Patents

Literature

65results about How to "Reduce the effective volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

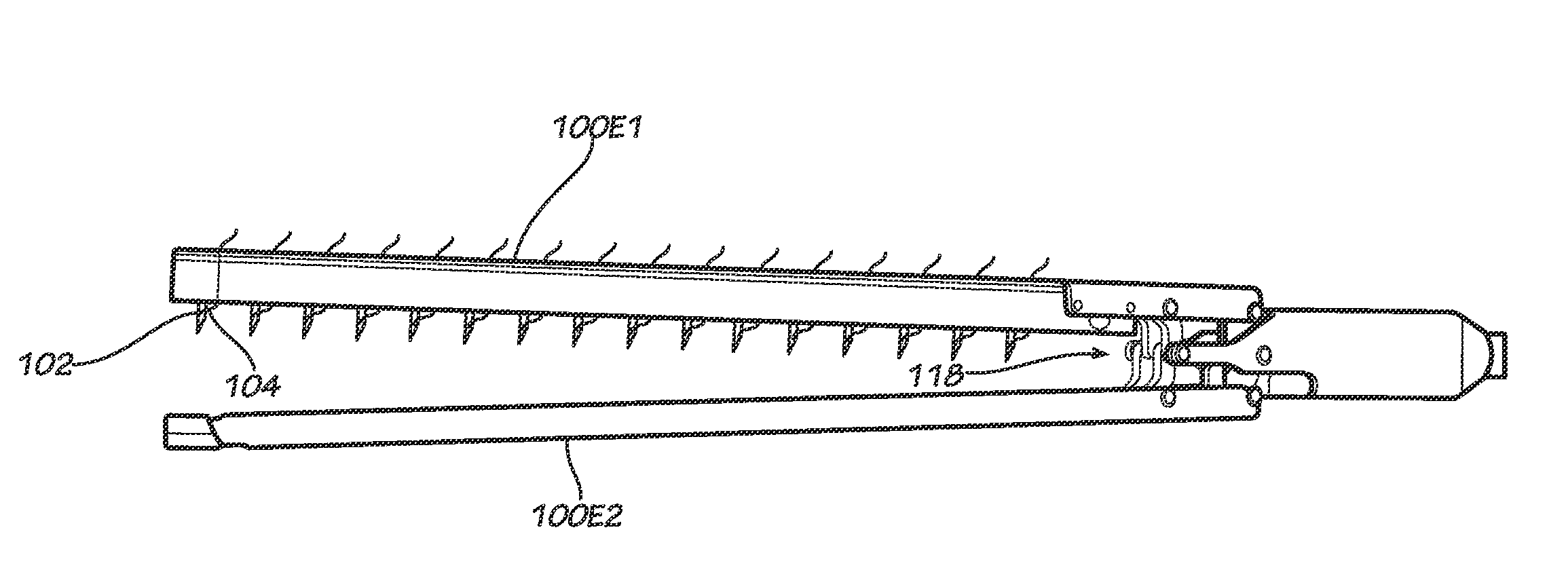

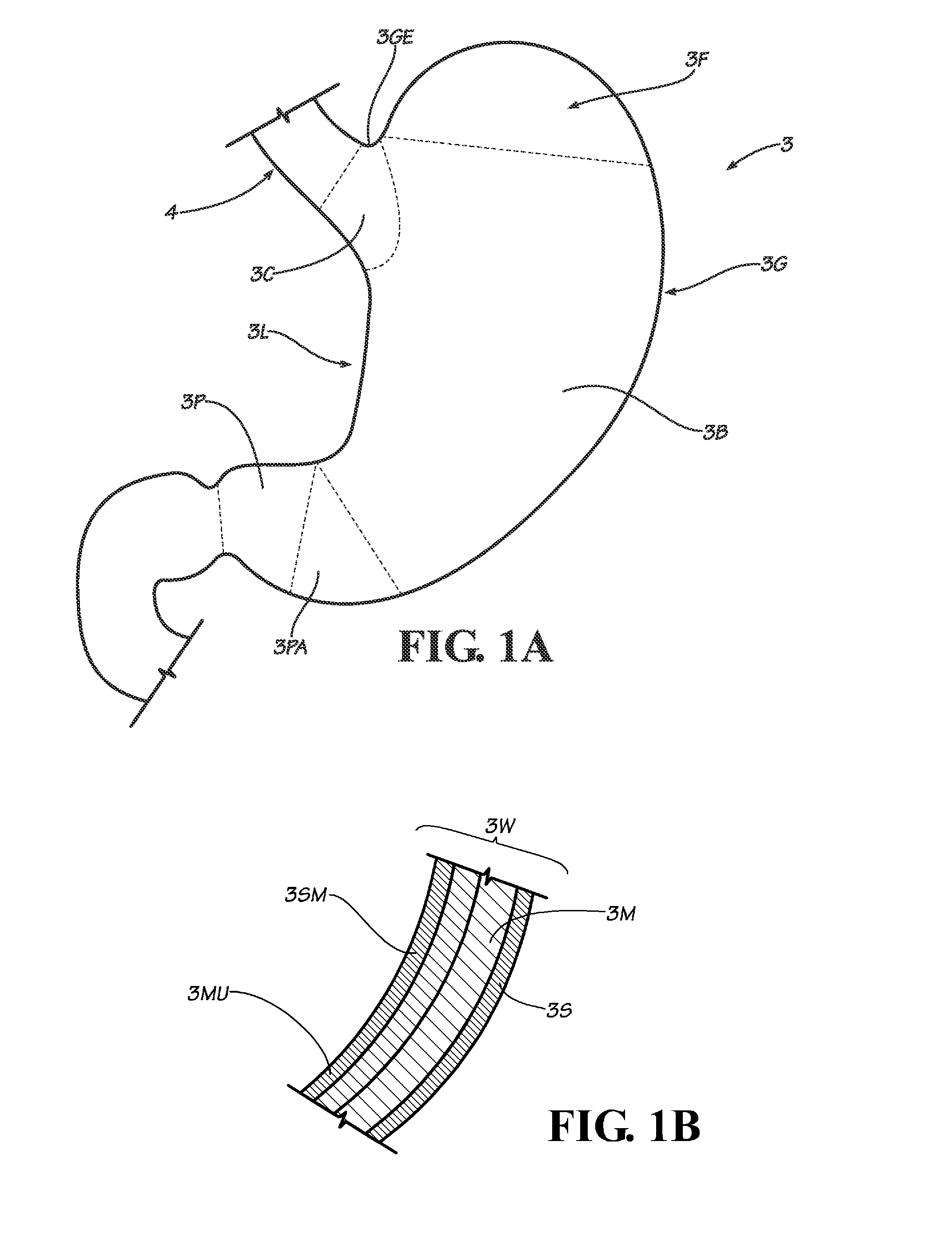

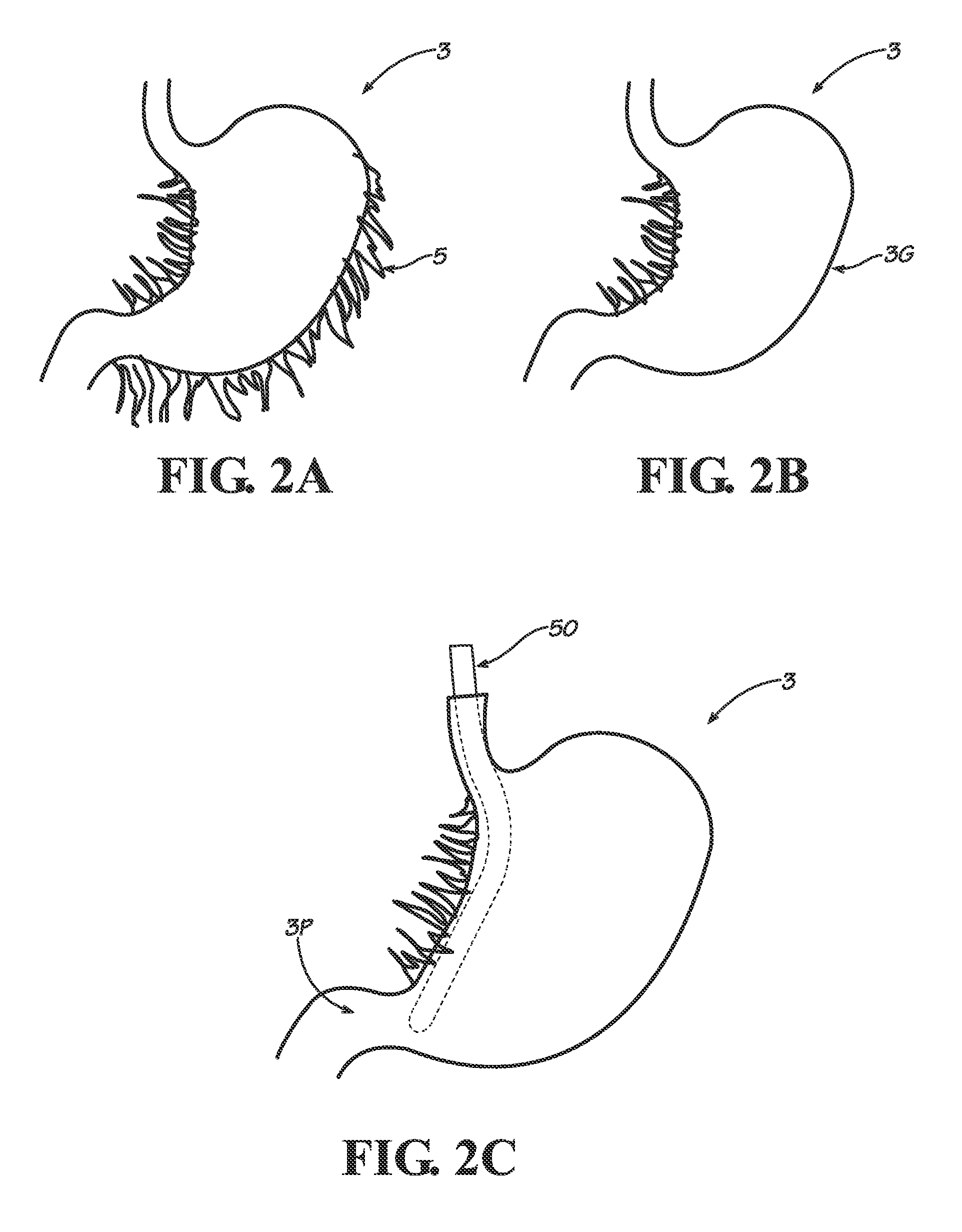

Methods, instruments and devices for extragastric reduction of stomach volume

ActiveUS8382775B1Reduce the effective volumeReduce volumeSuture equipmentsSurgical needlesStomachInstrumentation

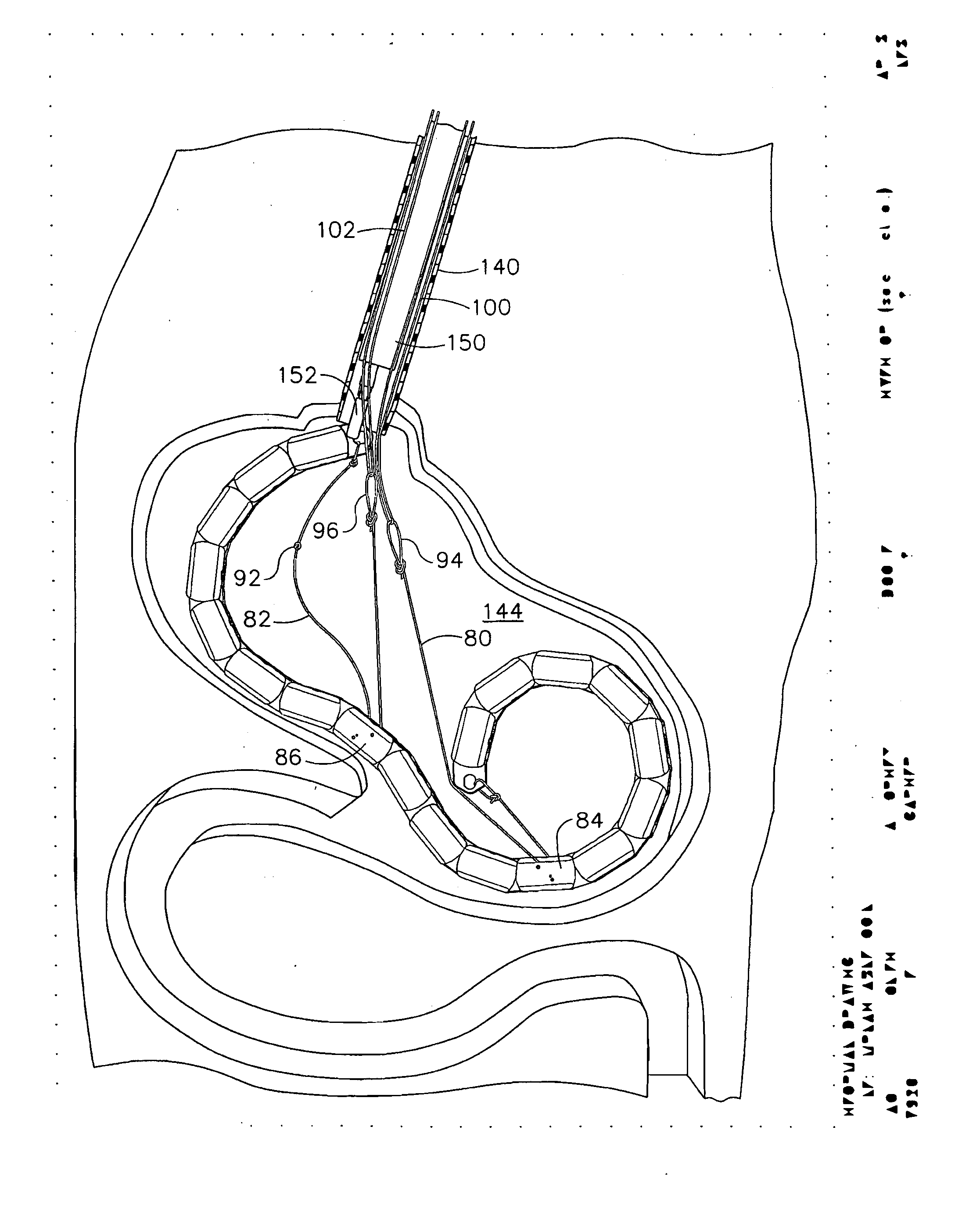

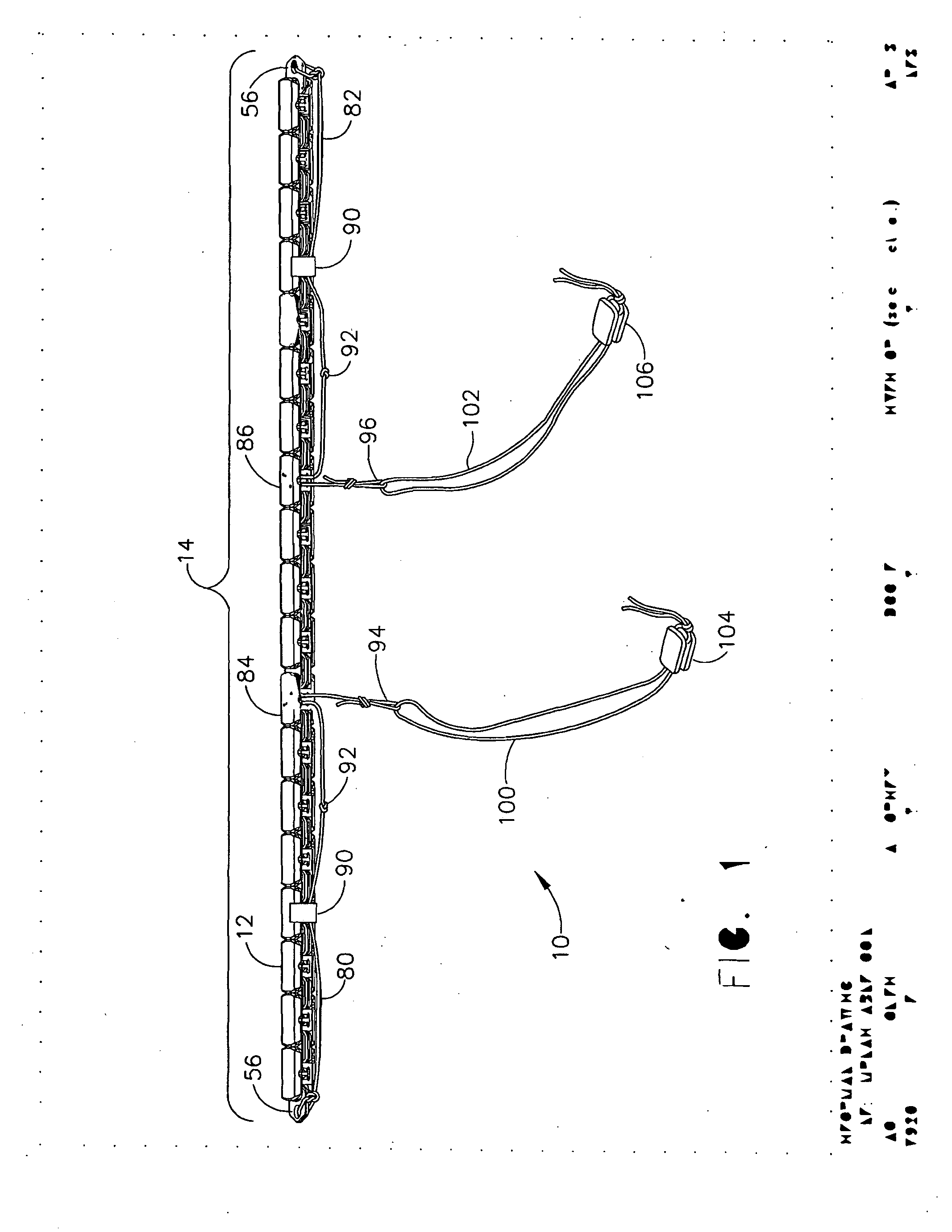

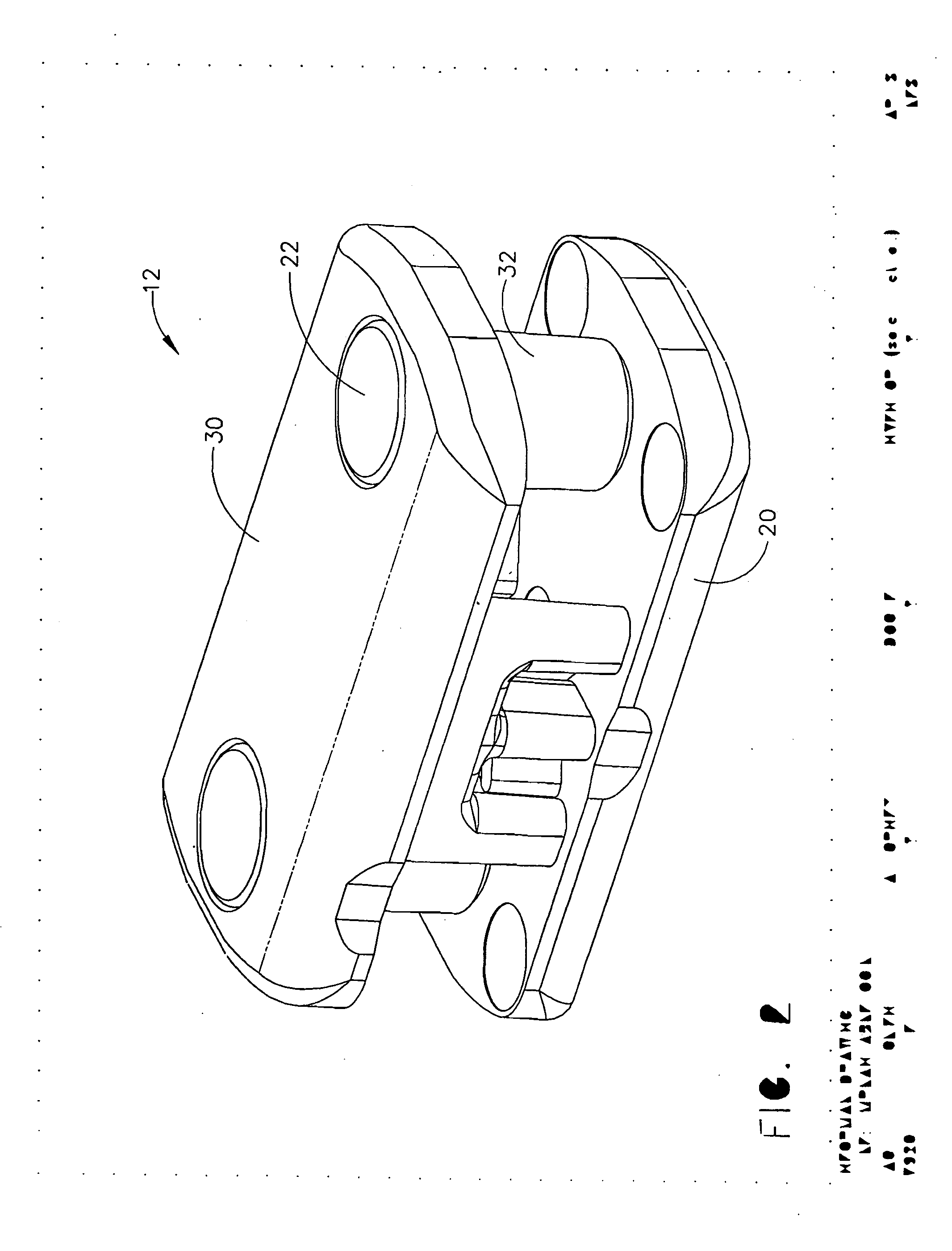

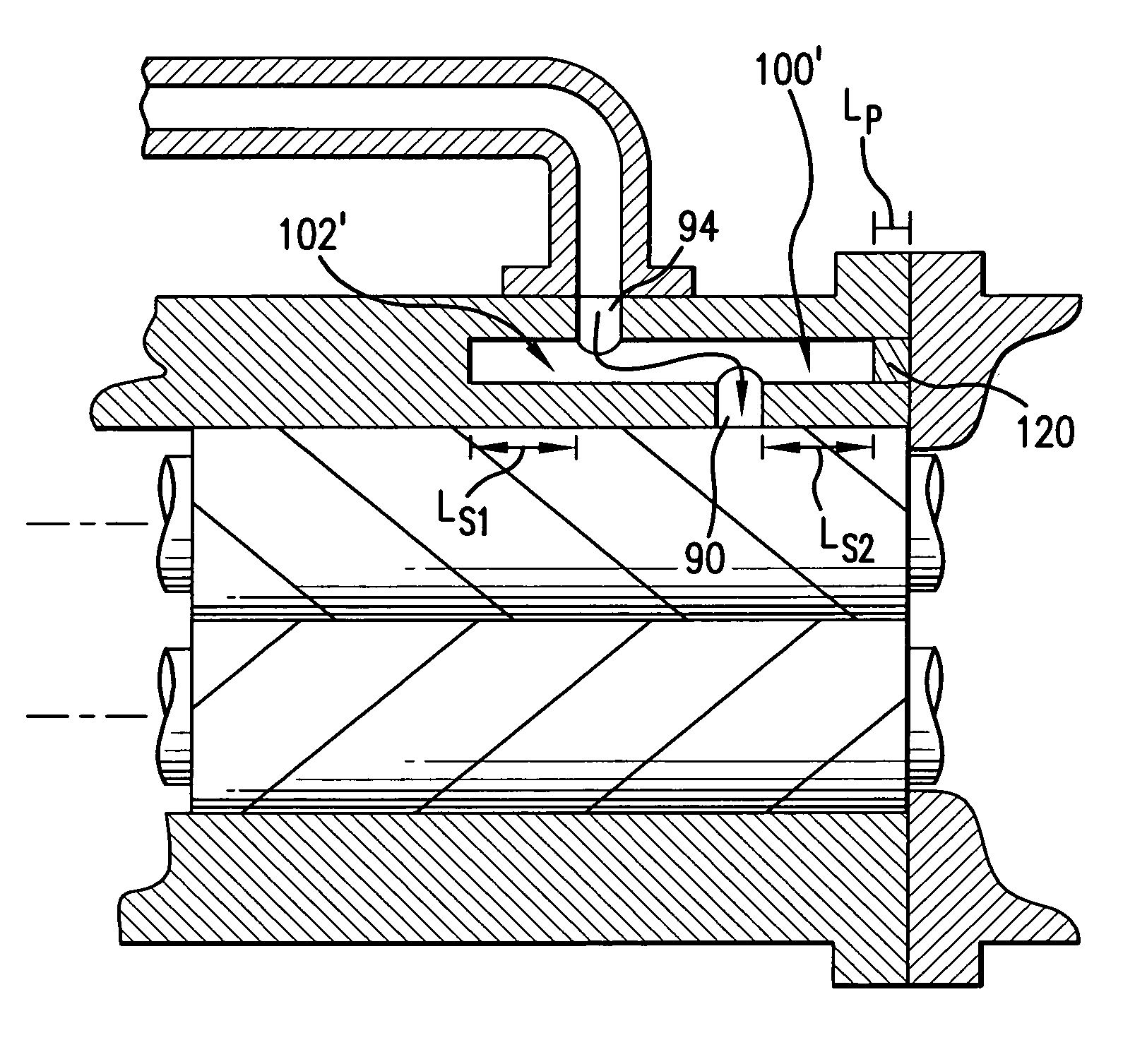

Methods, instruments and systems are provided for separating opposite walls of the stomach by extragastric application of suction. Plication of the stomach can be performed between the separated walls after which the separate walls are brought back toward one another. In another aspect, methods, instruments, devices and systems are provided for reducing the effective volume of a stomach by performing one or more extragastric plications of the stomach.

