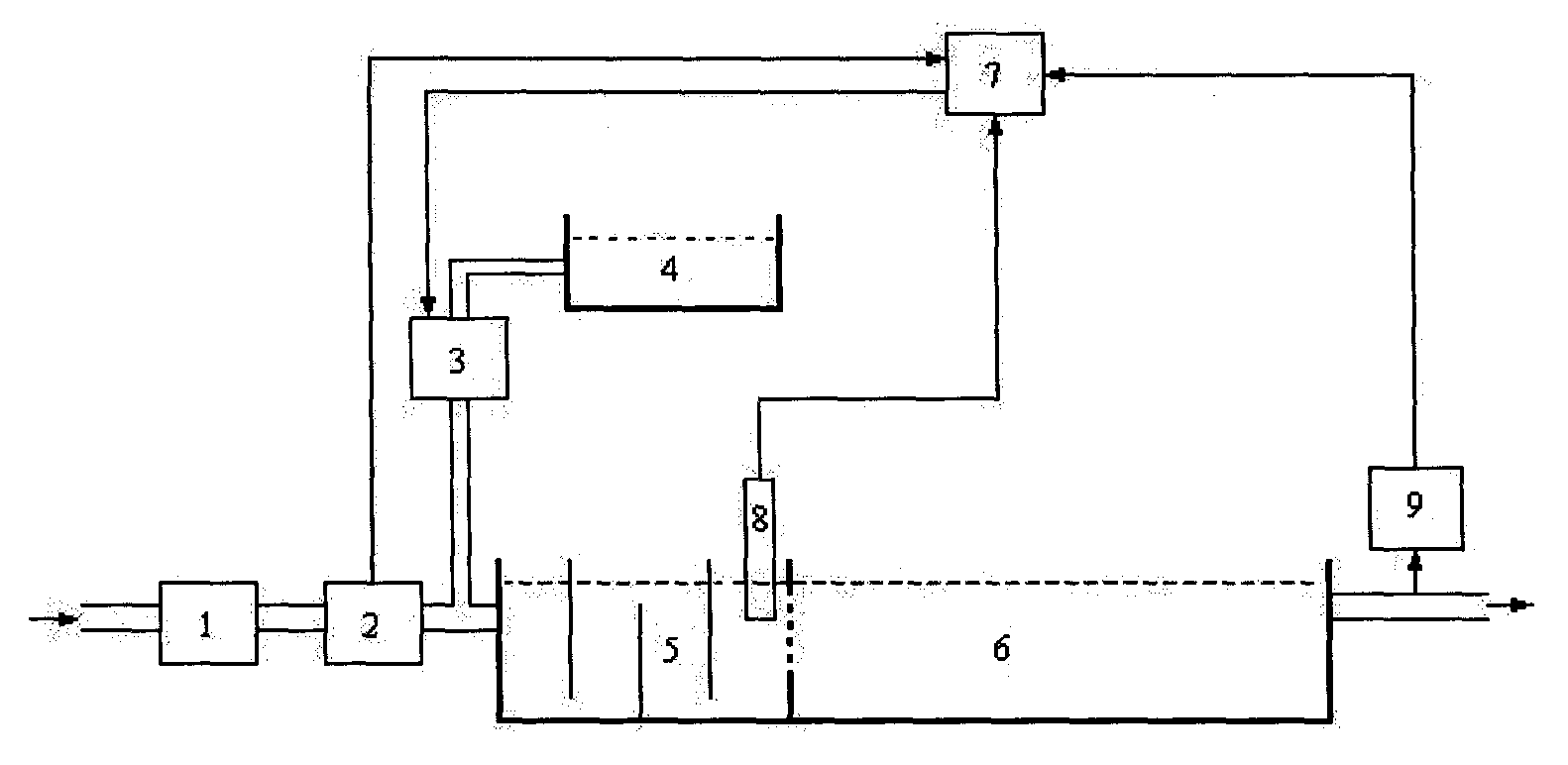

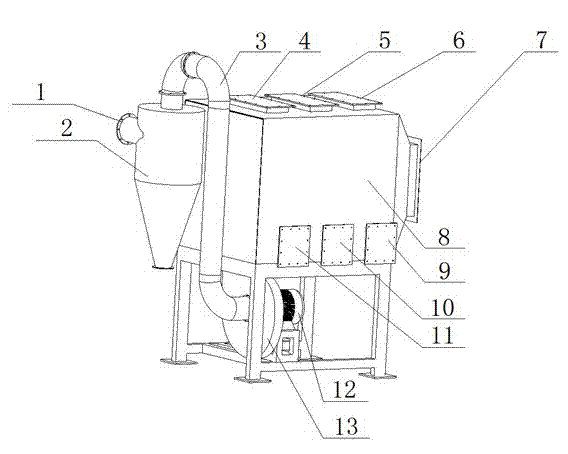

Method and equipment for treating volatile organic compounds by low-temperature plasma coupling adsorption

InactiveCN105833677AReduce fill volumeExtended regeneration cycleAuxillary pretreatmentBenzenePlasmonic coupling

The invention provides equipment and a method for treating volatile organic compounds by low-temperature plasma coupling adsorption, wherein a low-temperature plasma process and an adsorbing process are adopted, and volatile organic waste gas and odor gas are firstly treated by a low-temperature plasma device, and then enter an adsorbing device to be treated. When a low-temperature plasma coupling adsorption method is applied to treat organic waste gas and odor waste gas with non-methane hydrocarbon lower than 6000 ppm and sulfuretted hydrogen lower than 100 ppm, benzene in exhaust is lower than 4mg / m<3> and various odorous substances completely reach the standards in comparison with a mode of purely using an adsorbing method or purely using low-temperature plasmas; and the filling amount of an ozone disintegrant can be reduced by more than 50% and the regeneration period is prolonged by one time and more in comparison with a mode of independently using low-temperature plasmas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oblique throwing blasting mining method for gently-inclined thin ore body

InactiveCN107165635AReduce depletion rateReduce mining costsUnderground miningBlastingUnit structureMineralogy

The invention provides an oblique throwing blasting mining method for a gently-inclined thin ore body. The oblique throwing blasting mining method for the gently-inclined thin ore body comprises the following steps that structure parameters of an ore block stoping unit are determined, a stope is arranged in the direction of the ore body, two mining preparation upward-inclining roadways communicating the upper, middle and lower sections are arranged in the stope, and the upward-inclining roadways are arranged in spacer pillars; cutting roadways are sequentially constructed between the two upward-inclining roadways from a bottom pillar to a top pillar of the stope; the oblique distance between the center line of the first cutting roadway and the bottom pillar is 2.5 m, and the oblique distances between the center lines of the subsequent cutting roadways and the bottom pillar are 5 m; stoping starts from the first cutting roadway, backward stoping is adopted, and two controlled blasting methods including oblique pre-splitting blasting and throwing blasting are adopted in order to reduce dilution and loss; after stoping of the first cutting roadway is completed, wooden walls are erected on two sides of the spacer pillars and cementing filling is conducted; after a filling curing period is finished, the second cutting roadway is stoped upwards, and the same stoping process is adopted; and stoping is sequentially recycled until stoping of a mining room is finished. The oblique throwing blasting mining method for the gently-inclined thin ore body is safe, efficient and low in loss, and the loss of mineral resources is reduced.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

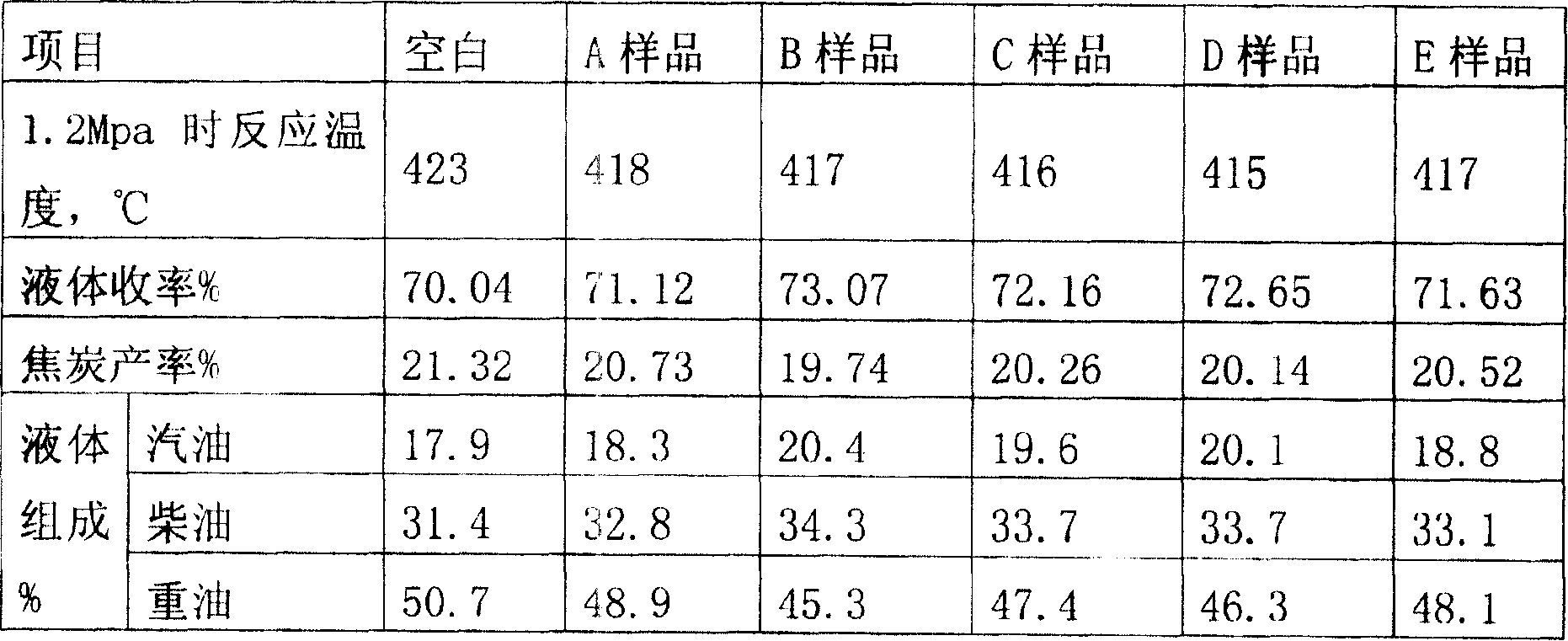

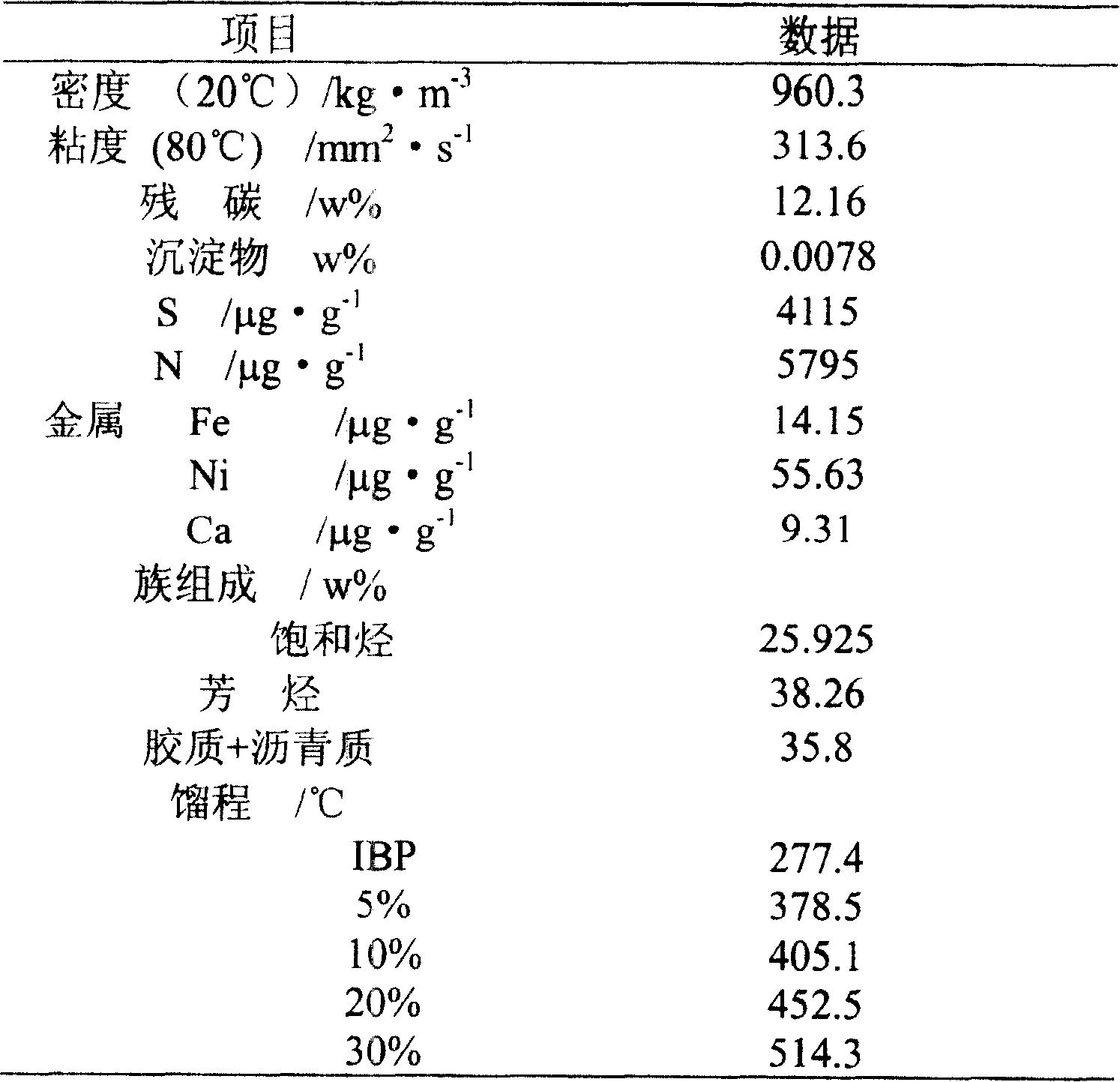

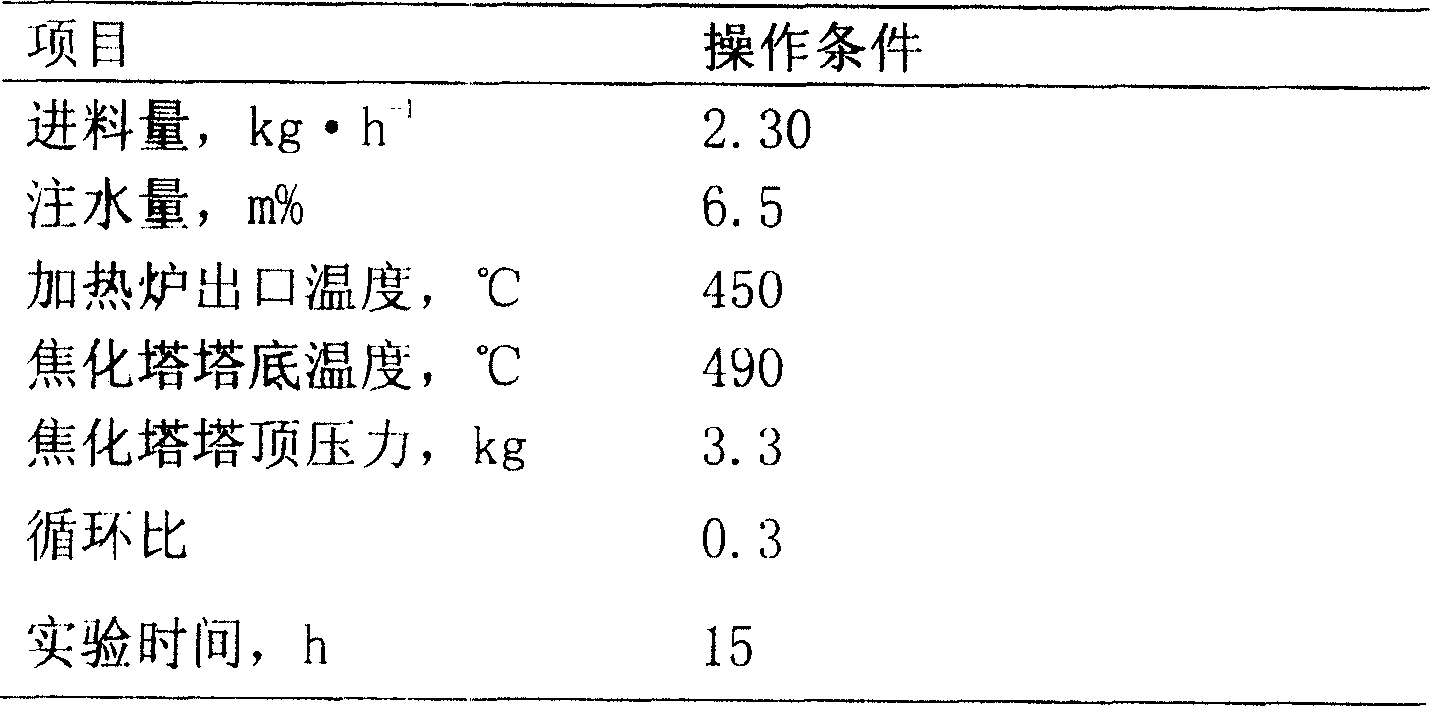

Auxiliary agent capable of improving delayed coking liquid yield, preparation method and application thereof

