'One-stop' solution system and 'one-stop' solution method for tap water plant sludge treatment

A technology for waterworks and sludge treatment, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, special treatment targets, etc., can solve the problem of low recycling of waterworks sludge and effective treatment of structures Problems such as large volume and high infrastructure cost of treatment facilities can achieve the effect of shortening the sludge treatment cycle, shortening the sludge treatment cycle, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the following embodiments are only to illustrate the present invention rather than limit it.

[0038] system structure:

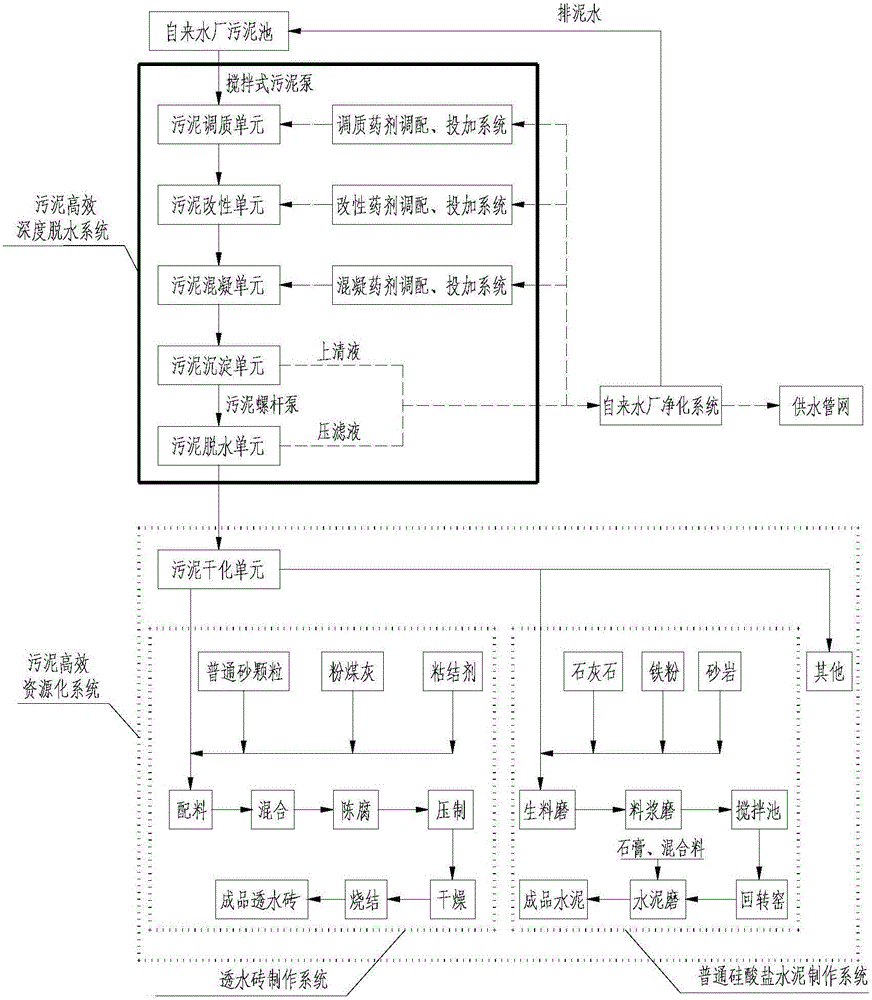

[0039] Such as figure 1As shown, a "one-stop" solution system for sludge treatment in waterworks, including a sludge high-efficiency deep dewatering system and a sludge high-efficiency recycling system, the sludge high-efficiency deep dewatering system includes a sludge conditioning unit , a sludge modification unit, a sludge flocculation unit, a sludge sedimentation unit and a sludge dehydration unit, the sludge efficient recycling system includes a permeable brick production system and an ordinary portland cement production system; the sludge conditioning unit The inlet is connected to the sludge tank, the sludge outlet of the sludge conditioning unit is connected to the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com