Owner:VIBRYNT

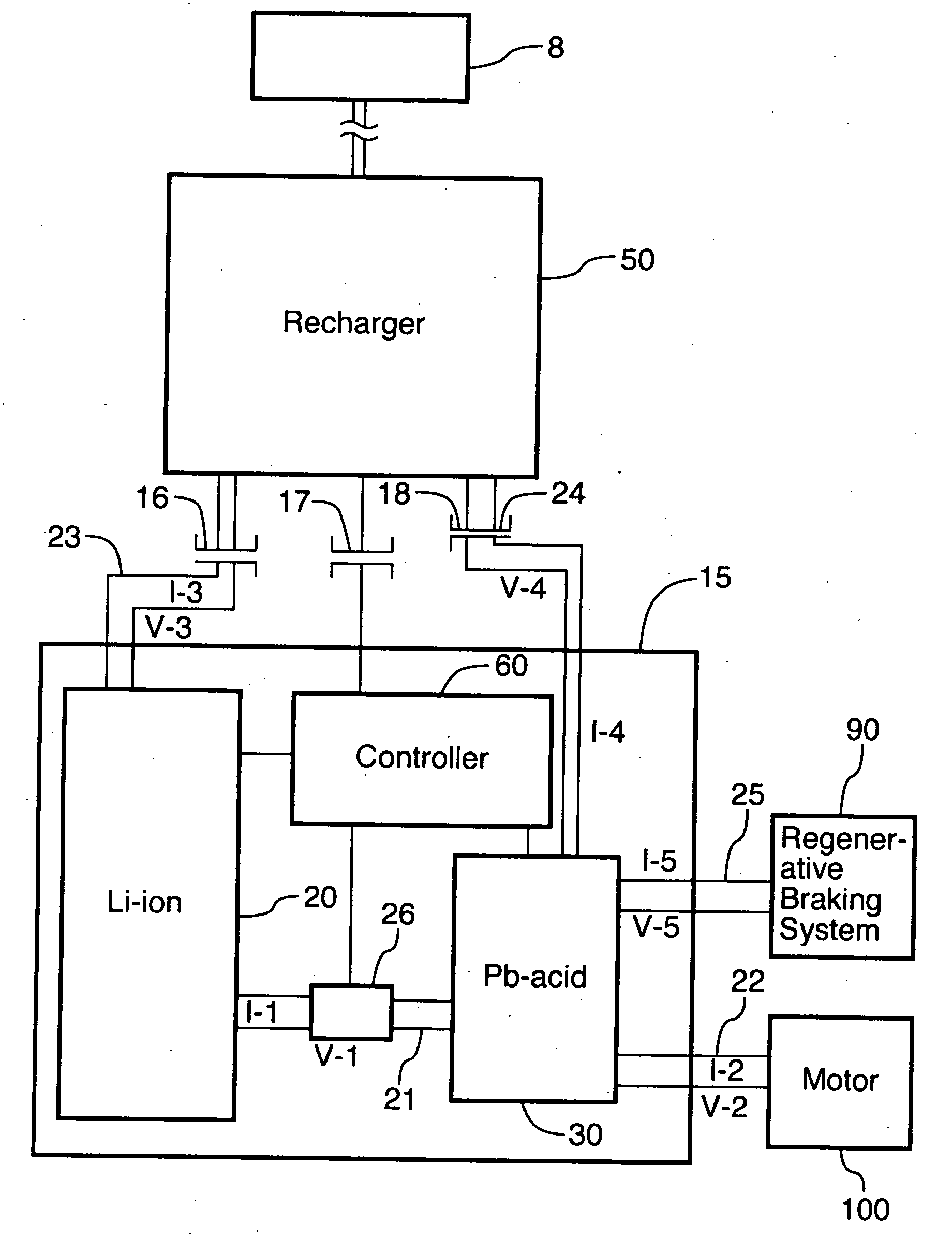

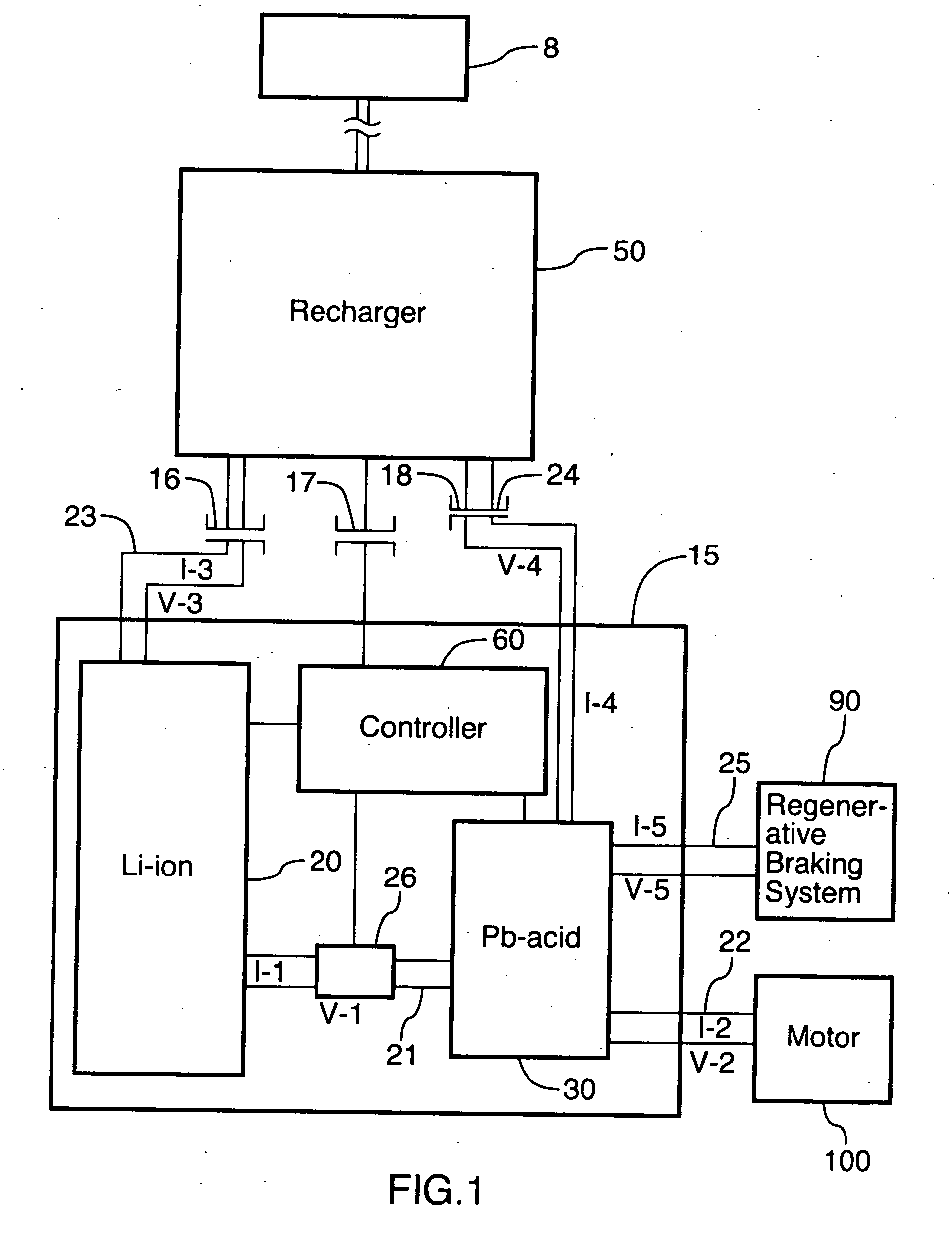

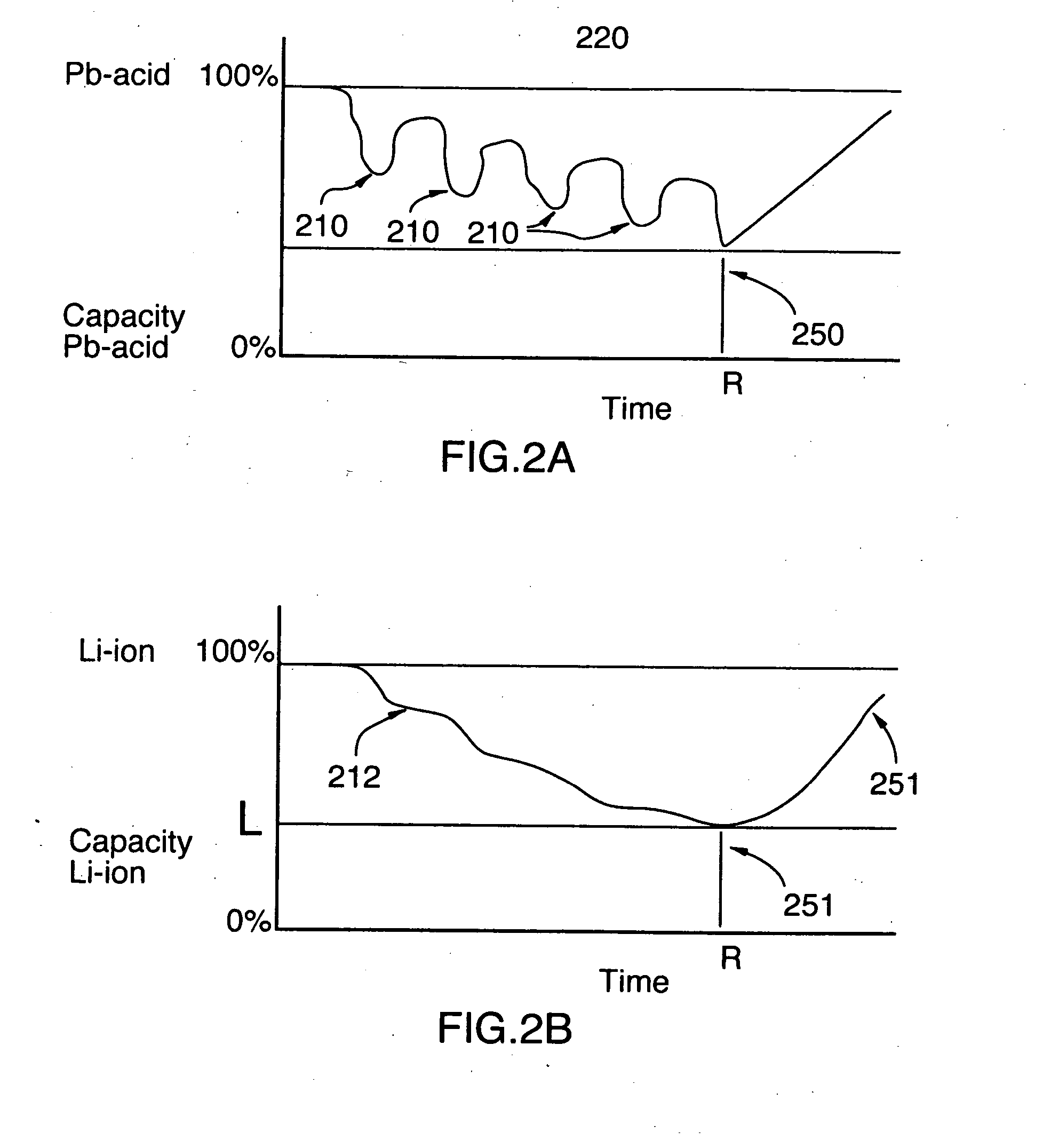

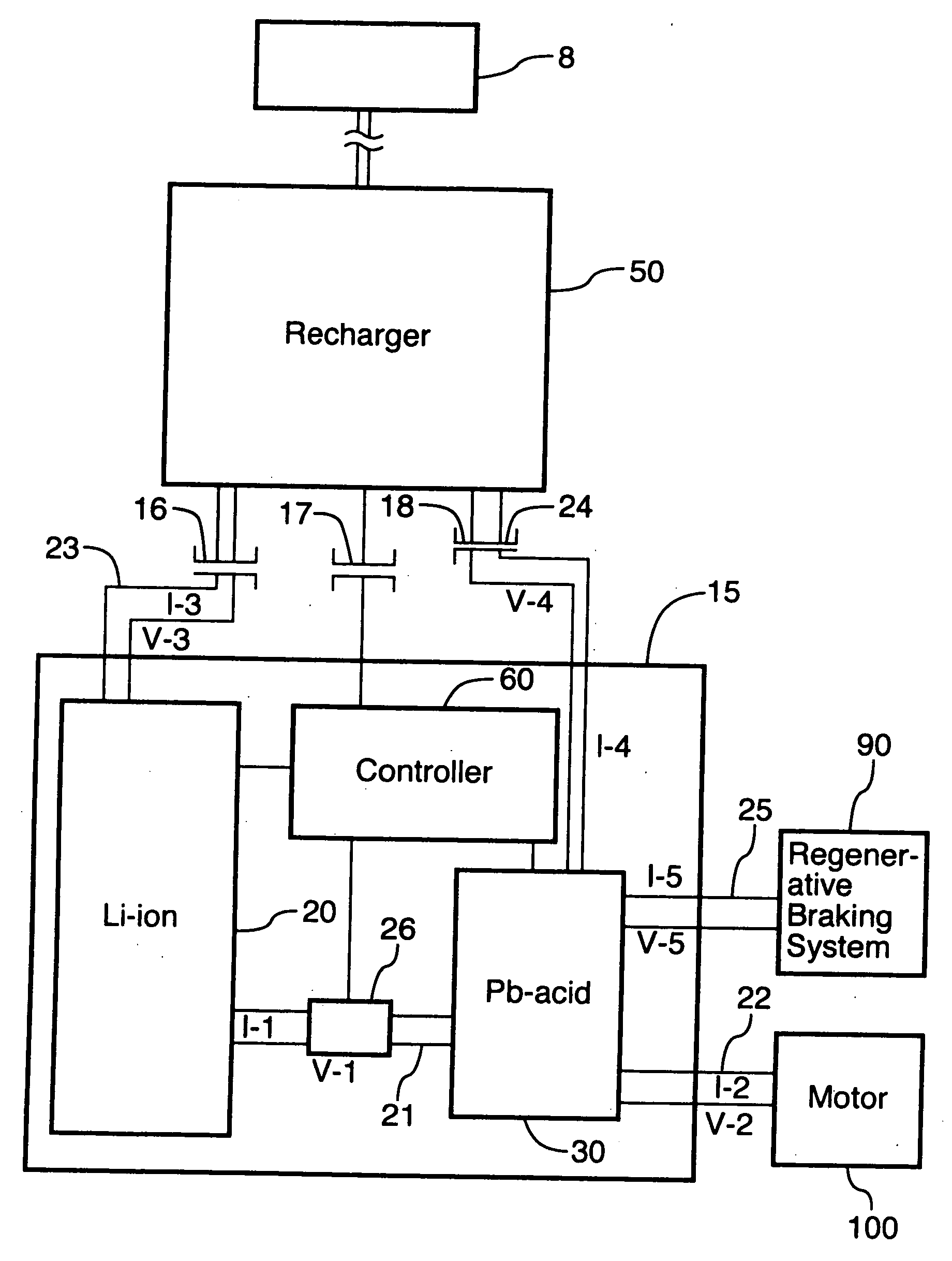

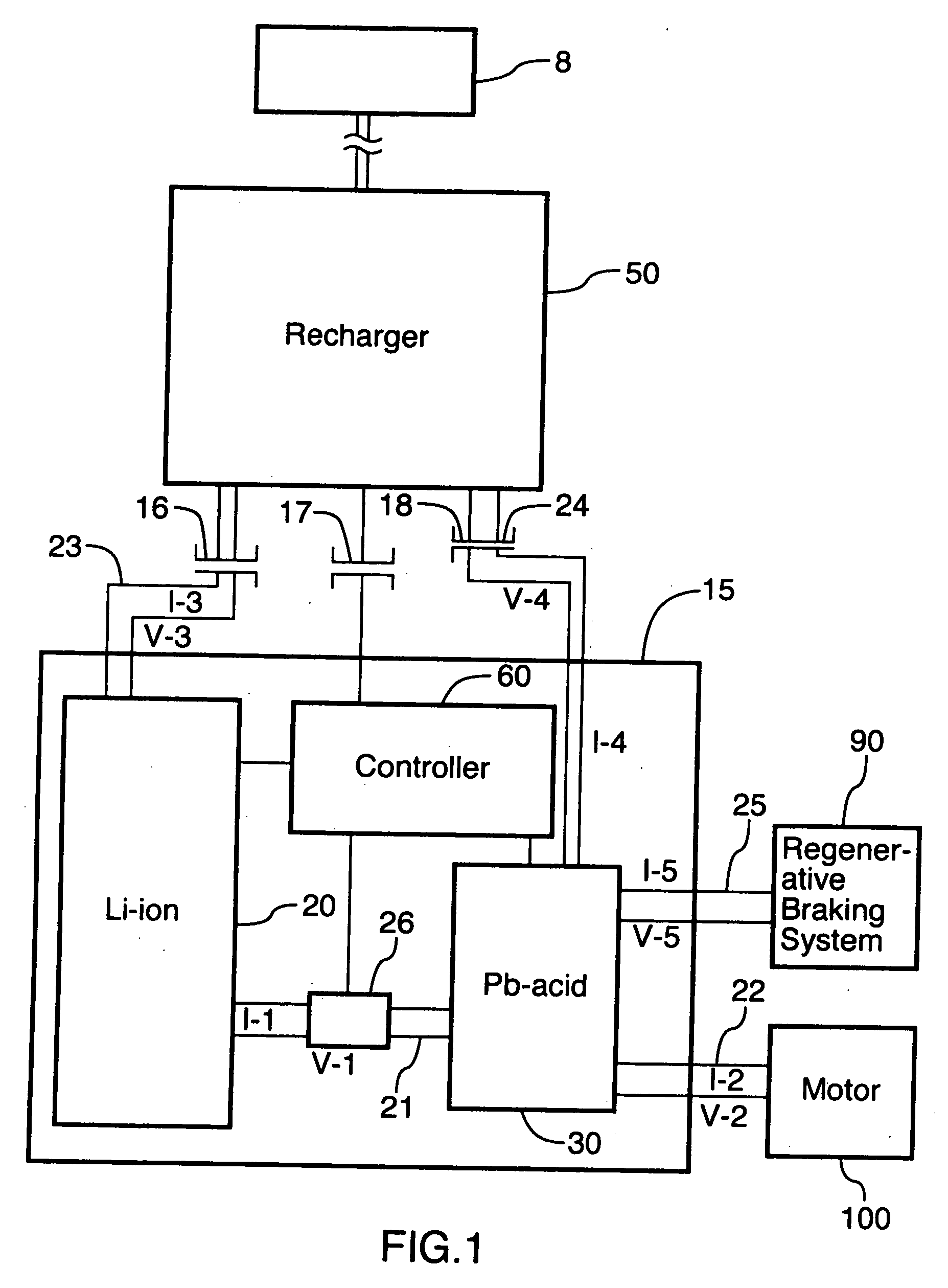

Energy storage device for loads having variabl power rates

InactiveUS20080111508A1Increase energy densityExtend your lifePrimary cell to battery groupingCells structural combinationHigh energyDrive motor

An electrical energy storage device for storing electrical energy and supplying the electrical energy to a driving motor at different power levels is disclosed. The electrical storage device has an energy battery connected to a power battery. The energy battery has a higher energy density than the power battery. However, the power battery can provide electrical power to the electrical motor at different power rates, thereby ensuring that the motor has sufficient power and current when needed. The power battery can be recharged by the energy storage battery. In this way, the power battery temporarily stores electrical energy received from the energy battery and both batteries can provide electrical energy at the different power rates as required by the motor. The energy storage device can be releasably connected to an external power source in order to recharge both batteries. Both batteries can be recharged independently to optimize the recharging and lifetime characteristics of the batteries.

Owner:ELECTROVAYA

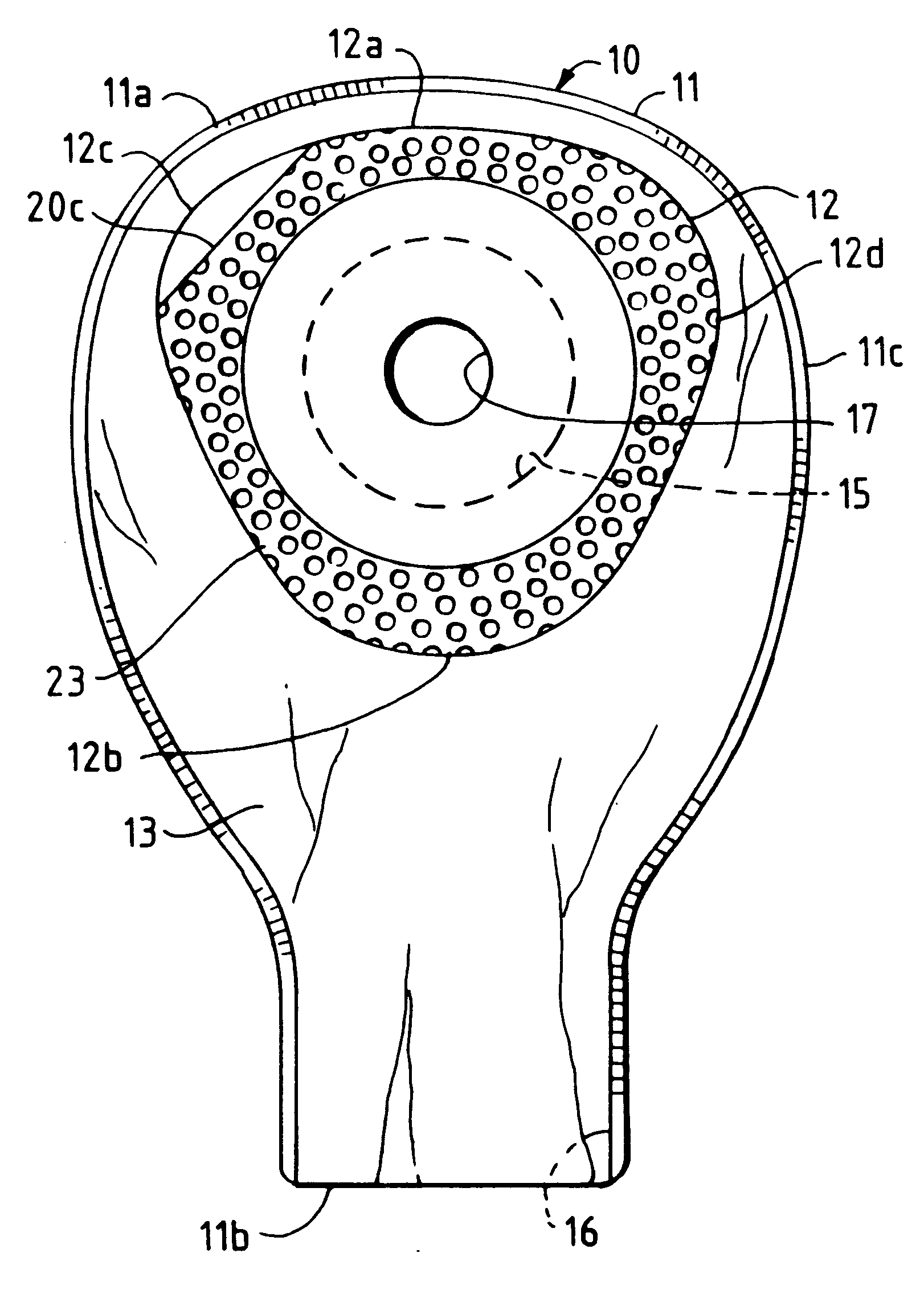

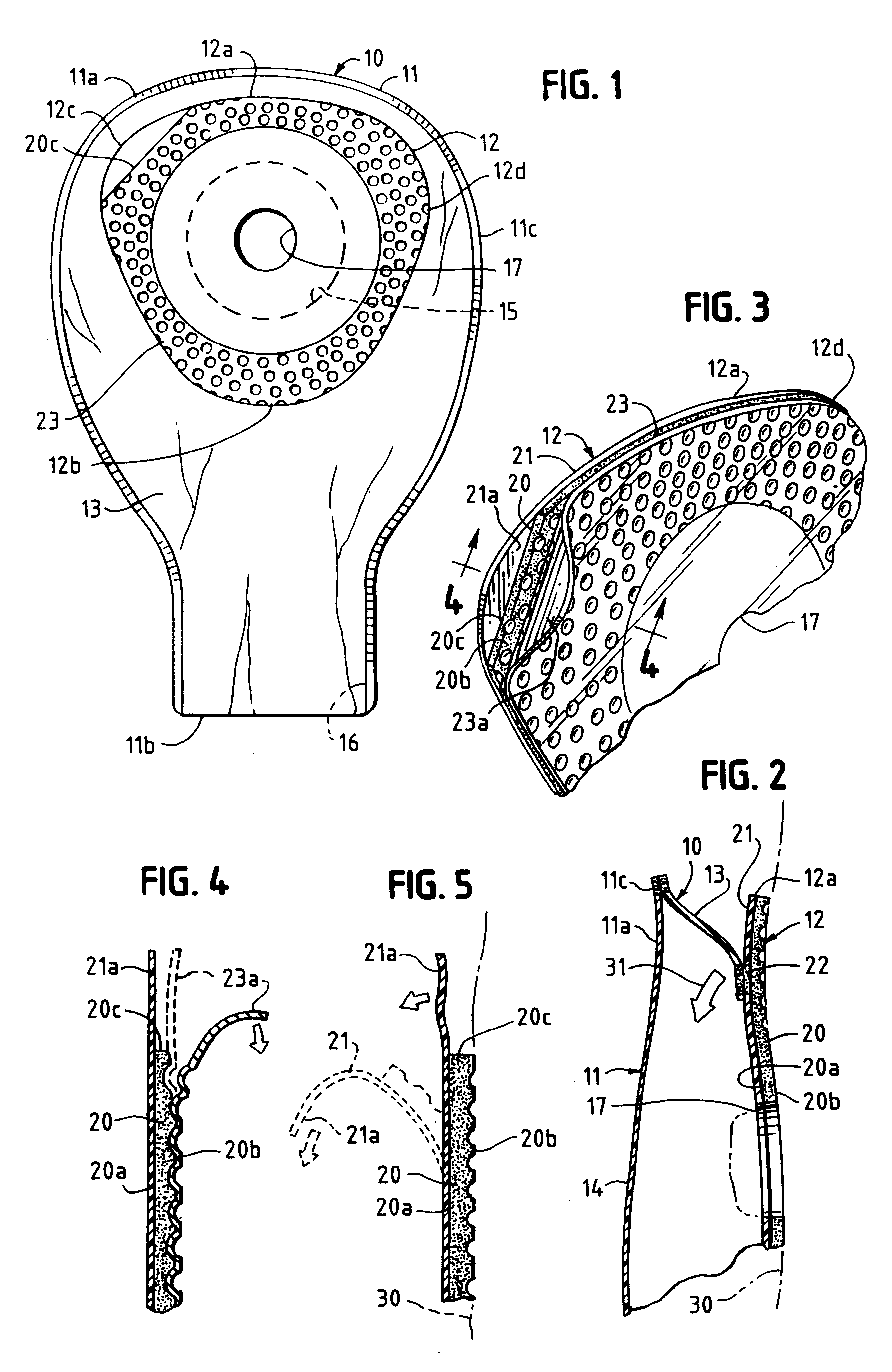

Ostomy appliance with inverted triangular faceplate and non-protruding pull tabs

InactiveUS6206864B1Reduces effective volumetric capacityEasy accessNon-surgical orthopedic devicesColostomyPressure sensitiveOstomy appliances

An ostomy appliance is disclosed in which the adhesive faceplate for holding the appliance in place is of inverted triangular shape with rounded corners. The faceplate includes an adhesive layer composed of a hydrocolloid-containing pressure-sensitive adhesive, a protective release sheet removably covering the bodyside surface of the adhesive layer, and a flexible backing layer covering the opposite (pouchside) surface of the adhesive layer and permanently securing the faceplate to an ostomy pouch about the perimeter of a stoma-receiving opening. Because of its orientation, the triangular faceplate has one of its side edges extending across the upper end of the pouch (i.e., facing upwardly when the pouch is worn), resulting in a construction in which the area of the faceplate's adhesive layer is wider above the faceplate's opening than below it. In a preferred embodiment, the adhesive layer is recessed or set back at one of the faceplate's upper corners to provide both the release sheet and backing layer with non-protruding tab portions that facilitate both application and removal of the appliance.

Owner:HOLLISTER INCORPORAED

Energy storage device for loads having variable power rates

InactiveUS20080113226A1Increase energy densityExtend your lifeSecondary cells charging/dischargingPropulsion by batteries/cellsPower batteryHigh energy

An electrical energy storage device for storing electrical energy and supplying the electrical energy to a driving motor at different power levels is disclosed. The electrical storage device has an energy battery connected to a power battery. The energy battery has a higher energy density than the power battery. However, the power battery can provide electrical power to the electrical motor at different power rates, thereby ensuring that the motor has sufficient power and current when needed. The power battery is continuously recharged by the energy storage battery. In this way, the power battery temporarily stores electrical energy received from the energy battery and provides the electrical energy at the different power rates as required by the motor. The energy storage device can be releasably connected to an external power source in order to recharge both batteries. Both batteries can be recharged independently to optimize the recharging and lifetime characteristics of the batteries.