InactiveCN100387686CHigh yieldRaw materials are easy to getThermal non-catalytic crackingNitrateSolvent

The present invention discloses one kind of assistant for raising the yield of delayed coking liquid and its preparation process and application. The assistant consists of alkyl nitrate 20-40 wt%, fatty alcohol 10-30 wt%, dimethyl polysiloxane 10-20 wt% and solvent for the rest. The present invention can raise the yield of delayed coking liquid and reduce the yield of coke obviously.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

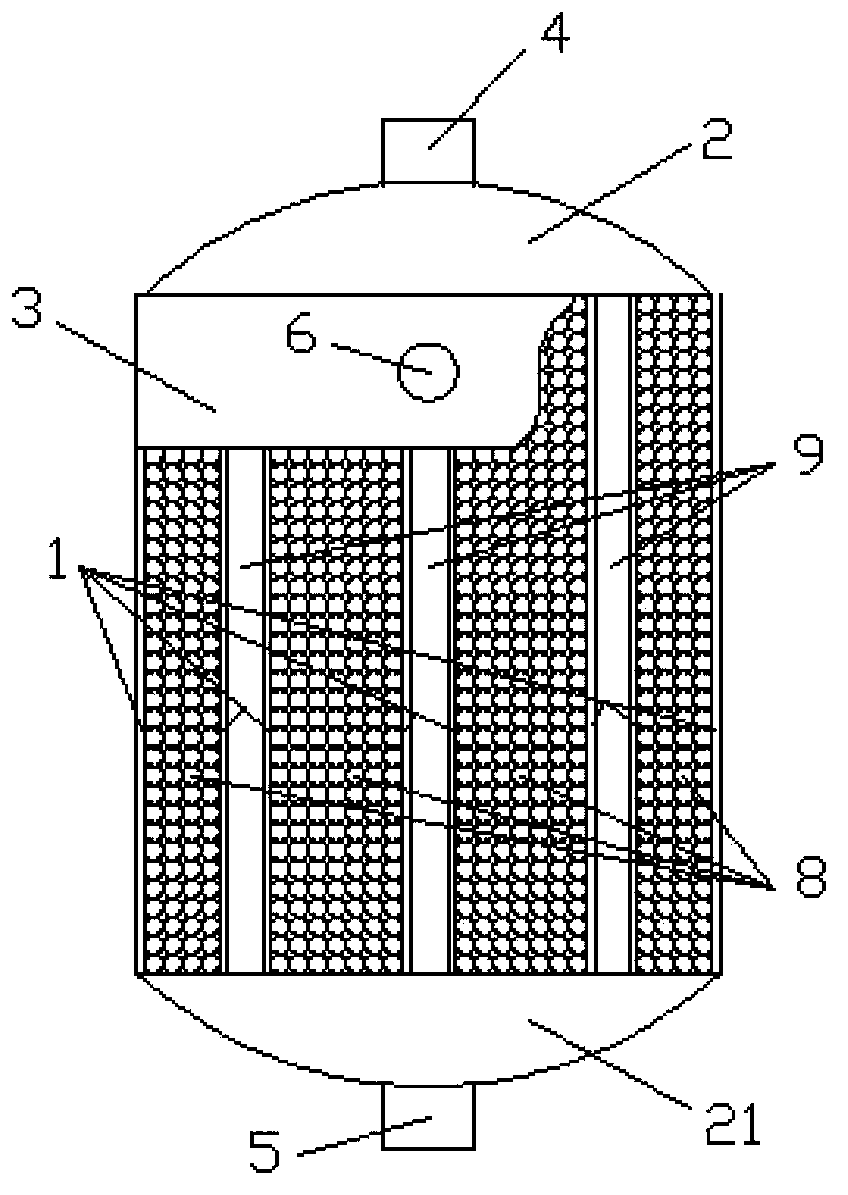

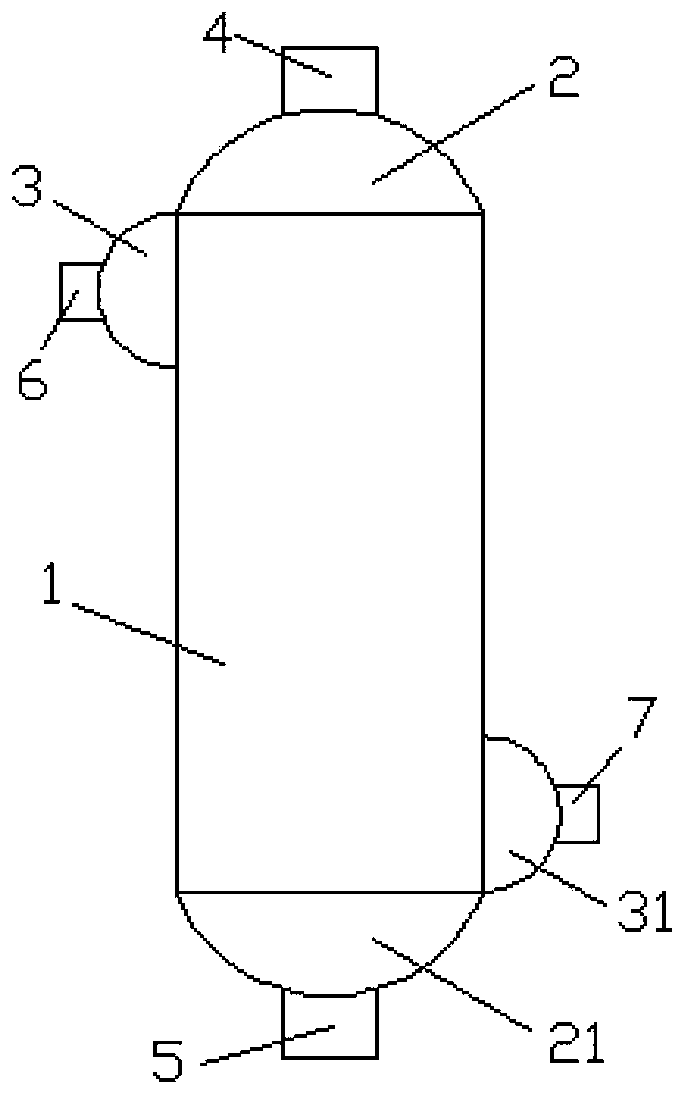

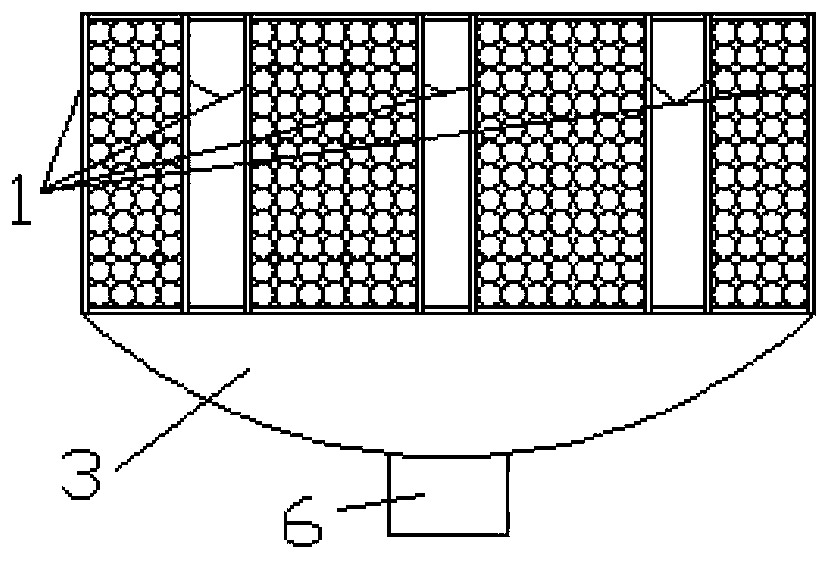

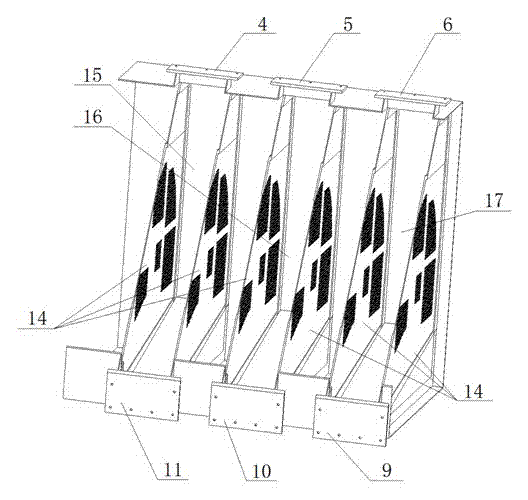

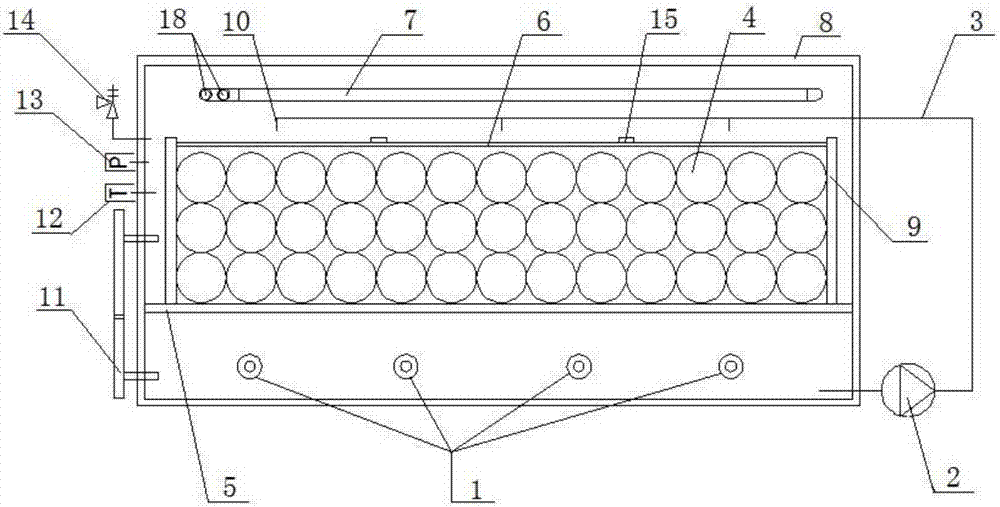

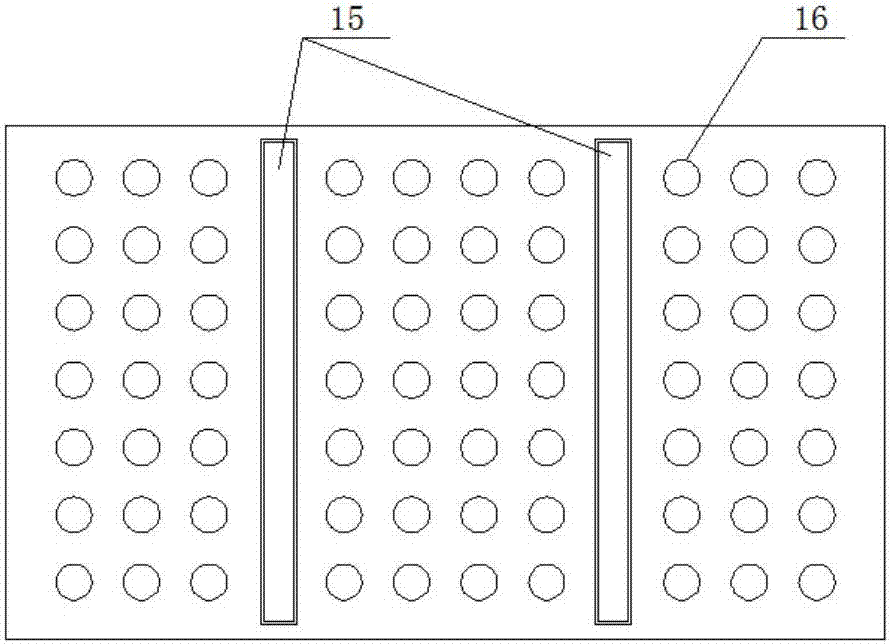

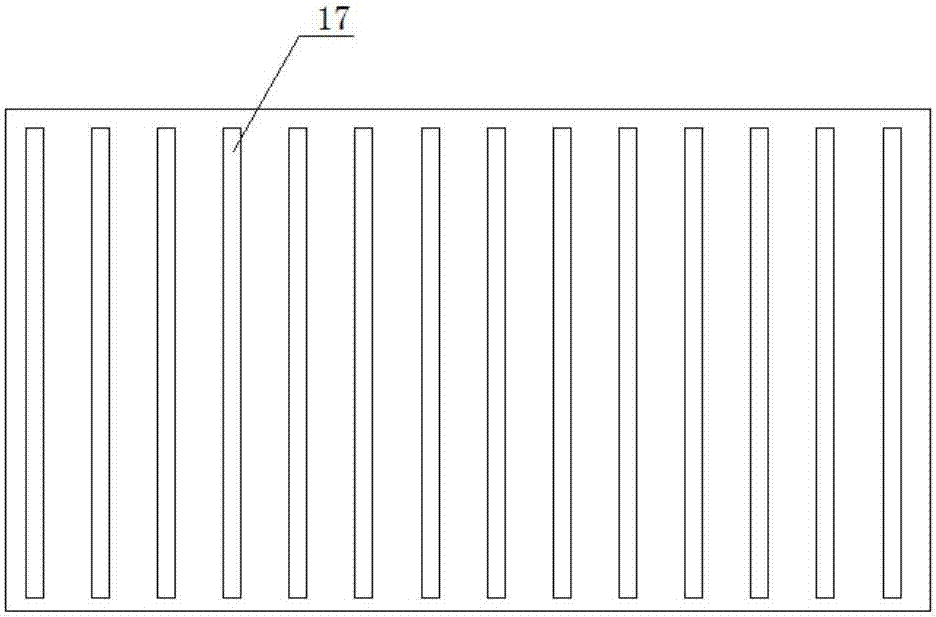

Molecular sieve adsorption tower provided with heat transferring medium channels

InactiveCN103463926AReduce fill volumeReduce wasteDispersed particle separationMolecular sieveSorbent

