Patents

Literature

36results about How to "Reduce landfill volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pet used cat litter and preparation method thereof

The invention relates to pet cat litter and its preparation method, which comprises preparing organic base-material 20- 60%, clay 30-80%, binder 0-10%, water absorber 0-20%, surface adsorption substance0- 5%, crushing organic base-material to 30 screen mesh bulkload, processing clay to powder finer than 200 screen mesh, picking organic base material and clay proportionally to making cat litter base body, mixing and stirring the remaining material to making mixed covering material, placing cat litter base body in high-velocity rotating vibration machine, rotating making hydrosphere seeping to the surface of base body, then adding mixed covering material, vibrating slightly for mixing, then sifting and drying, sifting out powder. The inventive cat litter has good deodorant effect, good conglobation property after using, and waste cat litter can combust in favor of environment protection.

Owner:HANGZHOU LINAN KUROKAWA BENTONITE

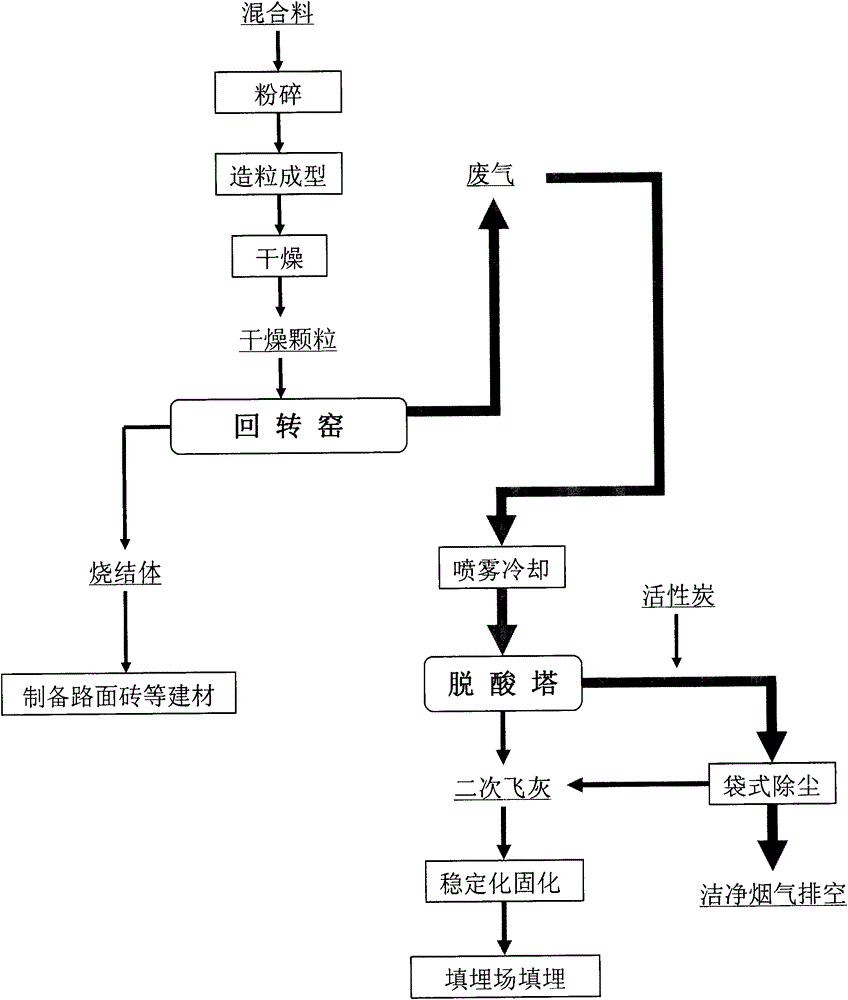

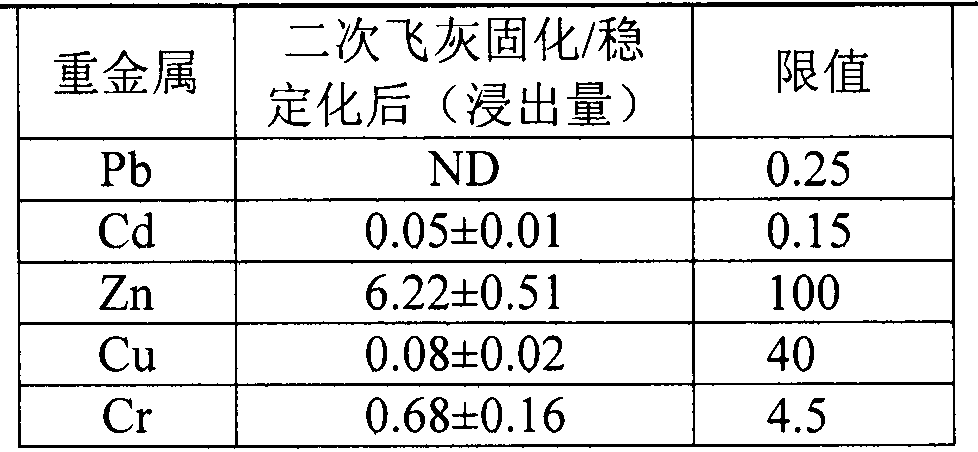

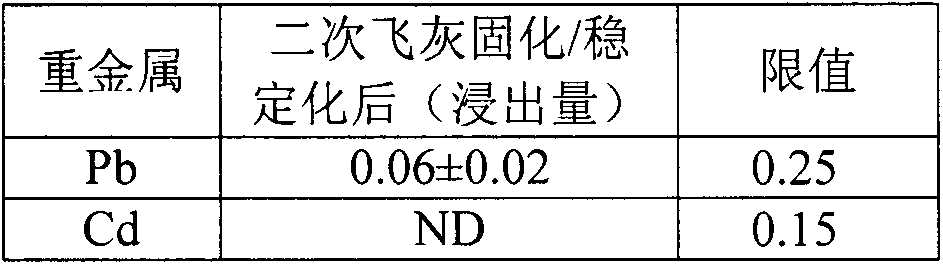

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

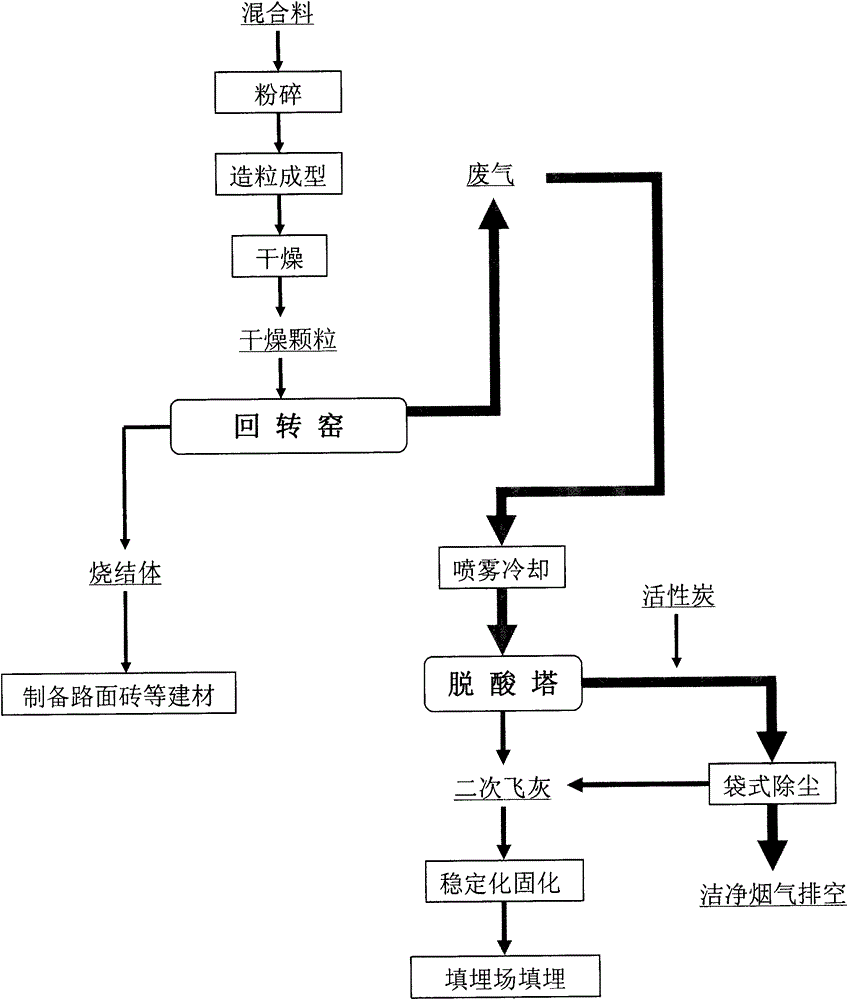

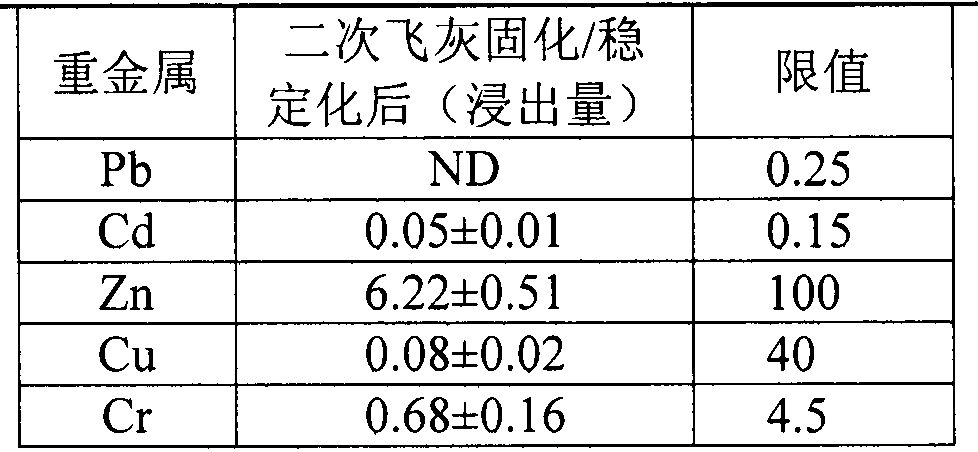

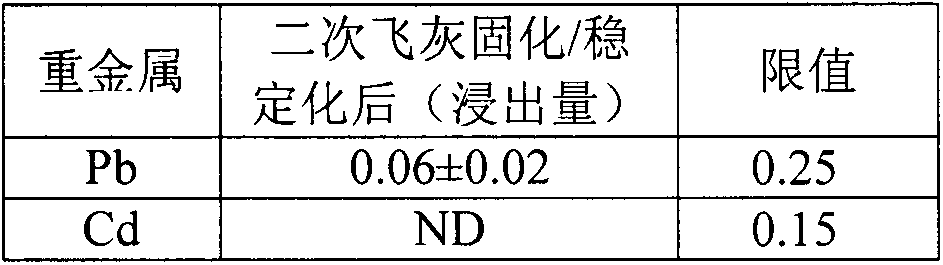

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

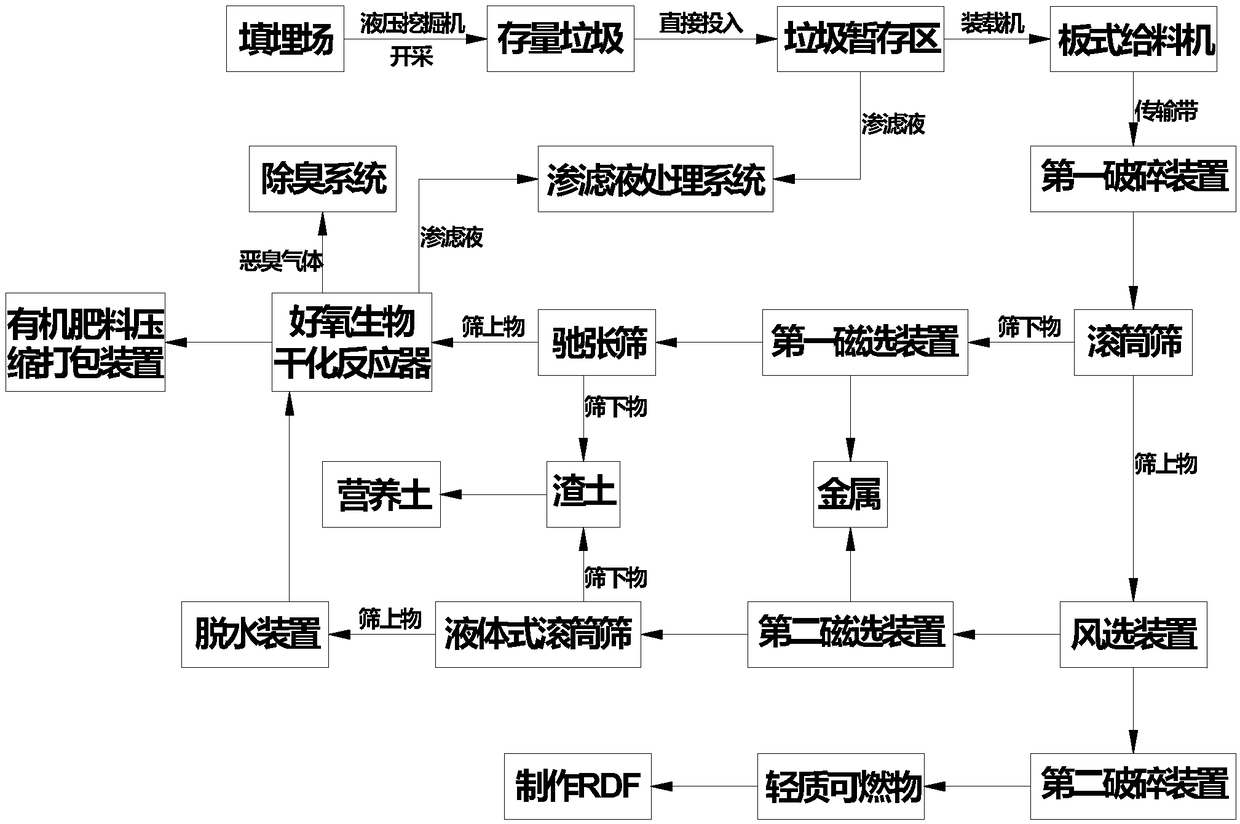

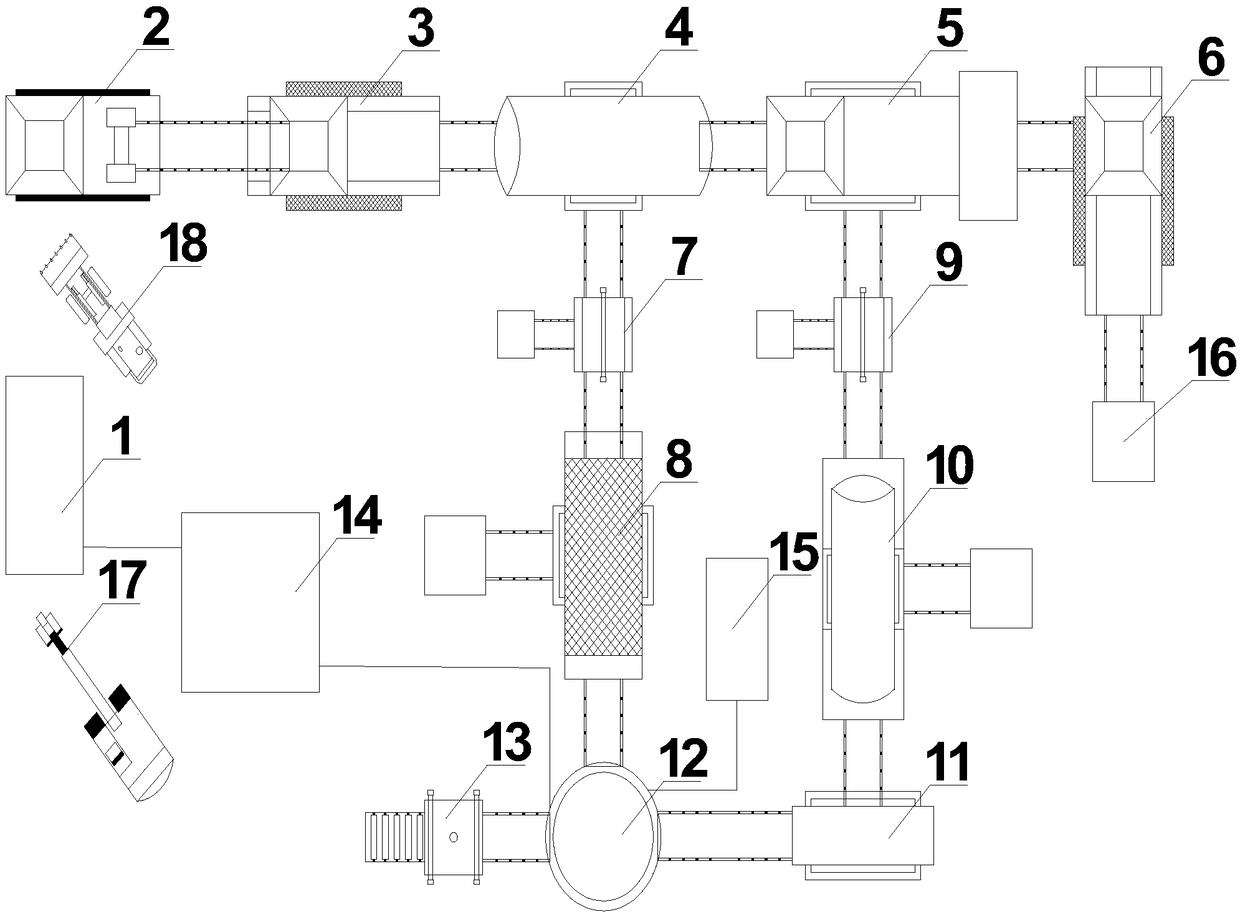

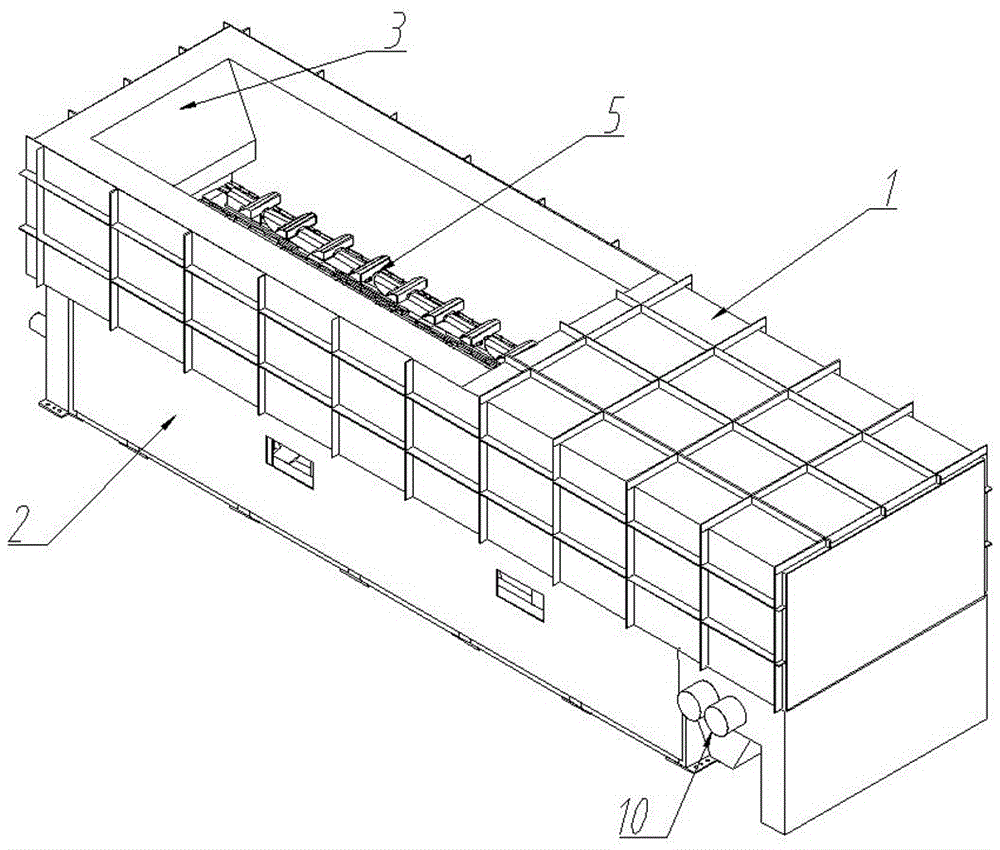

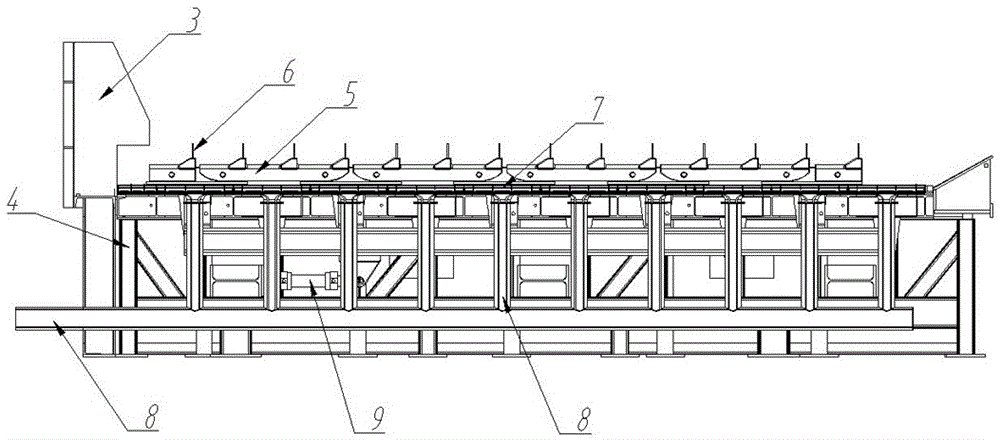