Owner:ELECTROVAYA

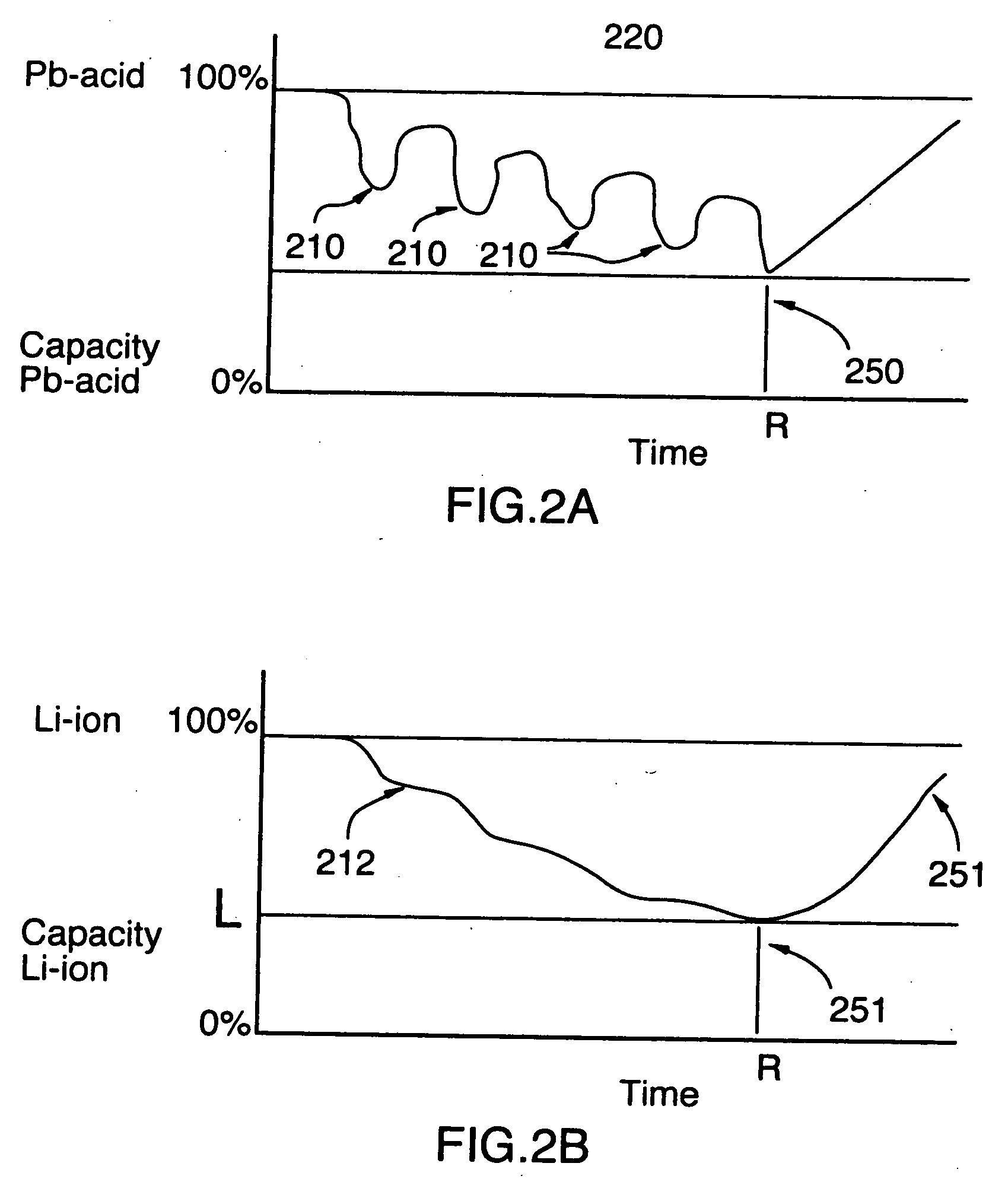

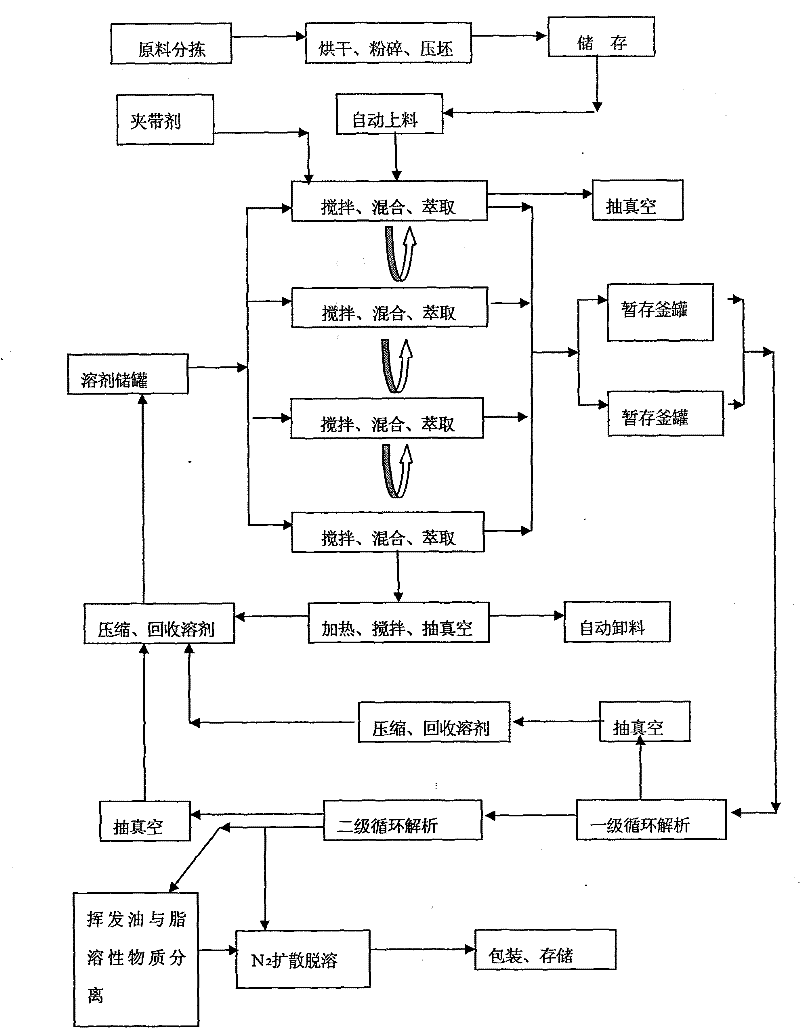

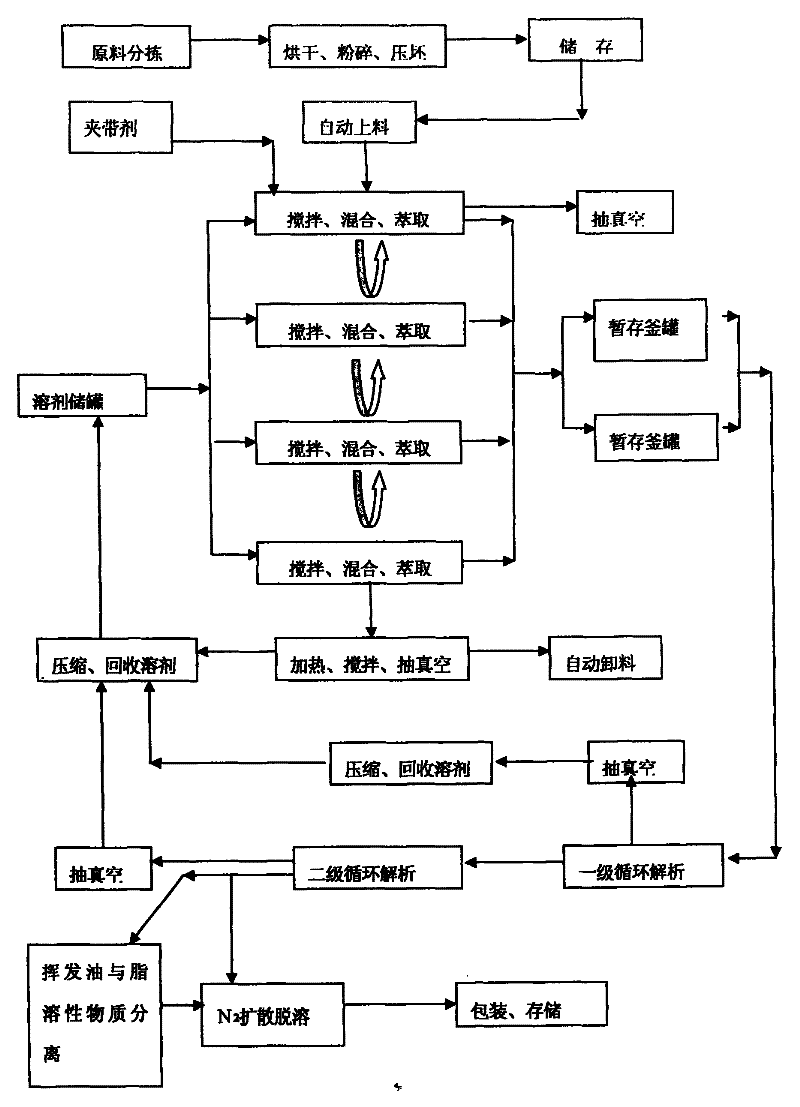

Sub-critical fluid extraction solvent and abstraction method

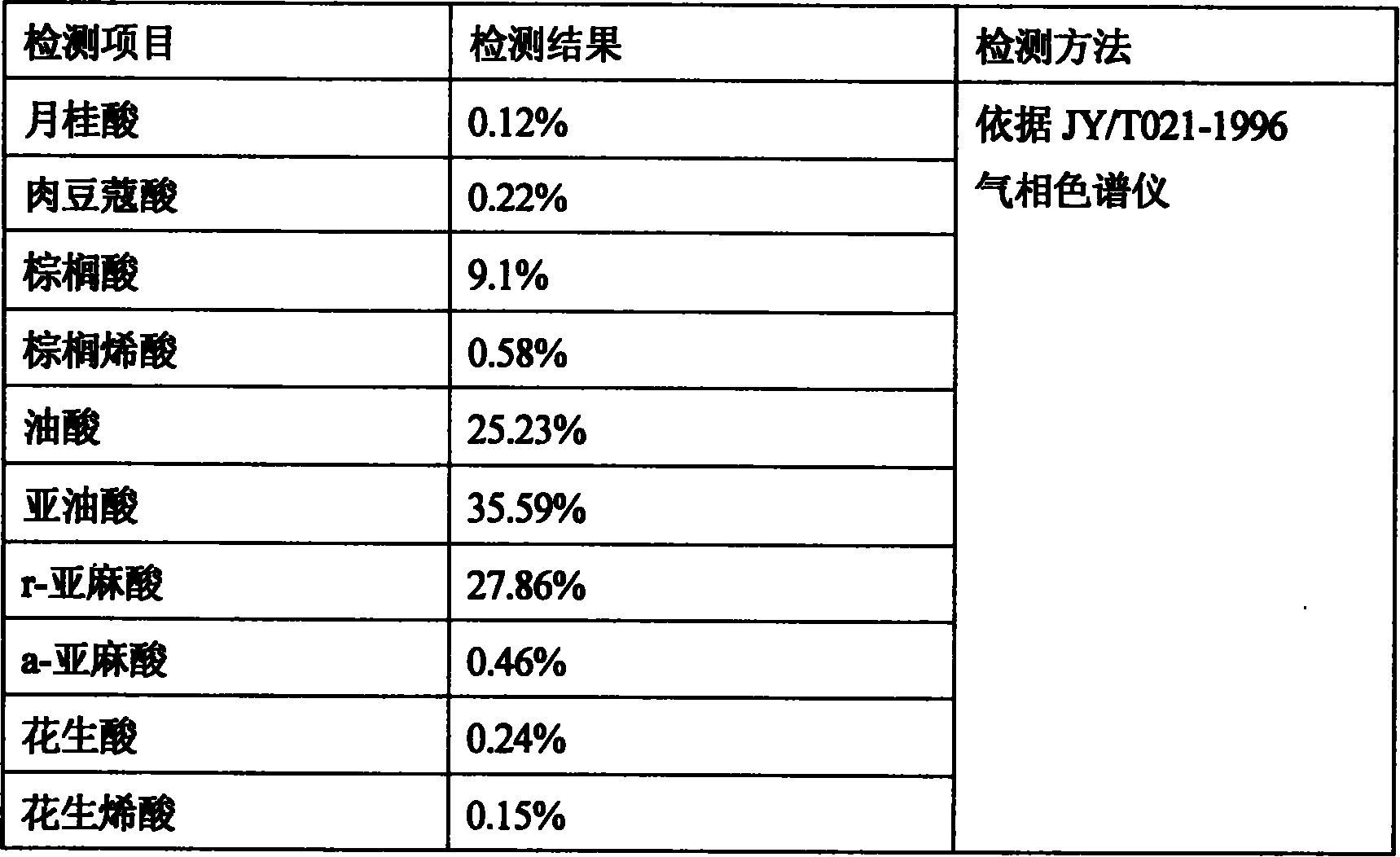

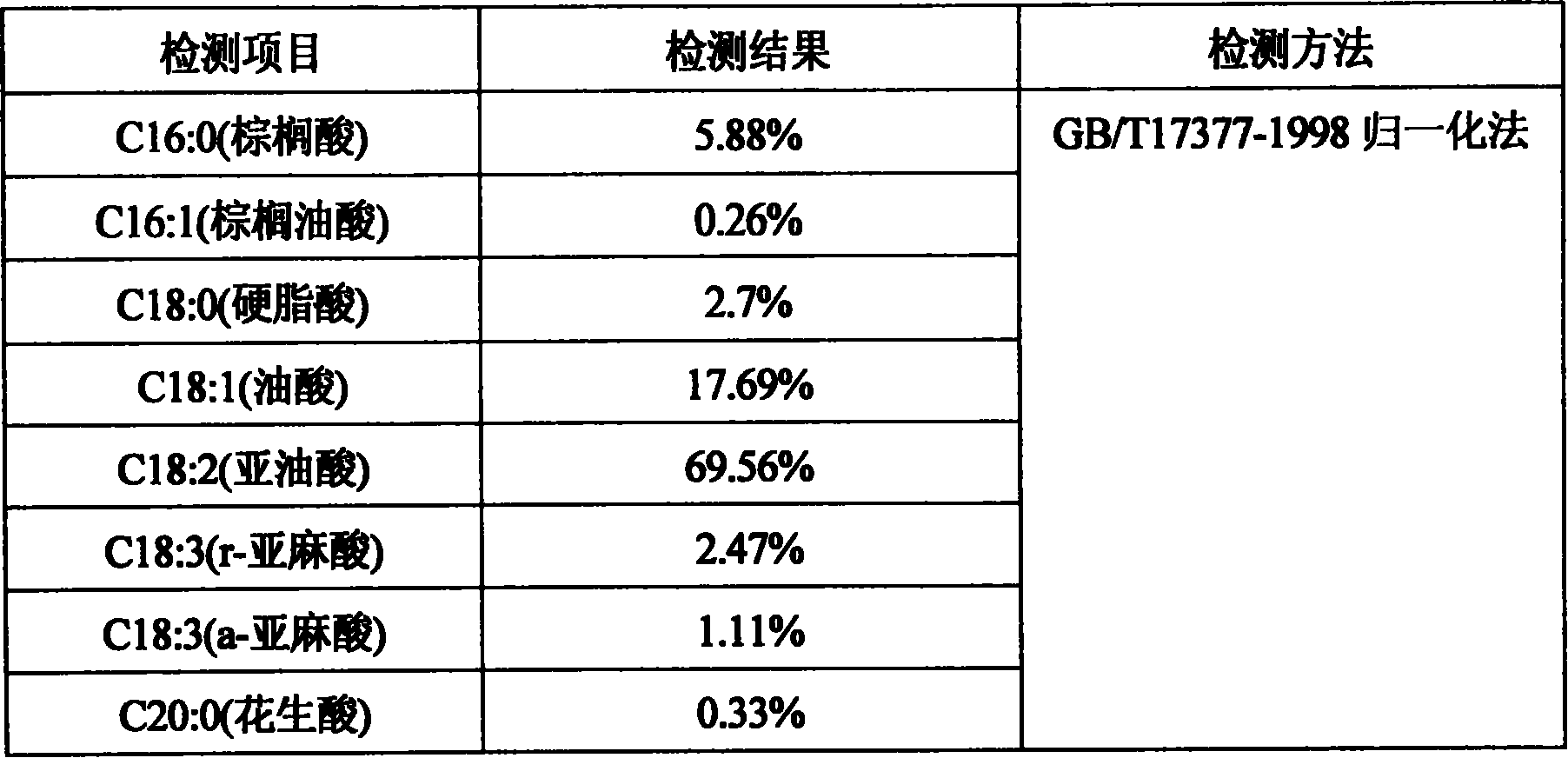

InactiveCN101161324AHigh extraction rateIncrease profitSolid solvent extractionSulfur hexafluorideAdditive ingredient

The present invention relates to a dissolvent with effective ingredient extracted from the plant-and-animal raw material and the extraction method thereof. One subcritical fluid extraction solvent includes an extraction solvent of a compound or composition extracted from the raw material containing compound or composition as component element, and the solvent is mainly characterized in that the liquid sulfur hexafluoride works as the extraction solvent. The invention also includes a method for extracting the subcritical fluid extraction solvent. The advantage of the invention is that the extraction and separation of the target component in the natural product are optionally executed to further increase the extraction rate of the intermediate product and the usage factor of the raw material while the unique dissolving character of the sulfur hexafluoride and the mixed solvent thereof to the liposoluble active ingredient is used. The physical features of strong dissolving capacity and low boiling point of the sulfur hexafluoride and the mixed solvent thereof are used to reduce the consumption quantity of the energy source, dissolvent of the system and the cost, and increase the market competition ability of the intermediate product.

Owner:韩延欣 +2

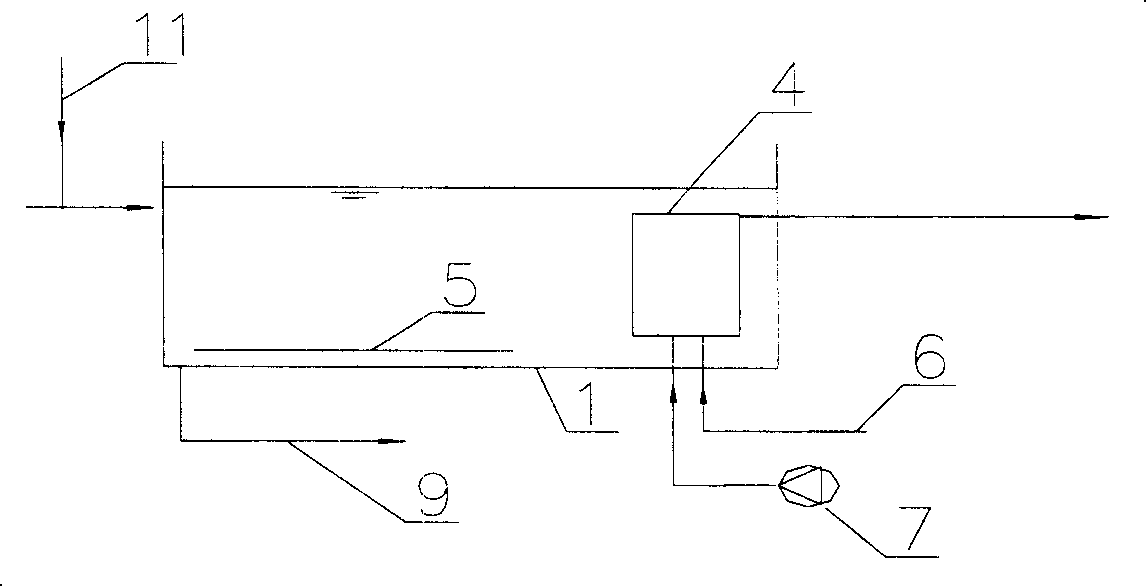

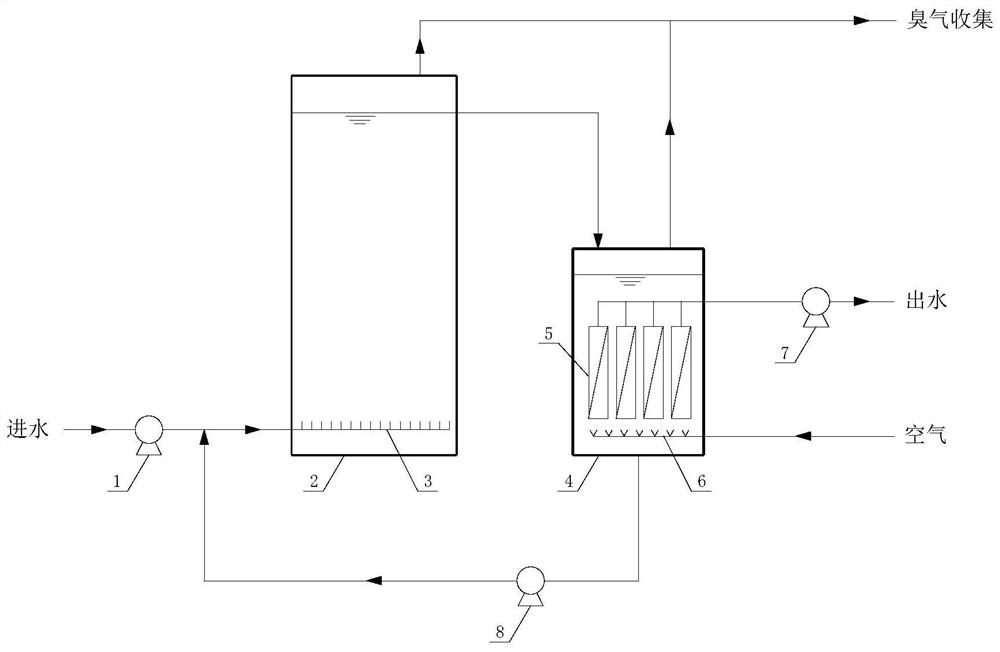

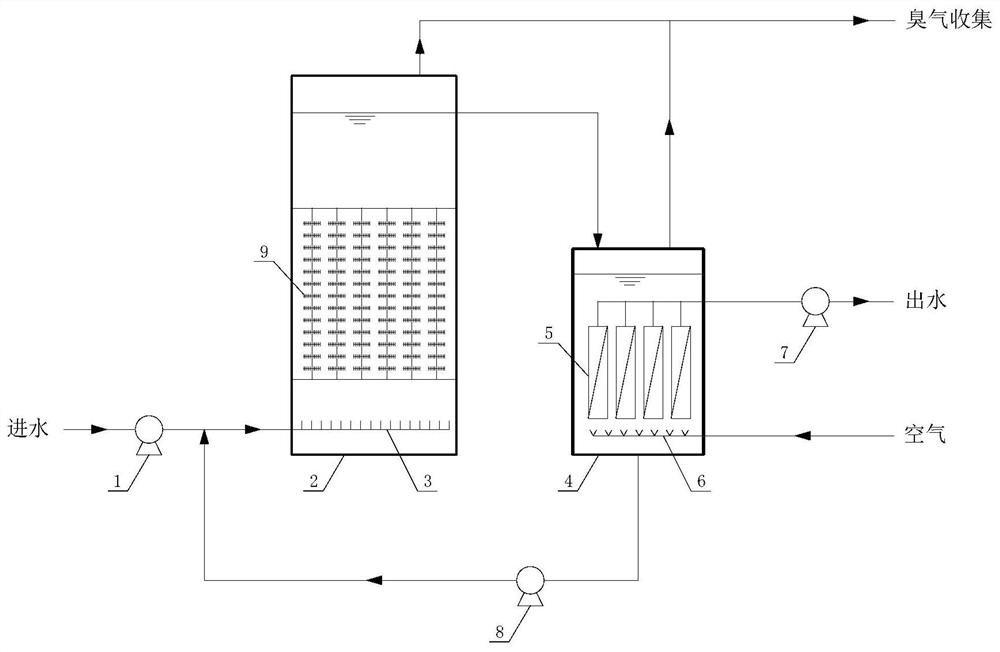

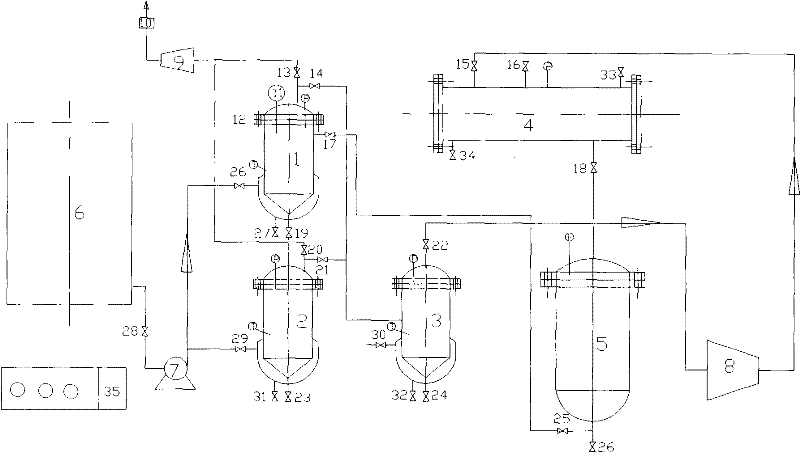

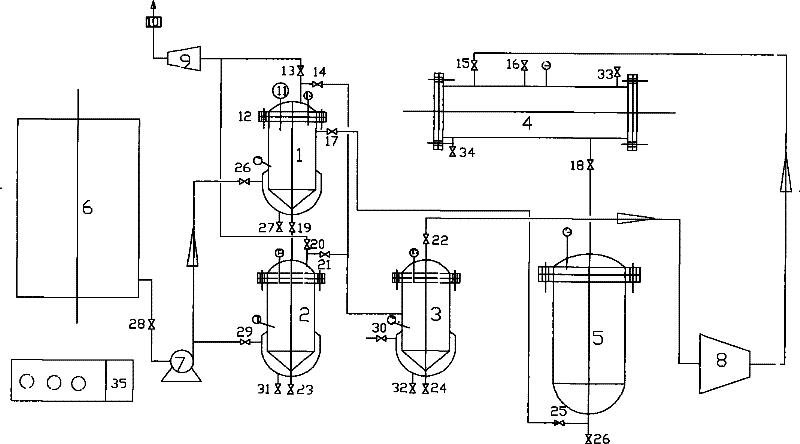

Room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and sewage treatment method

InactiveCN102531172AReduce yieldReduce aerationTreatment with aerobic and anaerobic processesChemical oxygen demandNitration

The invention provides a room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and a sewage treatment method and relates to a sewage treatment method, solving the technical problems that in the existing nitration-anaerobic ammoxidation process, occupied area is large and operation cost is high. The method comprises the following steps of: carrying out film formation with an intermittent film formation mode; introducing municipal sewage; completing the removal of COD (chemical oxygen demand) in the outer barrel and generating a small amount of NO2<-1>-N; and introducing mixed sludge subjected to nitrosation and anaerobic ammoxidation into the outer barrel so as to realize nitrosation-anaerobic ammoxidation coupling symbiotic denitrification. According to the invention, a continuous operation mode is adopted for the device; the device is small in occupied area, and the effective volume of a structure is reduced; and the device is simple and convenient in management, high in treatment efficiency, low in operation cost and the like, and specifically aims at domestic sewage having the characteristics of low substrate concentration and large water yield.

Owner:NORTHEAST FORESTRY UNIVERSITY

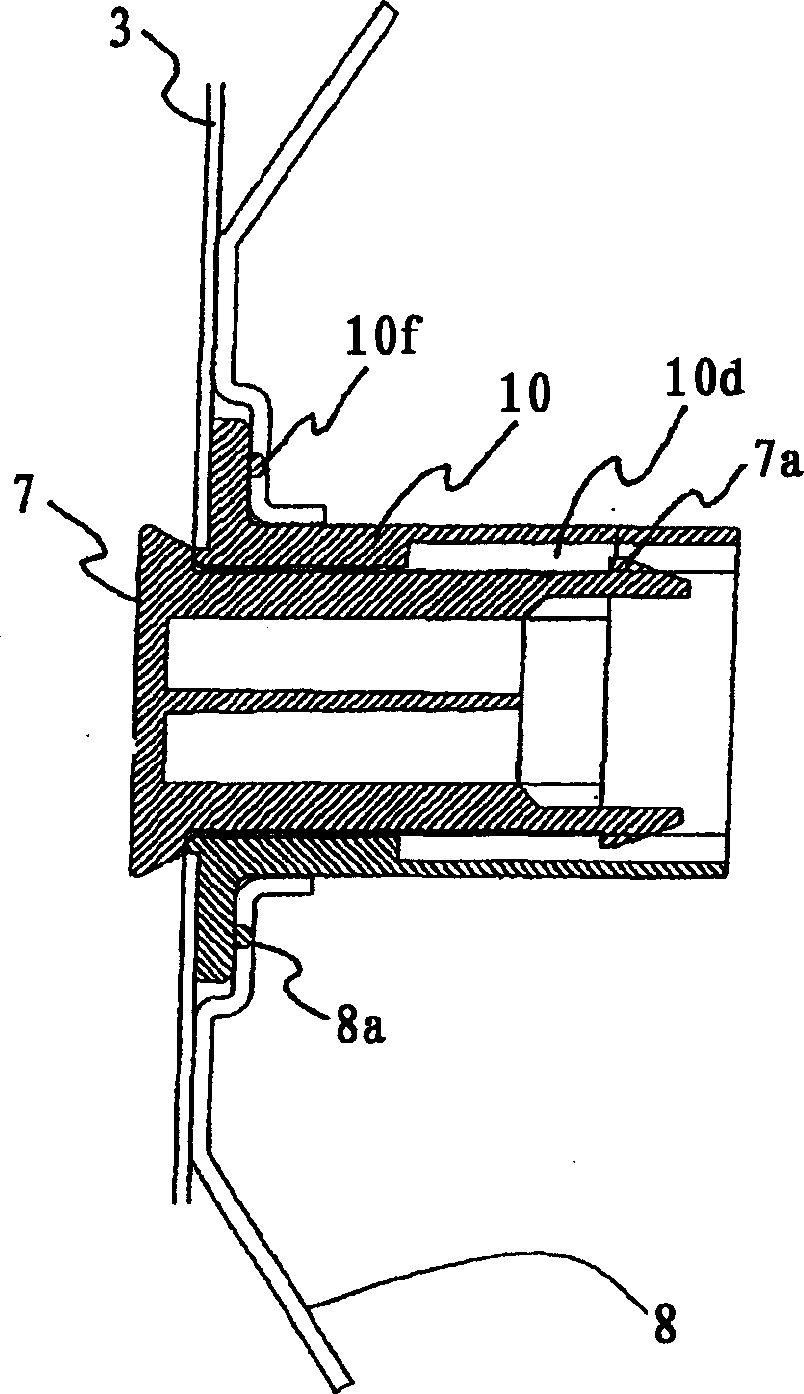

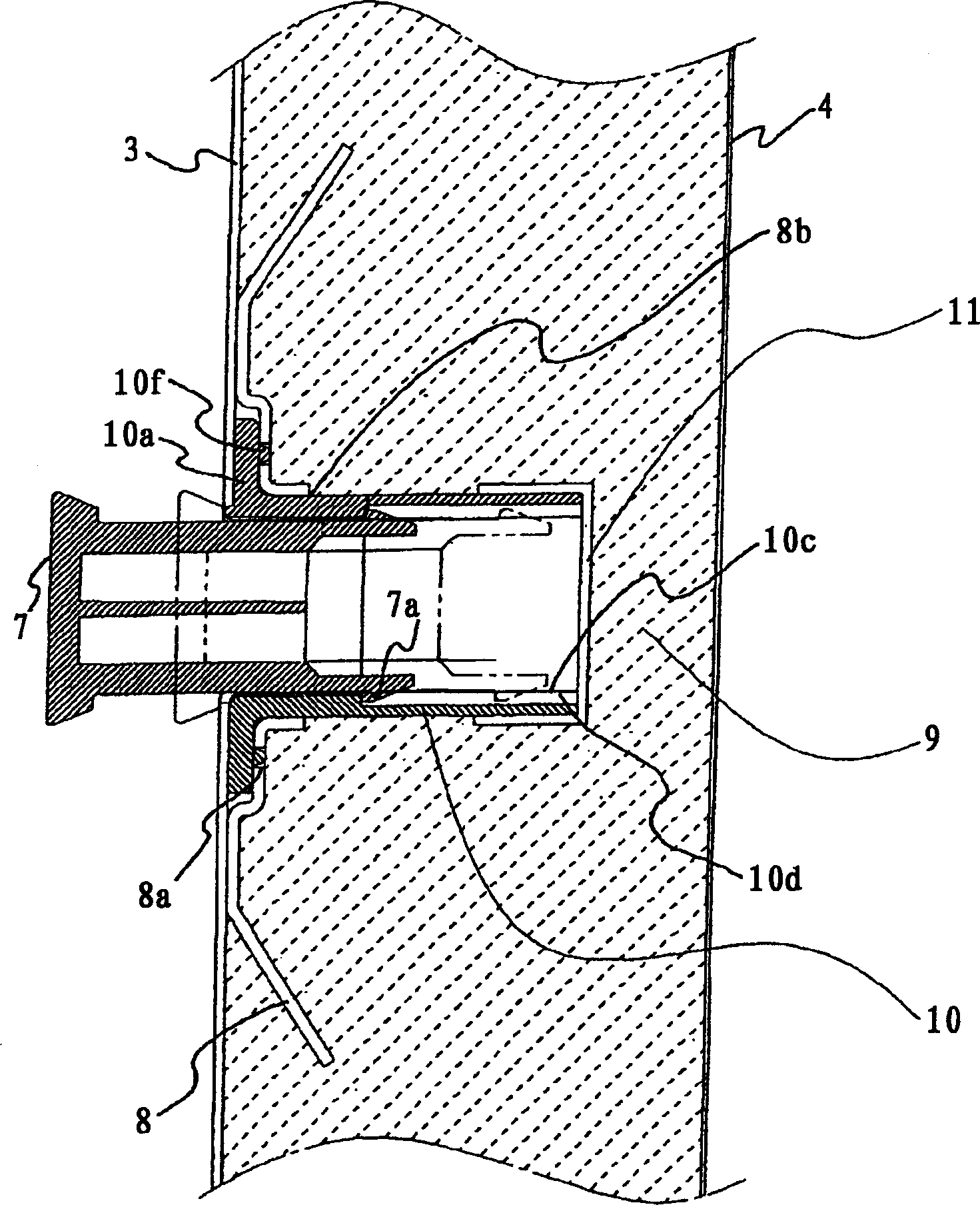

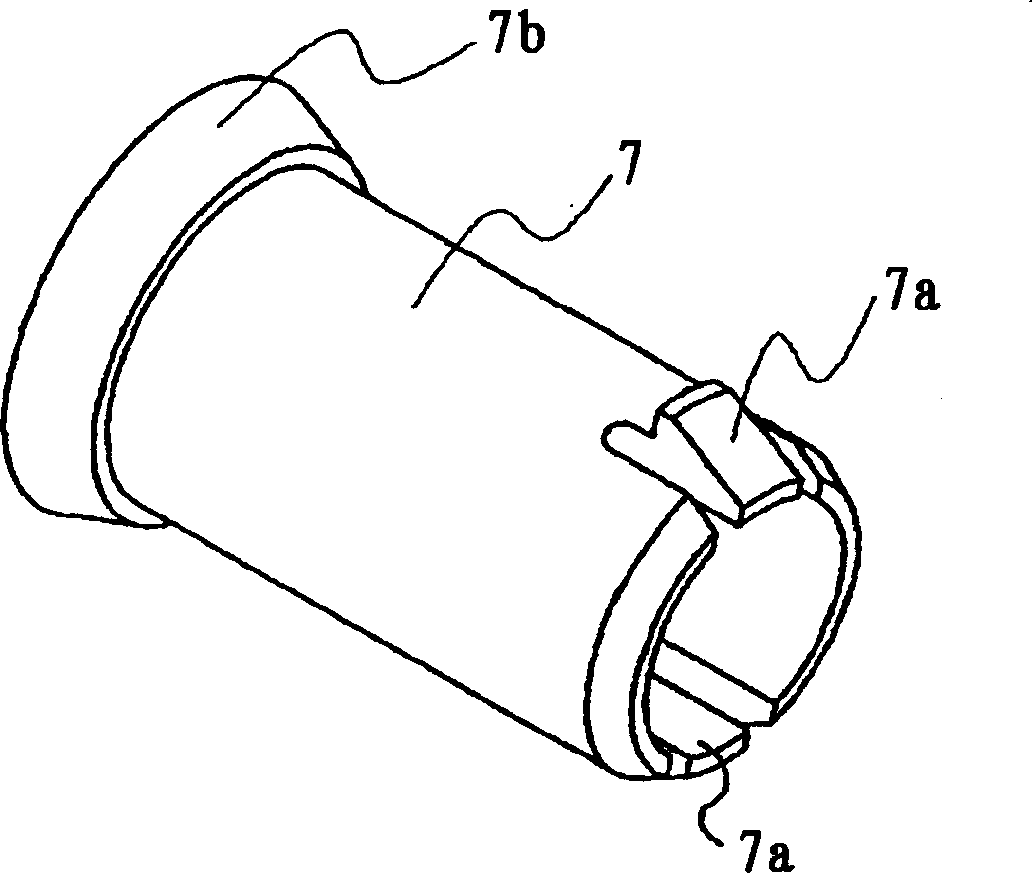

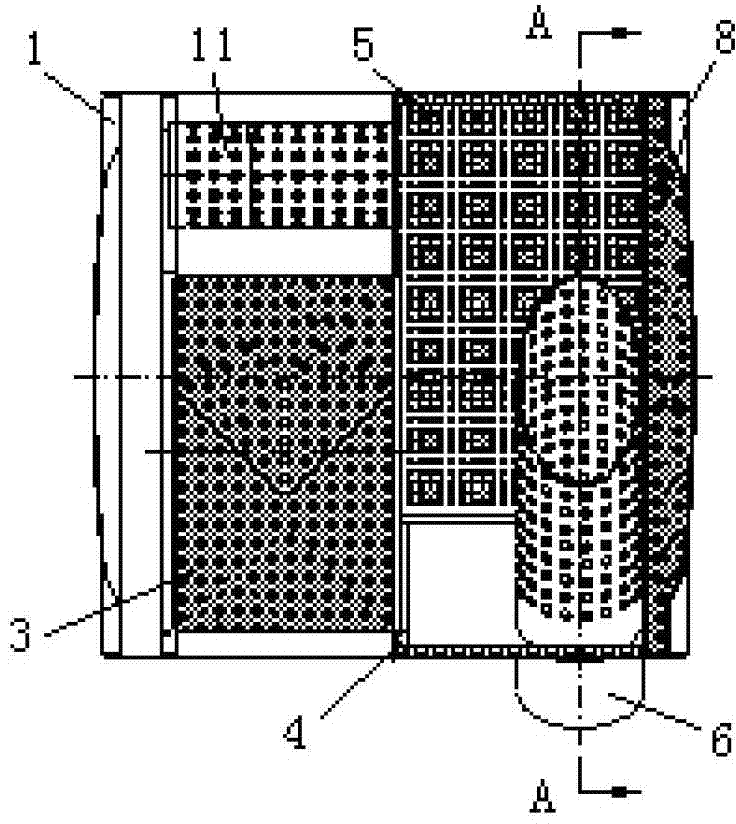

Implantable device for the treatment of obesity

InactiveUS20090326433A1Reduce the effective volumeLower the volumeElectrotherapySurgeryBody organsObesity

A method for placing an implant within a hollow body organ by providing a member with distal and proximal ends. The member has at least one tensioning tether with a first end attached to at least one of the distal and proximal end and a second ends attached to the member between the distal and proximal ends. The step includes moving the member towards the deployed shape by applying tension to the tether.