The invention discloses a molecular sieve adsorption tower provided with heat transferring medium channels. The molecular sieve adsorption tower comprises vertical separator plates arranged in a adsorption tower container; space flow channels are formed by adjacent vertical separator plates, and a plurality of the space flow channels distributed at intervals are filled with a molecular absorbent, and are called as process gas channels; the rest space flow channels are taken as the heat transferring medium channels; the upper end and the lower end of the adsorption tower are provided with an upper process gas shell cover and a lower process gas shell cover respectively; the ends of the upper process gas shell cover and the lower process gas shell cover are provided with a process gas inlet and a process gas outlet respectively; two opposite side walls of the container are provided with an upper heat transferring medium shell cover and a lower heat transferring medium shell cover respectively; the ends of the upper heat transferring medium shell cover and the lower heat transferring medium shell cover are provided with a heat transferring medium inlet and a heat transferring medium outlet respectively; the process gas inlet and the process gas outlet are communicated with the process gas channels via the process gas shell covers respectively; and the heat transferring medium inlet and the heat transferring medium outlet are communicated with the heat transferring medium channels via the heat transferring medium shell covers respectively. The molecular sieve adsorption tower is provided with the heat transferring medium channels, so that the molecular sieve can be heated or cooled by the heat transferring medium, molecular sieve regeneration time and adsorption cycle period are shortened, and regeneration gas consumption is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

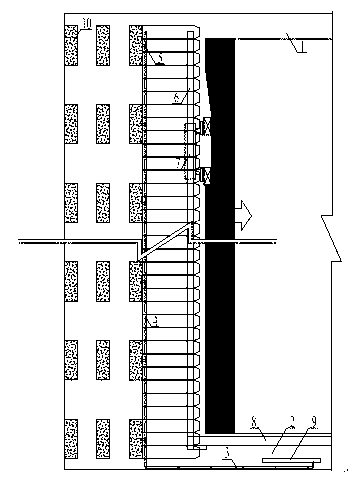

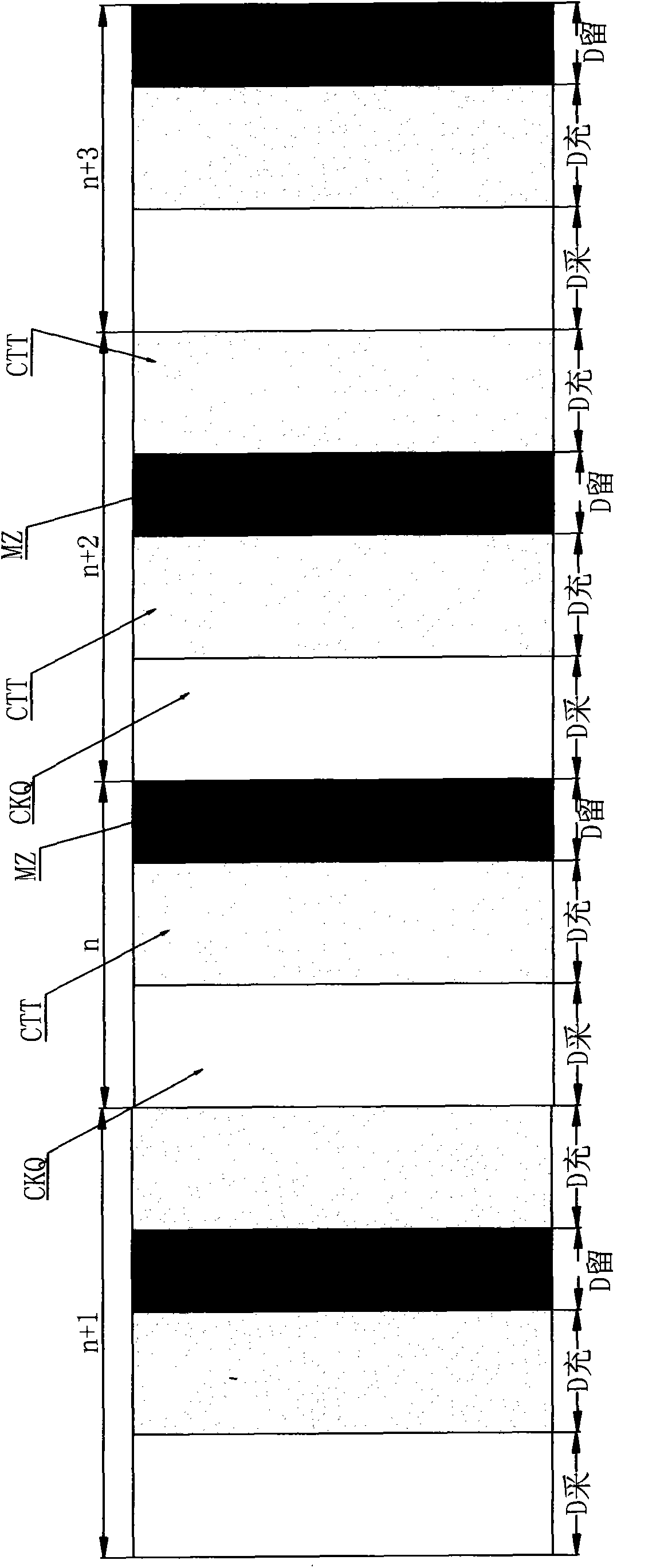

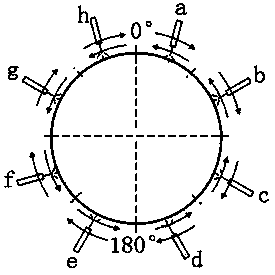

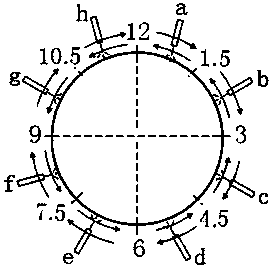

Pipeline multipoint synchronous automatic welding process

ActiveCN104209635AReduced fill volumeImprove welding efficiencyArc welding apparatusMetal working apparatusStress concentrationEngineering

The invention discloses a pipeline multipoint synchronous automatic welding process used for root welding conducted through an inner welding machine. The process is designed for increasing the welding speed. According to the welding process, the eight-welding-torch pipeline synchronous automatic welding inner welding machine is adopted, a first welding gun, a second welding gun, a third welding gun and a fourth welding gun are used for segmented independent welding on the side ranging from 0 degree to 80 degrees of a pipeline, the fifth welding gun, the sixth welding gun, the seventh welding gun and the eighth welding gun are used for segmented independent welding on the side ranging from 180 degrees to 0 degree of the pipeline, and the welding directions, on the two sides of the pipeline, of the welding machine are opposite. The process includes the steps that a specially-designed U-shaped groove is formed in the end of the large-caliber oil and gas pipeline; the inner welding machine is aligned with the pipeline; welding parameters of the inner welding machine are adjusted; root welding of the groove is conducted through the inner welding machine; thermal welding, filling welding and cosmetic welding of a weld joint are conducted; after the whole annular joint is welded completely, an arc is quenched. In the welding process, the U-shaped groove of the weld joint is small, the volume needing to be filled is small, the welding speed can be increased three to four times, and construction efficiency is improved to a great extent. Welding stress can be evenly distributed through segmented multipoint synchronous welding, potential safety hazards caused by stress concentration are eliminated, and the welding pass percent is kept over 97%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

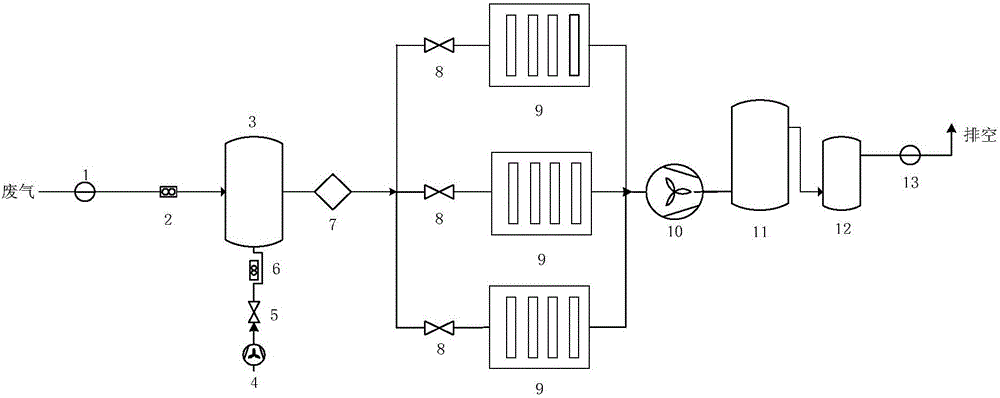

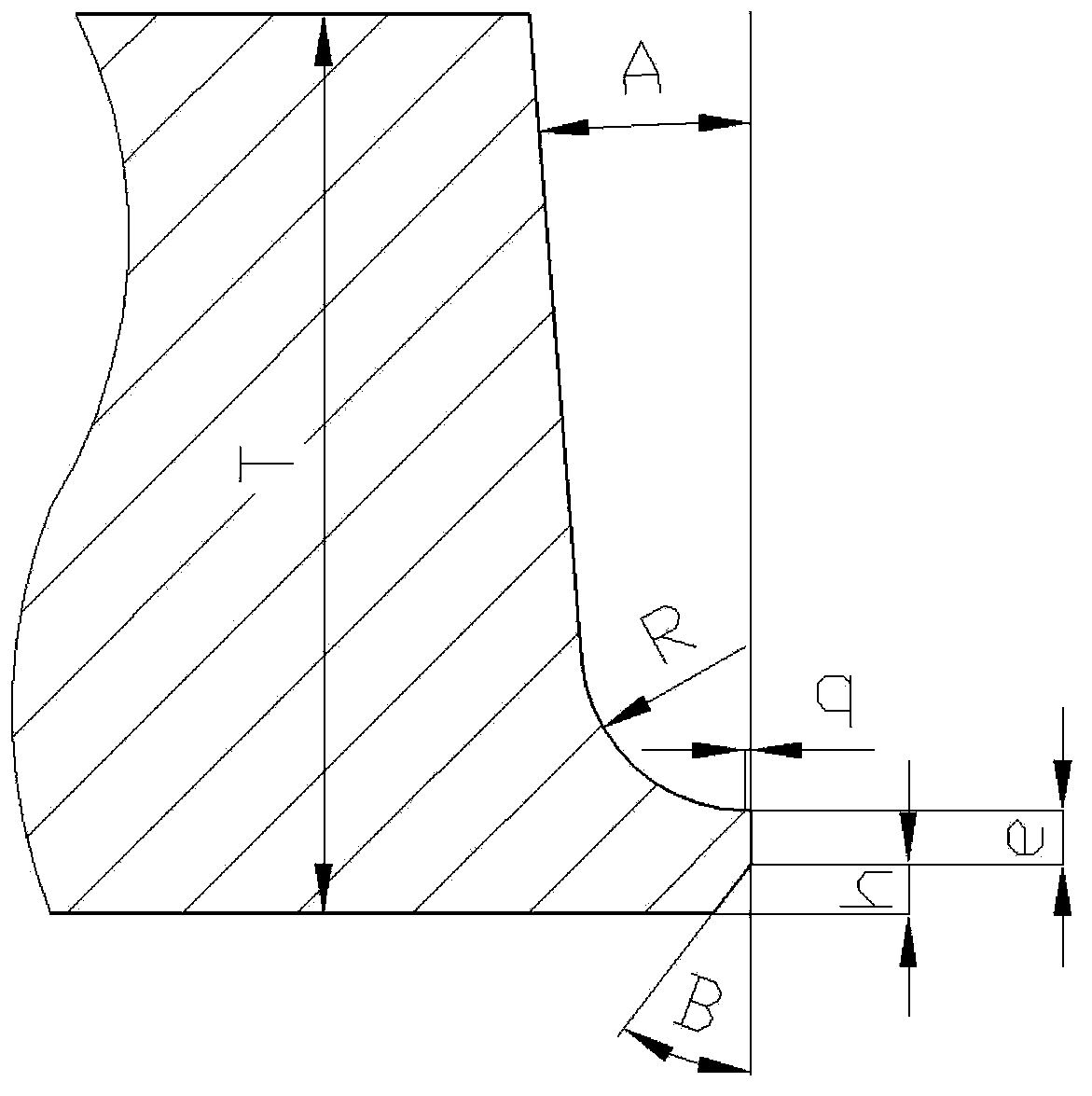

Integral process for desulfurizing, denitrating and purifying coke oven smoke by dry-method

ActiveCN109482049ASolve processing problemsReduce processing costsGas treatmentDispersed particle separationCoke ovenImpurity

The invention provides an integral process for desulfurizing, denitrating and purifying coke oven smoke by a dry-method. Coke oven smoke enters a dechlorination reactor to remove chlorine, fluorine and partial fume in the raw material, enters desulfurization and denitration reactor to further remove impurities in the raw material, wherein the Sox is less than 10mg / m<3> and NOX content is less than50mg / m<3> after purification. The process can simultaneously remove sulfide, nitride, fluorine, chlorine, dioxin and the like, and has the characteristics of wide impurity removing range, high removing accuracy, simple process, small pressure and temperature drop, small investment and low operation cost.