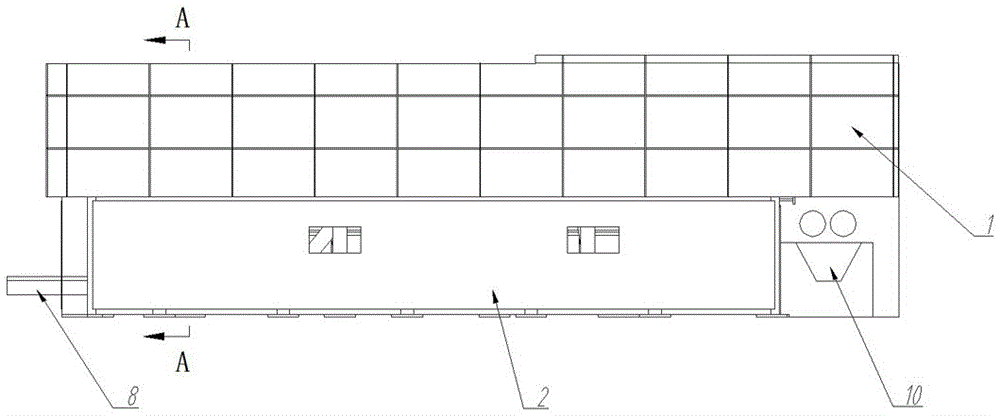

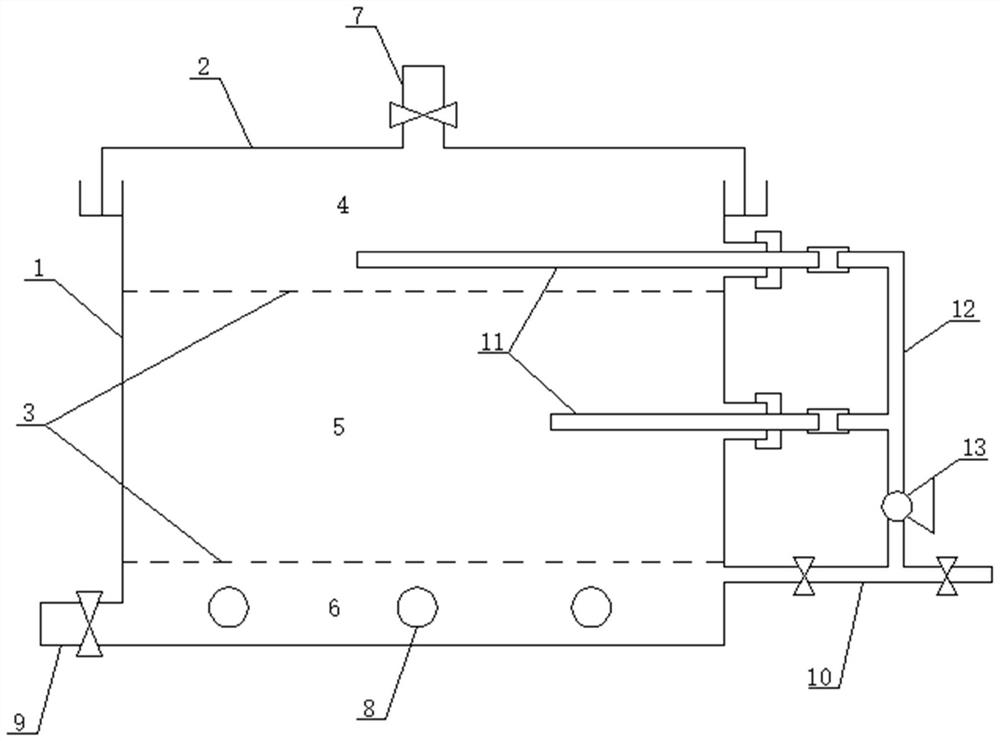

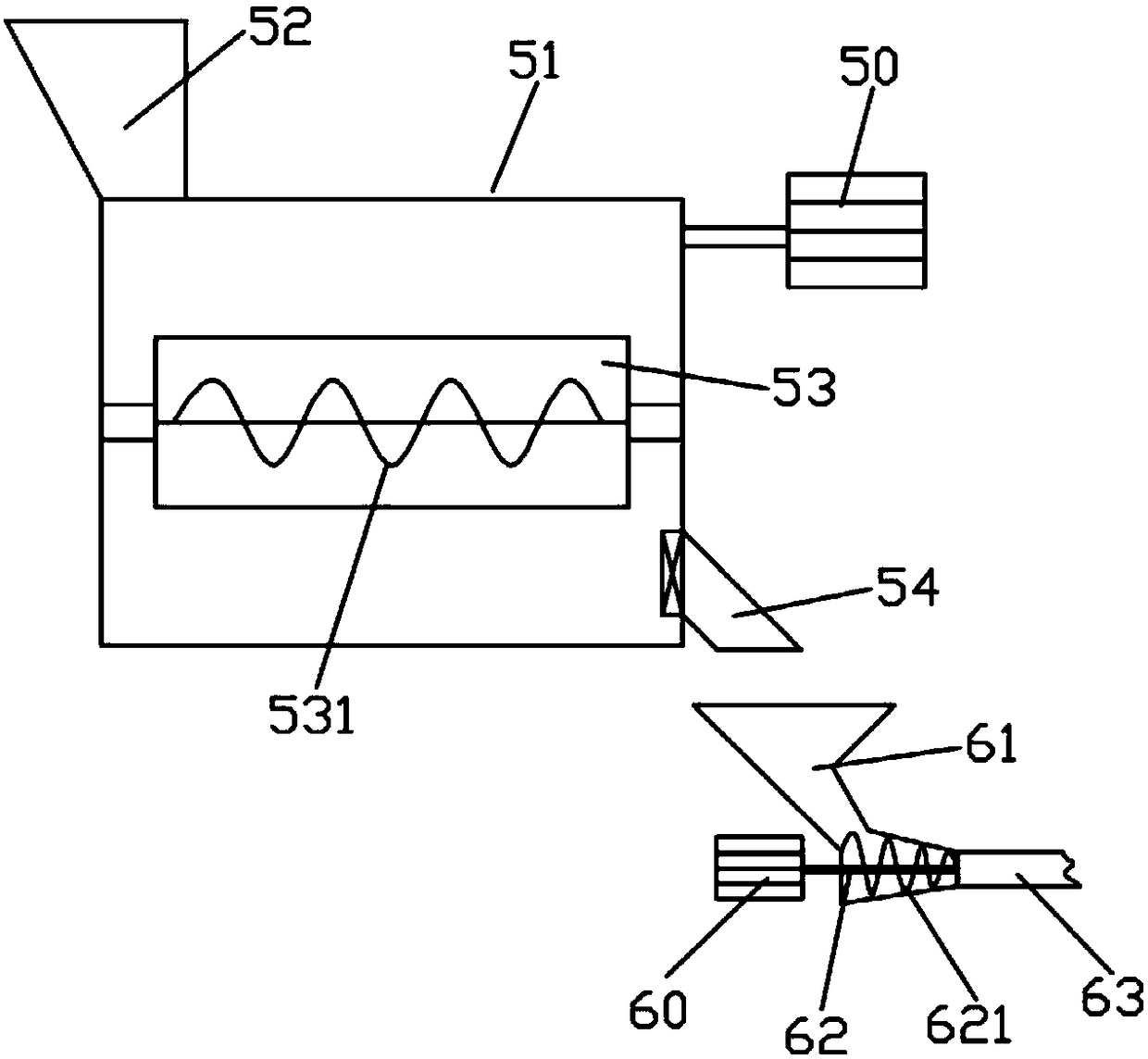

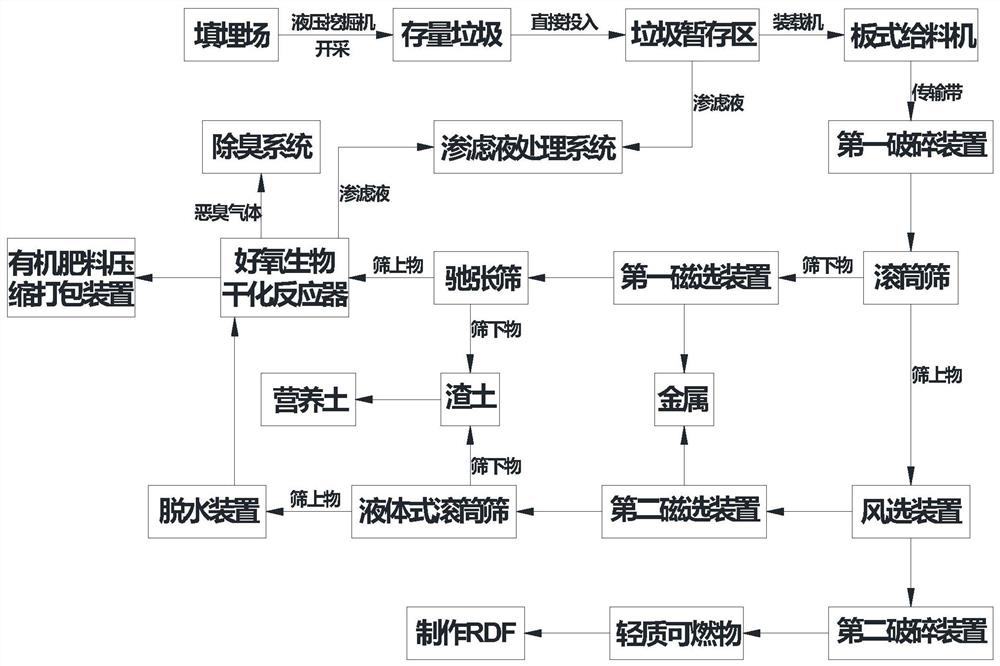

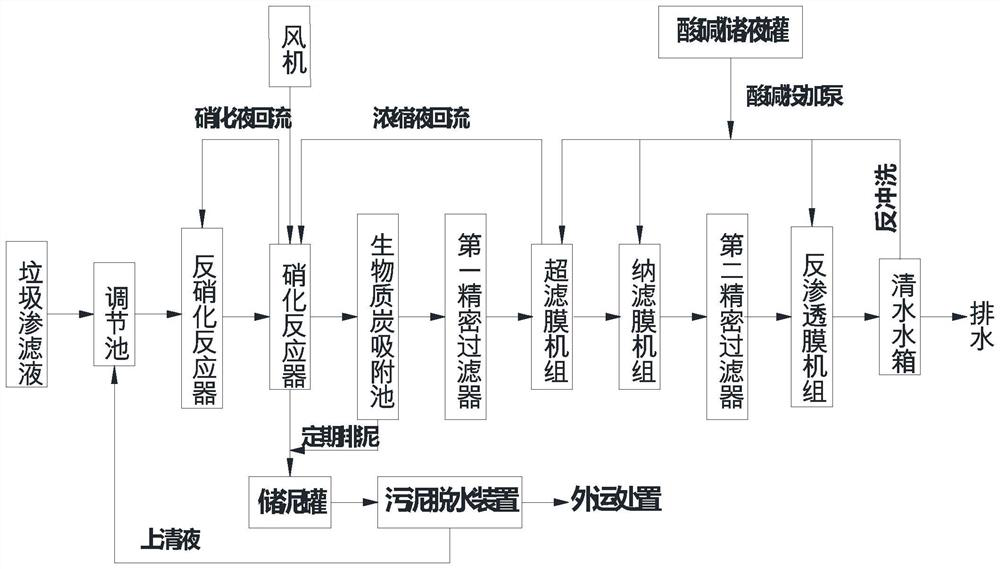

Stock garbage in-situ resourceful treatment method and stock garbage in-situ resourceful treatment system

ActiveCN108787699ARealize high resource utilizationReduce landfill volumeSolid waste disposalDispersed particle separationAir separationOrganic fertilizer

The invention discloses a stock garbage in-situ resourceful treatment method and a stock garbage in-situ resourceful treatment system. The system comprises a garbage temporary storage area, a plate feeder, a first breaking device, a drum screen, an air separation device, a second breaking device, a first magnetic separation device, a tension and relaxation screen, an aerobic biological drying reactor, an organic fertilizer compressing and packing device, a second magnetic separation device, a liquid type drum screen, a dewatering device, a percolating liquid treatment system and a deodorization system; garbage in the garbage temporary storage area is transported to the plate feeder; the plate feeder is sequentially connected with the first breaking device and the drum screen; a first outlet of the drum screen is connected with the air separation device; a first outlet of the air separation device is connected with the second breaking device; a second outlet of the air separation deviceis sequentially connected with the second magnetic separation device, the liquid type drum screen and the dewatering device; an outlet of the dewatering device is connected with a first inlet of theaerobic biological drying reactor; a second outlet of the drum screen is connected with the first magnetic separation device and the tension and relaxation screen; an outlet of the tension and relaxation screen is connected with a second inlet of the aerobic biological drying reactor; an outlet of the aerobic biological drying reactor is connected with the organic fertilizer compressing and packing device; the aerobic biological drying reactor is further connected with the percolating liquid treatment system and the deodorization system; and the garbage temporary storage area is further connected with the percolating liquid treatment system. Production of secondary pollution can be completely prevented, and highly-resourceful utilization of the stock garbage can be achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