Owner:ETHICON ENDO SURGERY INC

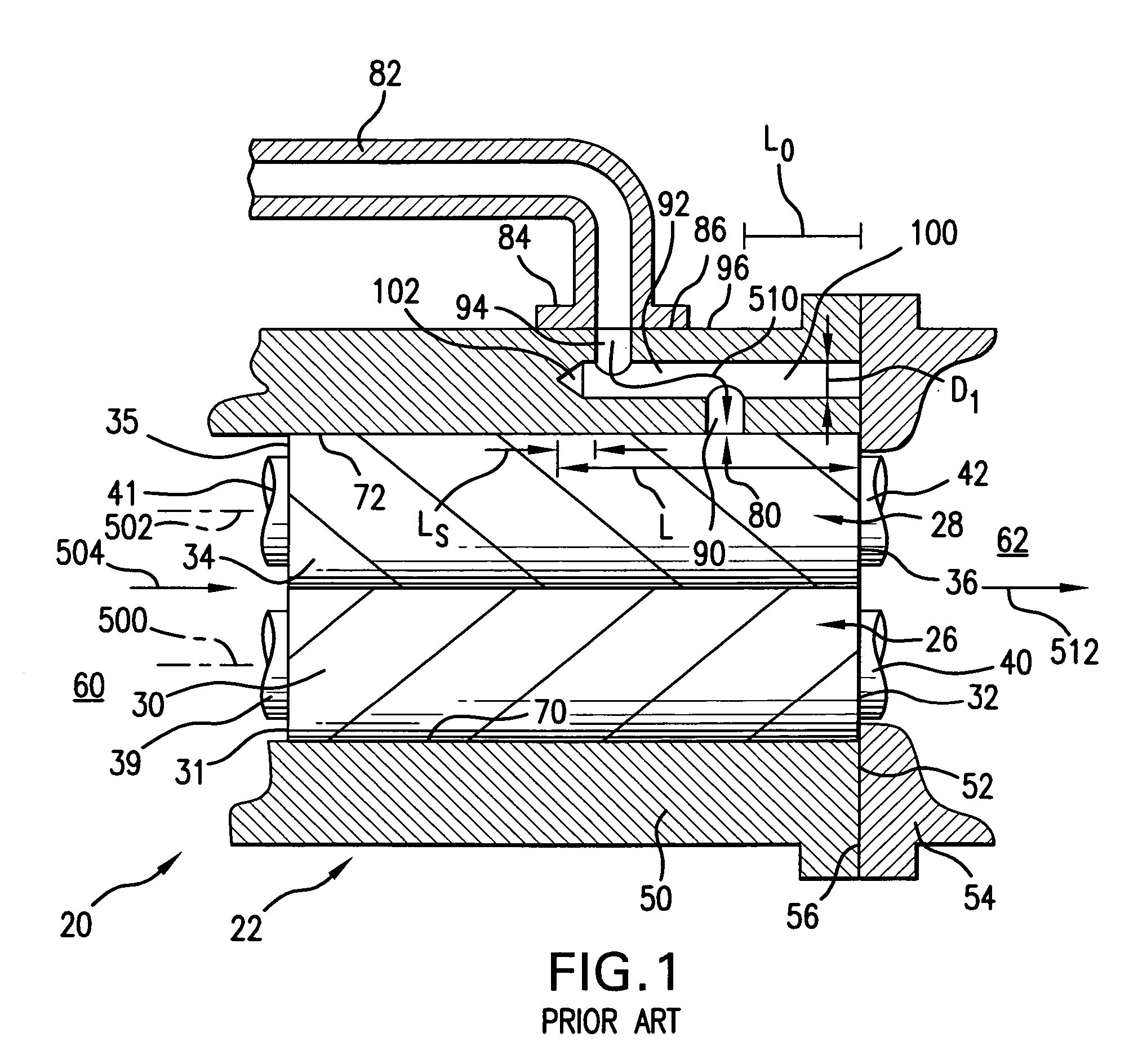

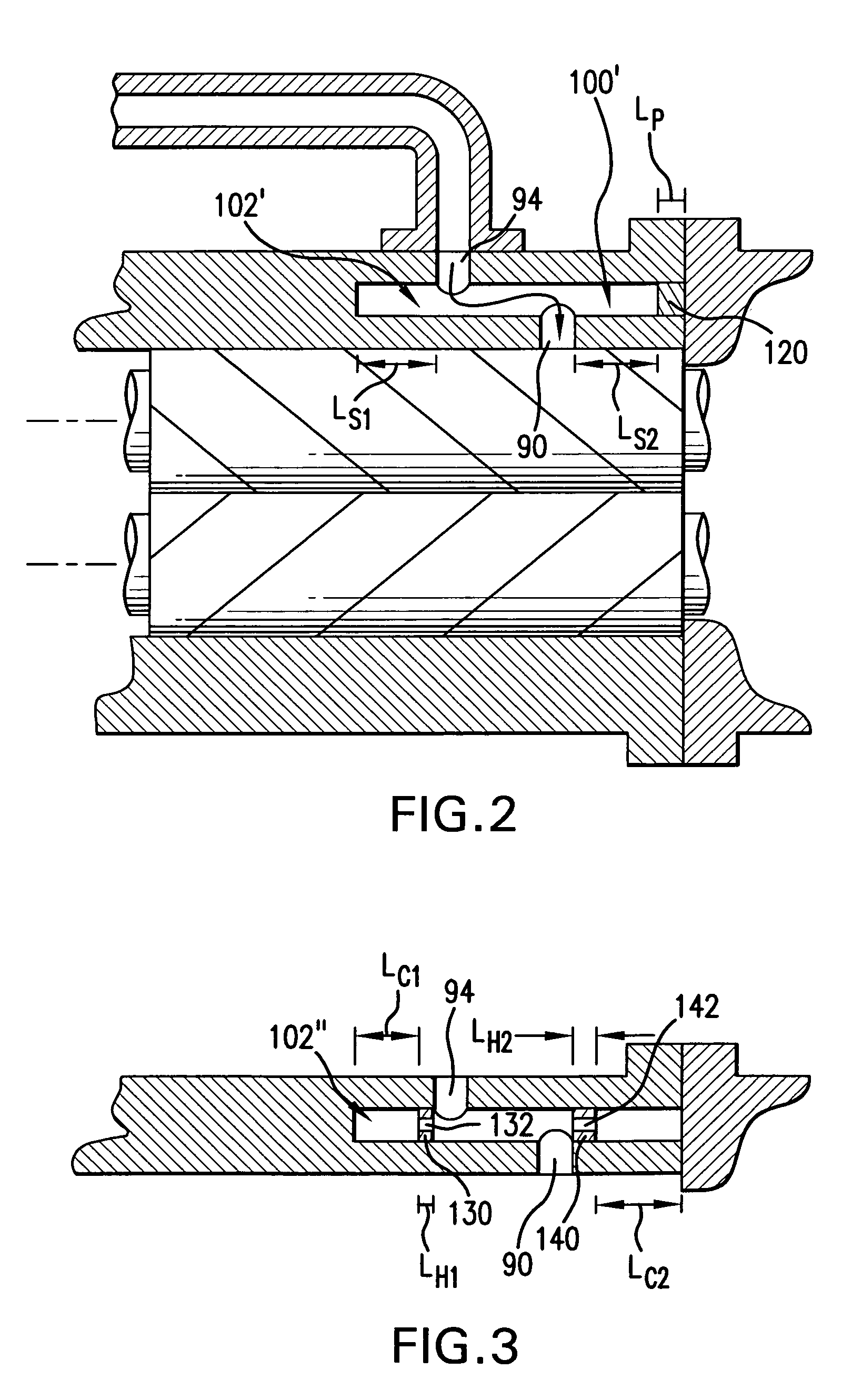

Compressor sound suppression

ActiveUS20060127235A1Reduce the effective volumeReduce volumePump testingPositive displacement pump componentsDischarge locationElectrical and Electronics engineering

A compressor has a housing. One or more working elements cooperate with the housing to define a compression path between suction and discharge locations. An intermediate port is located along the compression path. A branch path extends to the intermediate port. The compressor includes means for limiting pressure pulsations along the branch path.

Owner:CARRIER CORP

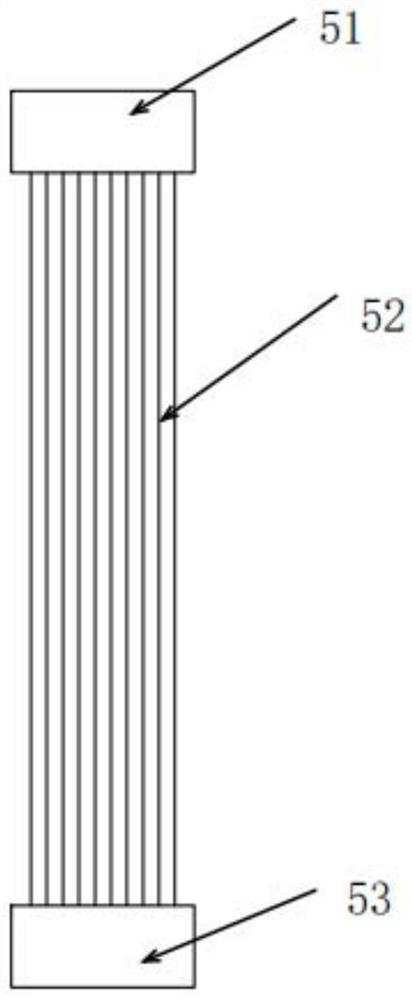

Sewage denitrogenation dephosphorylation treatment method by using biological film to filter

InactiveCN101168461ALow costEasy to operateSustainable biological treatmentBiological water/sewage treatmentSludgePhosphor

The invention relates to a sewage denitrification dephosphorization treatment method which uses biologic film to filter, wherein the invention arranges a biologic film filter in an aeration tank, which uses stainless steel or filter cloth as screen to replace traditional two deposit tanks to separate sludge and water. The invention is characterized in that the average aperture of stainless steel or filter cloth screen of the biologic film filter is 10-200mum, the screen is arranged with a biologic film to stop active sludge, the water flux at unit screen can reach more than 100l / h.m2, the highest filter resistance is controlled under 0.5m, the sludge of aeration tank can reach at least 2-3 times of general one, and the phosphor in the outlet water filtered by the biologic film filter is flocculated and deposited to reach denitrification and dephosphorization demands, the resistance of biologic filter is increased when serves some time, while the water flux is reduced, and the biologic film filter can come back to normal running after being blown reversely and washed reversely via a water pump.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

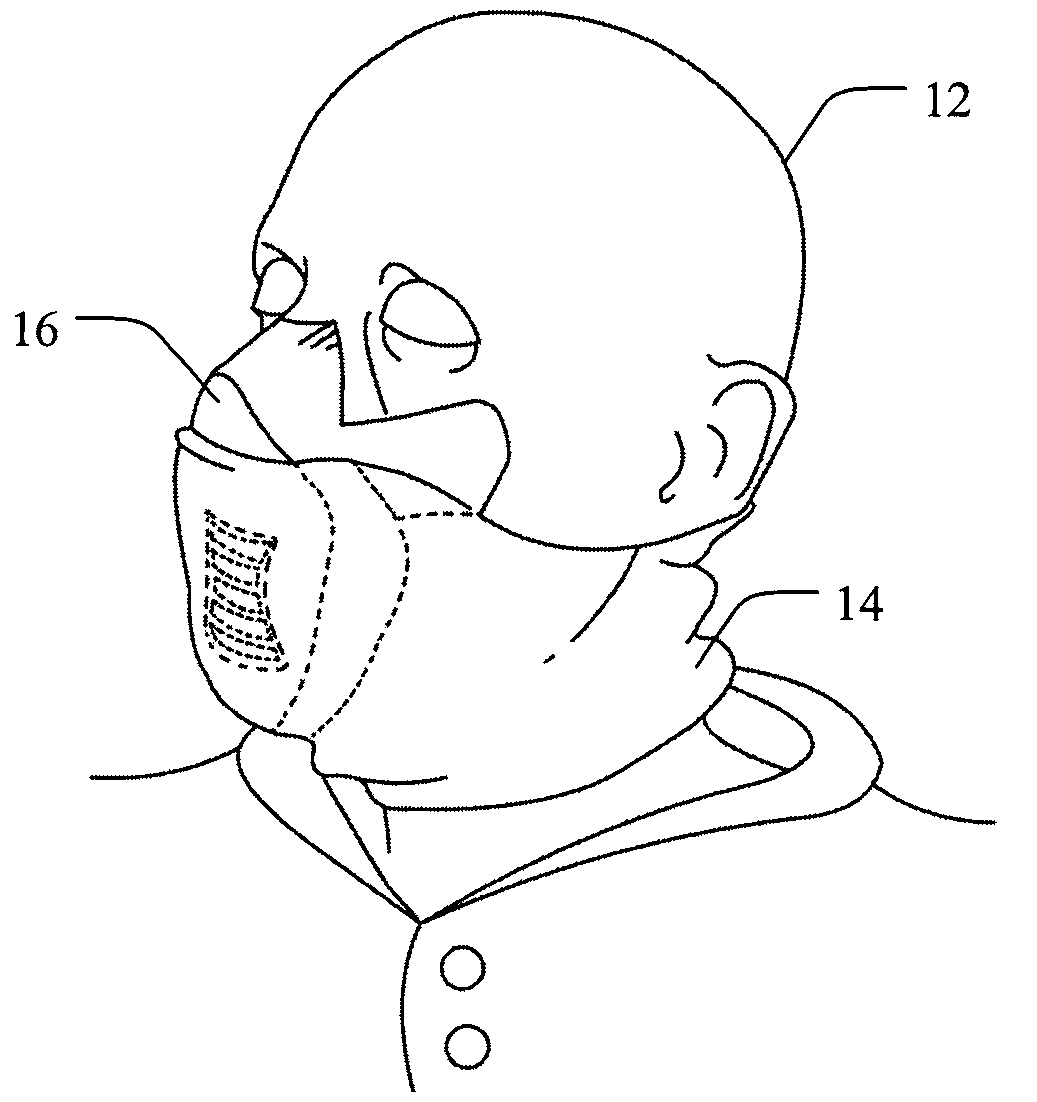

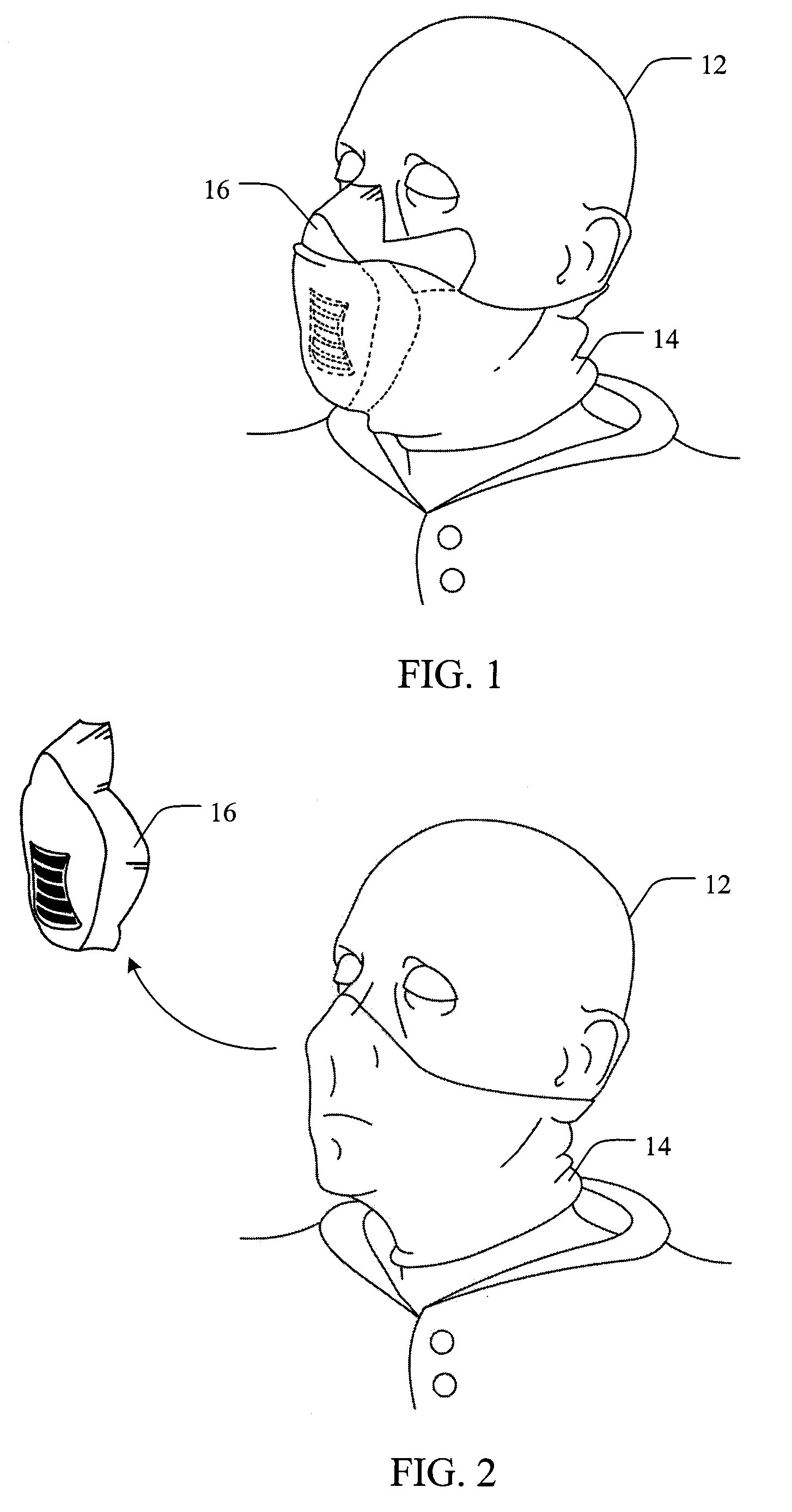

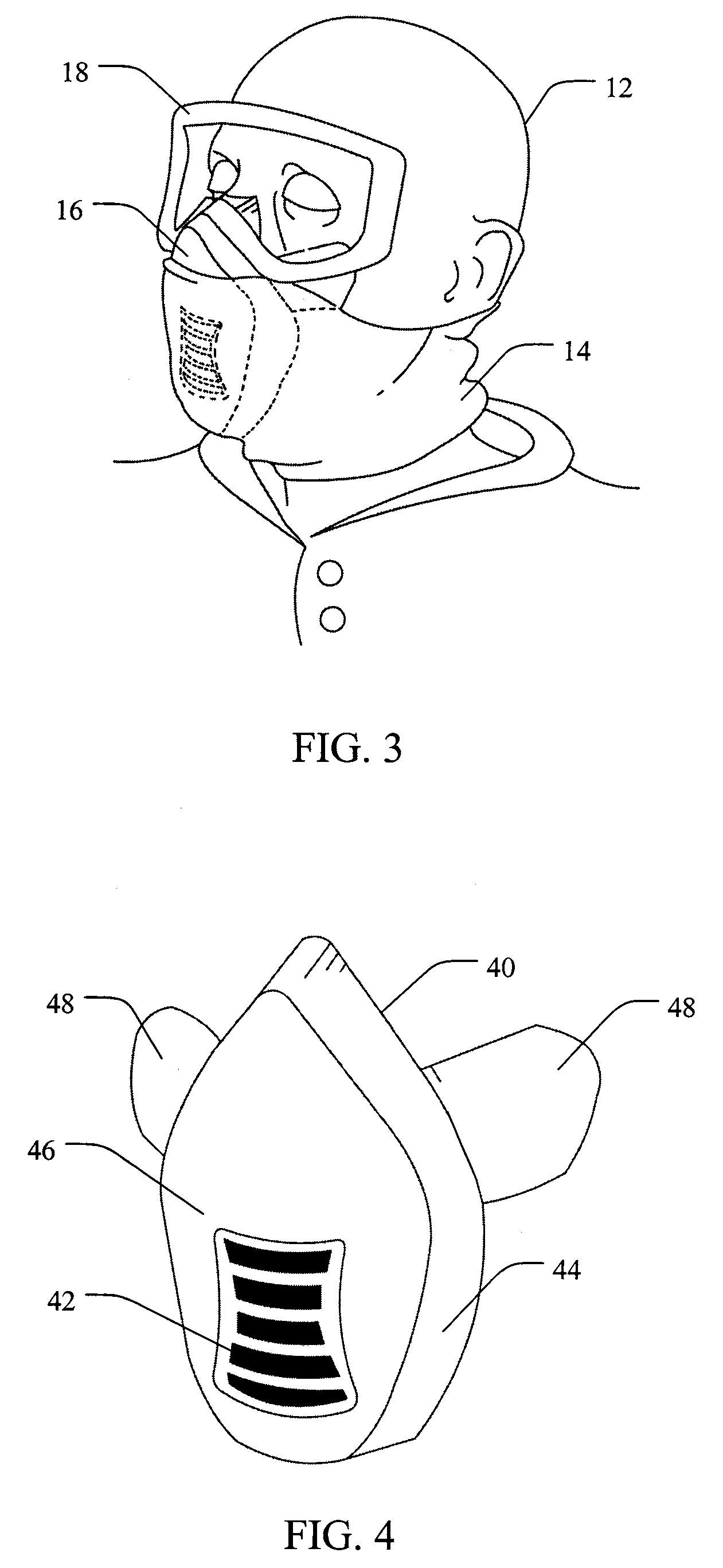

Facial Spacer Device and Associated Methods

InactiveUS20100319105A1Reducing breath condensationReduce the effective volumeScarvesHead-scarvesNoseSpacer device

The present invention provides systems and methods for decreasing breath condensation on a facial garment or covering. In one aspect, for example, a system for creating a breathing space between a facial covering and a subject's mouth and nose can include a facial covering operable to at least partially encircle at least a portion of a subject's head and / or neck and a facial spacer operable to be removably positioned between the facial covering and the subject adjacent the subject's mouth and nose. The facial spacer is free to move relative to the facial covering when the facial covering is in position adjacent the subject's mouth and nose.

Owner:FAIRBANKS CODY

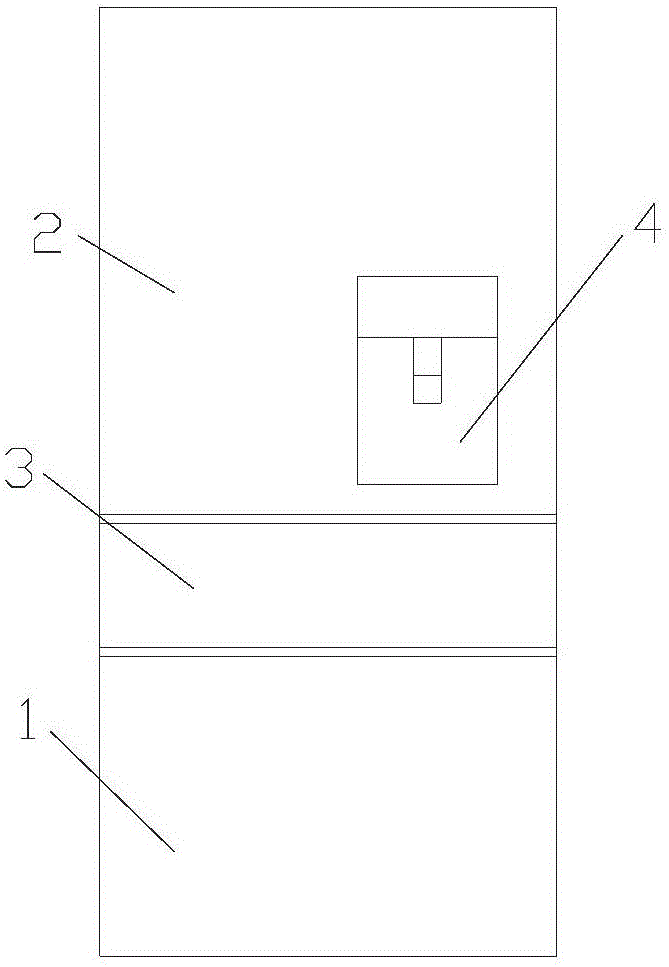

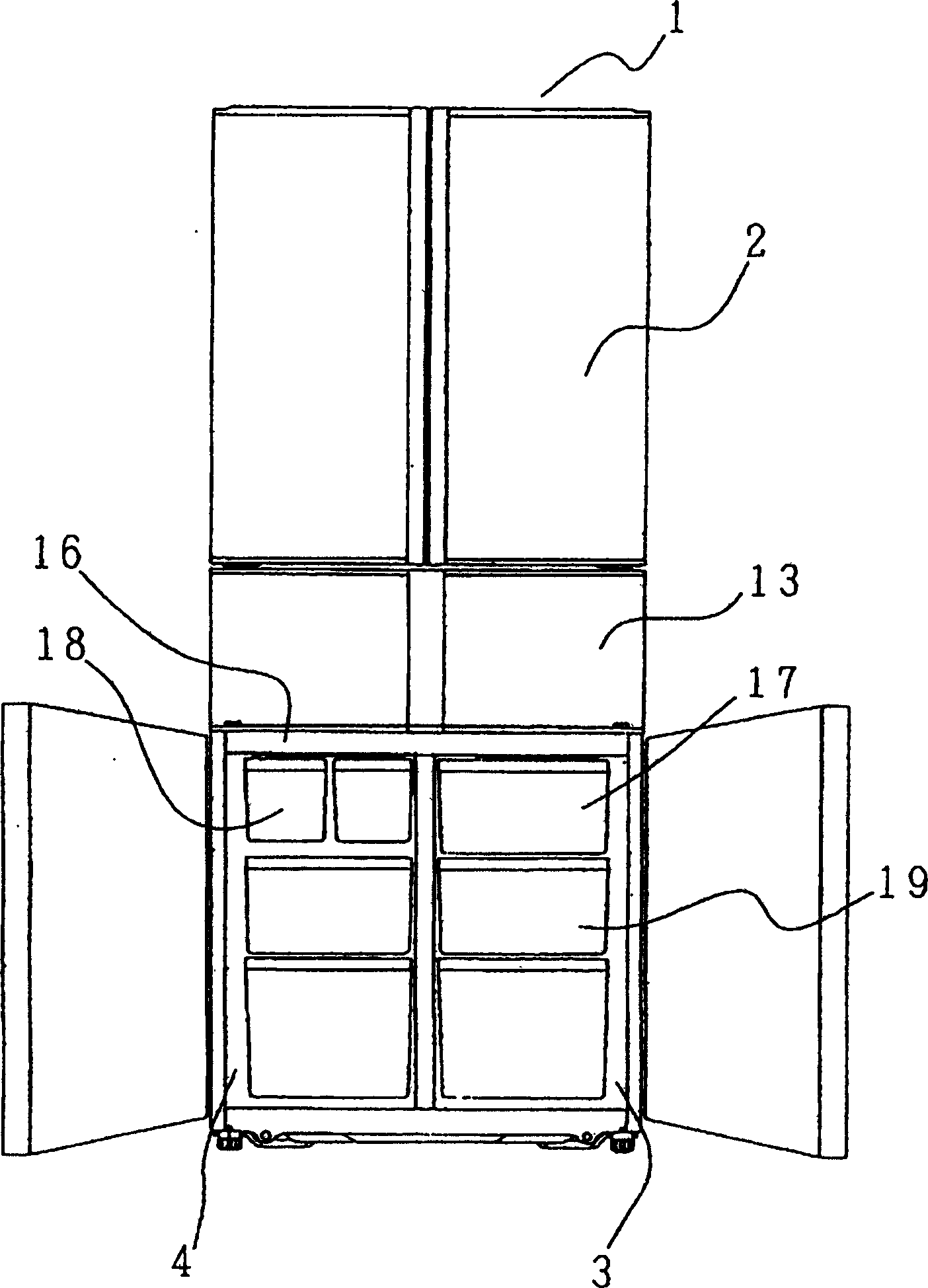

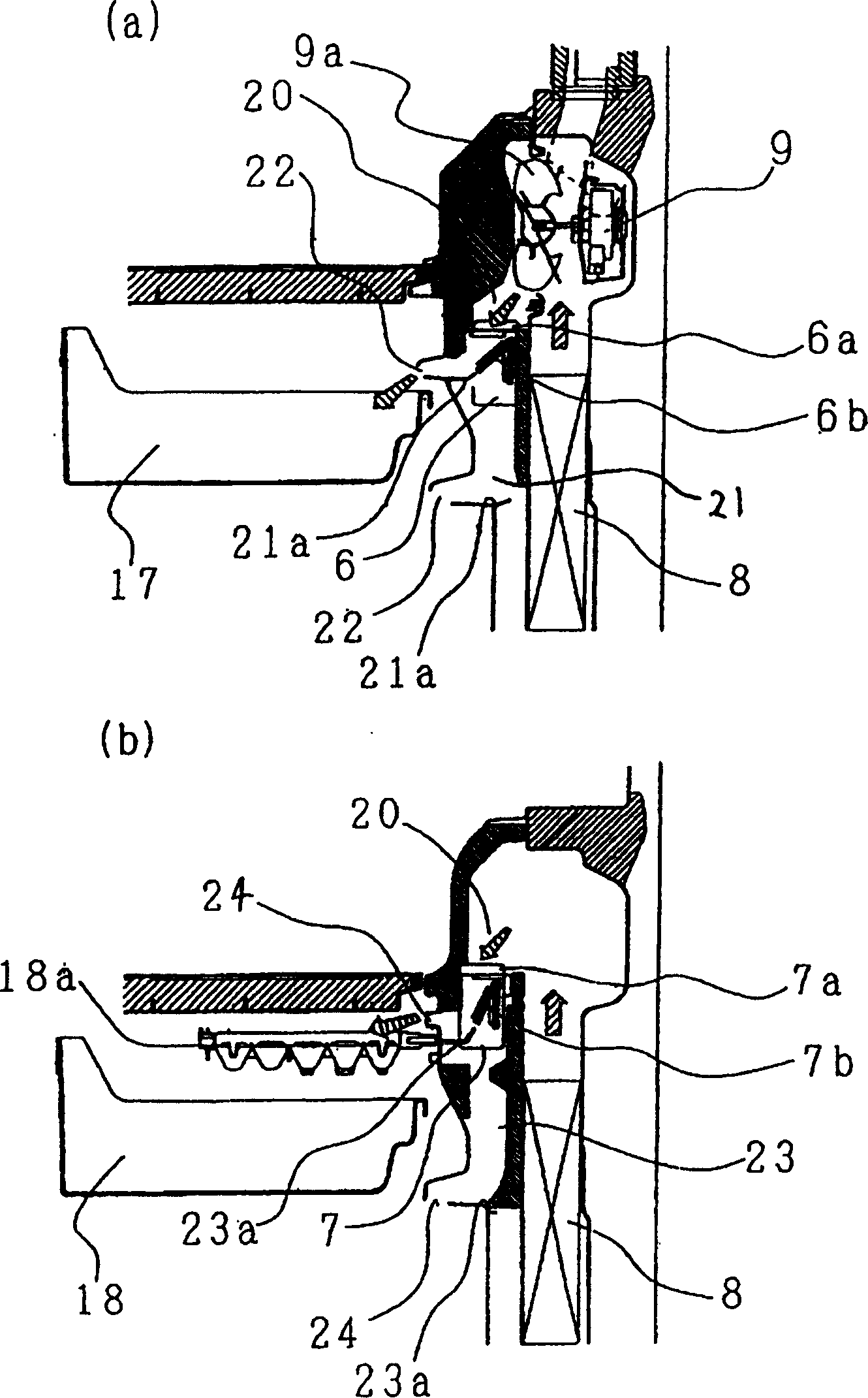

Refrigerator

InactiveCN1487255AReduce the effective volumeLighting and heating apparatusDomestic refrigeratorsEffective volumeRefrigerated temperature

Provided is a refrigerator not reducing its inside effective capacity so much while allowing replacement of a shelf plate even when its door cannot be opened by 90[deg.] or more. This refrigerator is provided with an outside plate, an inside box, a heat insulating material arranged between an outside box and the inside box, a storage room having a plurality of shelf plates inside, and a shelf plate receiving shaft buried inside the side face of the storage room and protruded to the inside of the storage room for placing the shelf plates.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

