Method for recovering germanium in lignite smoke

A soot and lignite technology, which is applied in the field of resource utilization and industrial waste treatment, can solve the problems of long reaction time, waste acid generation, complicated process, etc., and achieve the effect of long reaction time, low recovery rate and clean treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

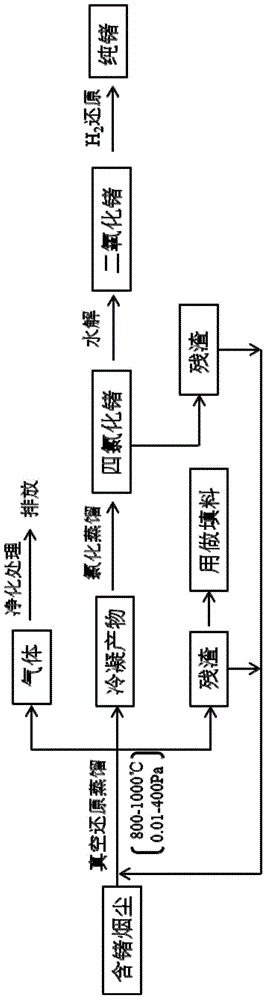

Method used

Image

Examples

Embodiment 1

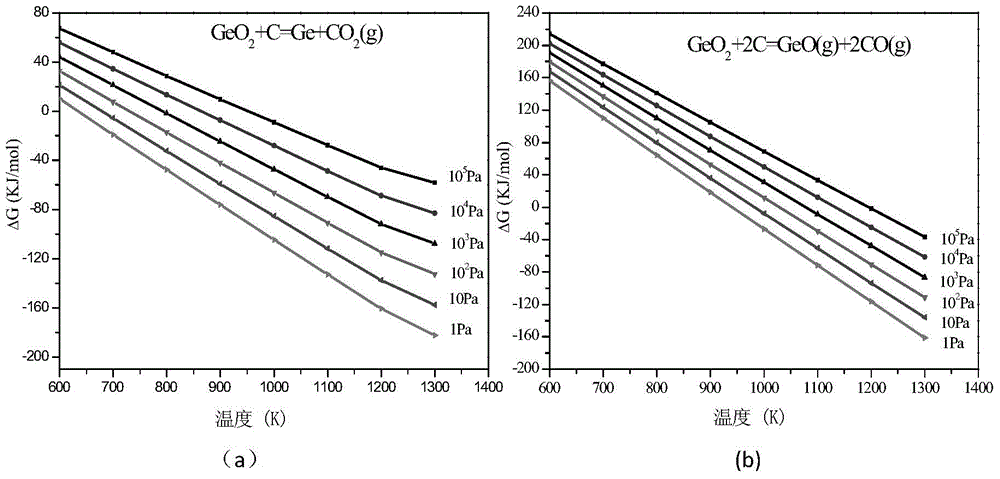

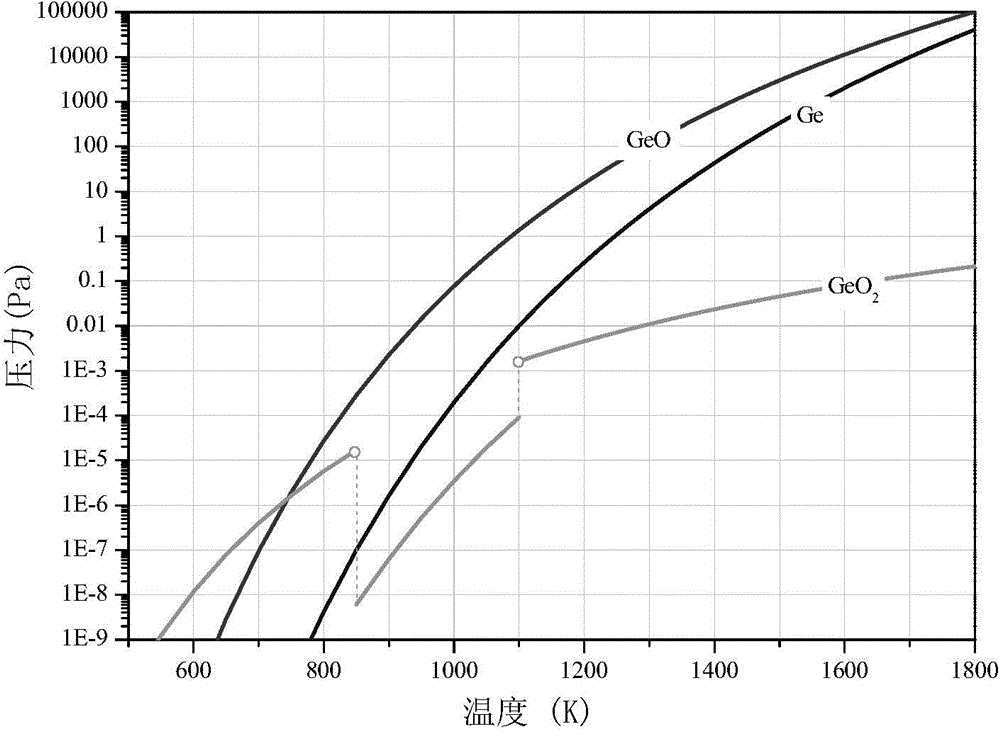

[0046] First place lignite dust and 5wt% coke in a vacuum furnace, then maintain the vacuum in the furnace below 0.1Pa, and keep the temperature at 1000°C, heat for 40 minutes to make it fully react, and the tail gas generated during the vacuum reduction process Pass through the gas discharge channel, and discharge after purification treatment; vacuum reduction reaction obtains germanium metal and its oxide with a recovery rate of 95.30%. Then through the chlorination distillation process, the chloride GeCl of germanium is obtained 4 , followed by hydrolysis and H 2 After reduction treatment, metallic germanium with a purity of more than 90% is obtained.

Embodiment 2

[0048] First place lignite dust and 15wt% coke in a vacuum furnace, then maintain the vacuum in the furnace below 10Pa, and keep the temperature at 1200°C for 40 minutes to fully react, and the tail gas generated during the vacuum reduction process passes through The gas is discharged from the channel and discharged after purification treatment; the vacuum reduction reaction obtains germanium metal and its oxide with a recovery rate of 96.48%. Then through the chlorination distillation process, the chloride GeCl of germanium is obtained 4 , followed by hydrolysis and H 2 After reduction treatment, metallic germanium with a purity of more than 90% is obtained.

Embodiment 3

[0050] First place lignite dust and 25wt% coke in a vacuum furnace, then maintain the vacuum in the furnace below 0.01Pa, and keep the temperature at 900°C, heat for 60 minutes to make it fully react, and the tail gas generated during the vacuum reduction process Pass through the gas discharge channel and discharge after purification treatment; the vacuum reduction reaction obtains germanium metal and its oxide with a recovery rate of 90.12%. Then through the chlorination distillation process, the chloride GeCl of germanium is obtained 4 , followed by hydrolysis and H 2 After reduction treatment, metallic germanium with a purity of more than 90% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com