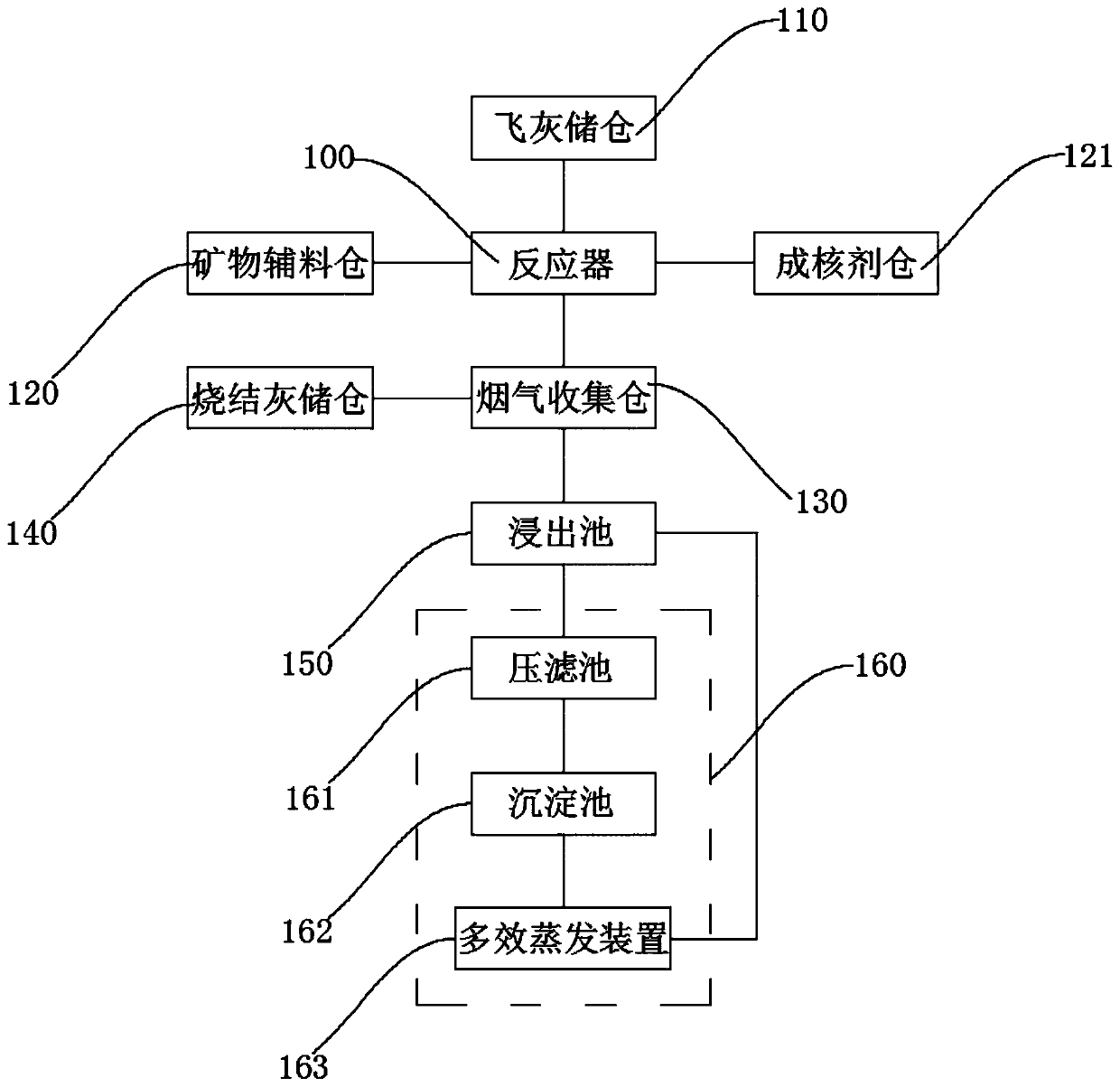

Method and device for treating waste incineration fly ash through cooperation of metallurgy waste residues

The invention discloses a method and device for treating waste incineration fly ash through cooperation of metallurgy waste residues, and relates to the field of treatment of solid wastes. The methodfor treating the waste incineration fly ash through the cooperation of the metallurgy waste residues comprises the following steps that the waste incineration fly ash, mineral auxiliary materials anda crystallization nucleation agent are added into blast furnace slag to be subjected to melting separation, and secondary smoke gas and glass solidified bodies are obtained; and the secondary smoke gas and sintering machine head dedusting ash are mixed and then are introduced into treatment water to obtain a treating fluid, and the treating fluid is separated to obtain a filtrate and filter residues. According to the method for treating the waste incineration fly ash through the cooperation of the metallurgy waste residues, chlorine, silicon and aluminum elements can be effectively recycled under the premise of heavy metal solidification. The invention further provides the device for treating the waste incineration fly ash through the cooperation of the metallurgy waste residues based on the method for treating the waste incineration fly ash through the cooperation of the metallurgy waste residues.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

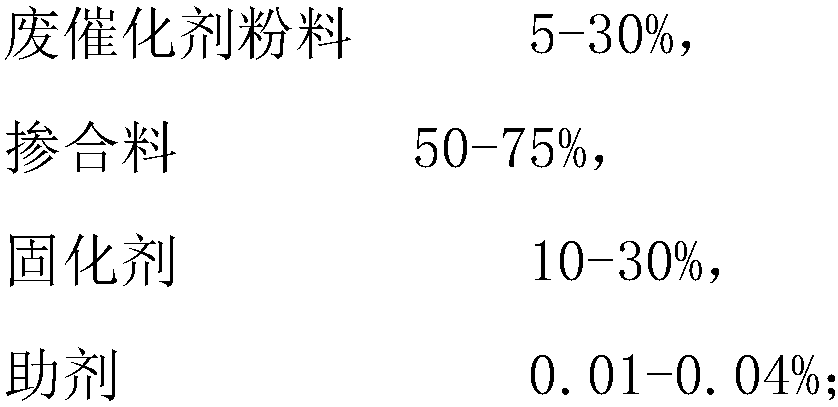

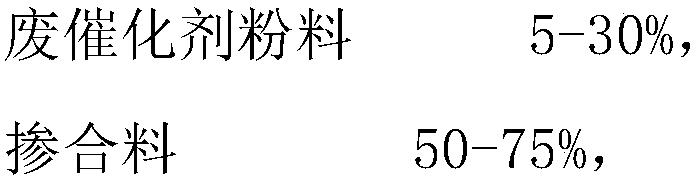

Curing method for heavy metal in waste catalyst

The invention relates to a curing method for heavy metal in a waste catalyst. The method comprises the following steps: grinding the waste catalyst to obtain waste catalyst powder, wherein the waste catalyst contains heavy metal; mixing the curing agent, admixture, an additive, the waste catalyst powder with water to obtain a mixture; sealing the mixture and ageing the mixture; compressing and shaping the aged mixture to obtain a green brick and maintaining the green brick to obtain a baking-free brick containing heavy metal. Results of a heavy metal element leaching test on the baking-free brick show that the method disclosed by the invention can effectively cure the heavy metal in the heavy metal. The method disclosed by the invention solves the problem of environmental pollution causedby waste catalyst landfill, reduces damage of the heavy metal to environment, improves a resource utilization rate at the same, reduces waste emission and achieves sustainable development.

Owner:CHINA BUILDING MATERIALS ACAD

Pet used cat litter and preparation method thereof

The invention relates to a cat litter for pets and a preparation method thereof. % Prepare the materials, pulverize the organic base material into granules finer than 30 meshes, process the clay into fine powders finer than 200 meshes, take the organic base material and clay in proportion to process the cat litter matrix, and then mix and stir the remaining materials to cover the surface. To mix the material, put the cat litter matrix into a high-speed rotary vibrating machine to rotate and vibrate to make the water vapor in the matrix seep out and adhere to the surface of the matrix, then add the surface to cover the mixed material, and then sieve and dry after a little vibration and mixing. The granules are sieved to remove powder and packaged for storage. It has good deodorizing effect, good particle agglomeration after use, will not cause the consolidation of pellets to break when cleaning waste cat litter, easy to clean, waste cat litter can be burned, which is beneficial to environmental protection, and the product and production cost are low. Cat litter for pets and preparation method thereof.