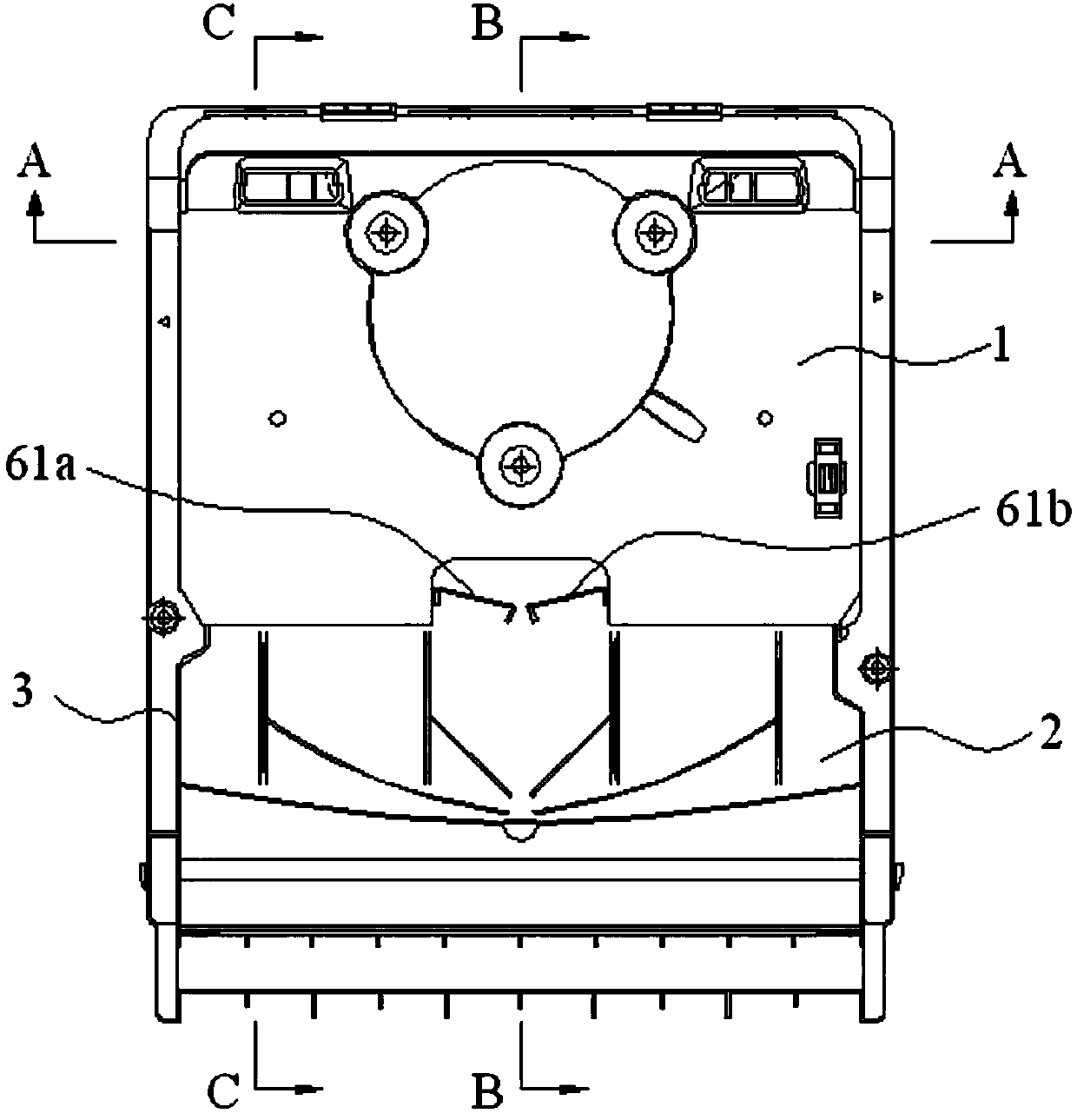

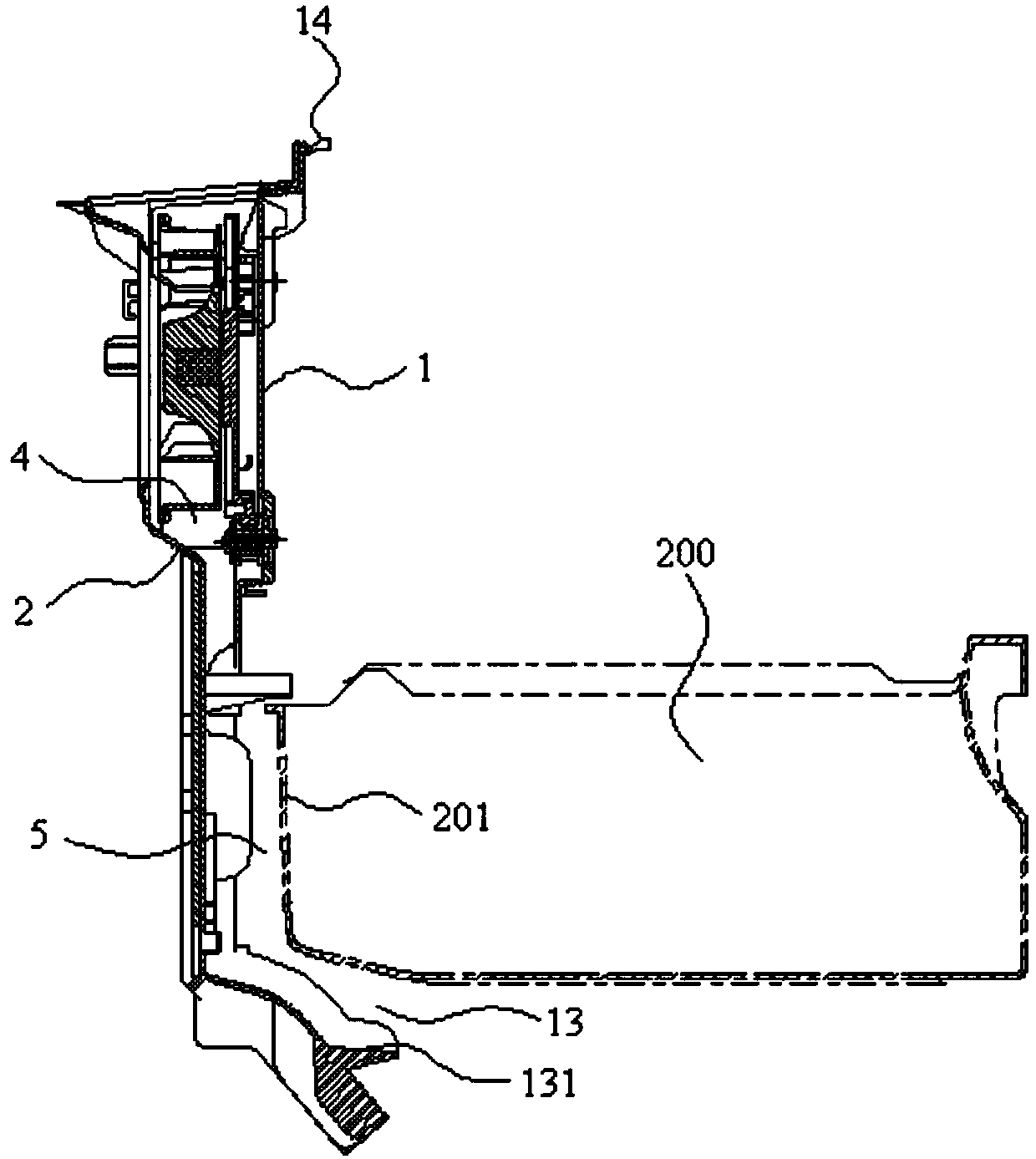

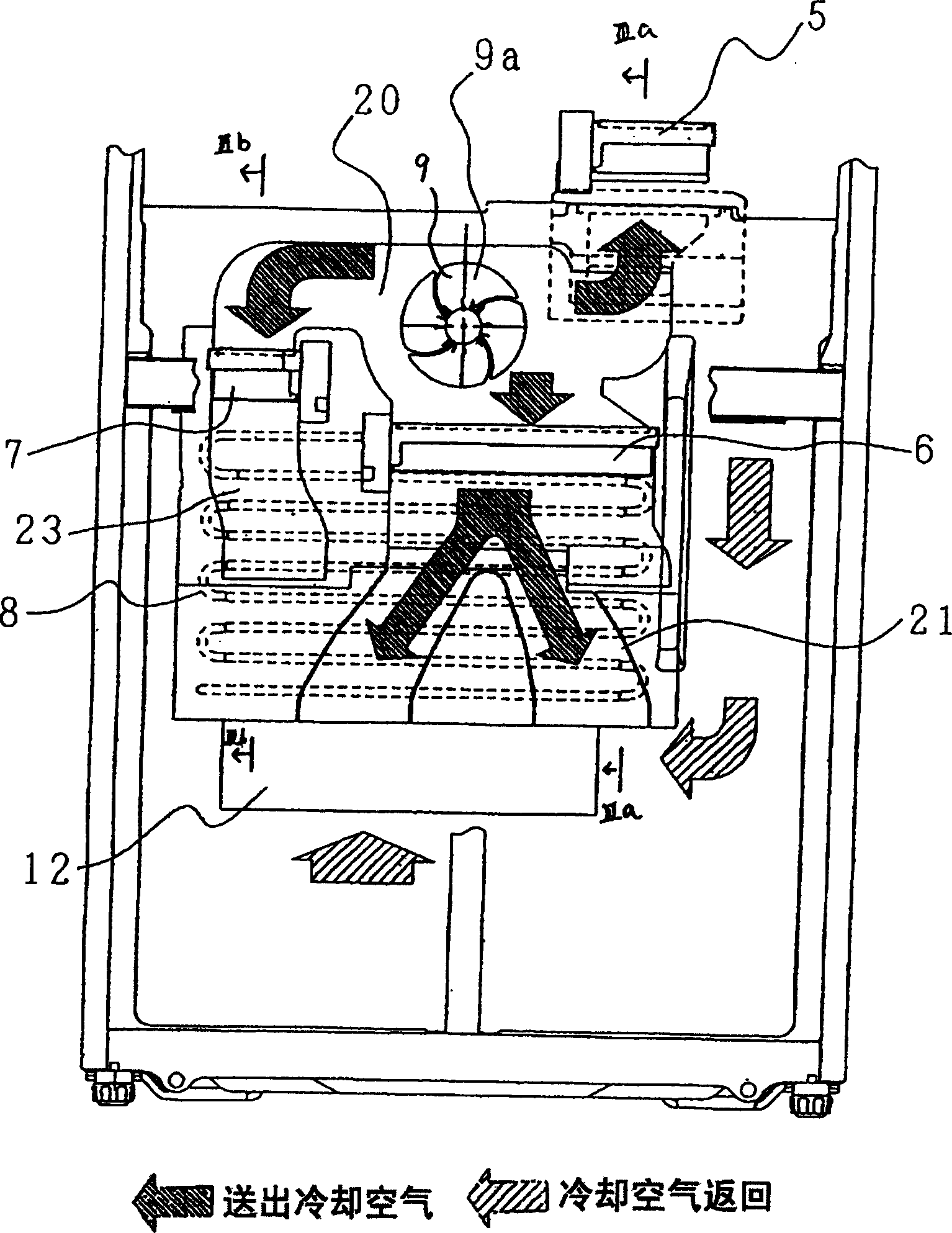

Air duct assembly of air-cooled refrigerator and air-cooled refrigerator

ActiveCN107560287AReduce the effective volumeReduce thicknessLighting and heating apparatusCooling fluid circulationAgricultural engineeringEffective volume

The invention discloses an air duct assembly of an air-cooled refrigerator and the air-cooled refrigerator and relates to the technical field of refrigerators. The thickness of the air duct assembly can be reduced, and the effective volume of the refrigerator is saved accordingly. The air duct assembly of the air-cooled refrigerator comprises an air duct front cover plate, an air duct rear cover plate and an air duct sidewall. The height of the air duct front cover plate is less than the height of the air duct rear cover plate. The upper portion of the air duct front cover plate is opposite tothe upper portion of the air duct rear cover plate. The lower portion of the air duct rear cover plate is opposite to the rear sidewall of a storage drawer of the refrigerator. One part of the air duct sidewall is located between the air duct front cover plate and the air duct rear cover plate to define an upper air duct. The other part of the air duct sidewall is located between the lower portion of the air duct rear cover plate and the rear sidewall of the storage drawer of the refrigerator to define a lower air duct. The upper air duct communicates with the lower air duct. The air duct assembly can be used for air outlet distribution of the air-cooled refrigerator.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

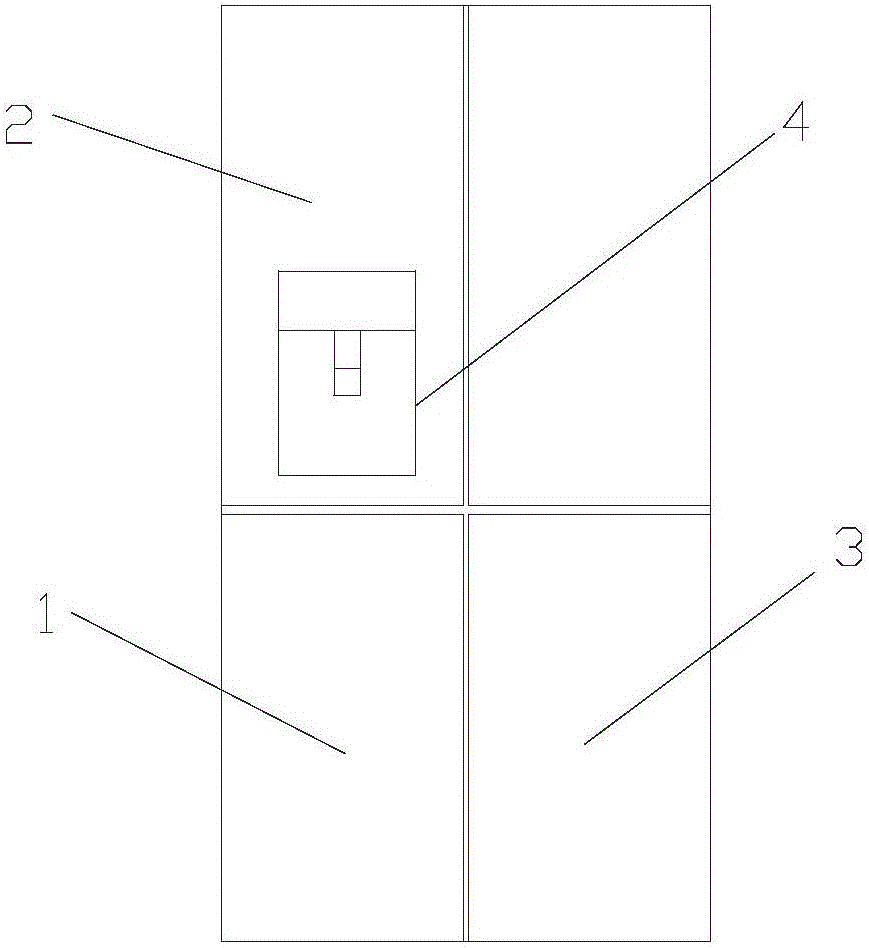

Refrigerator with ice-making chamber

InactiveCN105698466ASimple structureReduce the effective volumeLighting and heating apparatusDomestic refrigeratorsGreenhouseEngineering

The invention relates to the technical field of a refrigerator, and provides a refrigerator with an ice-making chamber. The refrigerator with the ice-making chamber comprises a variable temperature chamber, a refrigerating chamber, a freezing chamber and the ice-making chamber, wherein a first evaporator is arranged in the variable temperature chamber, a second evaporator is arranged in the refrigerating chamber, and a third evaporator is arranged in the freezing chamber; the ice-making chamber is formed in the refrigerating chamber or on a door body of the refrigerating chamber, and the ice-making chamber adopts the first evaporator to carry out refrigeration. The ice-making chamber adopts the first evaporator in the variable temperature chamber, and thus, ice cubes made in the ice-making chamber have no odor. Moreover, the variable temperature chamber, the refrigerating chamber, the freezing chamber and the ice-making chamber do not need to share one evaporator, and thus, air ducts inside the variable temperature chamber, the refrigerating chamber, the freezing chamber and the ice-making chamber are simple in structure; the variable temperature chamber, the refrigerating chamber and the freezing chamber are separately provided with the evaporators, so that temperatures of the variable temperature chamber, the refrigerating chamber and the freezing chamber are easier to control. Moreover, one evaporator does not need to be additionally arranged for the ice-making chamber, and thus, an effective volume inside the refrigerator can be saved.

Owner:HEFEI HUALING CO LTD +1

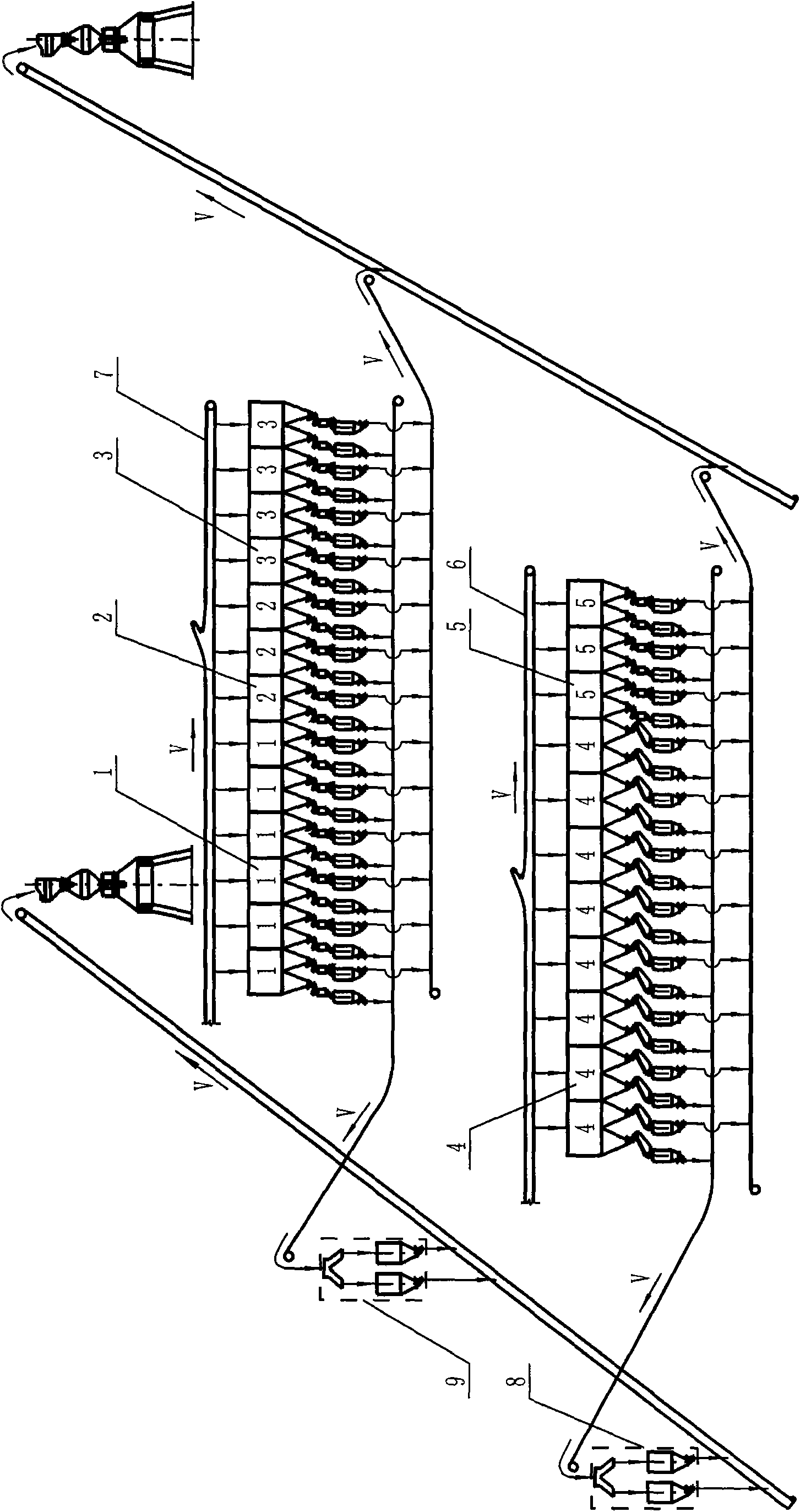

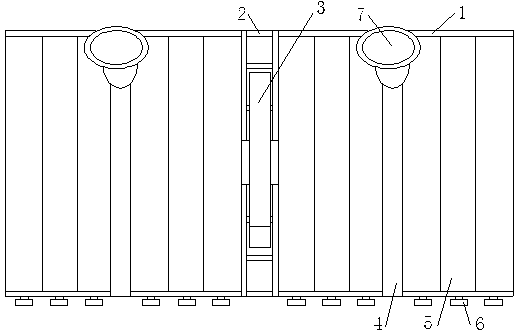

Feeding system for blast furnace ore and coke channel system

ActiveCN101792835ASmall footprintSave construction investmentBlast furnace componentsBlast furnace detailsBelt conveyorMaterials science

The invention relates to a feeding system for a blast furnace ore and coke channel system, belonging to the technical field of the iron making and producing in the metallurgy industry. The feeding system comprises a blast furnace ore and coke channel system and a feeding system; the blast furnace ore and coke channel system comprises a blast furnace ore and coke channel and equipment arranged on the blast furnace ore and coke channel; the feeding system comprises equipment arranged below the blast furnace ore and coke channel and loading equipment; the equipment arranged on the blast furnace ore and coke channel comprises auxiliary equipment and belt conveyor with a storehouse, wherein the auxiliary equipment and the belt conveyor with a storehouse are arranged on the top surface of the blast furnace ore and coke channel, and the belt conveyor with a storehouse is connected with the top surface of the blast furnace ore and coke channel; each equipment arranged below the blast furnace ore and coke channel comprises a feeding port gate, a feeder, a vibrating screen, a weighing can and an unloading gate; the feeding port gate corresponds to the hopper of the blast furnace ore and coke channel and the outlet thereof one by one; the number of the equipment arranged below the blast furnace ore and coke channel, the number of the hoppers of the blast furnace ore and coke channel and the number of the outlets of the hoppers of the blast furnace ore and coke channel are equal and are 2 or 3 or 4 along the width direction; and the equipment arranged below the blast furnace ore and coke channel corresponds to the hoppers blow the body of the blast furnace ore and coke channel and the outlets of the hoppers along the length direction. The feeding system can serve 3 or 4 blast furnaces and can be used in various forms.

Owner:BEIJING SHOUGANG INT ENG TECH

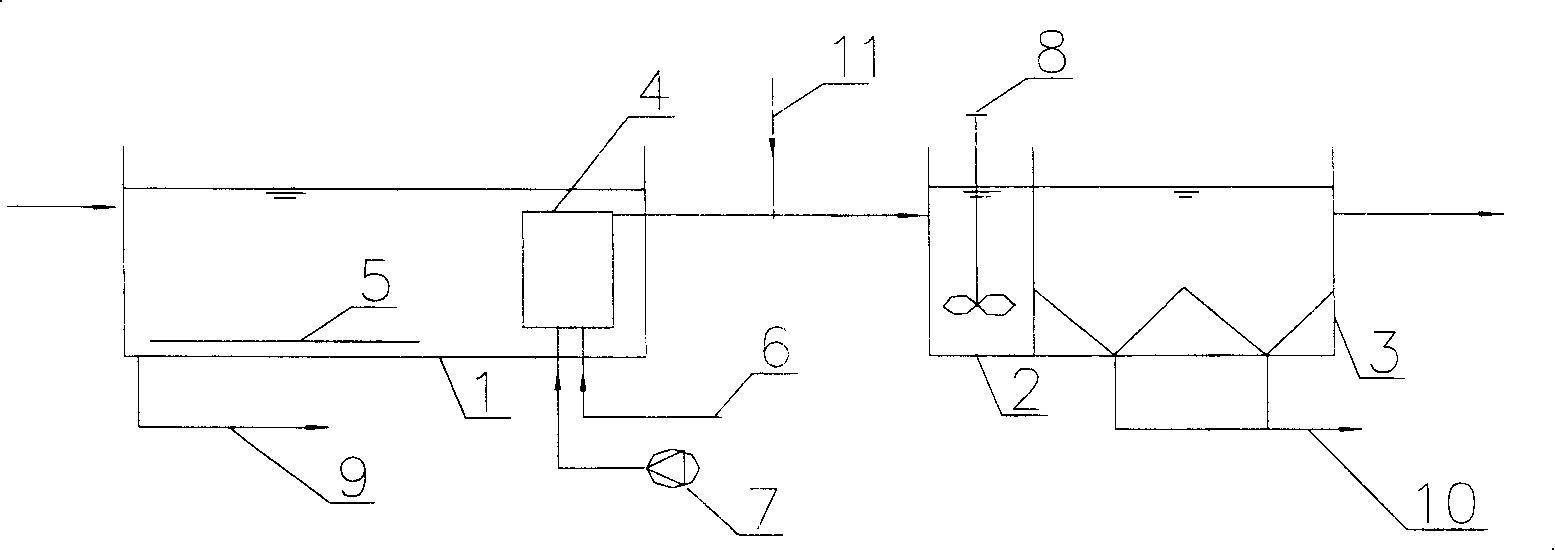

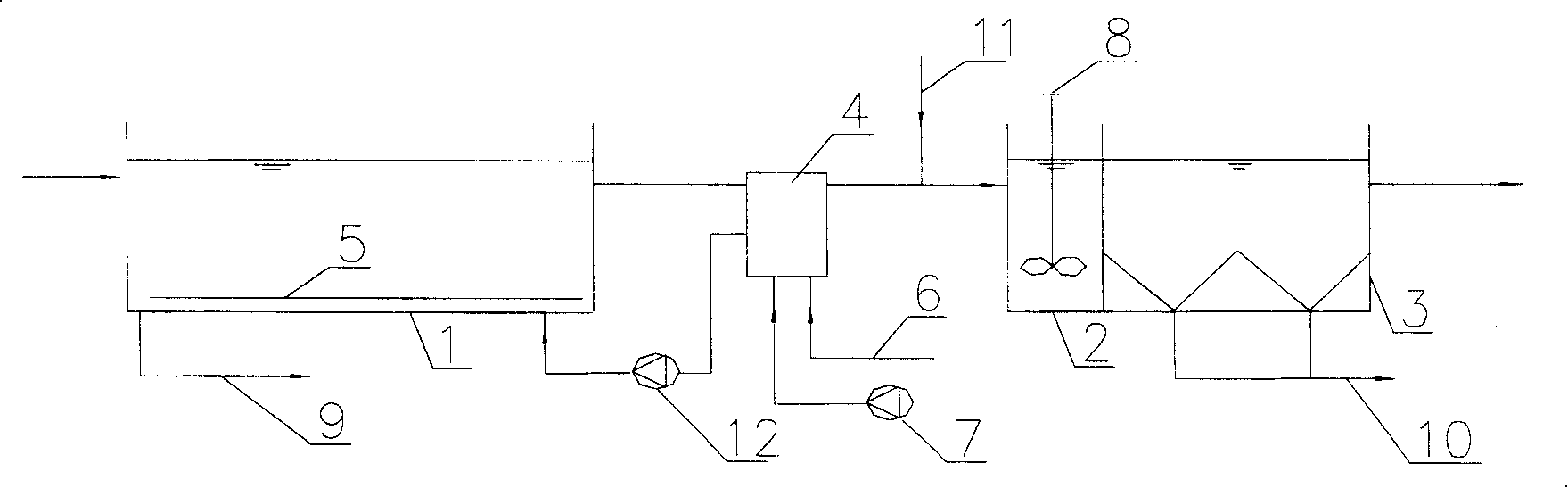

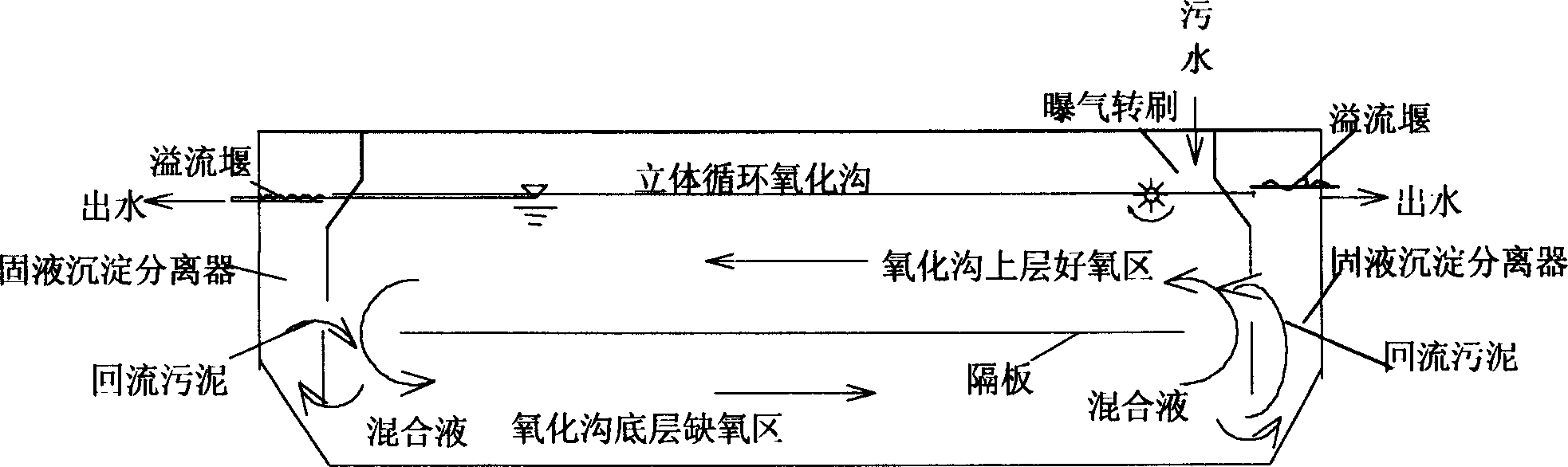

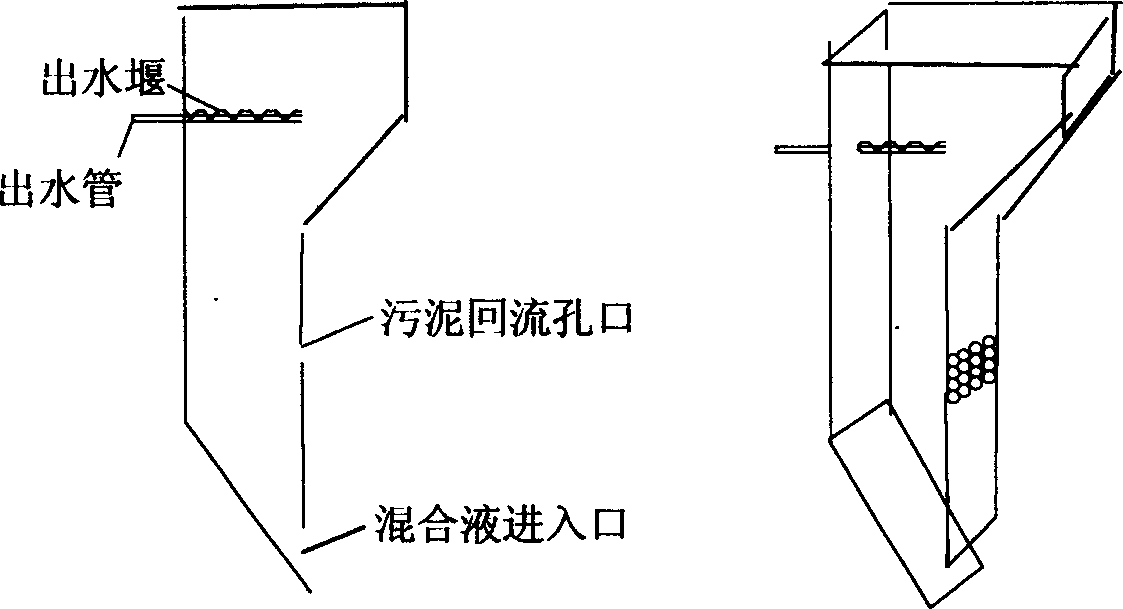

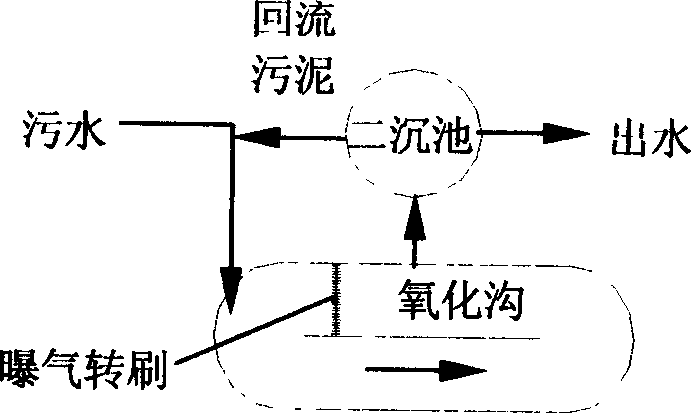

Incorporated double settling zone tridimensional circulating oxidation ditch facility and method of operating thereof

