A self-centering multi-axis linkage internal expansion clamping mechanism and clamping method

A clamping mechanism and multi-axis linkage technology, applied in the field of clamping tooling, can solve problems such as the inability to completely eliminate gap errors depending on dimensional accuracy, and achieve the effects of easy processing, expansion of use range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

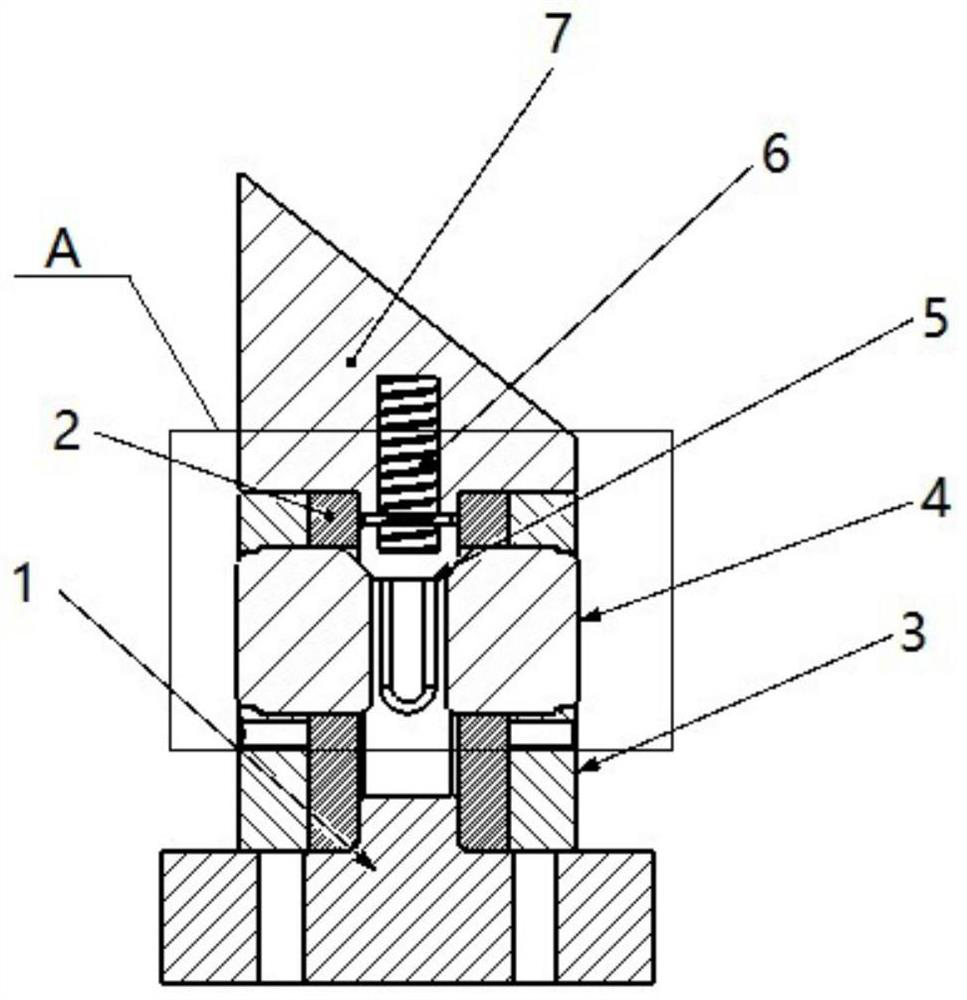

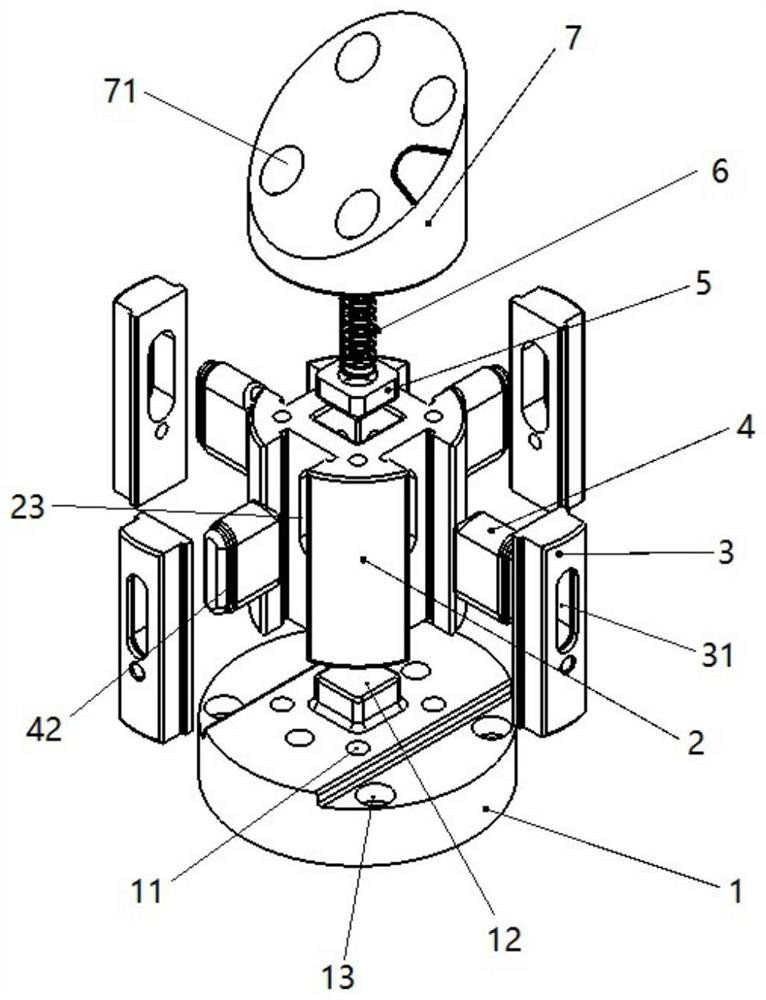

[0037] As shown in FIG. 2, in the first embodiment of the present invention, a fixing hole 13 can also be provided on the fixing base 1, and the fixing hole 13

[0038] As shown in FIG. 2 and FIG. 4, the outer circumference of the mandrel 2 is provided with a plurality of insert mounting grooves 22, and the plurality of insert mounting grooves 22 can be