Owner:WUHAN KELIN FINE CHEM

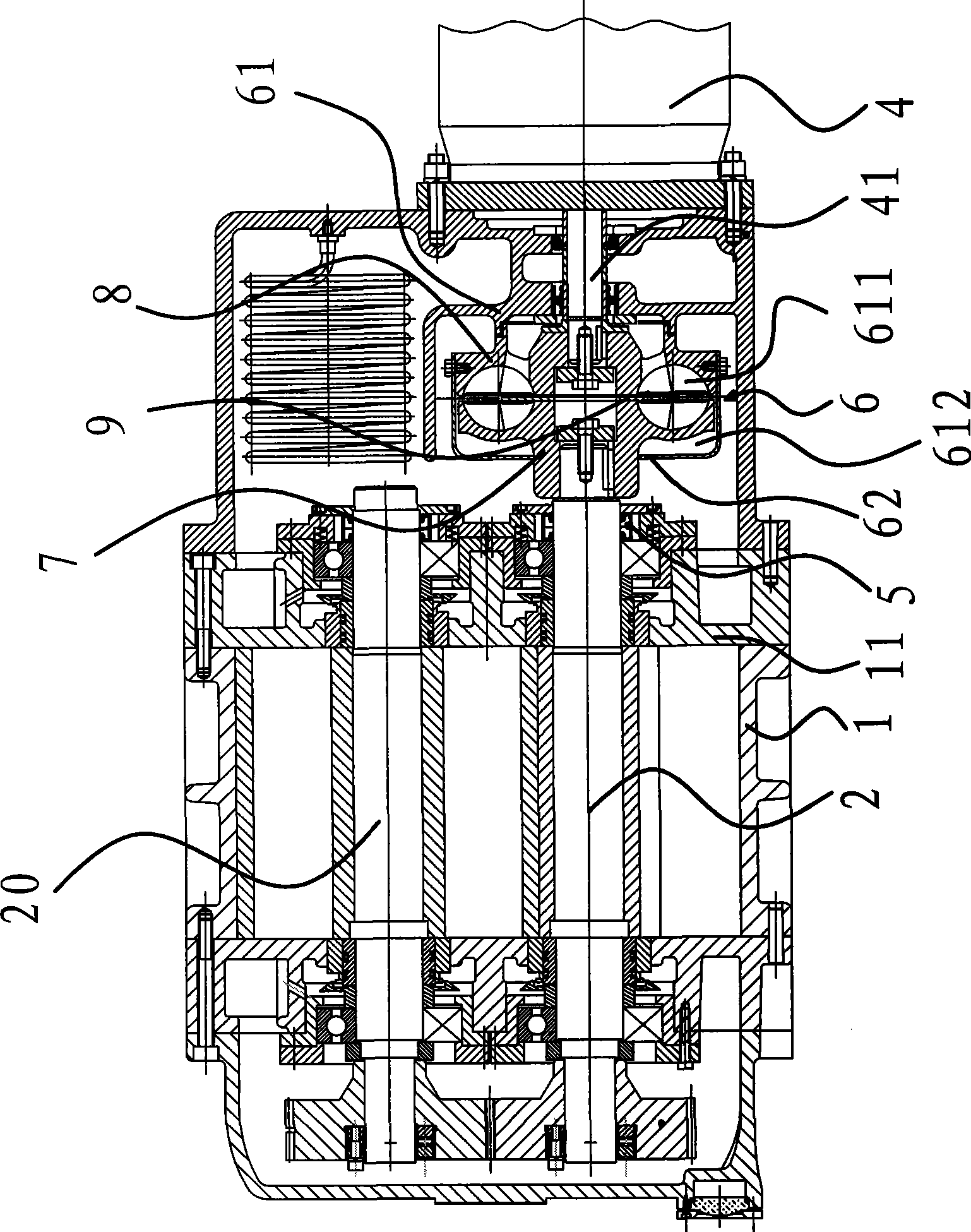

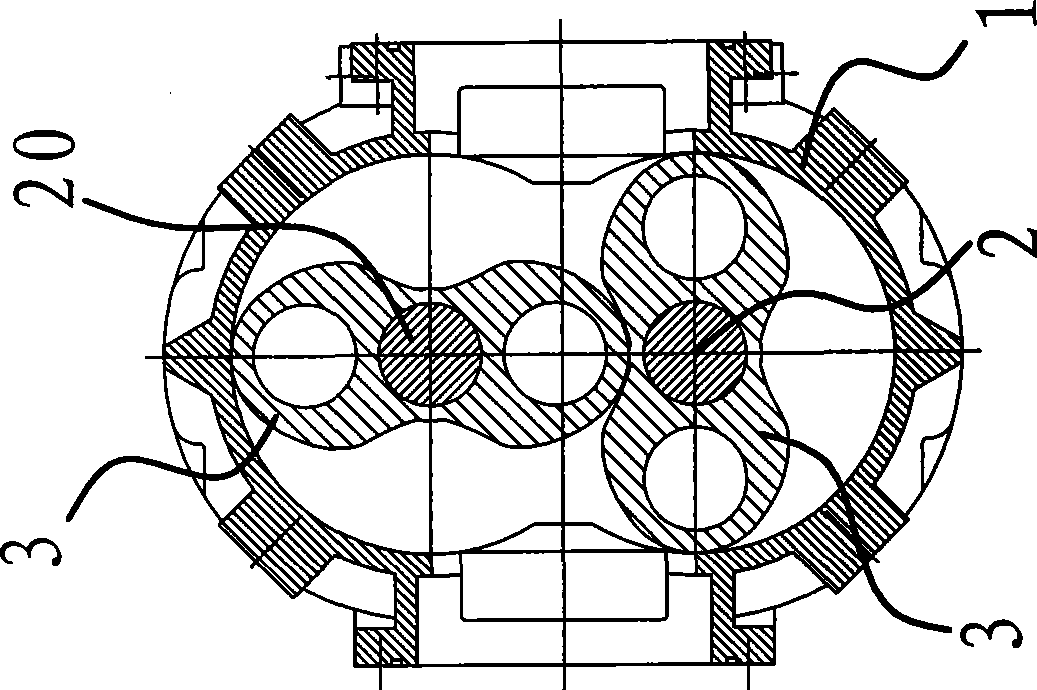

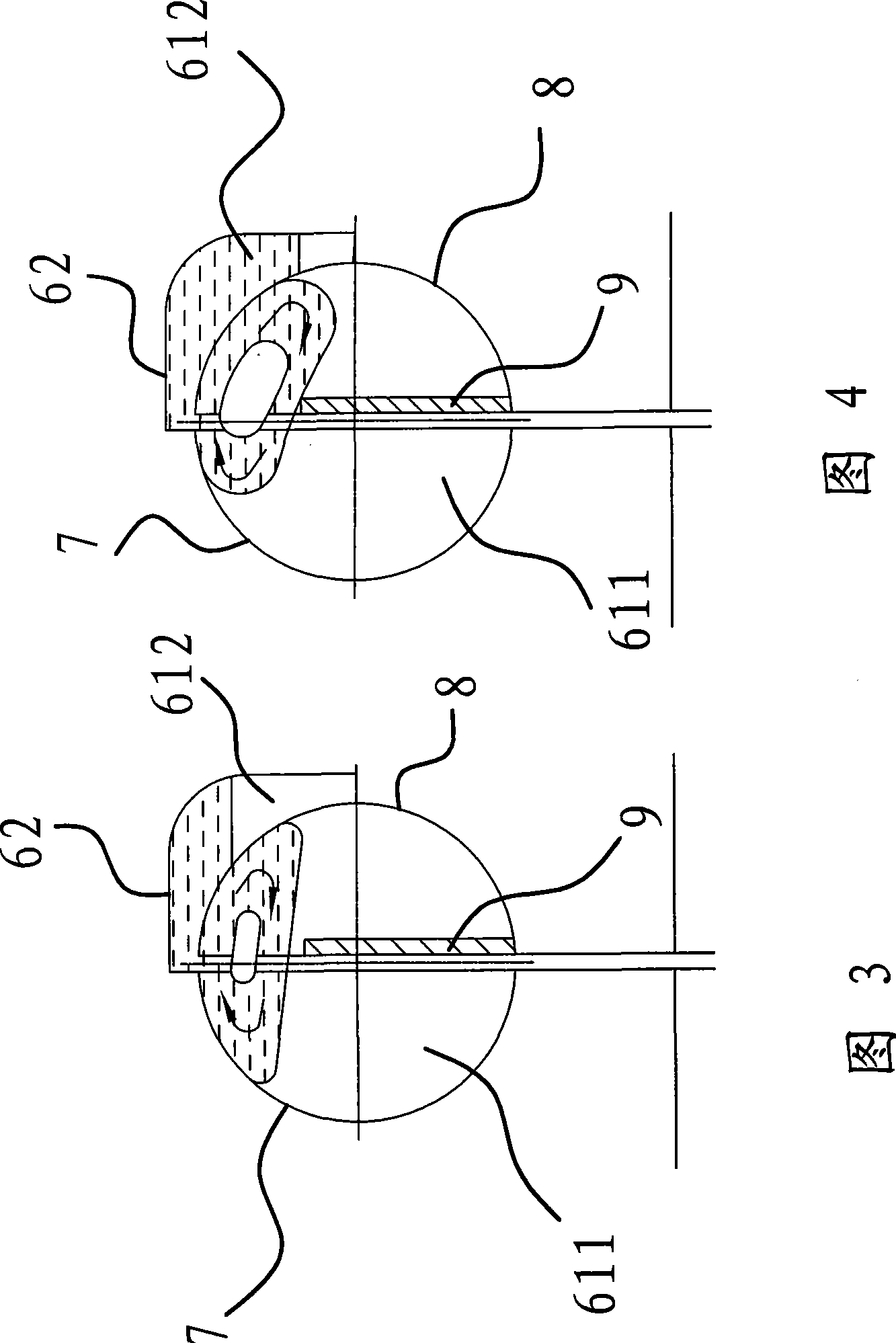

Roots vacuum pump

InactiveCN101463816ALow ultimate pressureReduce pumping timeRotary piston pumpsRotary piston liquid enginesPower gridEngineering

The invention provides a Roots vacuum pump, which belongs to the technical field of machinery and solves the technical problems of hard load start, high starting current, high impact on an electricity grid, high bearing impact, and the like of the existing Roots vacuum pump. The Roots vacuum pump comprises a pump body and a long pump shaft and a short pump shaft arranged in the pump body, wherein, rotors are respectively connected on the long pump shaft and the short pump shaft, the long pump shaft and the short pump shaft are connected with each other by a pair of engaged driver gears, one end of the long pump shaft extends out of the pump body on which an electric motor is arranged, and a rotating shaft of the electric motor and the pump shafts are connected by hydraulic driving mechanisms. The Roots vacuum pump has the advantages of favorable overload protection, low starting current, easy load start, short air suction time, etc.

Owner:ZHEJIANG VACUUM EQUIP GROUP

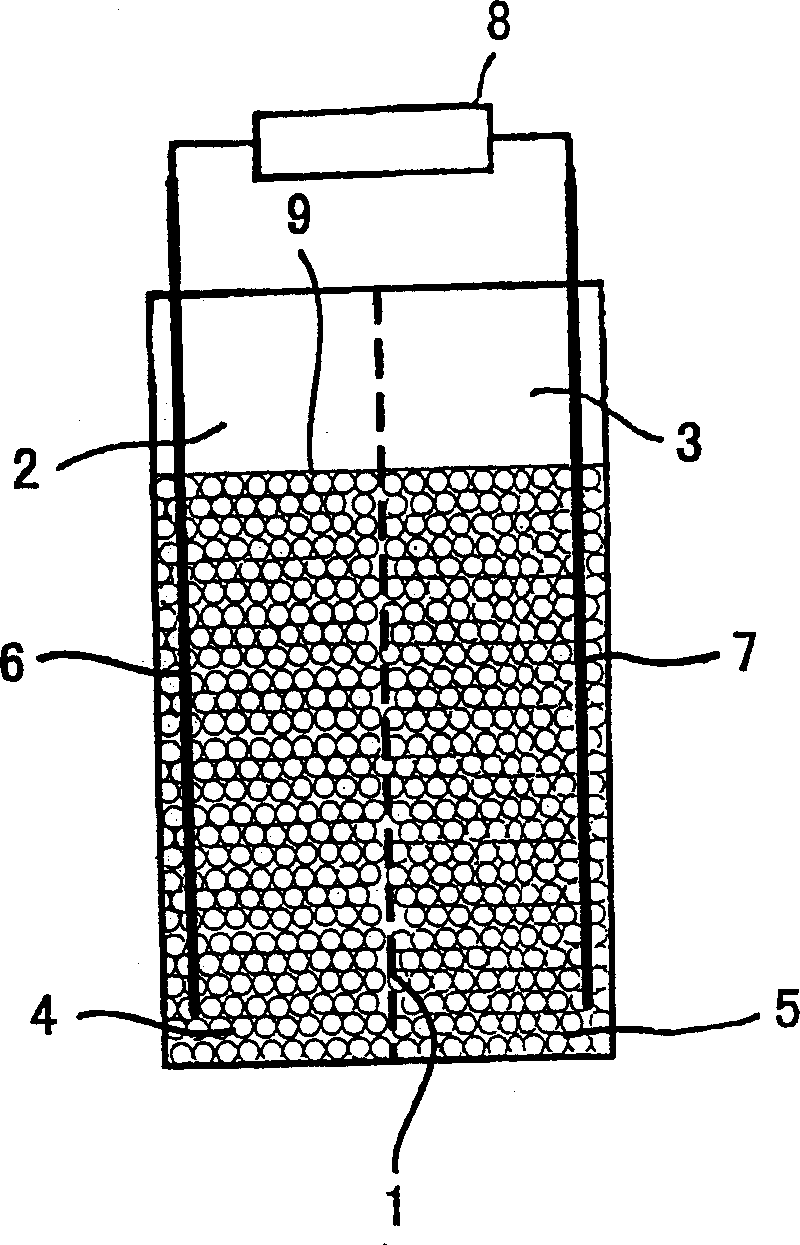

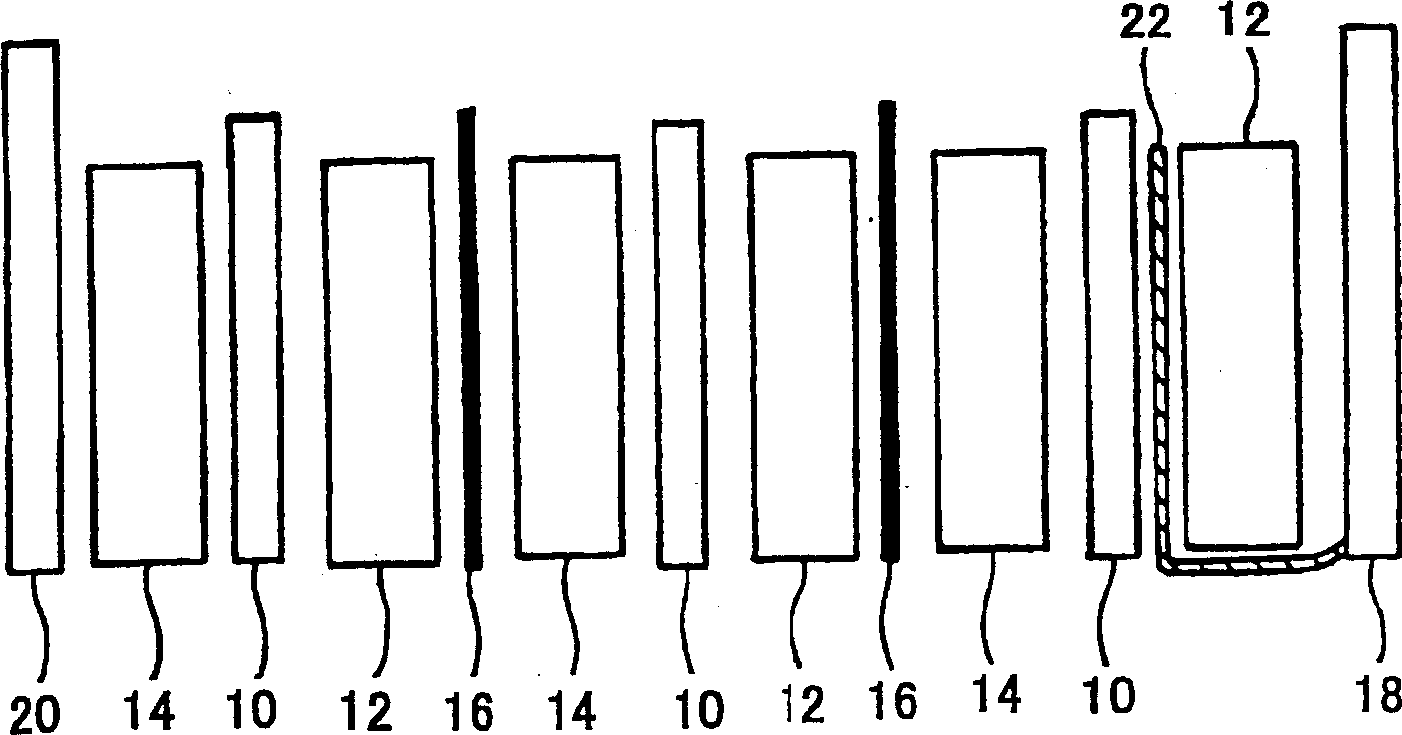

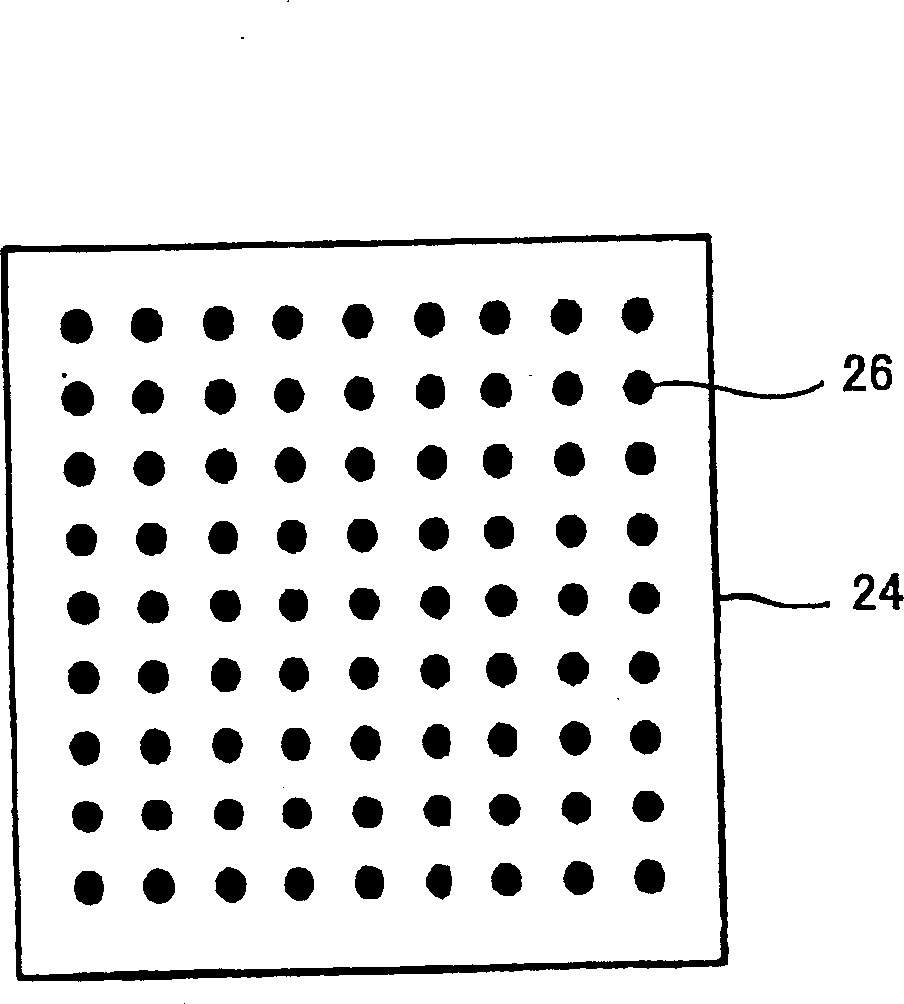

High performance type three-dimensional cell

InactiveCN1893161AReduce the numberAvoid time costCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesManufacturing cost reductionEngineering