InactiveCN1463933AUnique return methodEasy to separateSedimentation separationSustainable biological treatmentSewagePrecipitation

The present invention belongs to the sewage treating apparatus adopting biochemical technology. The integrated stereo oxidation channel has two rectangular solid-liquid depositing separators, and the oxidation channel is separated with partition board into the upper aerobic area and the lower anaerobic area. Each of the solid-liquid depositing separators has inclined mixed liquid inlet in the bottom, overflow weir and water outlet on one side wall, and sludge reflowing port on the other wall. The two solid-liquid depositing separators are installed separately on two side walls of the stereo circulating oxidation channel. The stereo circulating oxidation channel has bottom isolated from air and this is favorable to forming anaerobic state and raising denitrifying efficiency. Compared with available oxidation channel, the present invention has 50 % reduced covered area.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

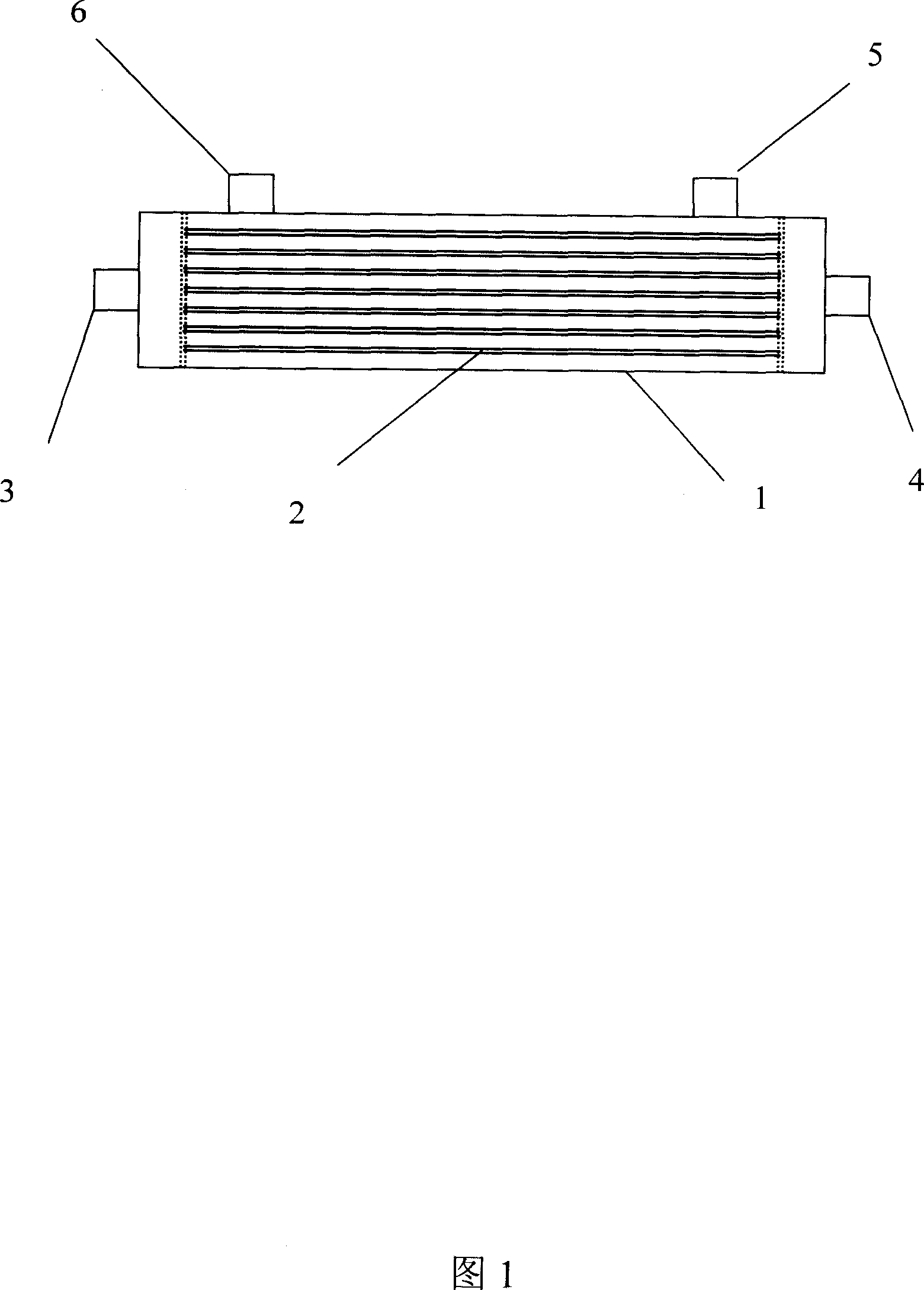

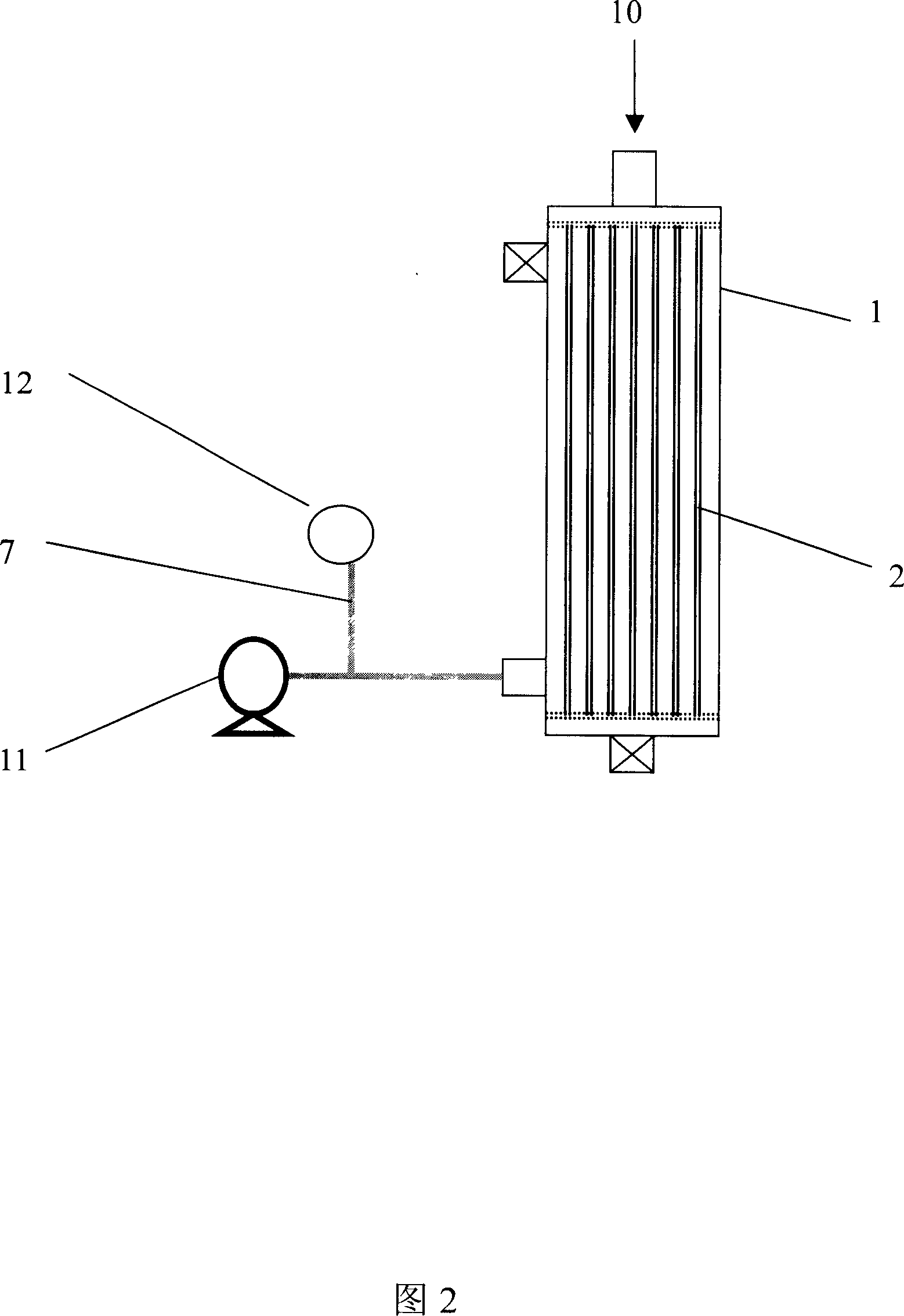

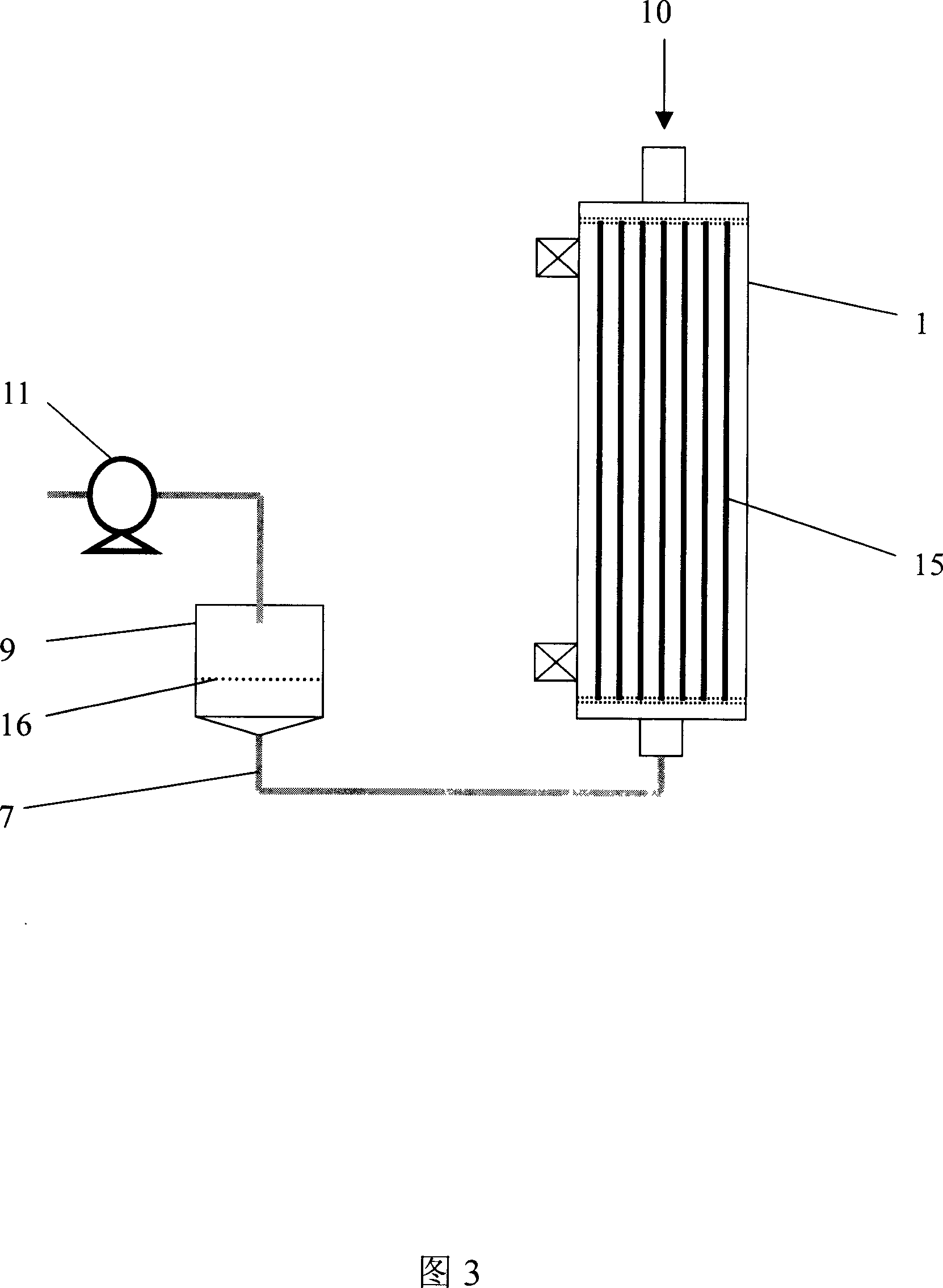

Process and apparatus for repeated use of dialysis device

InactiveCN1970099AQuick washEasy to cleanFluid pressure measurement using pressure-sensitive liquidVolume measurement and fluid deliveryPositive pressureWork flow

The invention discloses a dialyzer multiplying method, which comprises the following parts: multiplying channel, pipe, cleaning liquid container, negative pressure pump, negative pressure meter, positive pressure pump and positive pressure meter. The working flow path comprises the following steps: (1) washing; (2) proceeding double-pressure cleaning; (3) washing; (4) gauging pressure; (5) detecting bulk; (6) sterilizing dialyzer.

Owner:THE FIRST PEOPLES HOSPITAL OF FOSHAN

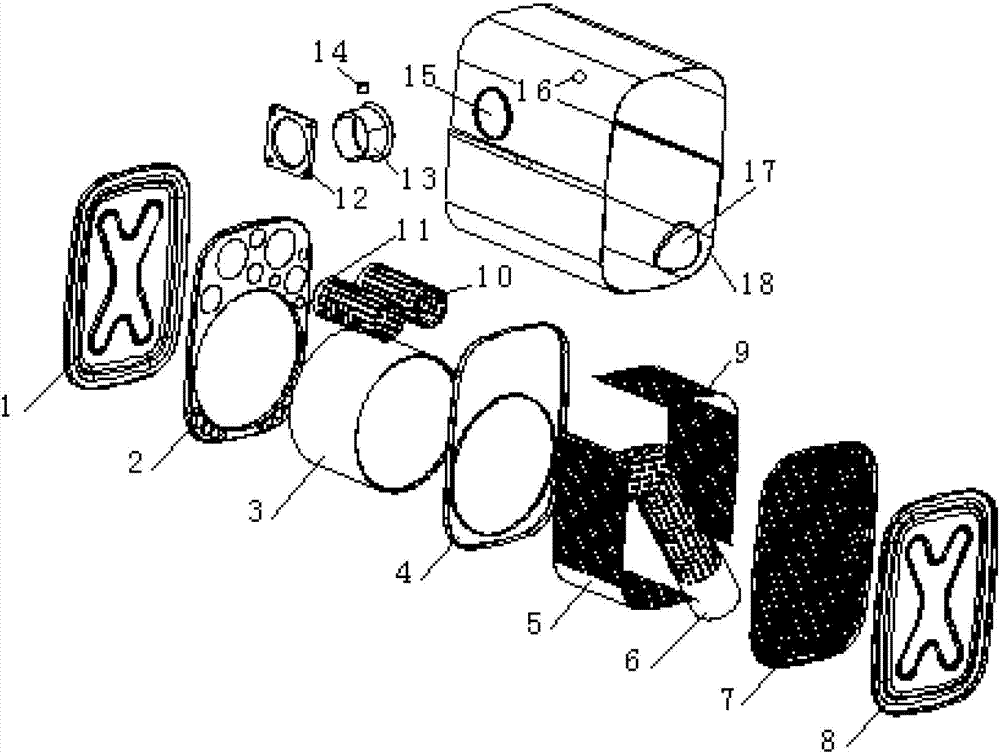

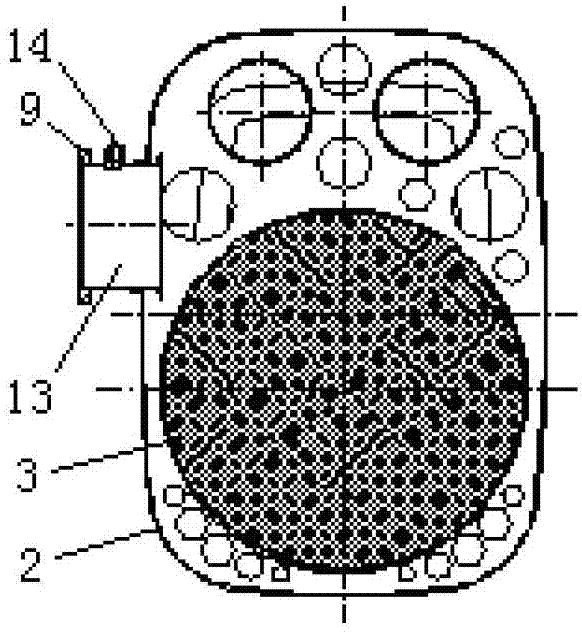

Box-type postprocessor assembly

InactiveCN103046987AIncrease profitImprove conversion efficiencyExhaust apparatusSilencing apparatusAcoustic boardDiesel particulate filter

The invention belongs to the technical field of automobile parts and relates to a box-type postprocessor assembly. The box-type postprocessor assembly comprises a mixed unit, a post-processing unit and a noise reduction unit and is provided with sensors, and each of the mixed unit, the post-processing unit and the noise reduction unit consists of some of end covers, a shell, baffles, sound-absorbing tubes, a post-processing packaging assembly, acoustic boards and an air intake pipe. The box-type postprocessor assembly can be applicable to an SCR (selective catalytic reduction) postprocessor, a transparent POC (particulate organic carbon) filtering postprocessor with a catalyst coating, a DOC (diesel oxidation catalyst) postprocessor and a DPF (diesel particulate filter) postprocessor, enables an engine to meet national IV and national V emission regulations by combining corresponding built-in emission reduction measures, is capable of making effective use of space and is high in conversion efficiency, high in noise reduction capability and low in back pressure.

Owner:CHINA FIRST AUTOMOBILE

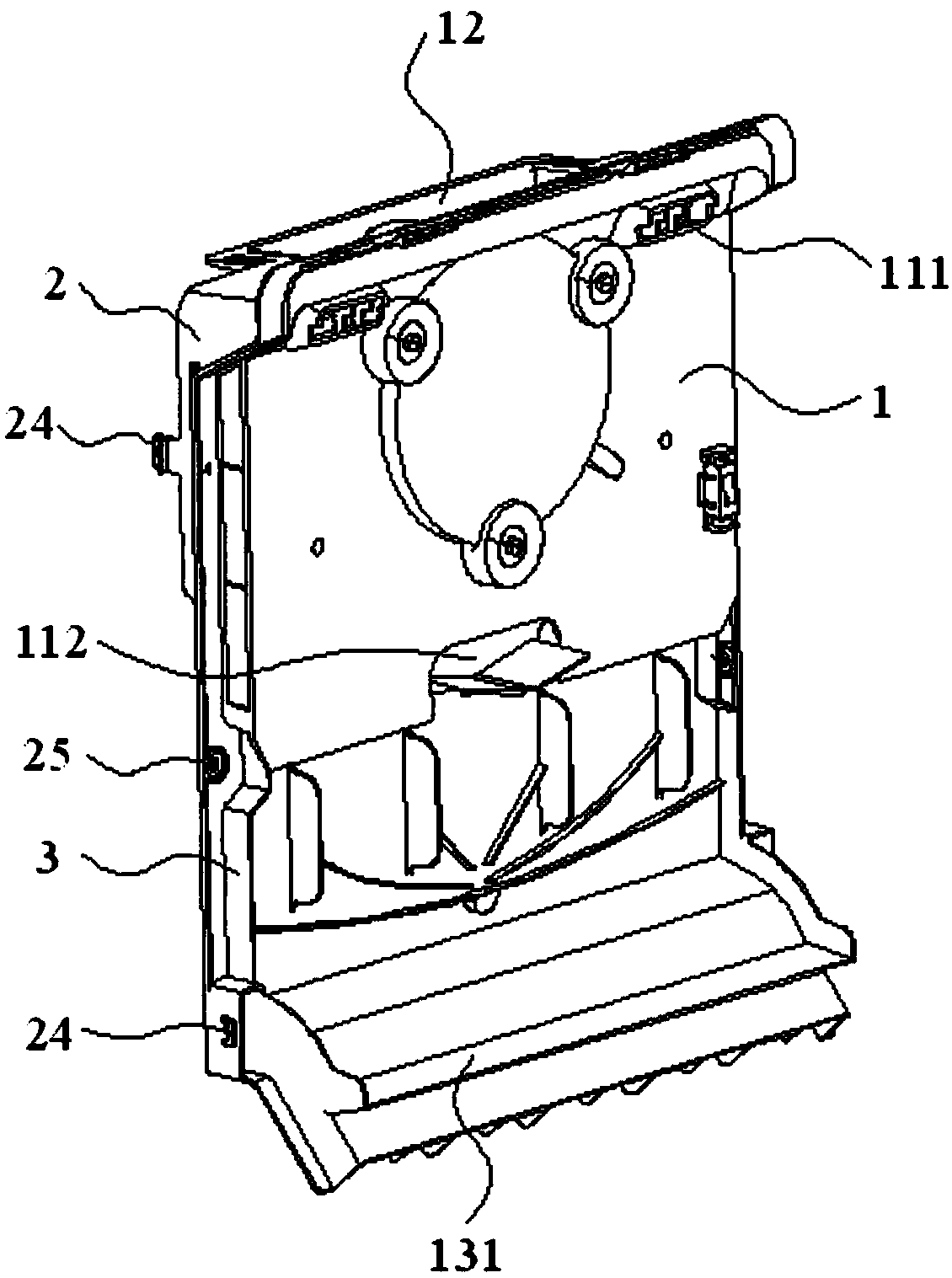

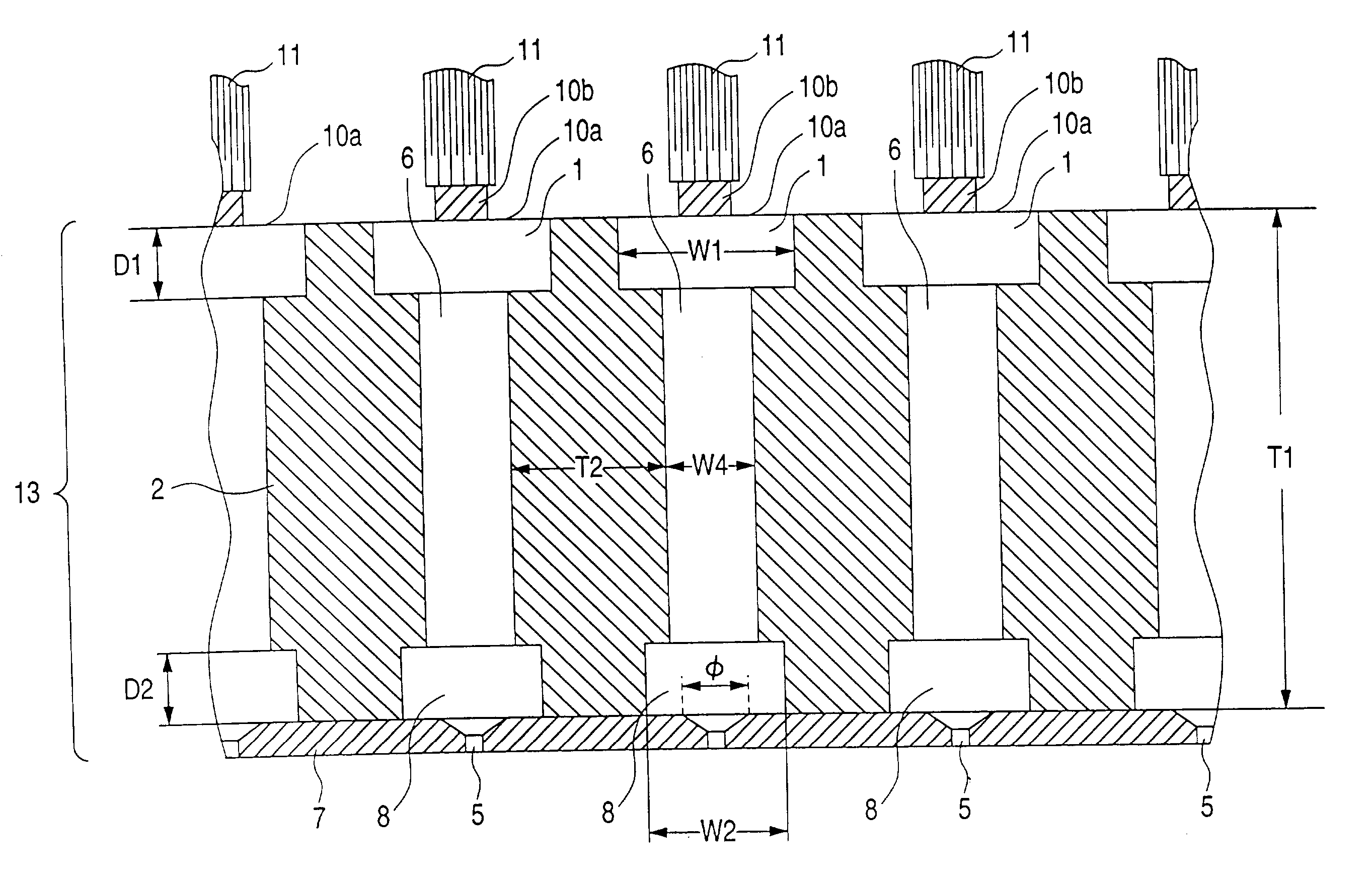

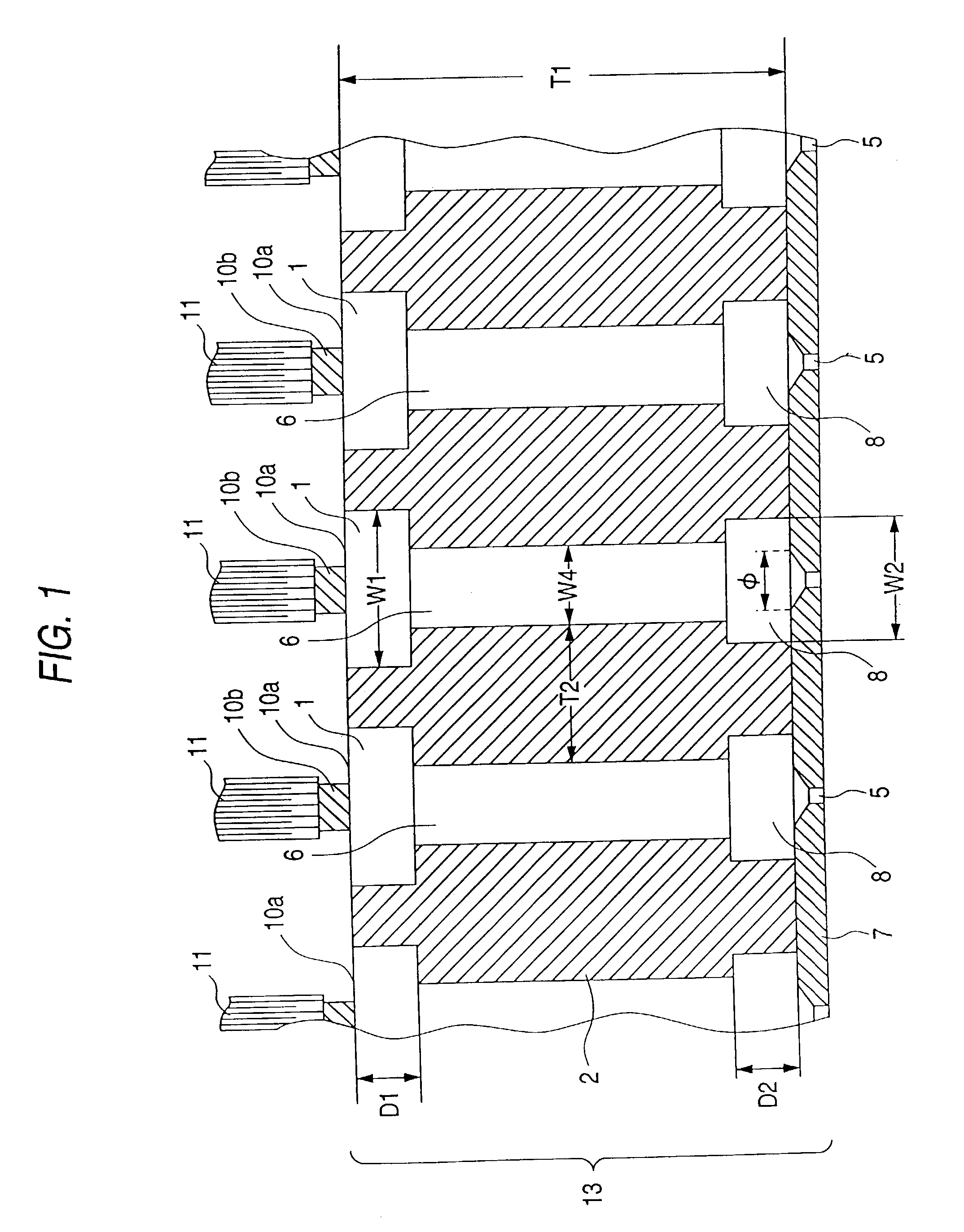

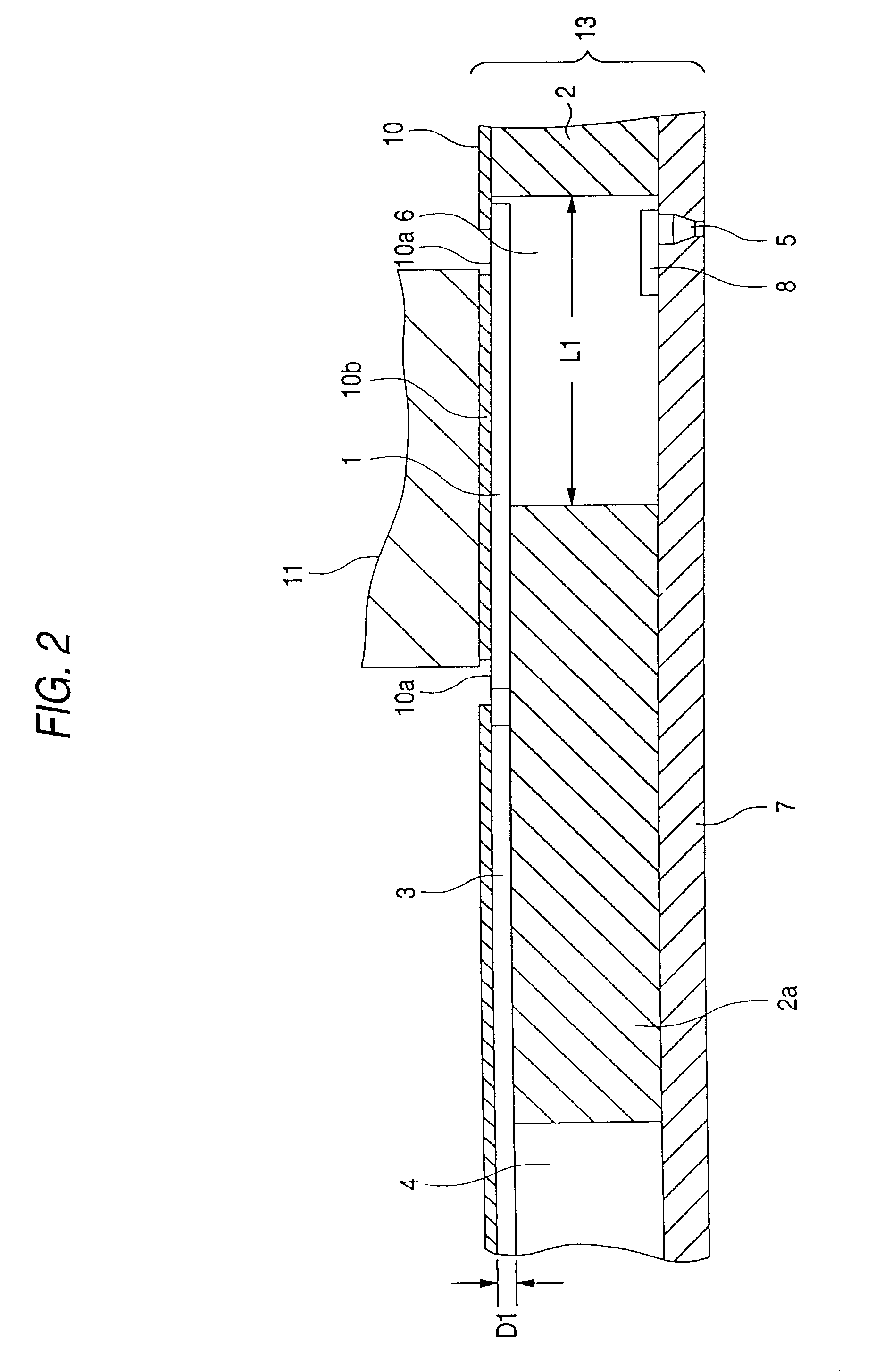

Method of producing an ink jet recording head

InactiveUS7028377B2Effective rigidityLower the volumeRecording apparatusAdhesive processesAdhesiveEngineering

A method of producing an ink jet recording head, which includes (1) fixing a passage unit in which a nozzle pate having a nozzle opening, a spacer forming a common ink chamber, and an elastic plate having a thick portion abutting against an end of a piezoelectric vibrating element are stacked, to an opening of a frame having an overhang portion which overhangs to a vicinity of the thick portion, (2) inserting a vibrating element unit into the frame, the vibrating element unit being configured by fixing piezoelectric vibrating elements operating in a longitudinal vibration mode to a fixing substrate, and (3) injecting an adhesive into a groove formed in a region opposing the fixing substrate of the frame.

