Pipeline multipoint synchronous automatic welding process

A welding process, synchronous and automatic technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of weld stress concentration, limited space for improving welding efficiency, and incomplete penetration, so as to eliminate stress concentration and improve welding quality. Efficiency, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] refer to Figures 1 to 8 Embodiments of the present invention are further described:

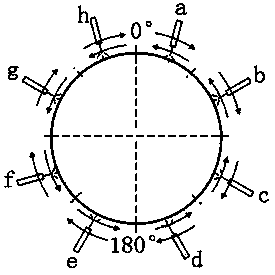

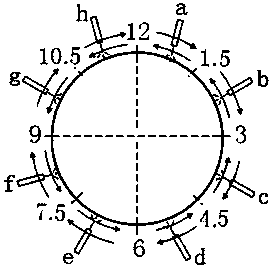

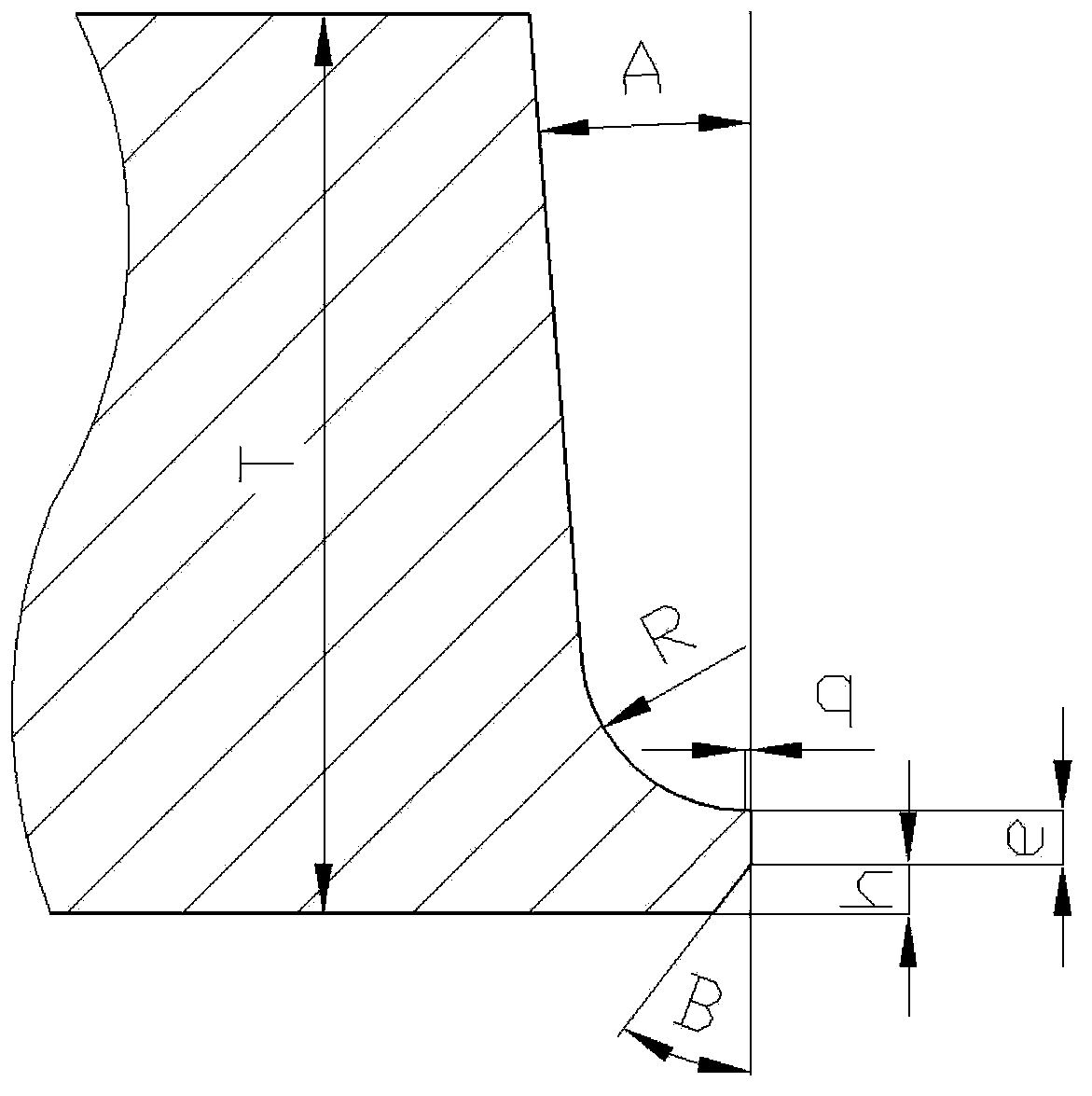

[0025] This welding process adopts eight welding torch pipeline synchronous automatic welding internal welding machine, which has eight welding torches, namely the first welding torch a, the second welding torch b, the third welding torch c, the fourth welding torch d, the fifth welding torch e, and the sixth welding torch f The seventh welding gun g and the eighth welding gun h, the welding length of each welding gun is 1 / 8 of the outer circumference of the pipeline. The 1.5 o'clock, 3 o'clock, 4.5 o'clock, 6 o'clock, 7.5 o'clock, 9 o'clock, 10.5 o'clock and 12 o'clock positions of the pipeline are the overlapping areas of the weld joints, and the sensing range of the angle sensor is the outer arc of the pipeline corresponding to the central angle of 0.5° Long (0.5 / 360×π×D). The first torch a to the fourth torch d are used for segmental independent welding on the 0°-180° side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com