Owner:HANGZHOU LINAN KUROKAWA BENTONITE

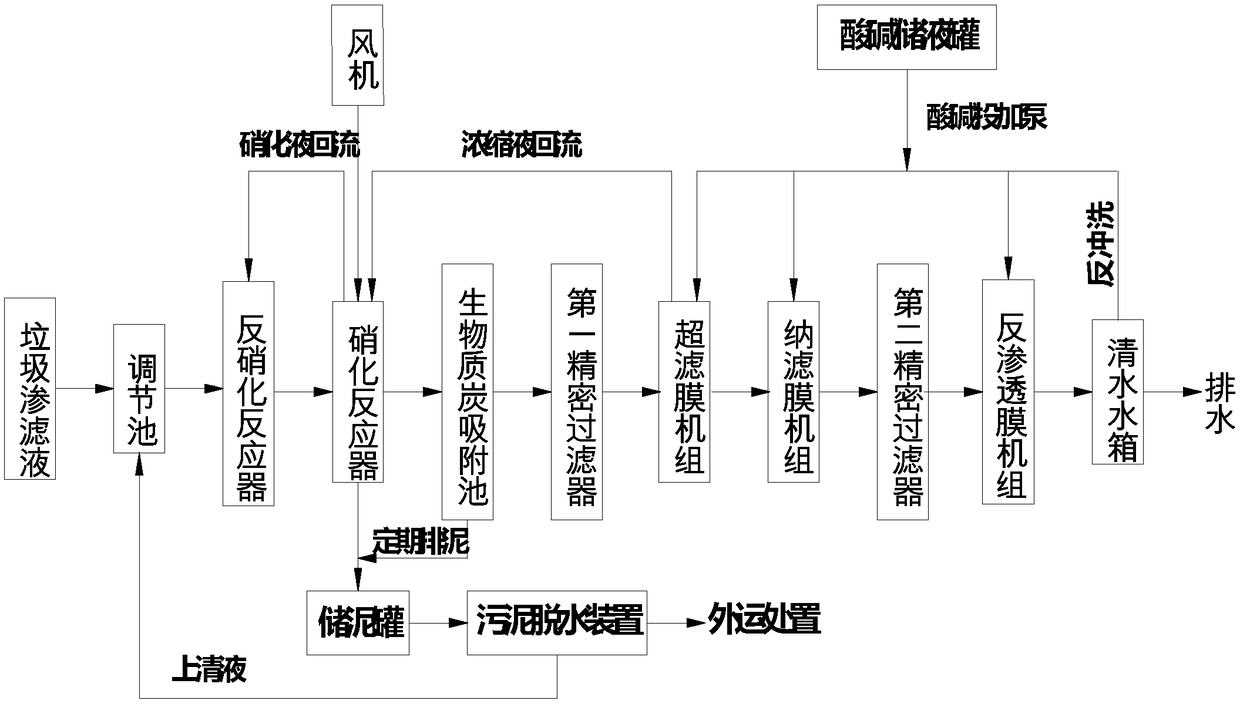

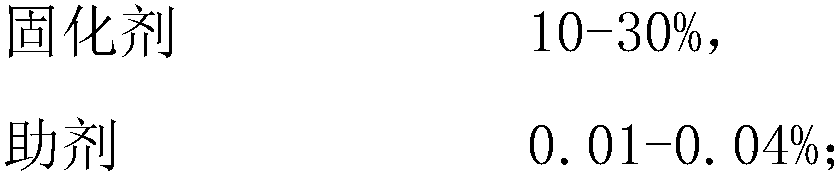

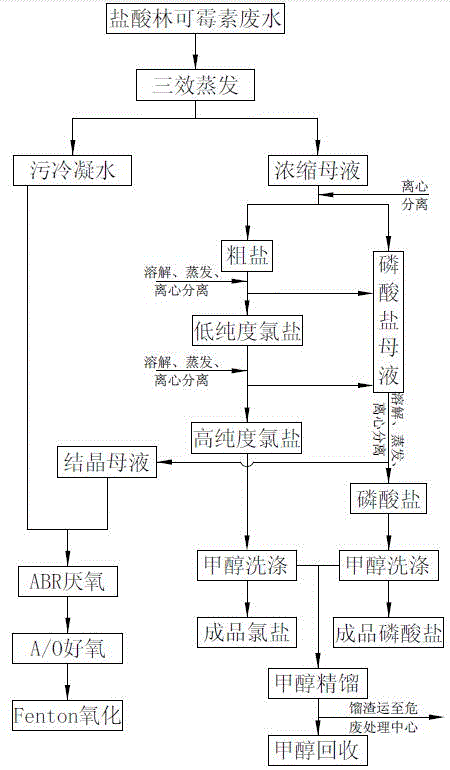

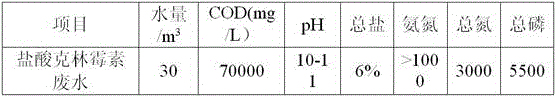

Integrated treatment process for clindamycin hydrochloride production wastewater

ActiveCN106348545AReduce landfill volumeRational use of resourcesWater/sewage treatment by centrifugal separationWater treatment compoundsPhosphateDistillation

The invention discloses an integrated treatment process for clindamycin hydrochloride production wastewater. The process comprises the following steps: performing triple-effect evaporation and concentration on the clindamycin hydrochloride production wastewater, performing centrifugal separation, feeding coarse salts produced by centrifugal separation into a salt refining workshop, collecting the mother solution to be used for extracting phosphate, and repeatedly performing dissolution, evaporation and centrifugal separation on the coarse salts in the salt refining workshop, thereby obtaining high-purity chlorine salts; washing by ethanol, thereby obtaining the finished chlorine salts; collecting the produced mother solution to be used for extracting phosphate; performing evaporation and concentration on the phosphate mother solution, centrifuging and washing, thereby obtaining the phosphate; rectifying the scrubbing solution, recycling the methanol, feeding the distillation residues into a hazardous waste treatment center, merging the foul condensate produced by multiple-effect evaporation and crystallization mother liquor produced by centrifugal separation, homogenizing, and performing anaerobic and aerobic biological treatment and advanced treatment. The method provided by the invention is an integrated method for combining multiple-effect evaporation, methanol rectification and biological treatment and has the characteristics of reasonable resource utilization, low cost, simplicity and convenience in operation, stable operation and the like.