Owner:SEIKO EPSON CORP

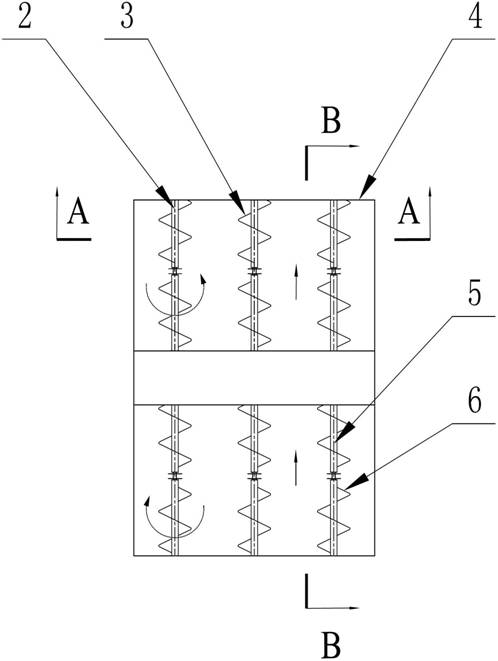

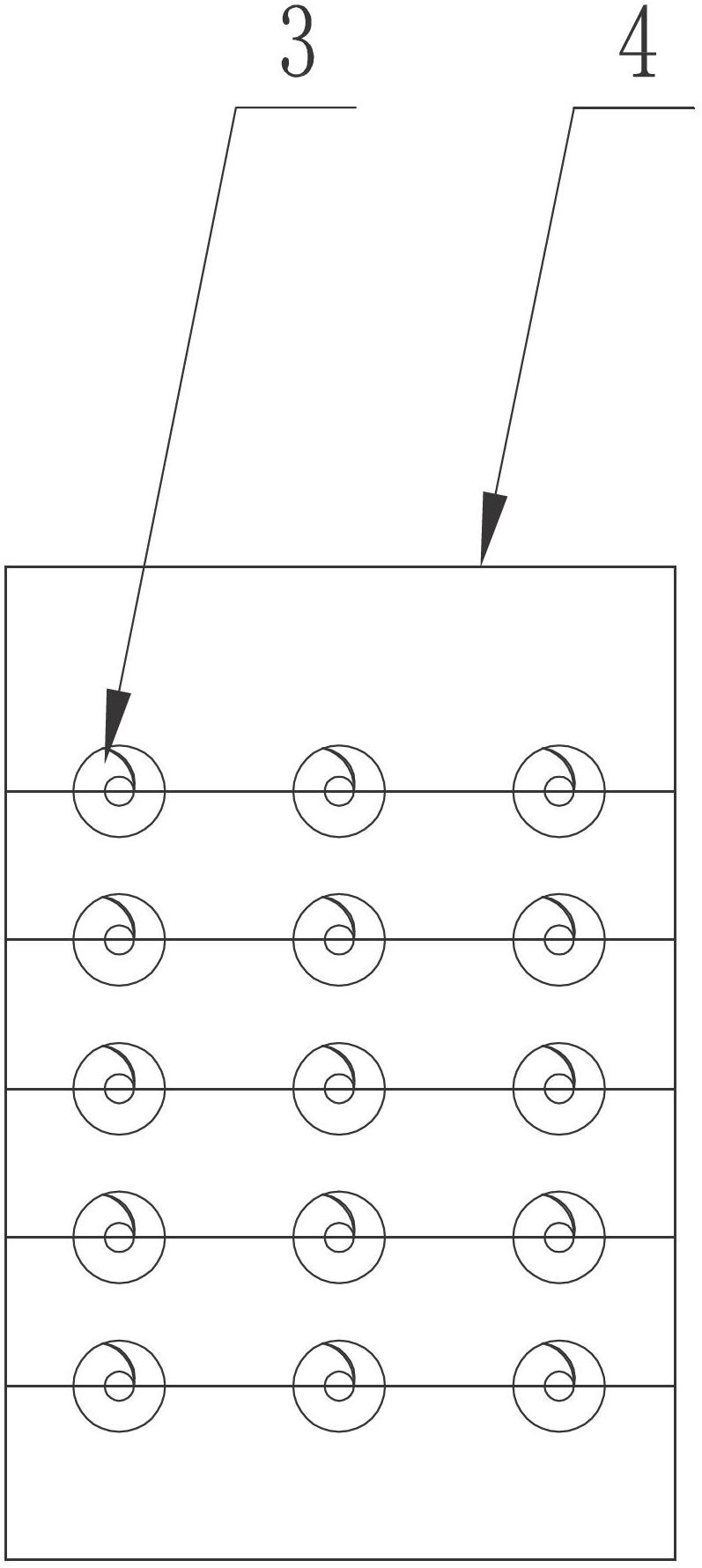

Spiral flocculator and application to folded plate type flocculation reaction tank

ActiveCN102674518AFully disturbedIncrease mixing intensityWater/sewage treatment by flocculation/precipitationSedimentation settling tanksFlocculationWater flow

The invention belongs to water treatment equipment, and particularly relates to a spiral flocculator which comprises a support. At least two spiral plates with opposite turning directions are longitudinally arranged on the support at intervals, the upper end and the lower end of each spiral plate are rotationally assembled on the support, and strip-shaped blades are radially fixed onto outer edges of the spiral plates. The spiral flocculator is mounted between two adjacent partition boards in a folded plate type flocculation reaction tank when applied to the folded plate type flocculation reaction tank. The spiral flocculator solves problems of large application limitation, poor flocculation effect and large occupied area of an existing reaction tank in the prior art, and has the advantages that a disturbance effect to water flow is good, the occupied area of the reaction tank is small, installation is simple, energy is saved, and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

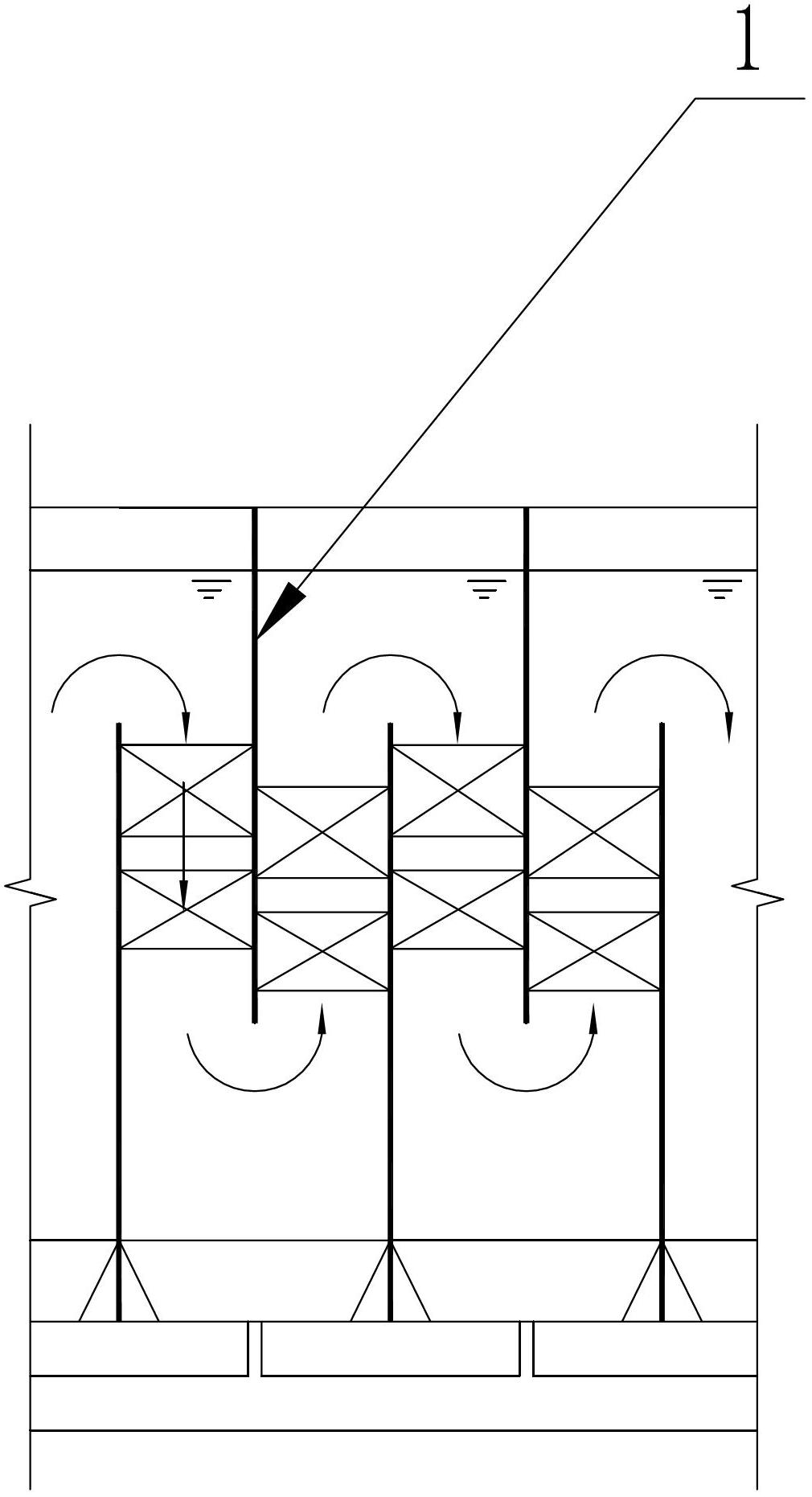

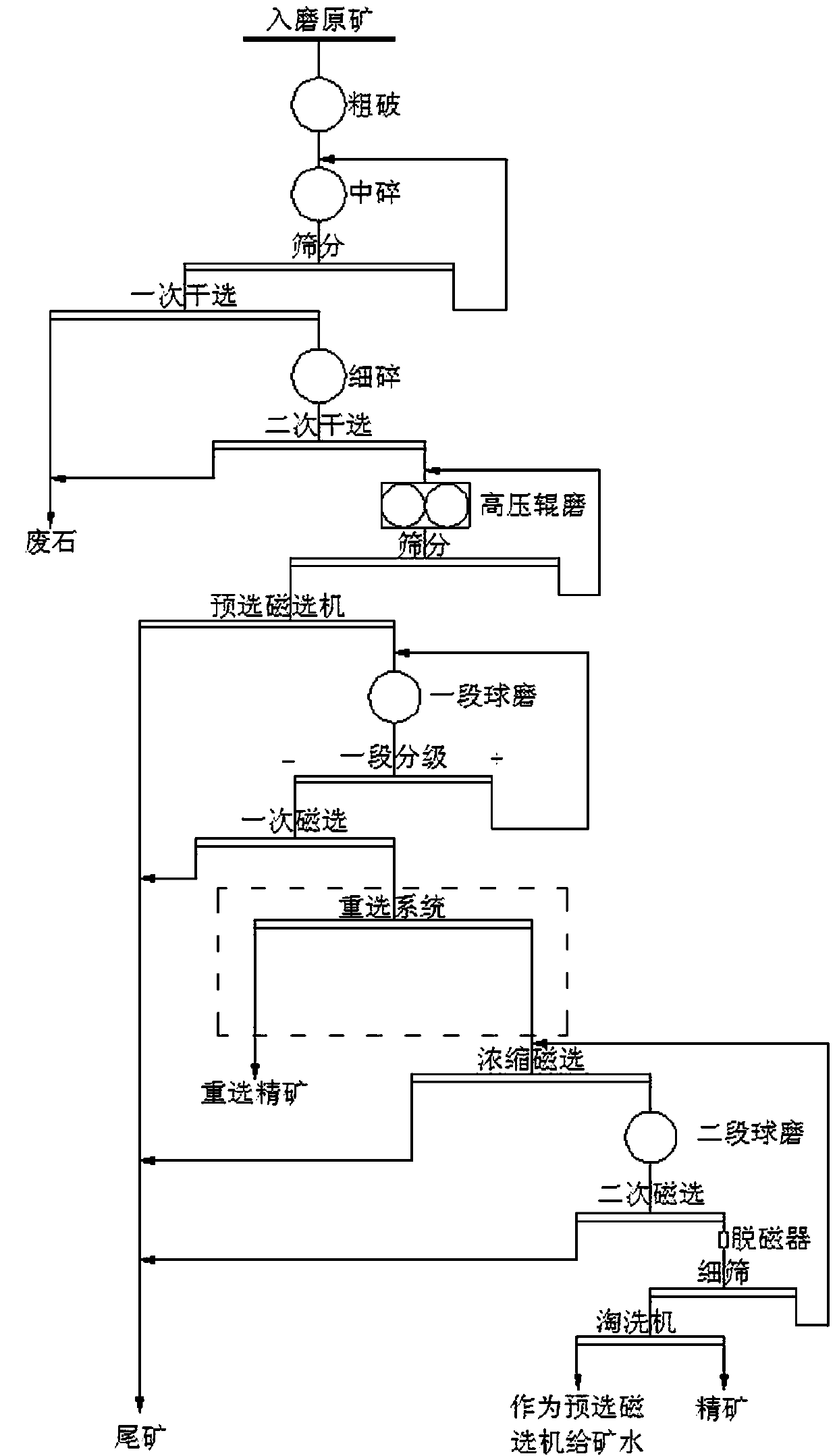

Magnetite beneficiation process capable of fully releasing mill capacity

InactiveCN110624686AReduce the effective volumeLow production costMagnetic separationGrain treatmentsMagnetiteVolumetric Mass Density

The invention relates to a magnetite beneficiation process capable of fully releasing mill capacity. The magnetite beneficiation process includes the steps that raw ore is subjected to three-section breaking and secondary dry separation and then ultrafine-ground through high-pressure roller milling, after high-pressure roller milling products are screened through screening equipment, undersize products are fed into a wet type preselection magnetic separator, wet type preselection rough concentrate is subjected to ore grinding, classifying, magnetic separating and reselecting, partially-qualified concentrate is obtained, reselecting process tailings are fed into second-section ore grinding after being subjected to concentration magnetic separation, second-section ore grinding products are subjected to magnetic separation, fine screening classification and elutriating selecting, and qualified concentrate is obtained. As the high-pressure roll milling products are subjected to wet type preselection, a large quantity of qualified tailings can be thrown out, the mill entering quantity is reduced, and the ore milling cost and the energy consumption are reduced; the partially-qualified concentrate can be recycled in advance through the magnetic and gravity combined separation process by means of the density difference between iron minerals and lean coenobium; and in the whole process,the mill capacity can be fully released, energy saving and consumption reduction are achieved, compared with current conventional processes, the effective volume of a ball mill can be reduced to be 50% or below, the investment can be greatly reduced, and the production cost is reduced.

Owner:魏建民

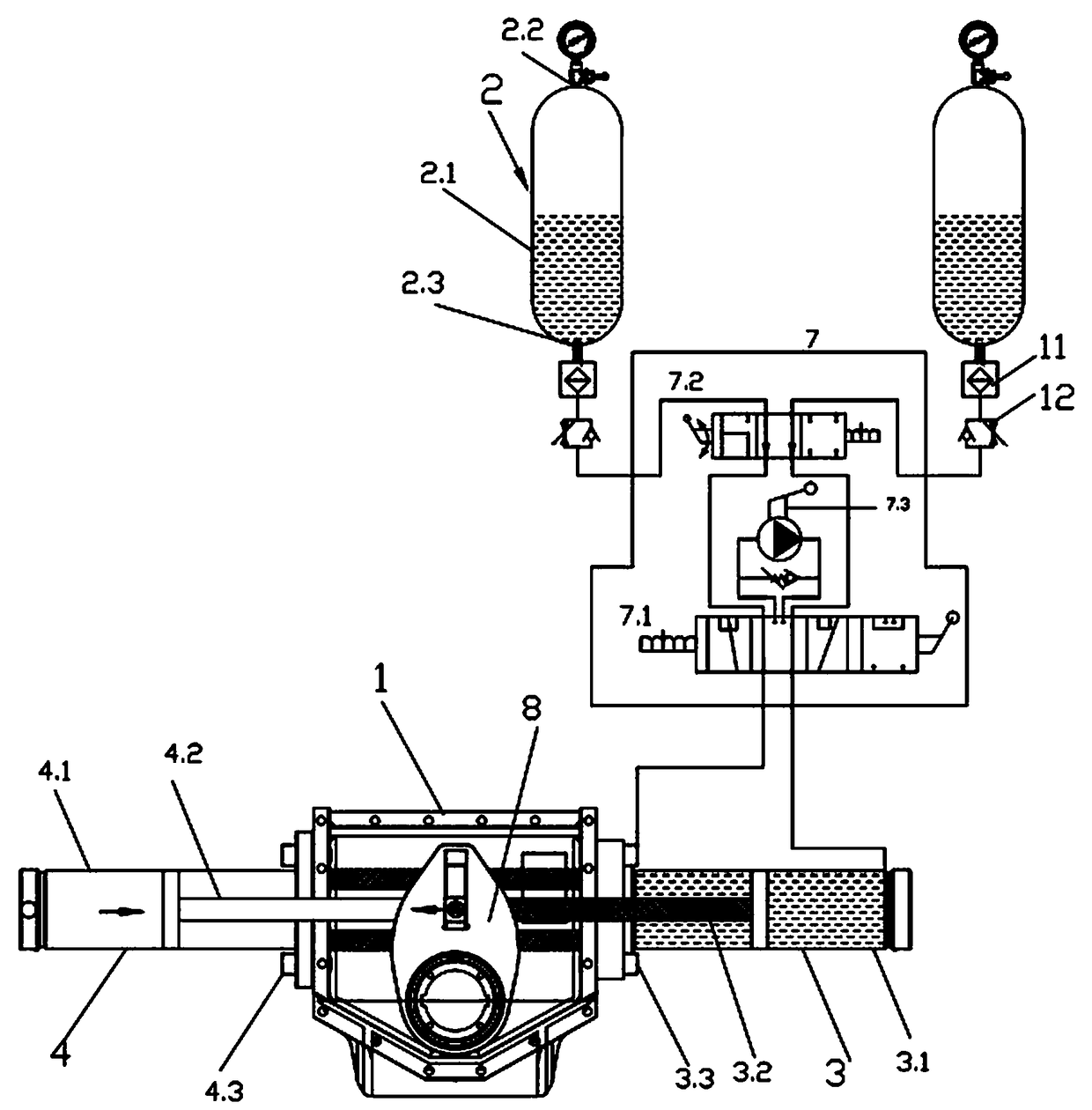

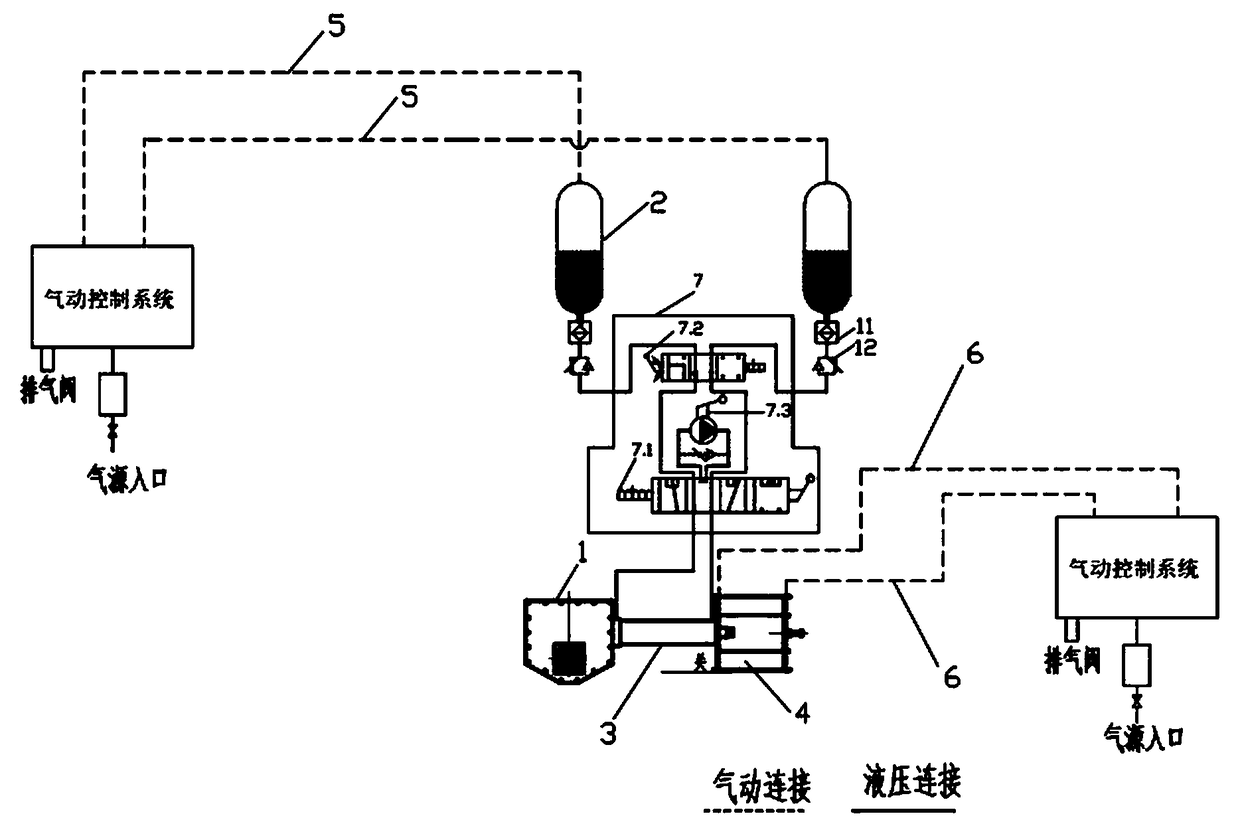

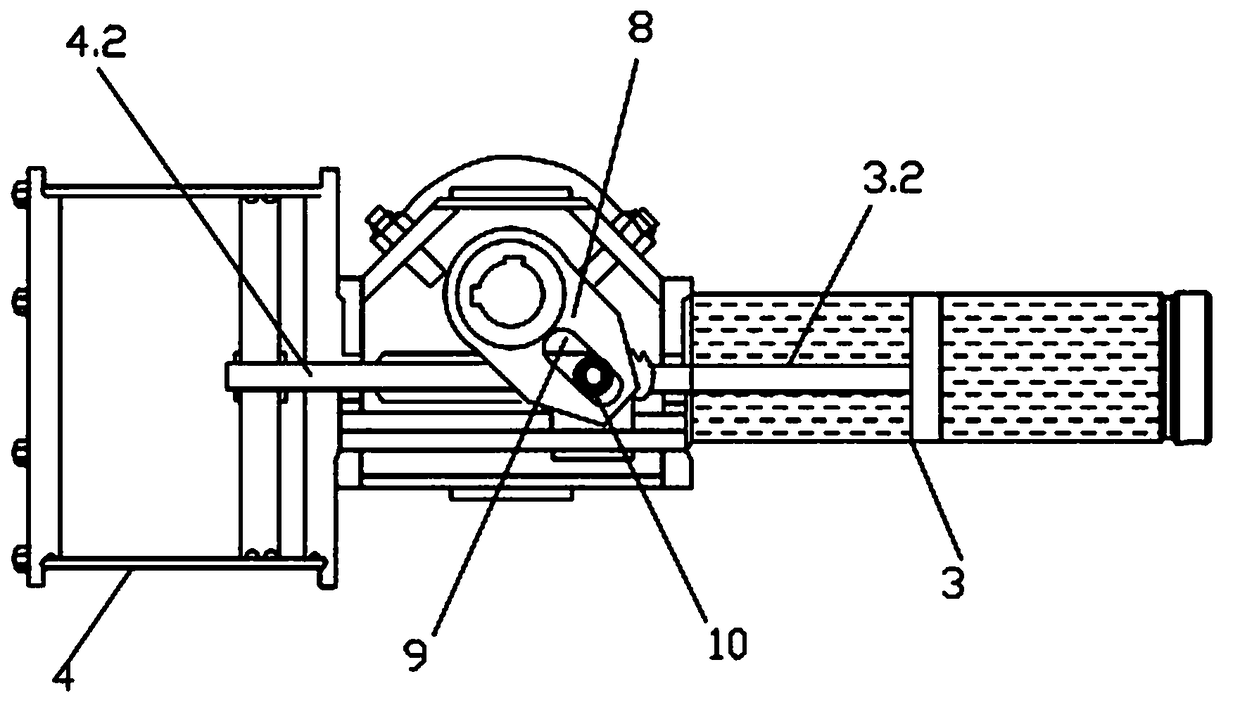

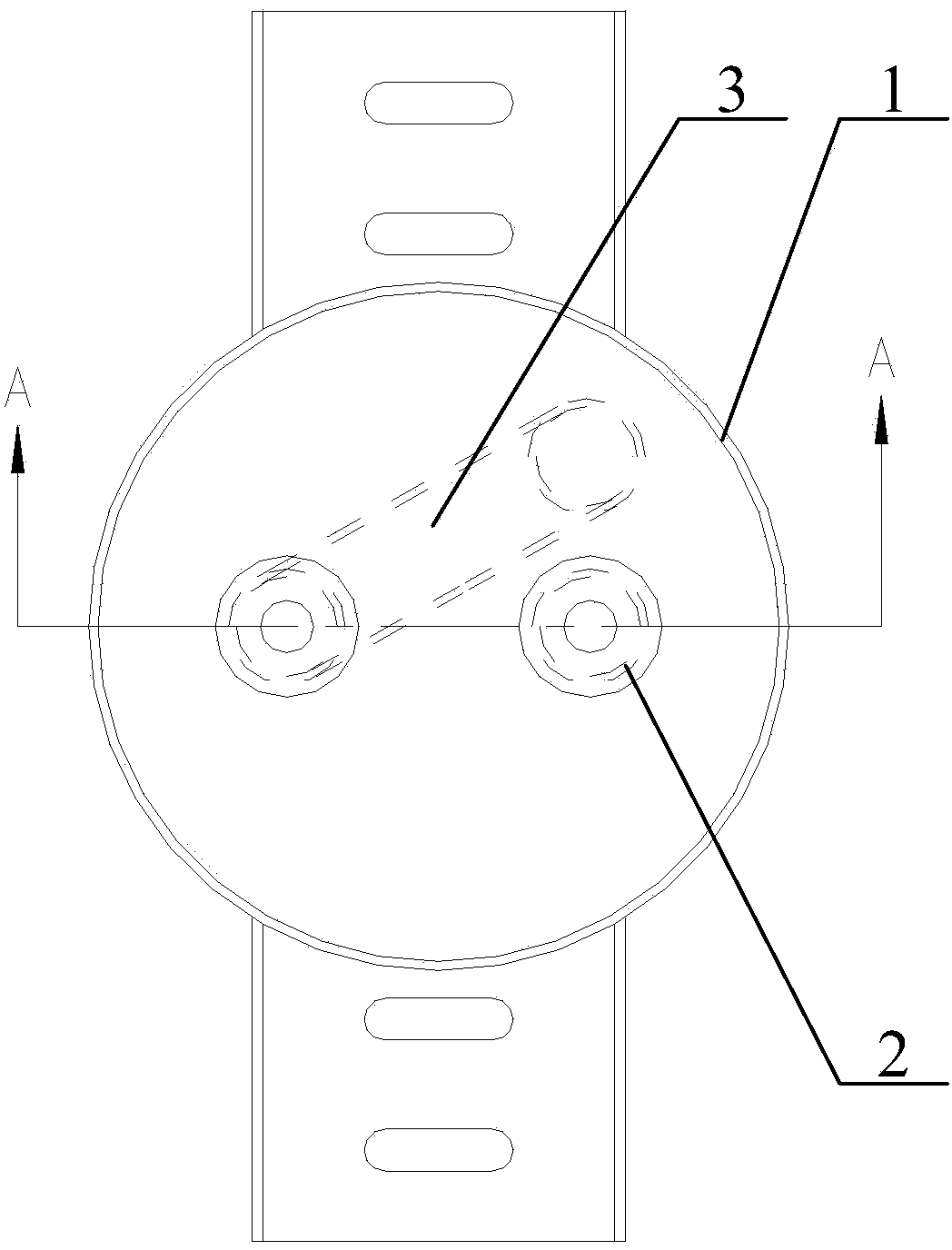

Miniaturized pneumatic-hydraulic linkage actuator for large-diameter valve and low air source

PendingCN109340443ADouble or multiply output powerReduce the effective volumeOperating means/releasing devices for valvesServomotor componentsControl systemEngineering

The invention discloses a miniaturized pneumatic-hydraulic linkage actuator for a large-diameter valve and a low air source. The miniaturized pneumatic-hydraulic linkage actuator comprises a shiftingfork transmission box, a gas-liquid tank assembly, a hydraulic actuating element and at least one pneumatic actuating element; each gas-liquid tank assembly is composed of two gas-liquid tanks, and gas inlets and gas outlets of tank bodies are connected with a pneumatic control system through gas path pipelines; two gas inlet and exhaust ports of the pneumatic actuating elements are connected withthe pneumatic control system through gas path pipelines; and the pneumatic actuating elements and the hydraulic actuating element are installed on one side of the shifting fork transmission box in series or installed on the two sides of the shifting fork transmission box separately. The miniaturized pneumatic-hydraulic linkage actuator is especially suitable for the condition that the gas sourcepressure is 0.6 MPa-1.2 MPa, no matter how the hydraulic actuating element and the pneumatic actuating elements are installed in series, power gas can continuously output hydraulic oil through the gas-liquid tanks to drive hydraulic oil cylinder acting valves and drive air cylinder acting valves through pneumatic output, air cylinders and hydraulic oil cylinders output thrust, the thrust is addedin series, and the output power is added multiple times.