When producing an electrode for use in a three-dimensional battery, an active material is combined with at least one of a separator, a dividing wall, and a current collector for simultaneous formation. Both the dividing wall and the current collector are planar or are so formed as to have projected portions in needle, plate, wave, particle, or the like form. Both the dividing wall and the current collector may be provided with a cooling structure. As an additional current collector, an ion permeable current collector, which has voids therein, permits passage of ions, and exhibits electrical conductive properties, is provided.

Owner:KAWASAKI HEAVY IND LTD +1

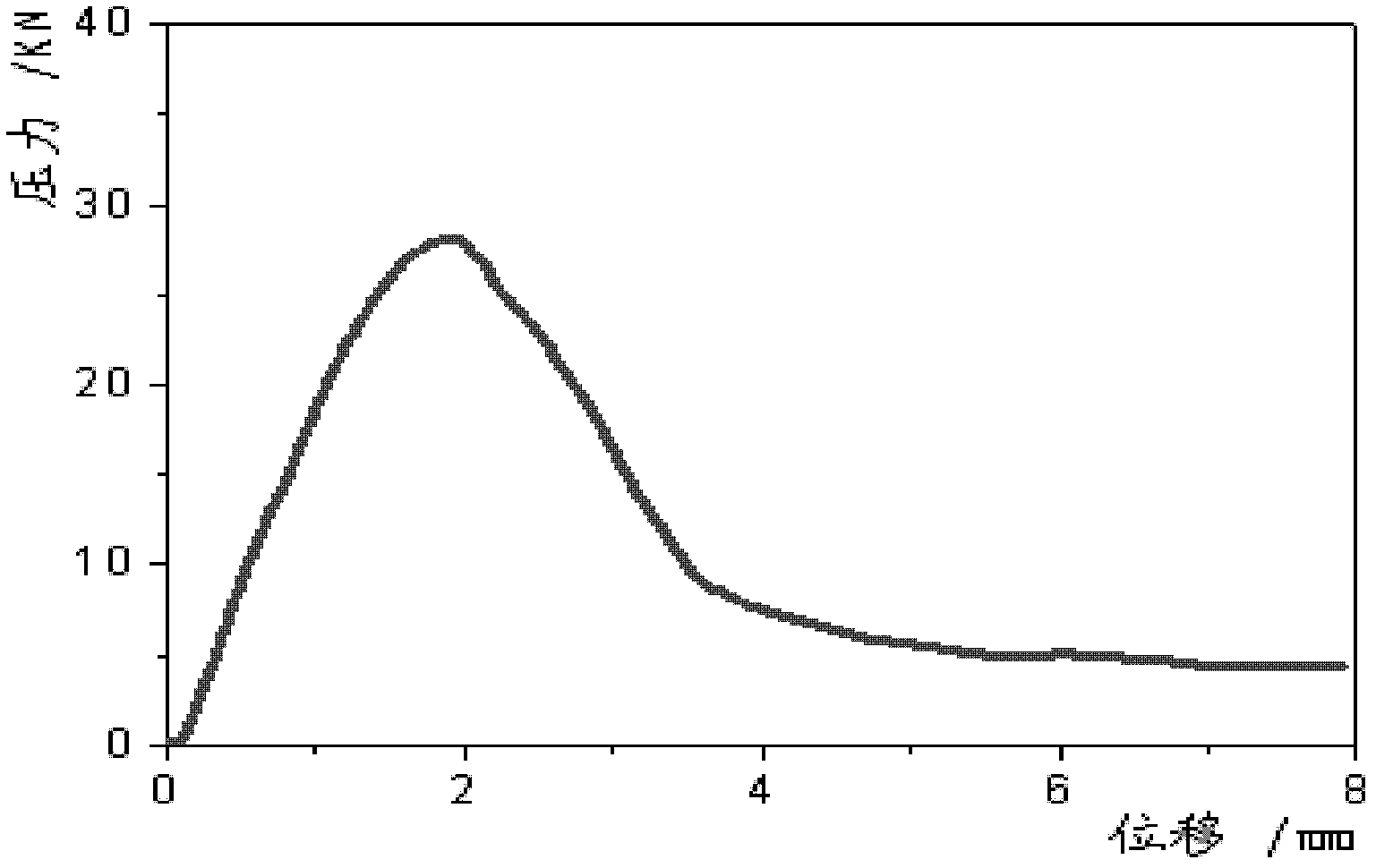

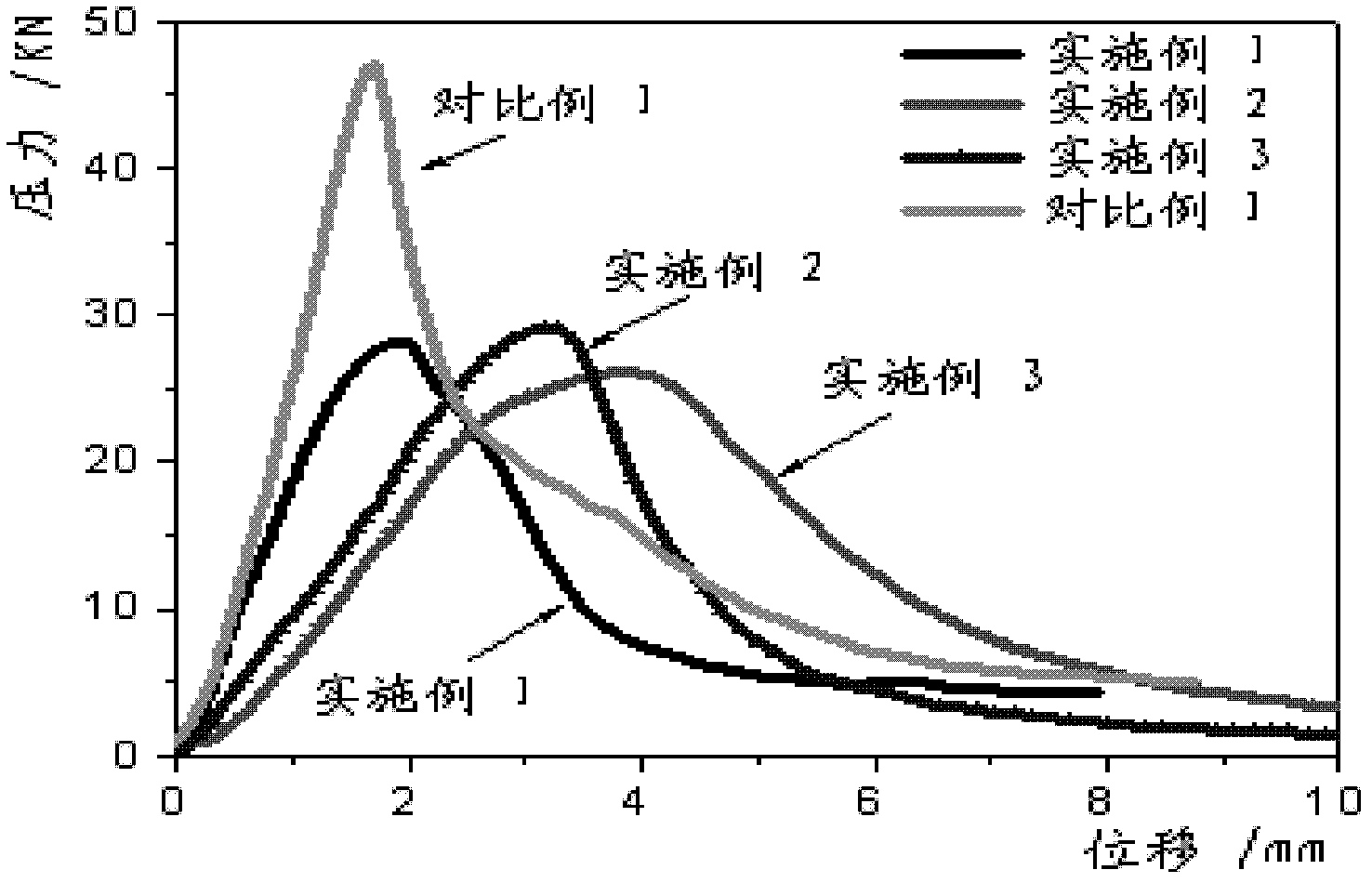

Cement-based waterproof and crack-resistant material suitable for foundation bed of railroad bed in expansive rock area

InactiveCN102503311AImprove elastic deformation abilityImprove waterproof performanceMaterials scienceSubgrade

The invention discloses a cement-based waterproof and crack-resistant material which is suitable for a foundation bed of a railroad bed in an expansive rock area. The cement-based waterproof and crack-resistant material consists of a gelling material component, a modified component and a sand system, wherein a mass ratio of the gelling material component to the modified component to the sand system is 1:(0.38-0.42):(5.0-5.5). The cement-based waterproof and crack-resistant material has high waterproof performance and elastic deformation performance and is suitable for the foundation bed of the railroad bed in the expansive rock area.

Owner:CENT SOUTH UNIV

Method for removing heteroatom from coal tar

ActiveCN107739627AReduced stabilityImprove removal effectTar working-up by chemical refiningHeteroatomAsphalt

The invention relates to a method for removing heteroatom from coal tar. The method comprises the following steps: fully mixing coal tar with a multifunctional complexing agent A at a certain temperature, and reacting the mixture; injecting a multifunctional complexing agent B into the mixture to perform oil and water separation, wherein the multifunctional complexing agent A is prepared from 70 to 100mug / g of acid ionic denitrfying agent, 50 to 80mug / g of metal removing agent, 50 to 70mug / g of demulsifying agent, 20 to 40mug / g of synergist and 3 to 10 percent by weight of water; the multifunctional complexing agent B is prepared from 60 to 80mumg / g of asphalt fluctuating agent, 10 to 30mug / g of accelerant and 50 to 70mug / g of dispersing agent. Counted by the total weight of the coal tar,non-metal nitride and heavy asphaltene can be removed from the coal tar specially, and the removing rates are 75 percent and 21 percent respectively; moreover, metal ion iron calcium and ash can be removed effectively, the removing rate is 95 percent or more basically, and the treated coal tar can meet the requirement on subsequent deep processing.

Owner:NORTHWEST UNIV(CN)

Gangue spacing filling coal mining method

InactiveCN108204244AEffective control of pollution problemsPollution controlMaterial fill-upMining engineeringTransportation cost

The invention discloses a gangue spacing filling coal mining method, and relates to the technical field of coal mining methods. According to an existing gangue filling coal mining method, gangue needsto be utilized to completely fill a goaf, the mine auxiliary transportation cost is increased, coal mining work is greatly affected, the labor amount of filling workers is large, the gangue generatedduring mining of a thick coal seam is insufficient to completely fill the goaf, and the existing gangue filling coal mining method cannot be applied. According to the technical scheme, the gangue spacing filling coal mining method comprises the steps that the caving step pitch of roof strata is calculated according to the roof conditions of each coal mine, and precise filling is conducted on theposition where a roof is likely to caving by utilizing an ordinary gangue filling method, so that the to-be-caved roof strata is supported; as for precise filling, only the position where a roof is likely to caving is filled with a filling gangue belt which is parallel to a coal mining working face, so that the to-be-caved roof strata is supported; and as for the gangue belt, the bottom width is 10m-20 m.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Metal mine transverse drift four-mining one-reserving retreat mining structure and method

InactiveCN105626072AIncrease productionImprove mining efficiencyUnderground miningSurface miningPhysicsMetal

The invention relates to a metal mine transverse drift four-mining one-reserving retreat mining structure and method. The structure comprises a drift roadway close to a mineral vein in the extending direction of the mineral vein and mining regions arranged on the mineral vein at equal intervals. Reserving regions are arranged between adjacent mining regions at intervals. Each mining region is internally provided with primary mining regions located on the two sides, a to-be-mined region and the corresponding reserving regions located between the primary mining regions and the to-be-mined regions. Transverse drifts are arranged on the two sides of each primary mining region, on the two sides of each to-be-mined region and the middle of each reserving region. Working roadways communicated with the transverse drifts on the two sides of the primary mining regions or the two sides of the to-be-mined regions are transversely arranged in the primary mining regions and the to-be-mined regions. The working roadways divide the mineral vein in the mining regions into an outer side front mining region and an inner side blast region. Mining efficiency can be greatly improved, mining safety is greatly improved, and the yield of high-quality ore can be increased.

Owner:林立荣

Purification device for mercury vapor

InactiveCN102805988AImprove purification effectReduce fill volumeDispersed particle separationEnvironmental engineeringMercury-vapor lamp

The invention discloses a purification device for mercury vapor. Mercury vapor purification is carried out by sulfurizing active carbon; a main body of the purification device is an absorption box; the bottom part of the absorption box is connected with a waste gas inlet through a fan; an exhaust port for processing the waste gas is arranged near the side; a plurality of feed ports and discharge ports are arranged on the absorption box; sealed switch boards are arranged on the feed ports and the discharge ports, while a waste gas purification device is arranged inside the absorption box; the waste gas purification device is a filter box structure with a plurality of partition layers; the adjacent partition layers are isolated by a mesh as a primary filtering unit, and meanwhile, an absorption device of a sulfurizing active carbon absorption unit is also arranged on the lateral wall of the filter box so as to be used as a secondary purification unit. According to the purification device for mercury vapor, the production cost can be effectively reduced, and the purification device has higher social value and economic value.

