Hydraulic shaping device of stainless steel lined compound pipe and its shaping method

A hydroforming, stainless steel technology, applied in the field of industrial and civil composite pipe processing, can solve the problems of difficult sealing of welded seam stainless steel inner pipe, large device, complicated structure of oil cylinder and support, and eliminates the need for coordinated control system, operation The effect of convenience and easy manufacturing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

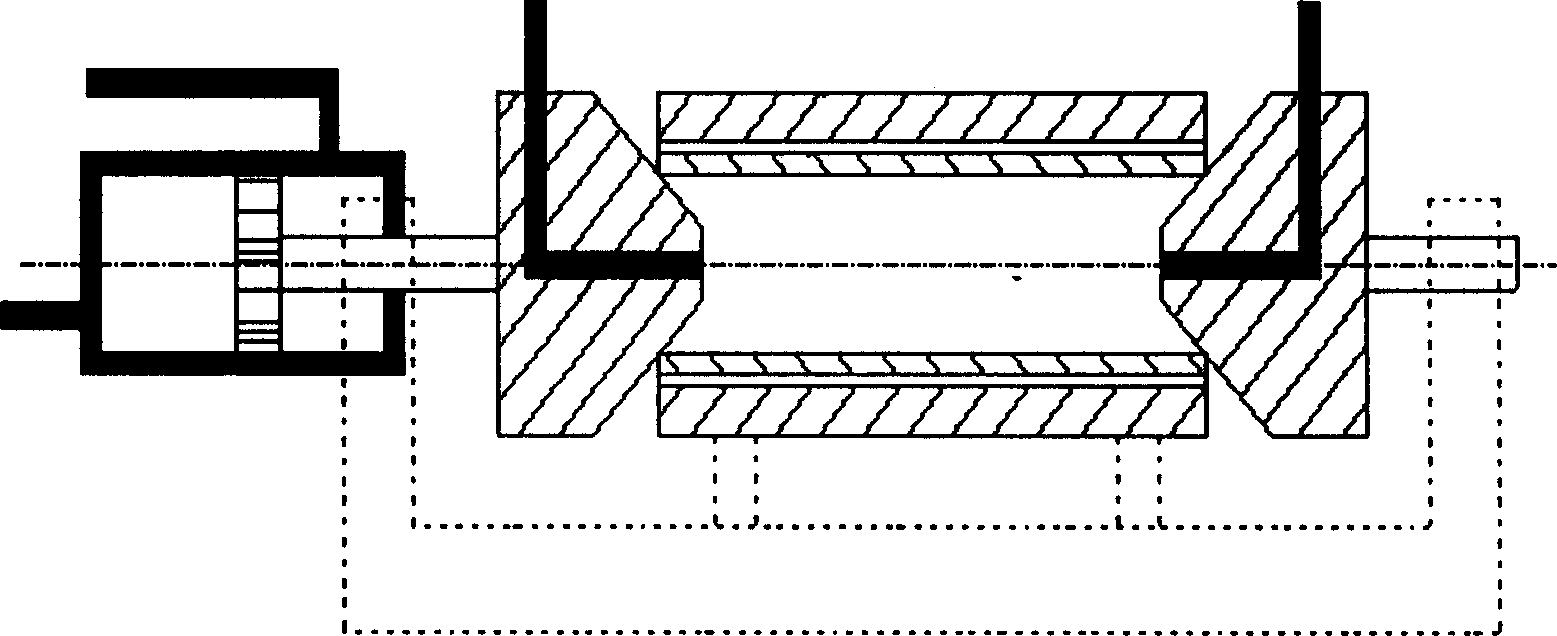

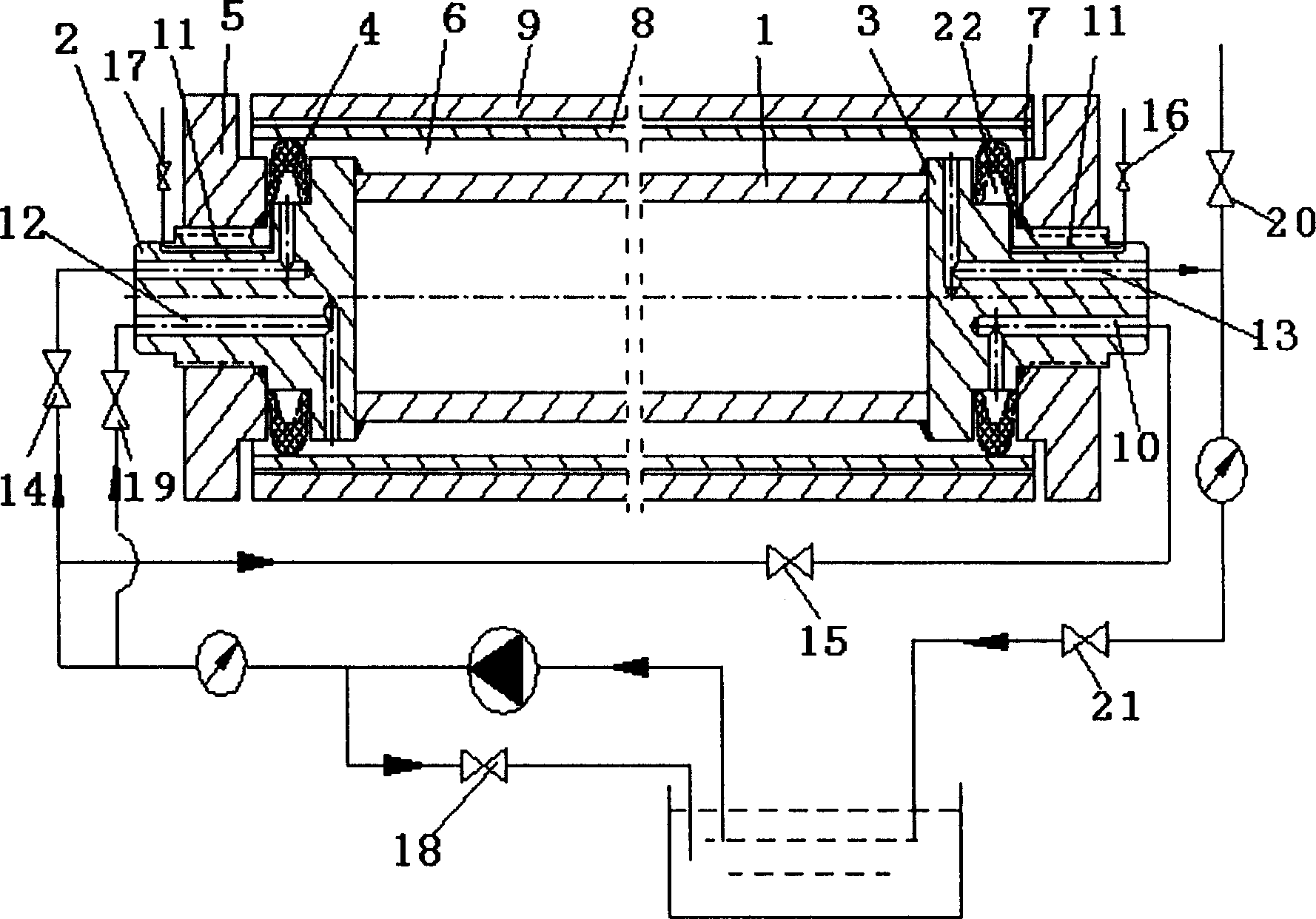

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

[0025] see figure 2 , the stainless steel lined composite tube hydroforming device of the present invention comprises a core rod 1, the two ends of the core rod 1 are respectively fixedly connected with a left expander 2 and a right expander 3, and the outer diameter of the core rod 1 is smaller than the stainless steel inner tube to be composited 8, self-tightening sealing rings 4 are respectively provided on the left and right expansion heads, and fixing devices 5 are provided at the ends of the expansion heads, and self-tightening sealing rings 4 on both sides, the outer diameter of the core rod 1 and the inner diameter of the stainless steel inner tube 8 are formed Sealed expansion cavity 6, the two sides of each self-tightening sealing ring 4 are respectively tightly attached to the fixing device 5 and the corresponding expansion head, and a sealing ring 7 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com