[0039] As shown in FIG. 2 and FIG. 4, in the first embodiment of the present invention, the insert mounting groove 22 can be, for example, a T-shaped groove, that is, in the groove

[0045] As shown in FIG. 2, in the first embodiment of the present invention, the mandrel through hole 21 can be square. At this time, in order to facilitate

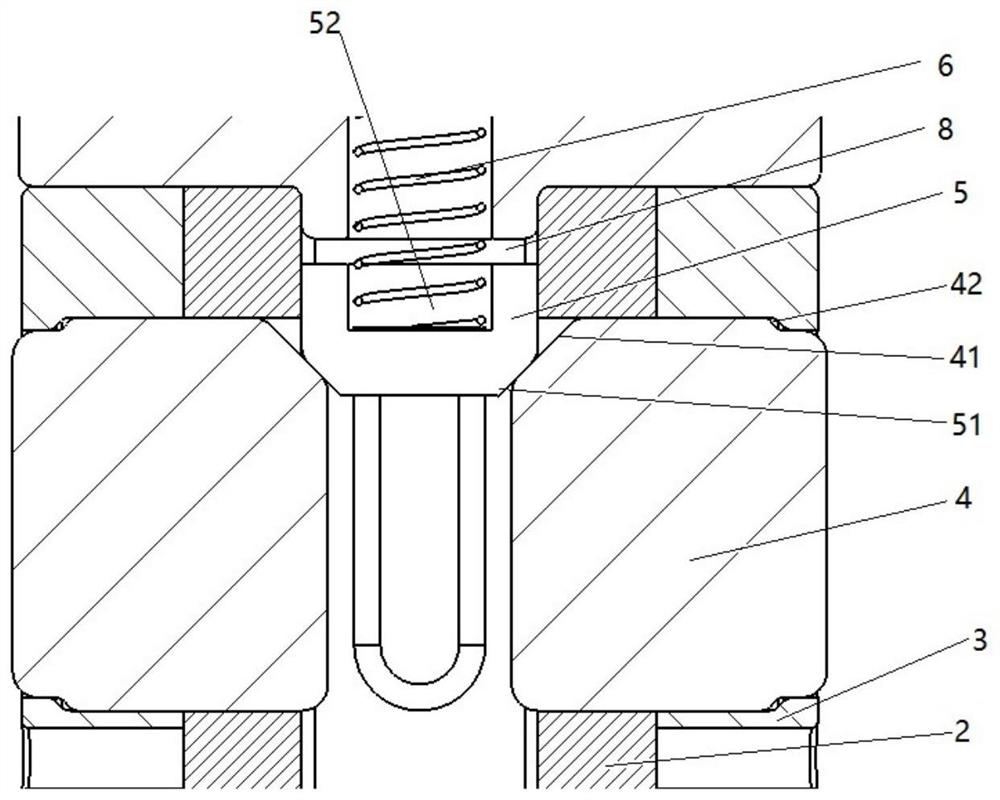

[0046] As shown in Figure 1 and Figure 3, in the first embodiment of the present invention, the upper surface of the elastic pin pressing block 5 is connected with the elastic member 6.

[0047] As shown in FIG. 3, in the first embodiment of the present invention, a spring can also be provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com