Owner:CHENGDU MAIKESEN FLUID CONTROL EQUIP

Refrigerator

InactiveCN1462860AReduce the effective volumeUniform temperatureLighting and heating apparatusDomestic refrigeratorsCold storeEffective volume

To provide a well convenient refrigerator having a wider effective internal volume and reduced power consumption. The refrigerator comprises a refrigerating room, a freezing room located under the refrigerating room, one evaporator, one blower for blowing cooled air heat-exchanged with the evaporator, a freezing room damper unit for controlling the blown cooled air to be blown to the freezing room, and a refrigerating room damper unit for controlling the blown cooled air to be blown to the refrigerating room. A cooled air suction port of the freezing room damper unit is located under the rotational center axis of the blower without being overlapped with the blower.

Owner:HITACHI APPLIANCES INC

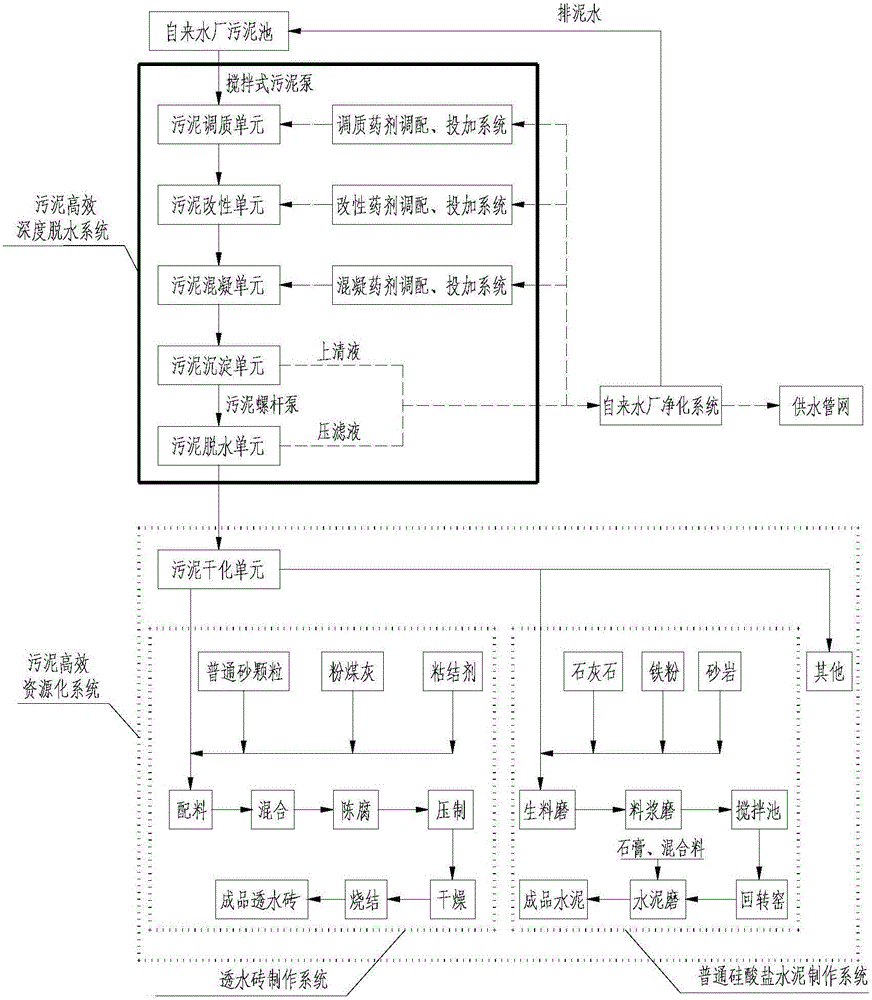

'One-stop' solution system and 'one-stop' solution method for tap water plant sludge treatment

InactiveCN105967493AHigh degree of resource utilizationNo secondary pollutionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationBrick

The invention relates to the field of sludge treatment, and in particular relates to a 'one-stop' solution system and a 'one-stop' solution method for tap water plant sludge treatment. The 'one-stop' solution system comprises a high-efficiency sludge deep-dehydration system and a high-efficiency sludge recycling system, wherein the high-efficiency sludge deep-dehydration system comprises a sludge conditioning unit, a sludge modification unit, a sludge flocculation unit, a sludge precipitation unit and a sludge dehydration unit; and the high-efficiency sludge recycling system comprises a water permeable brick manufacturing system and an ordinary Portland cement production system. After the system and the method are adopted, the sludge of a tap water plant is effectively reduced and recycled; and furthermore, the system and the method are free from secondary pollution, small in floor area, low in investment and operating cost, automatic in control of the whole process as well as safe and easy in operation.

Owner:安徽锋亚环境技术有限公司

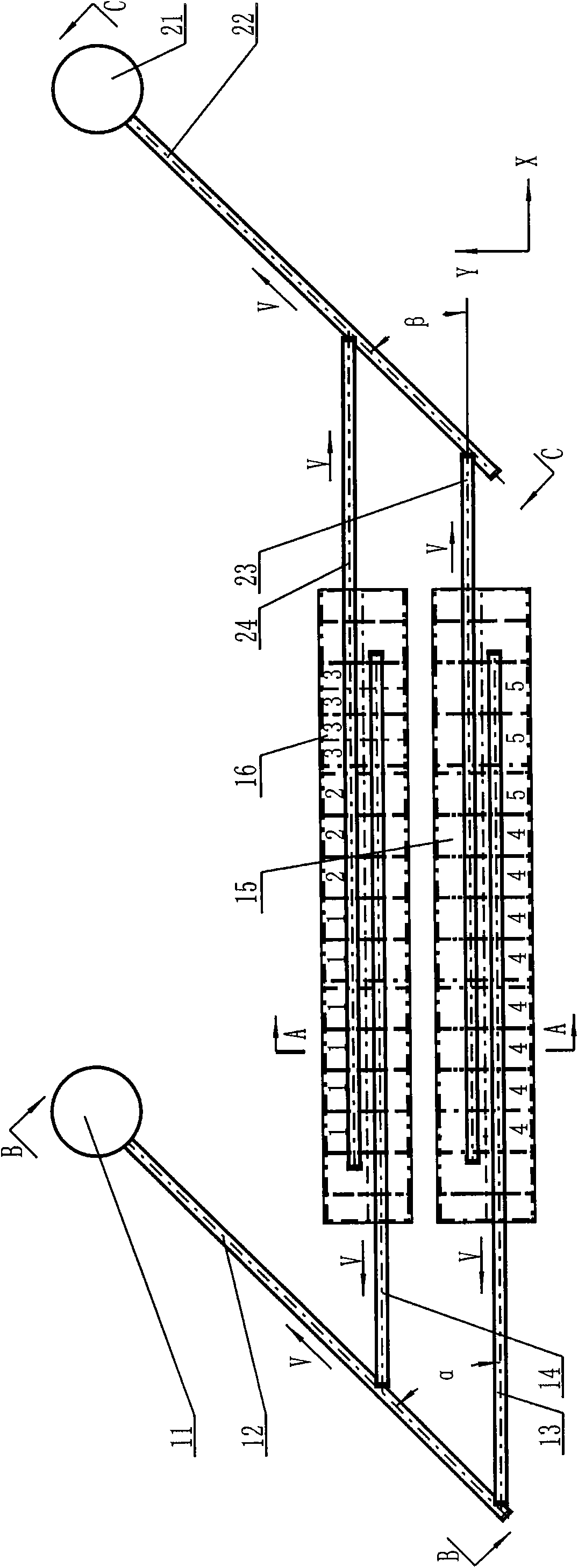

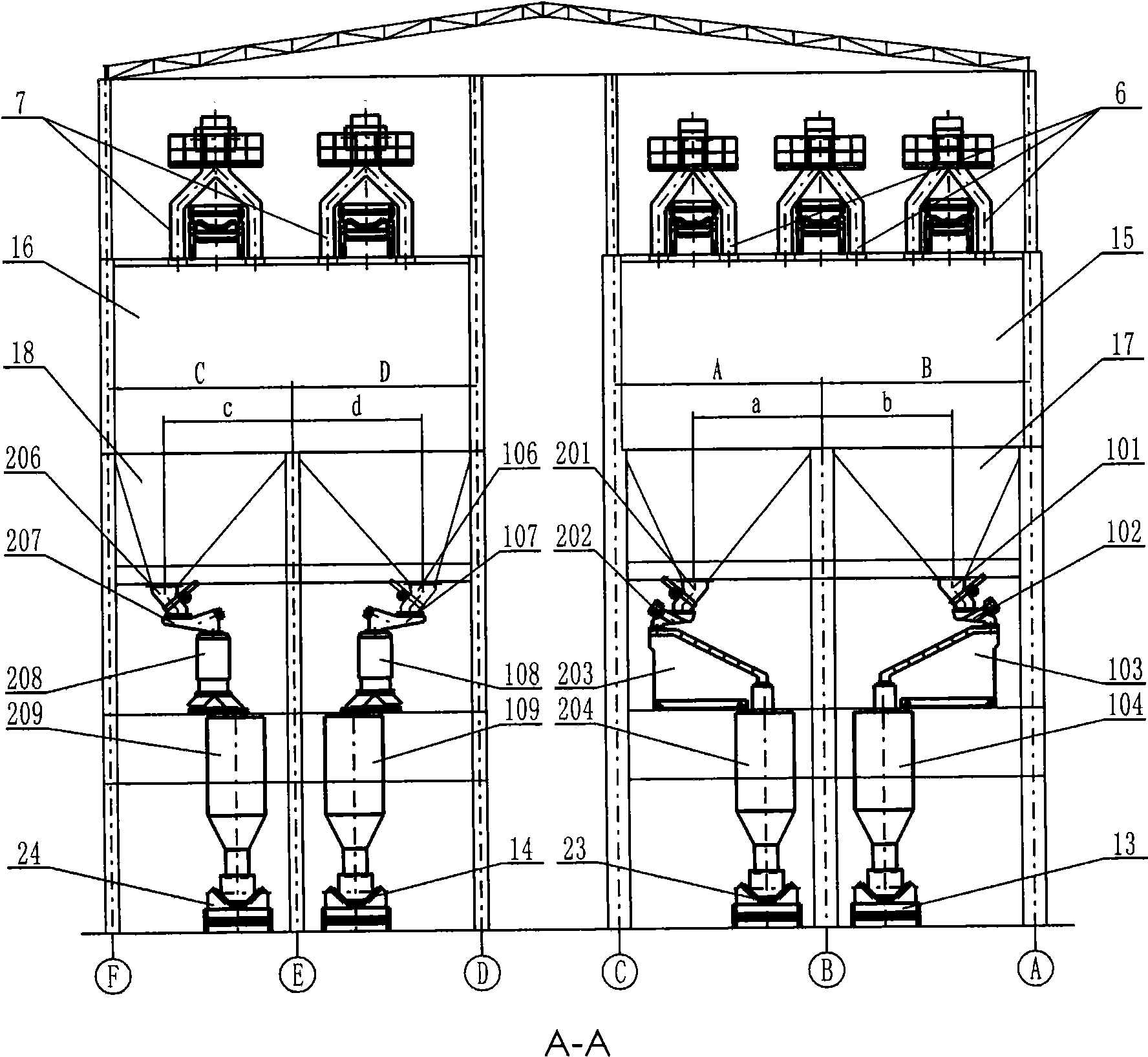

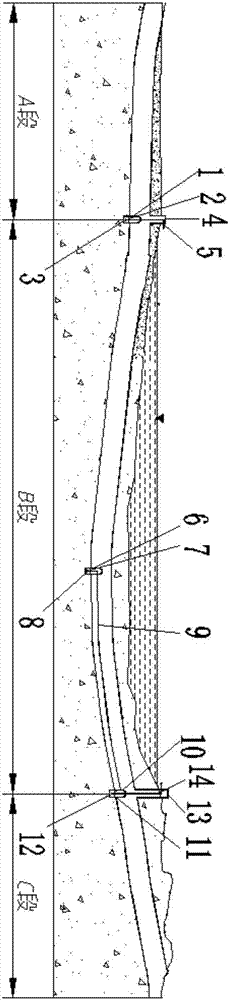

Sectioned-collecting and graded-raising structure for wastewater of mining method deeply-buried underwater transportation tunnel

ActiveCN107165673AReduce the effective volumeSmall footprintHydro energy generationDrainageWastewaterTunnel ventilation

The invention discloses a sectioned-collecting and graded-raising structure for wastewater of a mining method deeply-buried underwater transportation tunnel, and relates to the technical field of underwater transportation tunnels. Wastewater pump houses are arranged at the lowest points of a tunnel section A, a tunnel section B and a tunnel section C correspondingly; the middle wastewater pump houses and the lowest wastewater pump house are both composed of wastewater pools and wastewater pumps, wherein the wastewater pumps are located in the wastewater pools; the wastewater pump houses of the tunnel section A and the tunnel section C are arranged under a left-end tunnel ventilation shaft and a right-end tunnel ventilation shaft correspondingly, and wastewater lifting pipes in the wastewater pump houses in the tunnel section A and the tunnel section C are connected to outdoors through the corresponding tunnel ventilation shafts correspondingly; and the wastewater pump in the lowest wastewater pump house is connected with the wastewater pool in the tunnel section C through a wastewater raising pipe. The sectioned-collecting and graded-raising structure for the wastewater of the mining method deeply-buried underwater transportation tunnel has the advantages that a big wastewater pool is changed into the small wastewater pools, a big pump is changed into the small pumps, water draining is convenient and rapid, the safety and high efficiency are achieved, the pump house occupied land is reduced, and the construction cost and the pump house running cost are saved.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Developing solution wastewater treatment system

PendingCN113501621ALow toxicityReduce inhibitionWater contaminantsTreatment with anaerobic digestion processesSludgeTreatment system

The invention discloses a developing solution wastewater treatment system, the system mainly comprises a TMAH decomposition reaction tank and a membrane separation tank, a water distributor is arranged in the decomposition reaction tank, and the water distributor uniformly distributes reaction tank inlet water and membrane separation tank circulating reflux at the bottom of the tank; an immersed membrane component is mounted in the membrane separation tank, a perforated aeration pipe is arranged at the lower part of the membrane component, the aeration pipe is connected with an air pipeline outside the tank, membrane wires of the immersed membrane component are shaken through aeration, sludge is prevented from being deposited on the surfaces of the membrane wires, and the reaction tank and the membrane separation tank form a closed loop by the whole system through a connecting pipeline. The treatment system disclosed by the invention does not need to heat wastewater, and is simple to operate and relatively low in energy consumption; the treatment load of the reaction tank is improved, the effective volume of the reaction tank is reduced, and the occupied area of the system is saved; and moreover, the maximum concentration of TMAH (Tetramethyl Ammonium Hydroxide) tolerated by the whole system is 2000mg / L, and the removal rate of the TMAH can reach more than 80%.

Owner:上海东振环保工程技术有限公司

Efficient deep dehydration system for sludge

InactiveCN106045263ANo secondary pollutionNo overflowSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSmall footprint

The invention relates to the field of sludge treatment, in particular to an efficient deep dehydration system for sludge. The efficient deep dehydration system for the sludge comprises a stirring type sludge pump, a sludge comprehensive response system, a conditioned medicament blending and adding system, a modified medicament blending and adding system, a flocculation medicament blending and adding system, a sludge screw pump, a membrane filter press, a clear water tank, a clear water pump and an electric control cabinet used for controlling all devices. According to the efficient deep dehydration system for the sludge, water supply plant sludge reduction can be effectively achieved, secondary pollution does not exist, the occupied area is small, the investment and operating cost is low, automation control is achieved in the whole process, and operation is safe and easy.

Owner:安徽锋亚环境技术有限公司

Gas-liquid separator and air conditioner

ActiveCN104315768AGuaranteed separation effectAvoid disturbanceRefrigeration componentsProcess engineeringProduct gas

The invention discloses a gas-liquid separator which comprises a tank, a gas inlet pipe and an exhaust pipe, wherein the gas inlet pipe and the exhaust pipe are communicated with the tank. The bottom of the gas inlet pipe is closed, and the side wall of the gas inlet pipe is provided with gas inlets through which gas horizontally enters the tank. Because the gas inlets through which the gas horizontally enters the tank are formed in the gas inlet pipe, liquid left at the bottom of the tank cannot be directly injected through the gas, the gas enters the tank in parallel with the liquid level, the situation that the gas disturbs liquid at the bottom is effectively avoided, accordingly, the liquid level in the tank cannot rise, gas entrance cannot lead to decrease of the effective volume of the gas-liquid separator; in addition, the gas horizontally entering the tank cannot cause violent disturbance in the tank, the phenomenon that the gas is mixed with the liquid again cannot occur, and thus the separation effect of the gas-liquid separator is effectively guaranteed. The invention further discloses an air conditioner with the gas-liquid separator.

Owner:GREE ELECTRIC APPLIANCES INC

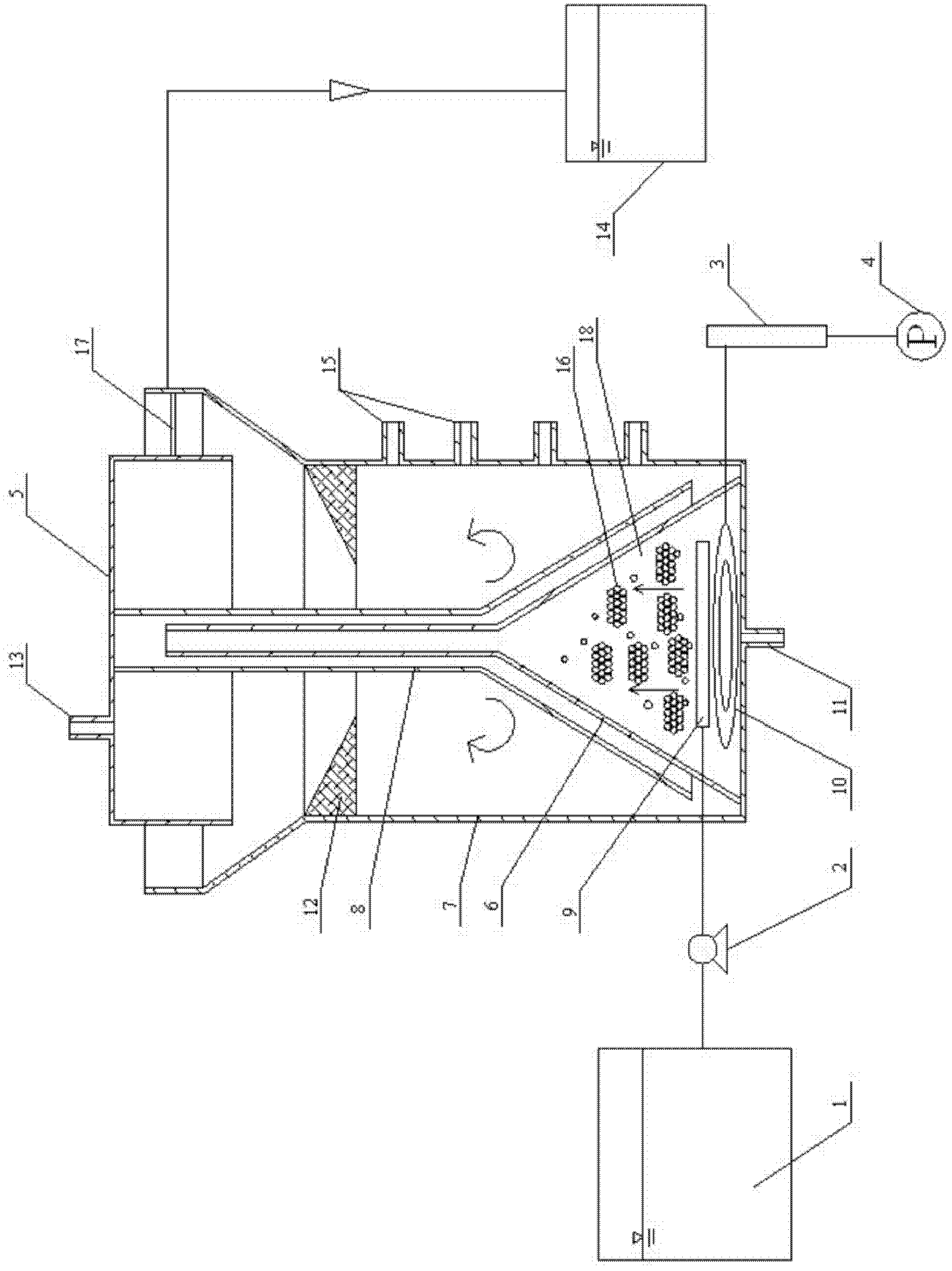

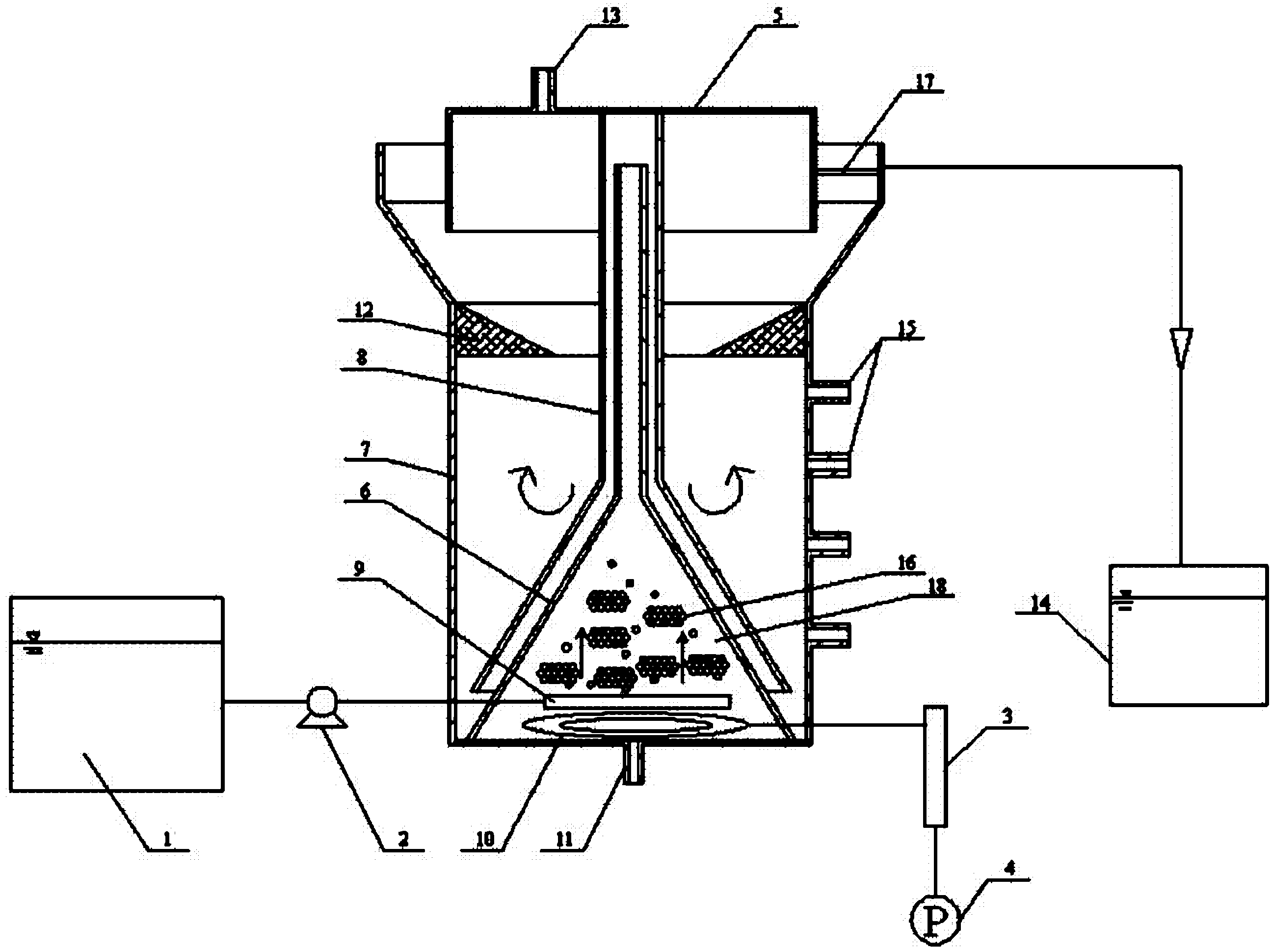

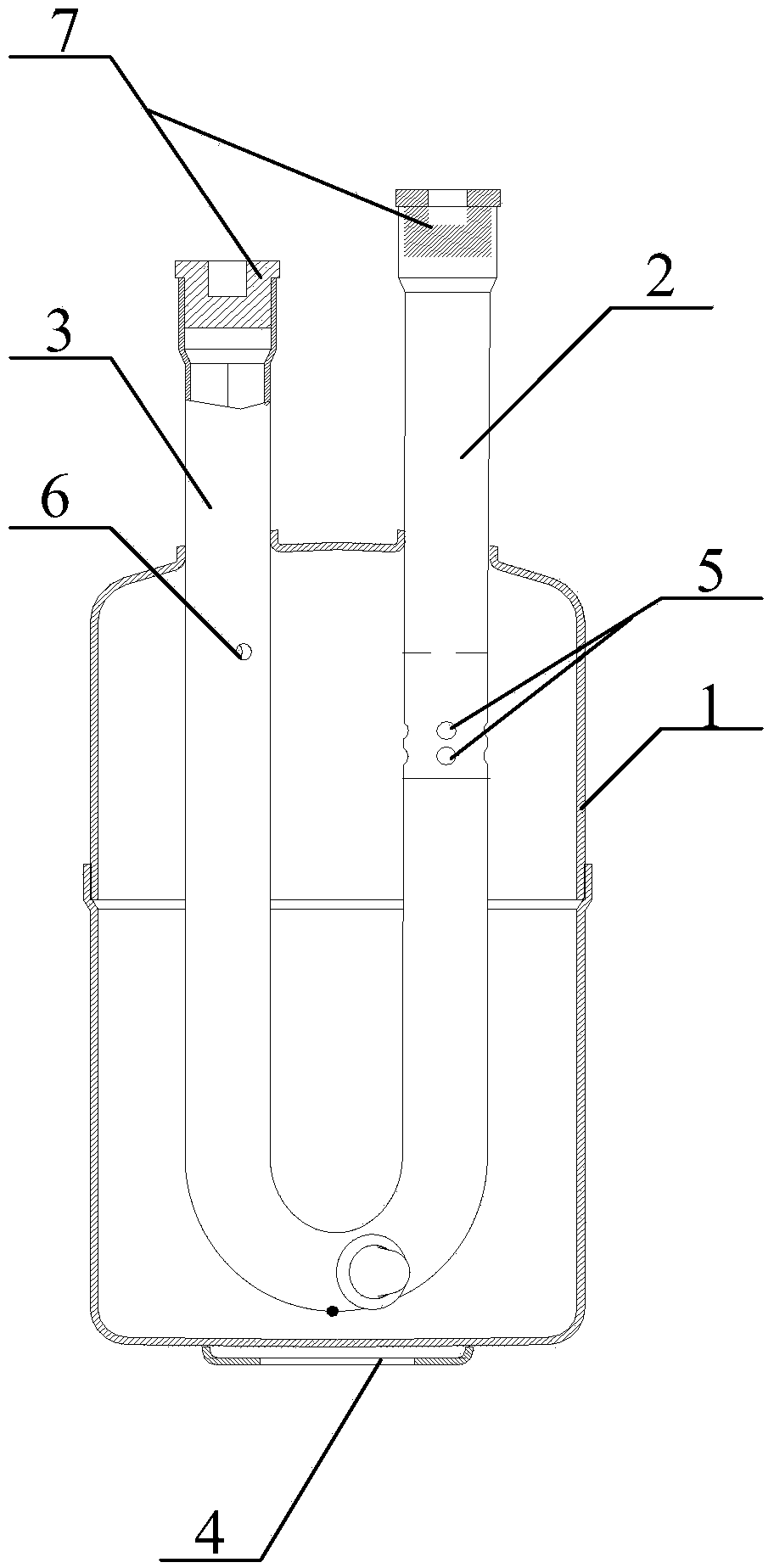

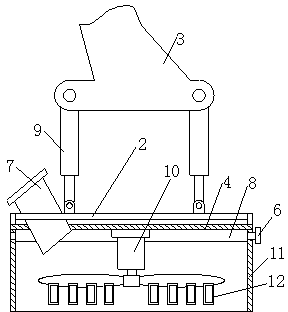

Subcritical liquid extraction device and subcritical liquid extraction method of active ingredients of natural products

InactiveCN101642632BMeet the extraction process requirementsHigh degree of automationSolid solvent extractionFlame arresterTemperature control

The invention provides a subcritical liquid extraction device and a subcritical liquid extraction method of active ingredients of natural products, relating to a device and a method for extracting active ingredients of natural products. The device comprises a control system part and a leaching system part, wherein the leaching system part comprises an extraction tank 1, an evaporating tank 2, a buffer tank 3, a condenser 4, a solvent tank 5, an ultrasound generating device 11, a vacuum pump 9, a fire arrester 10, a compressor 8, a hot water pump 7 and a hot water box 6; the control system part comprises a leaching temperature controller, a leaching time controller, a leaching frequency controller, a material dissolving ratio controller, an exsolution temperature regulation controller, an exsolution pressure feedback controller, an electric appliance controller of the device and an excess-temperature excess-pressure leaking alarm. The method can select different subcritical extraction media according to different extraction products, combines a subcritical liquid extraction technology and an ultrasonic extraction technology to increase extraction rate and reduce extraction time andis a new high-efficiency low-consumption environment-friendly technology for extracting active ingredients of natural products.

Owner:HENAN YALINJIE BIOLOGICAL TECH

River/lake heavy metal pollution sediment in-situ coverage method and device

ActiveCN102775035BReduce dosageEffectively fixedSludge treatmentStream regulationHydraulic cylinderSoil science

The invention provides a river / lake heavy metal pollution sediment in-situ coverage method and device. The method comprises the following steps: adding iron tailings to the surface layer of polluted sediment, evenly mixing, adding cement to the surface layer of the sediment, and evenly mixing to form a solidified coverage layer. The coverage device at least comprises two coverage units, wherein the coverage units are connected together in series; every two adjacent coverage units are connected together through a connecting frame which is connected with an undercarriage through a hydraulic cylinder; and each coverage unit comprises a frame, a fixed plate, a turnover board, an electric mixer and a feed port. By using iron tailing grains and cement as the coverage material, the invention can effectively fix the heavy metals, lower the consumption of the coverage material, avoid reducing the effective volume of the river or lake due to excessive addition of the coverage material, effectively prevent the sediment from resuspension, effectively prevent the sediment pollution on the deep layer from releasing to the overlap water body, and reduce the adverse effect of the treatment process on the overlap water body.

Owner:山东瑞密迪环保科技有限公司

Sub-critical fluid extraction solvent and abstraction method

InactiveCN101161324BHigh extraction rateIncrease profitSolid solvent extractionSulfur hexafluorideAdditive ingredient

The present invention relates to a dissolvent with effective ingredient extracted from the plant-and-animal raw material and the extraction method thereof. One subcritical fluid extraction solvent includes an extraction solvent of a compound or composition extracted from the raw material containing compound or composition as component element, and the solvent is mainly characterized in that the liquid sulfur hexafluoride works as the extraction solvent. The invention also includes a method for extracting the subcritical fluid extraction solvent. The advantage of the invention is that the extraction and separation of the target component in the natural product are optionally executed to further increase the extraction rate of the intermediate product and the usage factor of the raw material while the unique dissolving character of the sulfur hexafluoride and the mixed solvent thereof to the liposoluble active ingredient is used. The physical features of strong dissolving capacity and low boiling point of the sulfur hexafluoride and the mixed solvent thereof are used to reduce the consumption quantity of the energy source, dissolvent of the system and the cost, and increase the market competition ability of the intermediate product.

Owner:韩延欣 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com