Loading method for pipeline containing through cracks

A technology that penetrates through cracks and pipelines. It is applied in the field of high-temperature and high-pressure pipelines and high-temperature and high-pressure pipelines. It can solve the problems of static pressure experiment errors, impossibility, and difficult high-temperature and high-pressure experiments. It achieves uniform expansion force, simple equipment, and avoids pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] When the pressure medium is at normal temperature, the invention is used to load the sample of the heat transfer tube of the steam generator containing through cracks.

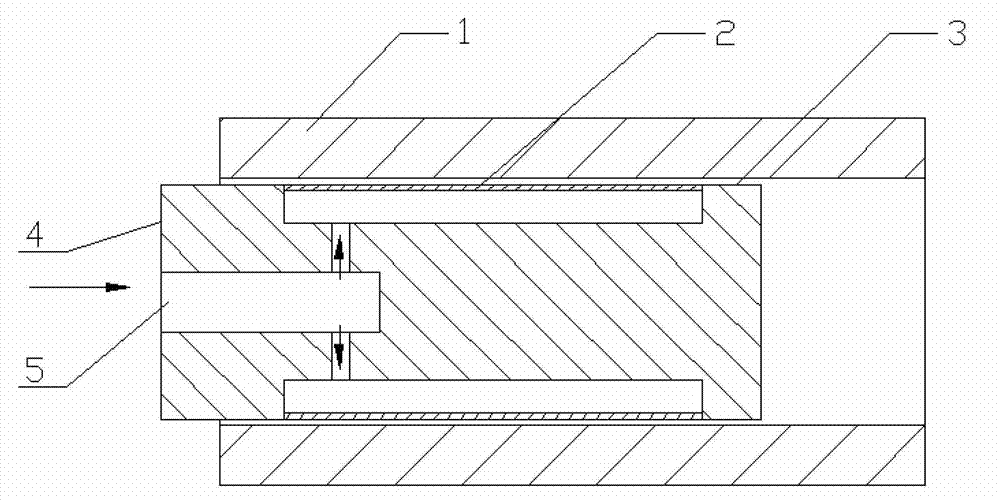

[0033] (1) First, process a pipe sample of appropriate size. In order to eliminate the end effect, the length of the sample pipeline 1 should be greater than twice the effective pressurized length of the expansion rod 3 during the sample preparation process. And prepare an axial crack on the pipeline 1;

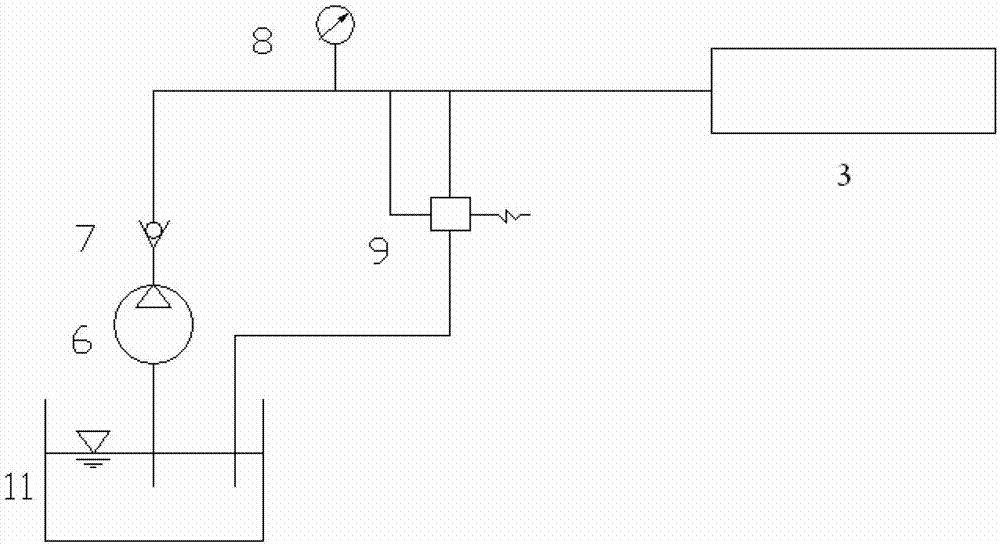

[0034] (2) Use a flexible container 2 whose size matches the internal size of the pipe 1, and install an expansion rod 3 in the direction of the inner axis of the flexible container 2 to control the deformation of the flexible container in the direction of the pipe axis, wherein the flexible container 2 is a fiber fabric The liquid bag made; the expansion rod 3 is provided with a pressure transmission medium channel 5; the flexible container 2 equipped with the expansion rod 3 is sent into the pipelin...

Embodiment 2

[0038] When the pressure medium is high temperature, the present invention is used to load the steam generator containing the through-crack heat transfer tube.

[0039] (1) First, process a pipe sample of appropriate size. In order to eliminate the end effect, the length of the sample pipeline 1 should be greater than twice the effective pressurized length of the expansion rod 3 during the sample preparation process. And prepare an axial crack on the pipeline 1;

[0040] (2) Use a flexible container 2 whose size matches the internal size of the pipeline 1, and install an expansion rod 3 in the direction of the internal axis of the flexible container 2 to control the deformation of the flexible container in the direction of the pipeline axis, wherein the flexible container 2 is formed by a deformable Made of metal; the expansion rod 3 is provided with a pressure transmission medium channel 5; the flexible container 2 equipped with the expansion rod 3 is sent into the pipeline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com