Owner:武宁亮宇照明电器有限公司

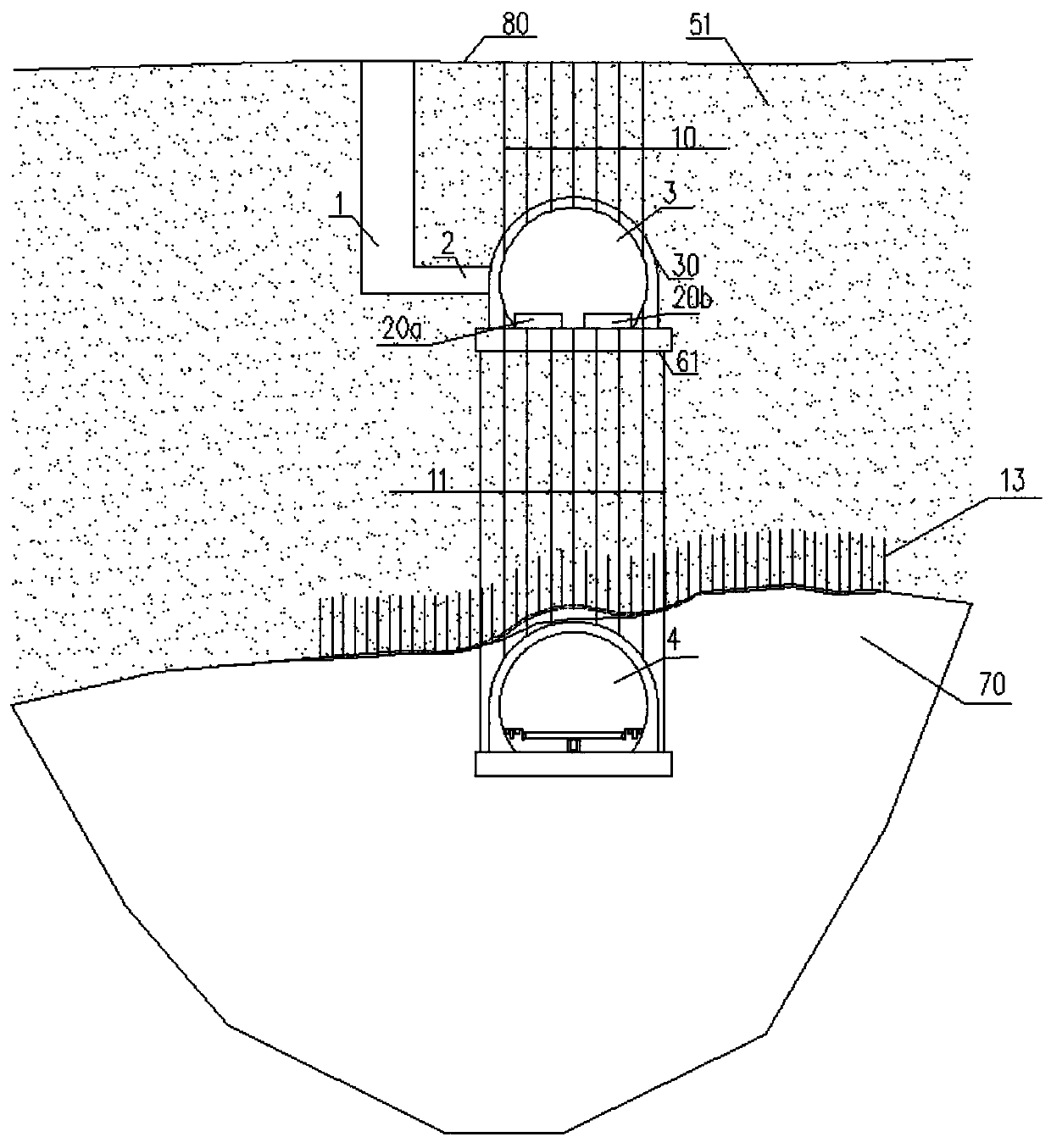

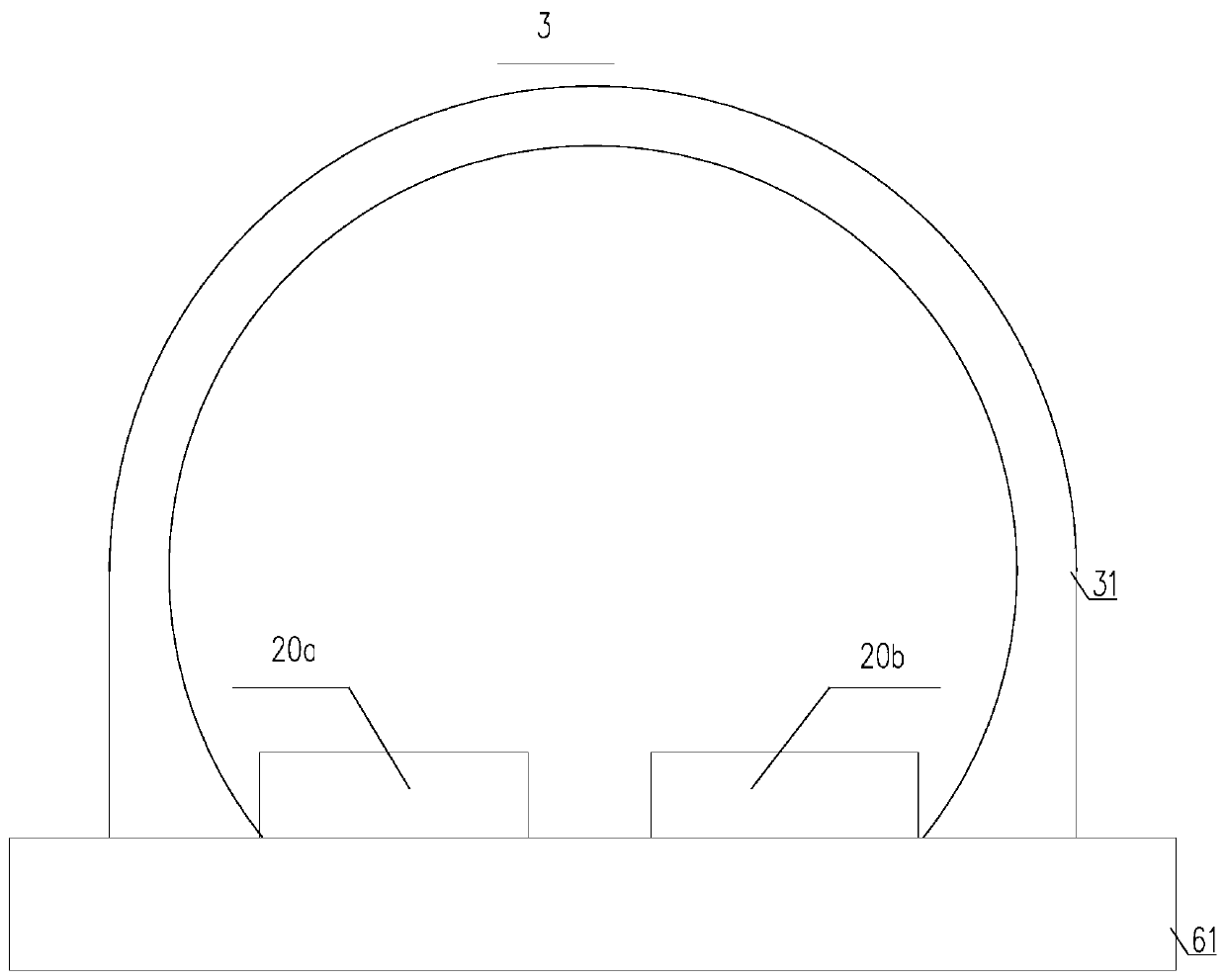

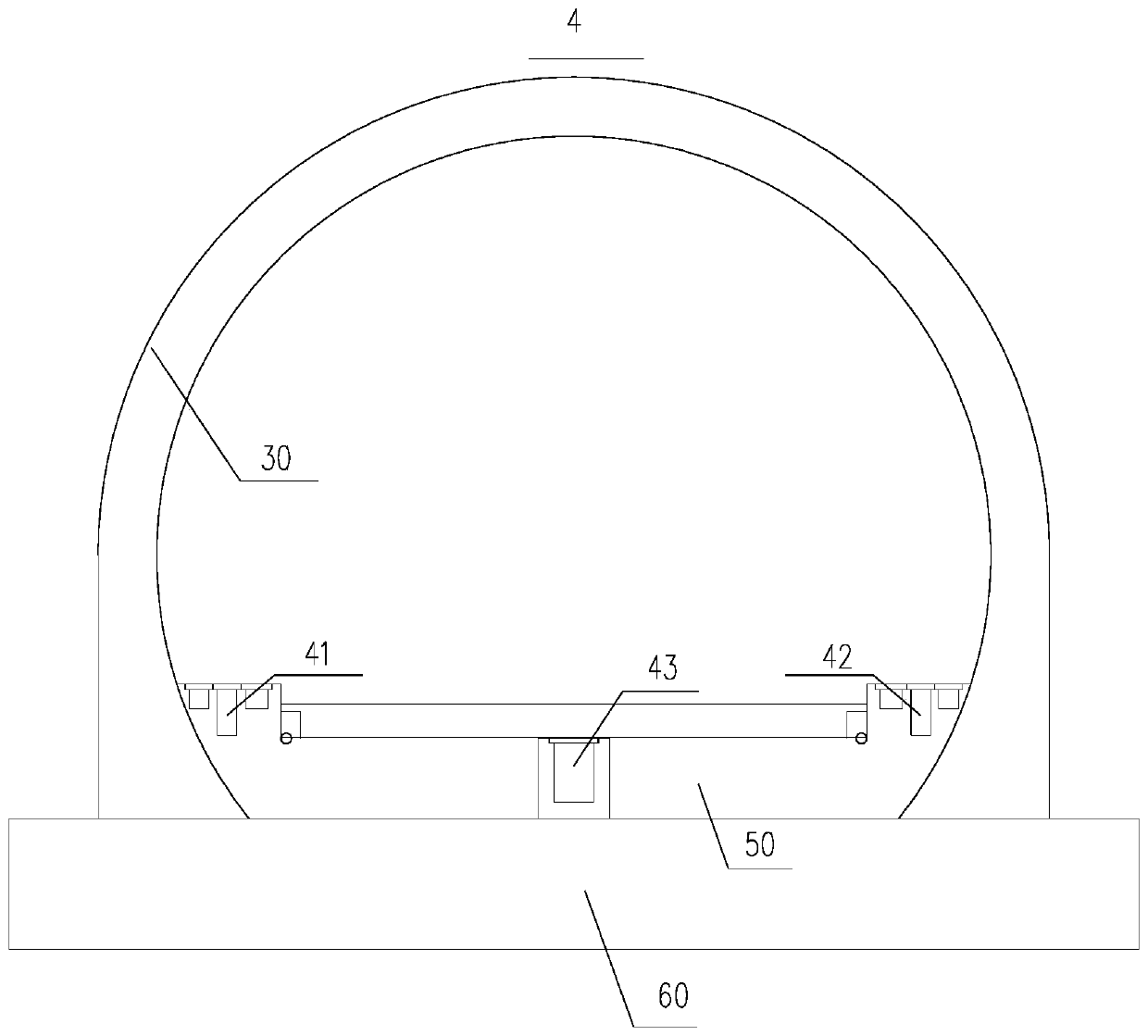

Anchor cable opposite-puling type supporting and protecting structure system and construction method thereof

PendingCN111412002AImprove the force characteristicsSolve problems such as uneven settlement deformationMaterial fill-upAnchoring boltsArchitectural engineeringStructure system

The invention relates to a tunnel supporting and protecting system, in particular to an anchor cable opposite-puling type supporting and protecting structure system and a construction method thereof.The supporting and protecting structure system comprises a vertical guide hole, a main tunnel, a first opposite-pulling anchor cable and a second opposite-pulling anchor cable; the vertical guide holeis arranged in a rock body above the main tunnel and is arranged parallel to the main tunnel; the first opposite-pulling anchor cable is arranged from top to bottom; the upper end of the first opposite-pulling anchor cable is fixed to the ground surface; the lower end of the first opposite-pulling anchor cable is fixed to the vertical guide hole; the second opposite-pulling anchor cable is arranged from the top to the bottom; the upper end of the second opposite-pulling anchor cable is fixed to the vertical guide hole; and the lower end of the second opposite-pulling anchor cable is fixed tothe main tunnel. The construction method is used for constructing the supporting and protecting structure system. The supporting and protecting structure system and the construction method provided bythe invention can effectively control the overall settlement of a tunnel structure, ensure the operating safety, and provide a new idea and a new method for a tunnel penetrating through a giant cavern hall.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

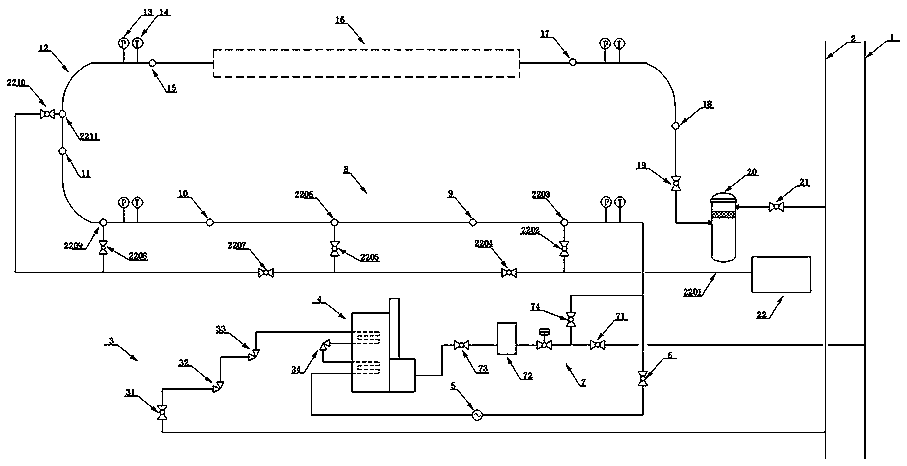

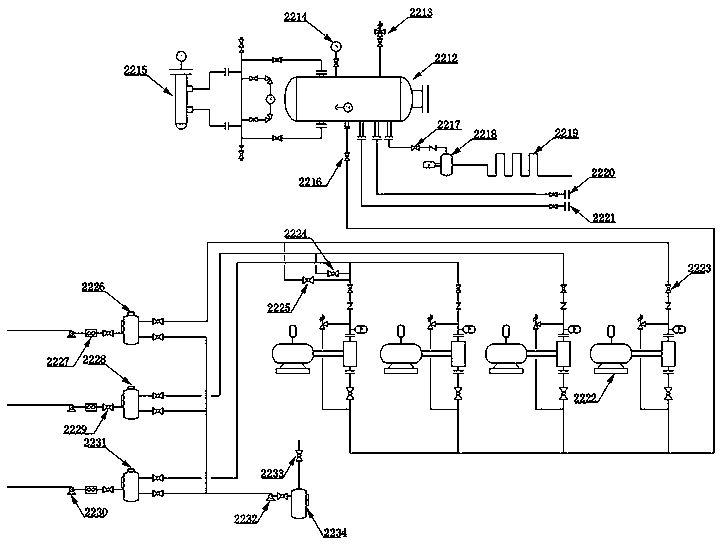

Onsite test device for testing concentration distribution of corrosion inhibitor, and method thereof

ActiveCN107907496AReduce fill volumeImprove economic efficiencyParticle size analysisColor/spectral properties measurementsProcess conditionsPetroleum

The invention relates to an onsite test device for testing the concentration distribution of a corrosion inhibitor, and a method thereof, and belongs to the technical field of petroleum and natural gas engineering. The method comprises the following steps: designing a corrosion inhibitor continuous-charging module, testing the influences of the type, the concentration, the temperature, the charging amount and the corrosion inhibitor liquid drop particle size of different corrosion inhibitors on the concentration distribution rule of a corrosion inhibitor; designing a corrosion inhibitor liquiddrop particle size test module, and testing the particle size of corrosion inhibitor liquid drops sprayed by several onsite common nozzles through experiments; and designing a corrosion inhibitor concentration analysis sampler to provide a means and way for circular test studying of the concentration distribution of the corrosion inhibitor. The onsite test device for testing the concentration distribution of the corrosion inhibitor, and the method thereof are used to test the concrete distribution of the corrosion inhibitor in a pipeline under different angle bends, different positions to a charging point, different pipeline gas pressures, different pipeline gas temperatures and different charging technology conditions and study the effective protection length of the corrosion inhibitor under different charging technologies.

Owner:SOUTHWEST PETROLEUM UNIV

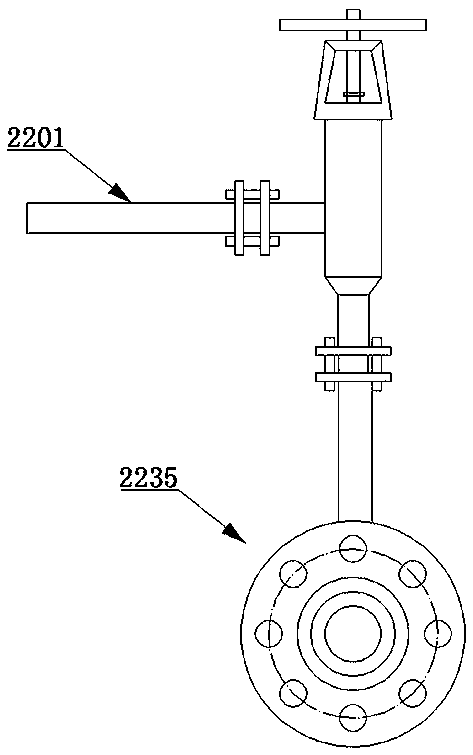

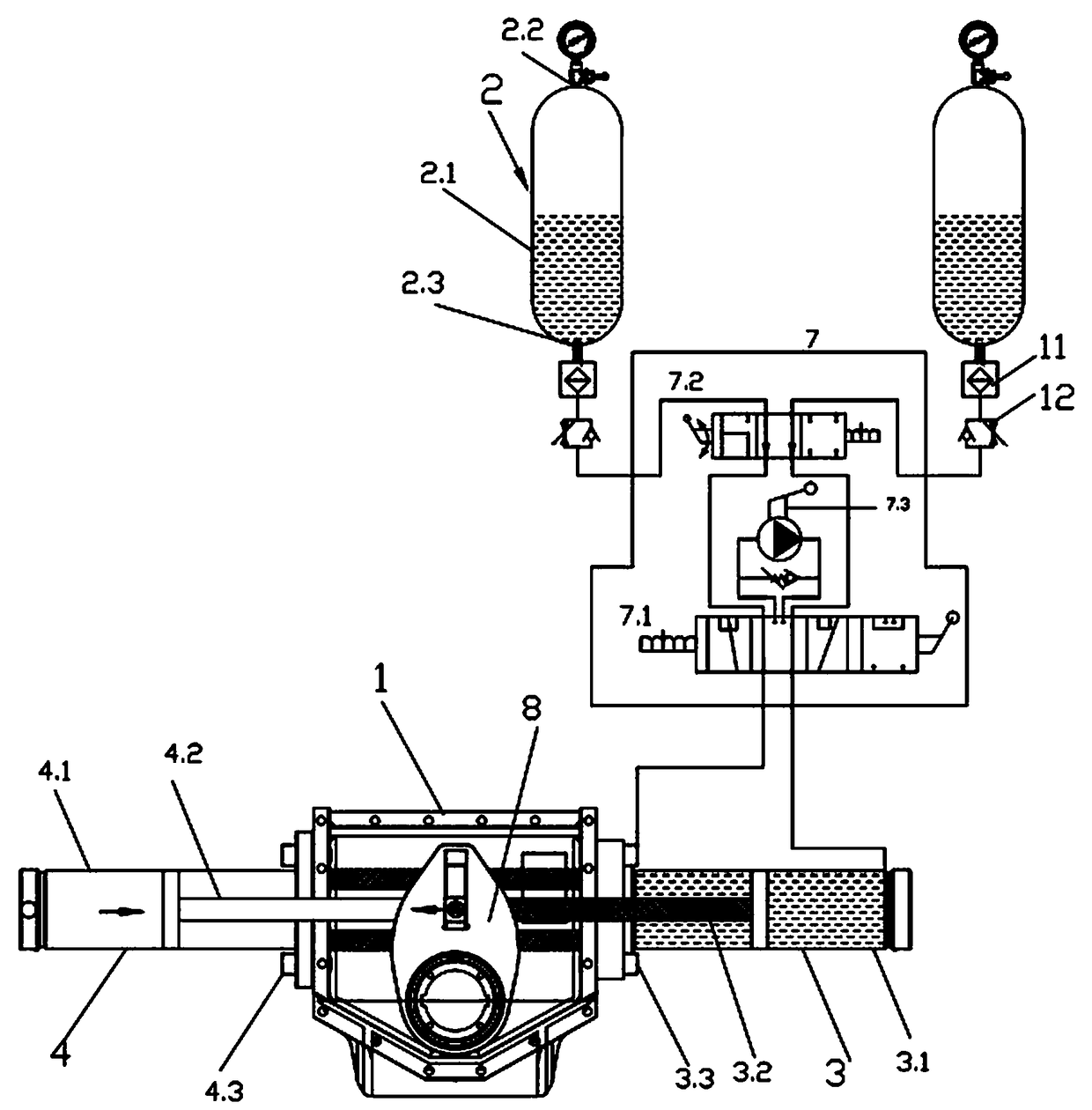

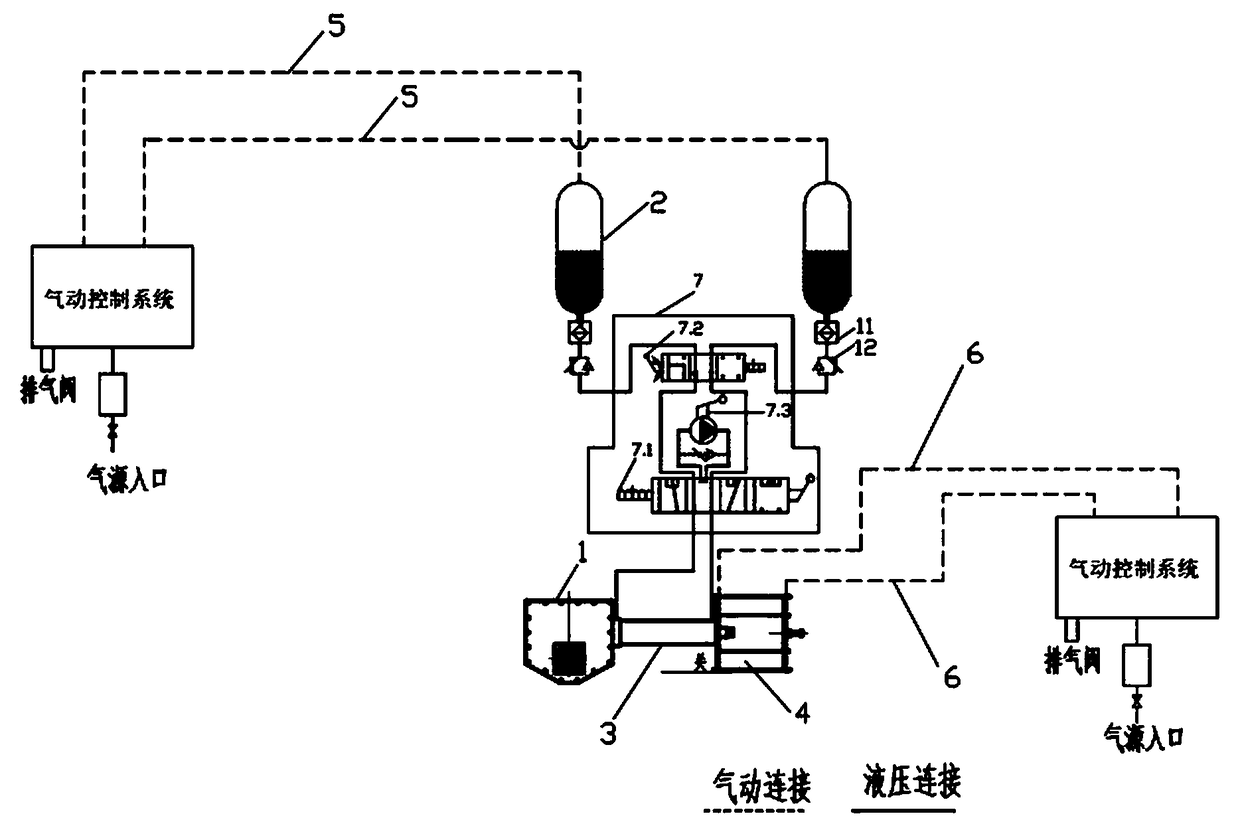

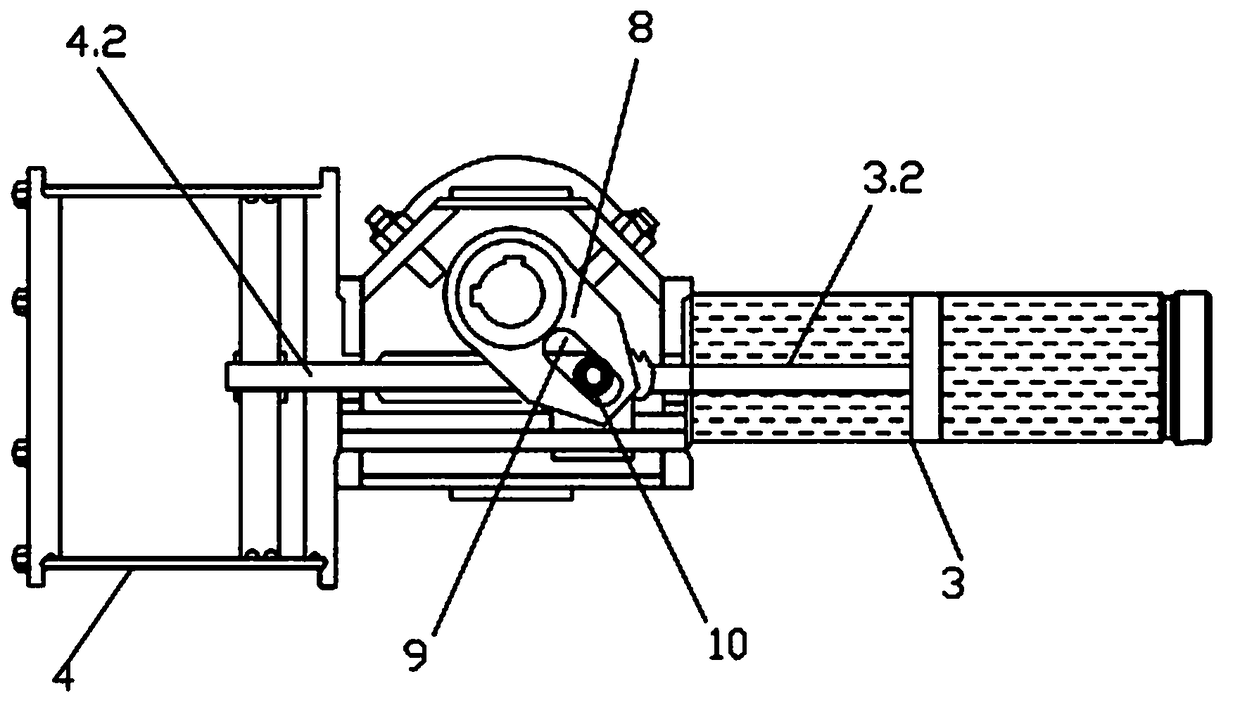

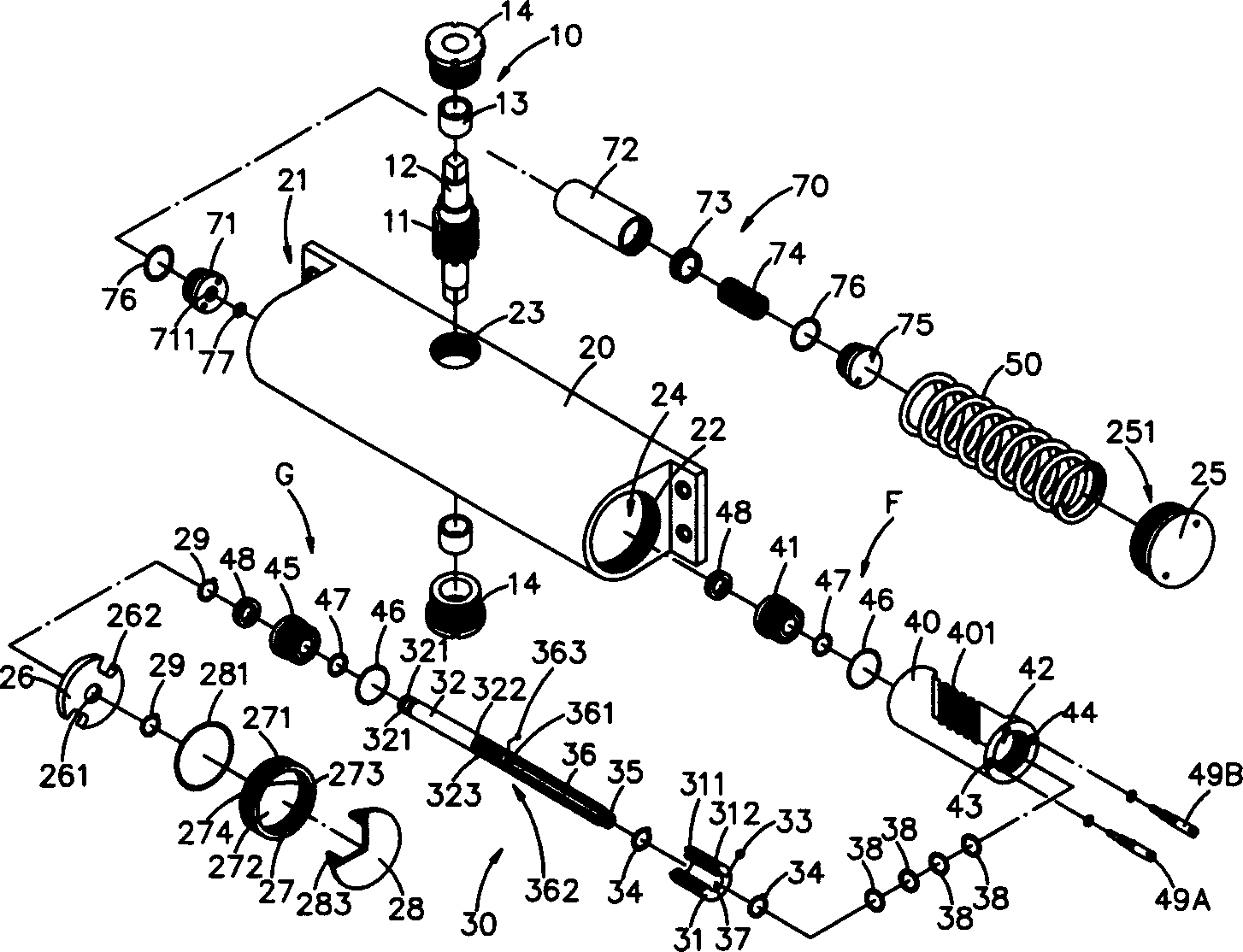

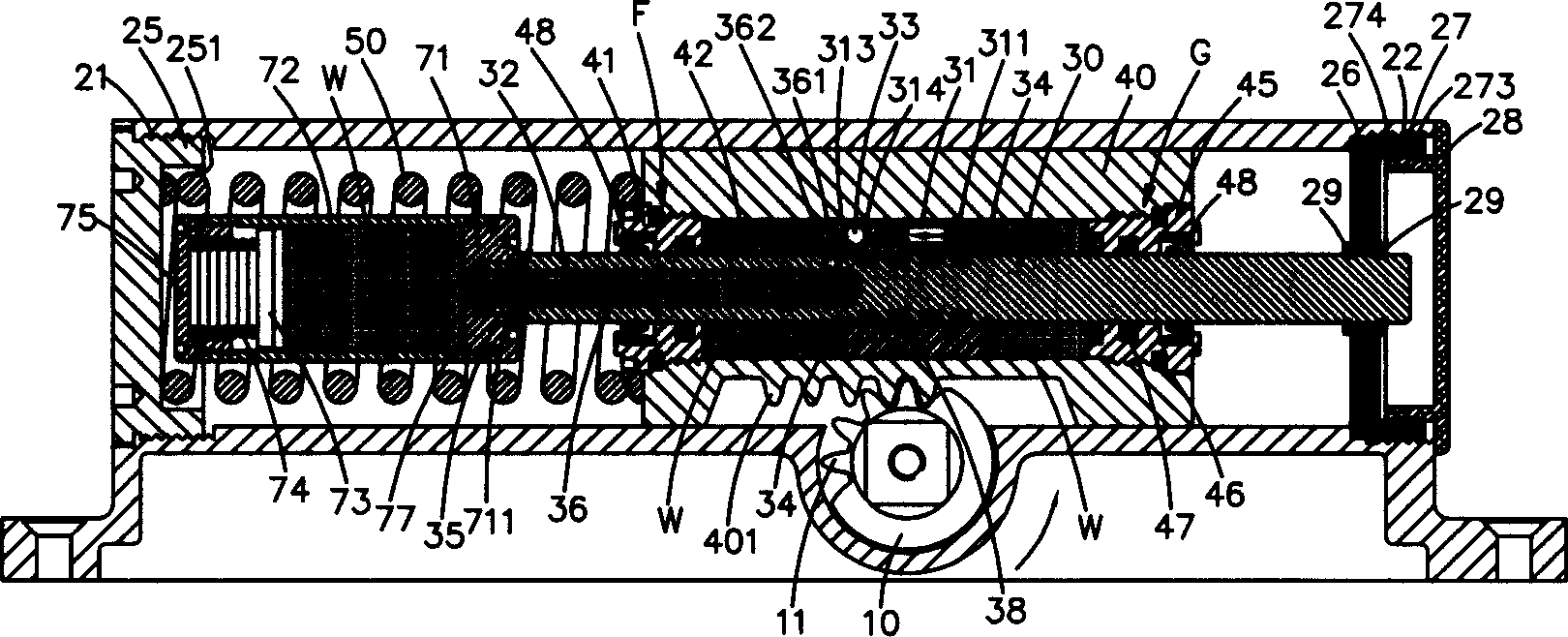

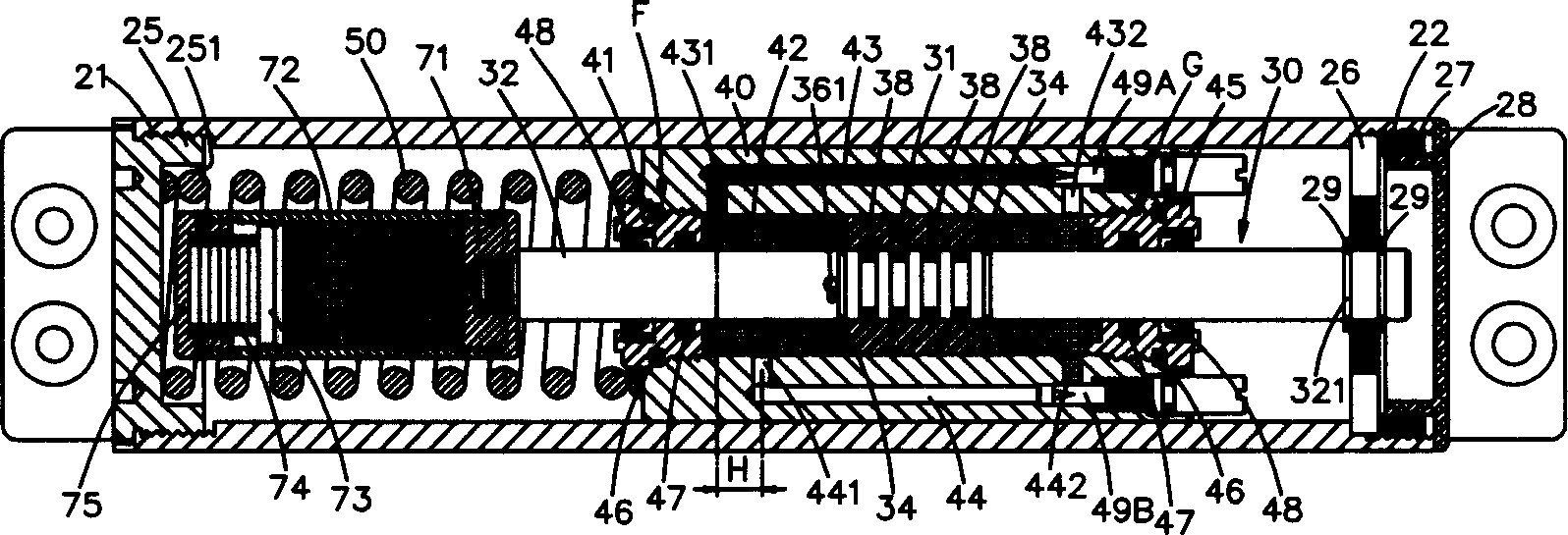

Miniaturized pneumatic-hydraulic linkage actuator for large-diameter valve and low air source

PendingCN109340443ADouble or multiply output powerReduce the effective volumeOperating means/releasing devices for valvesServomotor componentsControl systemEngineering

The invention discloses a miniaturized pneumatic-hydraulic linkage actuator for a large-diameter valve and a low air source. The miniaturized pneumatic-hydraulic linkage actuator comprises a shiftingfork transmission box, a gas-liquid tank assembly, a hydraulic actuating element and at least one pneumatic actuating element; each gas-liquid tank assembly is composed of two gas-liquid tanks, and gas inlets and gas outlets of tank bodies are connected with a pneumatic control system through gas path pipelines; two gas inlet and exhaust ports of the pneumatic actuating elements are connected withthe pneumatic control system through gas path pipelines; and the pneumatic actuating elements and the hydraulic actuating element are installed on one side of the shifting fork transmission box in series or installed on the two sides of the shifting fork transmission box separately. The miniaturized pneumatic-hydraulic linkage actuator is especially suitable for the condition that the gas sourcepressure is 0.6 MPa-1.2 MPa, no matter how the hydraulic actuating element and the pneumatic actuating elements are installed in series, power gas can continuously output hydraulic oil through the gas-liquid tanks to drive hydraulic oil cylinder acting valves and drive air cylinder acting valves through pneumatic output, air cylinders and hydraulic oil cylinders output thrust, the thrust is addedin series, and the output power is added multiple times.

Owner:CHENGDU MAIKESEN FLUID CONTROL EQUIP

Oil and electricity hybrid unmanned aerial vehicle

The invention discloses an oil and electricity hybrid unmanned aerial vehicle, which comprises an unmanned aerial vehicle body and a power driving unit, wherein the oil and electricity hybrid unmanned aerial vehicle comprises a fuel box which is used for storing a fuel, an engine which is used for providing power through combusting the fuel, a generator which is used for generating an electric current through rotational power provided by the engine, and a voltage stabilizing circuit which is used for carrying out voltage stabilization treatment on the electric current and outputting the electric current treated by the voltage stabilizing circuit to a driving motor of the unmanned aerial vehicle body. The oil and electricity hybrid unmanned aerial vehicle has advantages of being simple in structure, long in time of navigation and wide in scope of application, and the like.

Owner:长沙灵动航空科技有限公司

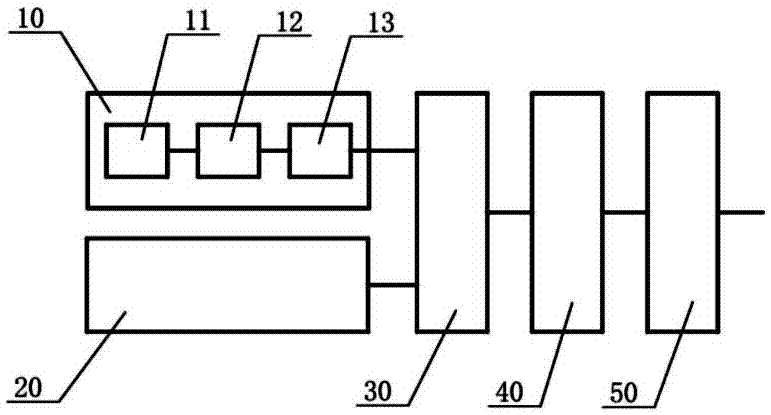

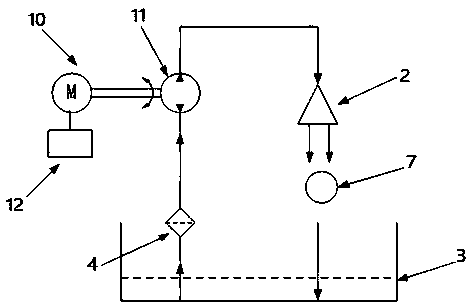

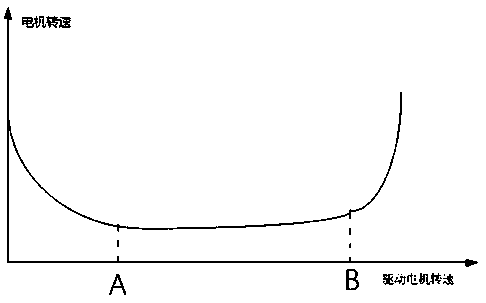

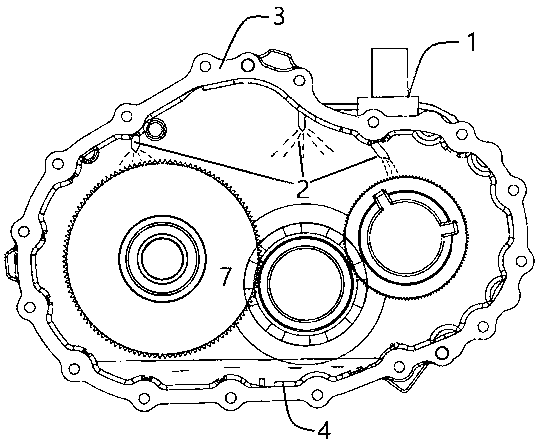

Method for actively lubricating reduction gearbox

The invention discloses a method for actively lubricating a reduction gearbox. The method for actively lubricating the reduction gearbox is characterized by being based on an electronic oil pump; theelectronic oil pump comprises a motor, a gear pump and a controller; the motor is connected with the gear pump; the controller is respectively connected with the motor and an automobile CAN bus, obtains the rotating speed of a driving motor through the CAN bus, and controls the rotating speed of the motor; and the motor controls the gear pump to inject oil through oil nozzles connected with the gear pump. By adopting the active lubricating mode, the problem that the lubricating effects are not ideal when the reduction gearbox runs at low speed and at ultra-high speed is solved, the reliabilityand durability of the reduction gearbox can be effectively improved, and the service life of the reduction gearbox is prolonged; meanwhile, the filling amount of the lubricating oil of the reductiongearbox can be reduced, so that the cost of a user is saved; and the lubricating oil can be directly and accurately injected to gears and gear shafts needing to be lubricated through the oil nozzles,so that the design difficulty is reduced without repeatedly modifying the design according to the positions of oil guide ribs.

Owner:ZHUZHOU GEAR CO LTD

Hydrocracking method for producing chemical materials to maximum with low cost

The invention relates to a hydrocracking method for producing chemical materials to the maximum with low cost, comprising the following steps: mixing raw oil and hydrogen gas , entering a first reaction area, sequentially contacting with hydrofining catalyst and hydrocracking catalyst, reacting under the pressure of 6.0-16.0 MPa; carrying out oil-gas separation and fractionation on the reaction products thereof to obtain liquefied gas, light naphtha fractions, heavy naphtha fractions, middle fractions and tail oil fractions; mixing the middle fractions and the hydrogen gas and enteringa second reaction area, contacting with the hydrocracking catalyst under the pressure of 1.0-5.5 MPa to react; and carrying out oil-gas separation on the reaction products thereof and entering a fractionation system . By adopting the method, heavy raw materials such as vacuum gas oil, coking gas oil and the like are treated to obtain more than 98 weight percent chemical materials. In the invention, themiddle fractions are wholly converted into the chemical materials in the low pressure condition, and low hydrogen consumption, low investment cost and low operation cost are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-working-condition heat storage type electric boiler

ActiveCN107036288AReduce fill volumeReduce heat transfer areaHeat storage plantsStorage heatersWater flowHeat storage material

The invention relates to a multi-working-condition heat storage type electric boiler. The multi-working-condition heat storage type electric boiler is characterized by comprising an electric heater, a circulating water pump, a circulating pipeline, heat storage balls, a supporting plate, a water distribution disc, a snakelike heat exchange coiled pipe and an envelope structure. According to the multi-working-condition heat storage type electric boiler, a heat source and a heat storage medium are integrated into one product, the structure is compact, and the heating function and the heat storage function are both met. A heat storage material is packaged through a spherical structure, the heat exchange area is large, heat storage and heat exchange in the heat release process are strengthened, the heat storage balls are stacked in the boiler, the structure is compact, a clearance exists between every two adjacent heat storage balls, and water steam and water flowing heat exchange is facilitated.

Owner:济南金孚瑞供热工程技术有限公司

Door closing device

InactiveCN1680678AAvoid oil spillsAvoid wear and tearBuilding braking devicesHydraulic cylinderDie casting

The invention adopt the combination operation between door pivot, action sliding cylinder, shutdown spring, oil supply tube and door closer, and the corresponding transmission between teeth set at outside of action sliding cylinder and door pivot. The one end of action sliding jar is against the shutdown spring, and the oil hydraulic cylinder bore and relevant sliding piston are set in action sliding cylinder. Both end of the piston has piston axis that is threading out. The end of piston axis has an oil supply tube, and hydraulic oil fills in the hydraulic cylinder bore and oil supply tube. The invention can reduce amount of filling hydraulic oil, and can prevent aluminum die-casting body from oil dripping.

Owner:黄潭城

Antisludging agent for low temperature flue gas heat exchange equipment of boiler and preparation method thereof

ActiveCN103193331APrevent coking and scaleAvoid cokingScale removal and water softeningFlue gasPhysical chemistry

The invention provides an antisludging agent for low temperature flue gas heat exchange equipment of a boiler and a preparation method thereof. The preparation method comprises: putting a solvent, 1 / 2 mass of polymerization inhibitor and 1 / 2 mass of metal passivator in a container, stirring the matters at a constant temperature until the matters are completely dissolved; adding a calcic detergent dispersant and an organic dispersant according to a proportion, stirring the mixture at a constant temperature until the mixture is completely dissolved; and finally, adding the 1 / 2 mass of polymerization inhibitor, the 1 / 2 mass of metal passivator and a diamine acid acceptor according to a proportion, and stirring the mixture at a constant temperature until the mixture is completely dissolved to obtain the antisludging agent for low temperature flue gas heat exchange equipment of boiler. The antisludging agent has the characteristics of little feeding dosage, good economical efficiency and practicability, and high scale inhibition rate, and the like, and the antisludging agent can be used for inhibiting and slowing the coking and scaling problems of low temperature flue gas in the heat exchange equipment, so that the antisludging agent has high generalization and application values and a brilliant market prospect.

Owner:蒲城驭腾新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com