Owner:河南君和环保科技有限公司

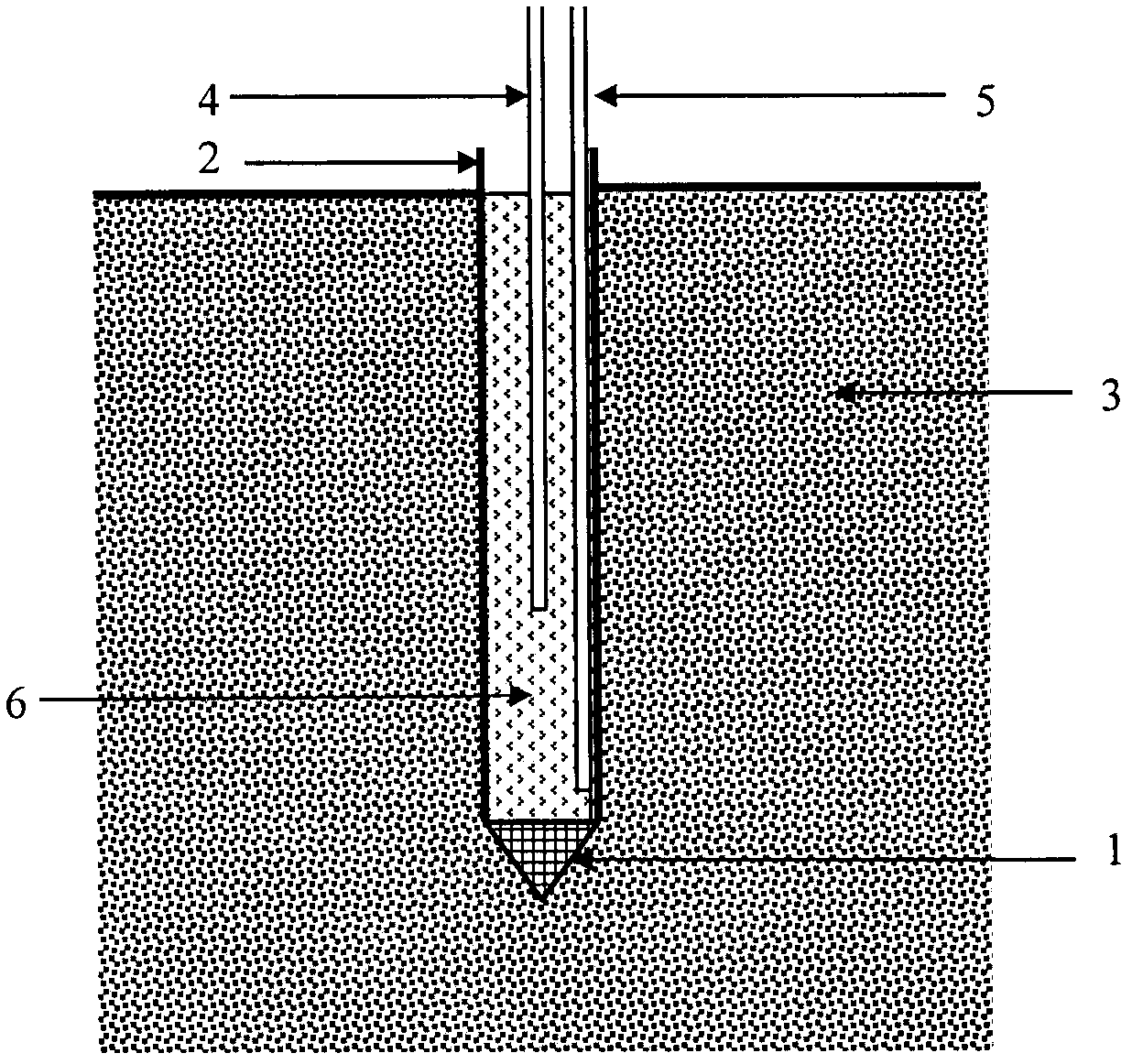

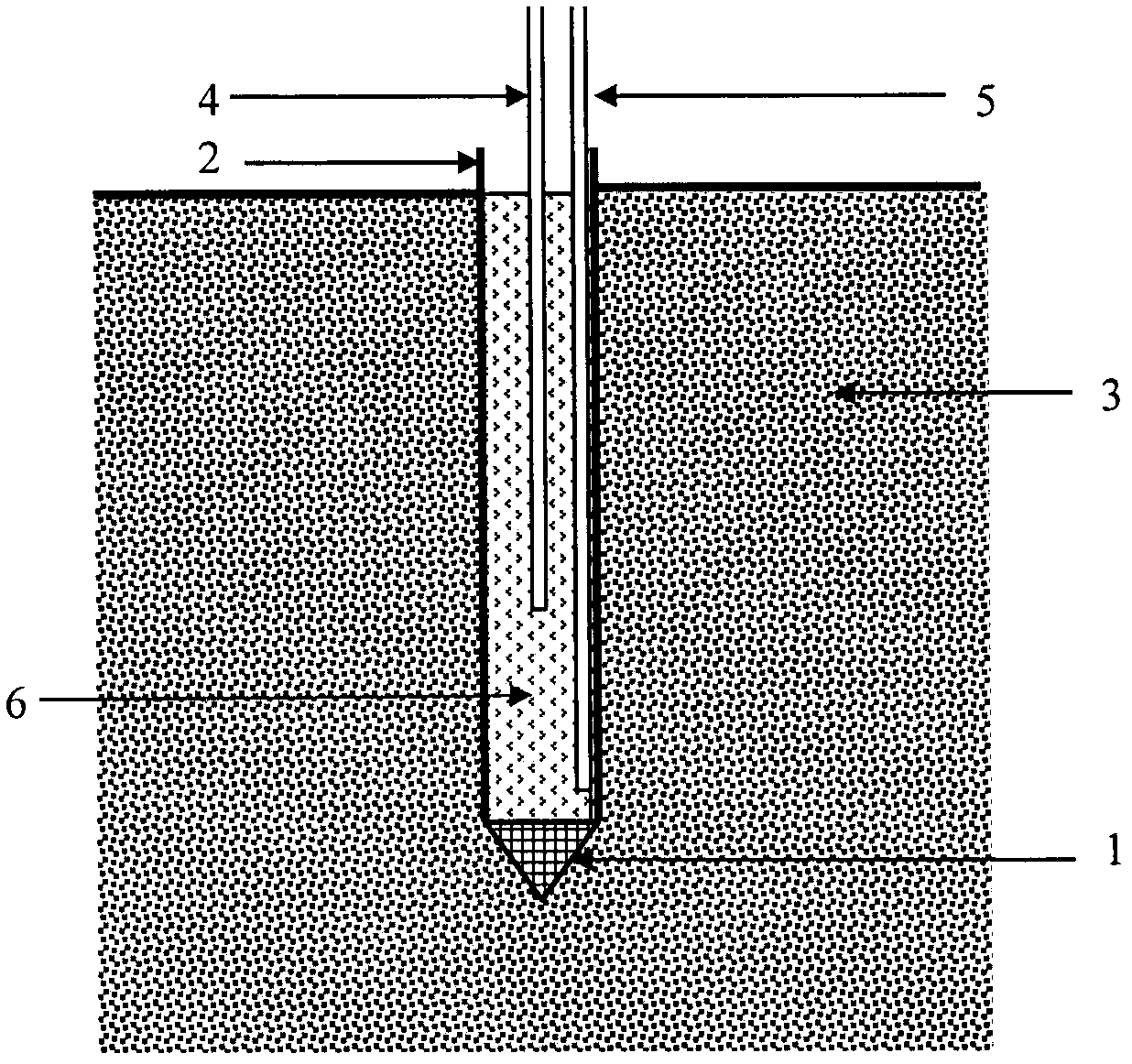

Construction method for incinerated garbage ash pile

ActiveCN107675702AReduce consumptionReduce landfill volumeBulkheads/pilesResource utilizationChloride

The invention discloses a construction method for an incinerated garbage ash pile, and belongs to the technical fields of solid waste resource utilization and foundation treatment. The construction method is used for solving the problem of waste utilization of incinerated garbage ash and is characterized by comprising the following steps that a, a steel pipe 2 provided with a concrete precast piletip 1 sinks into a foundation 3 so that a pile hole can be formed; b, bacteria liquid, medium sand and the incinerated garbage ash are uniformly mixed at first and then added with a 0.05 mol / L calcium chloride solution to be mixed into a mixture; c, the mixture is poured into the steel pipe 2 sinking into the foundation in advance, and a grouting pipe 4 and a grout extracting pipe 5 are buried inthe mixture 6 in the mixture filling process; d, after the pile hole is filled with the mixture 6, the steel pipe 2 is pulled out; e, liquid in pores of the mixture in the pile hole is completely extracted through the grout extracting pipe 5, then, consolidating fluid is injected through the grouting pipe 4 till the pores of the mixture in the whole pile hole is full of the consolidating fluid, and still standing is conducted for 6-24 h; and f, the step e is repeated for 4-6 times, and construction of the incinerated garbage ash pile is completed.

Owner:NANJING FORESTRY UNIV

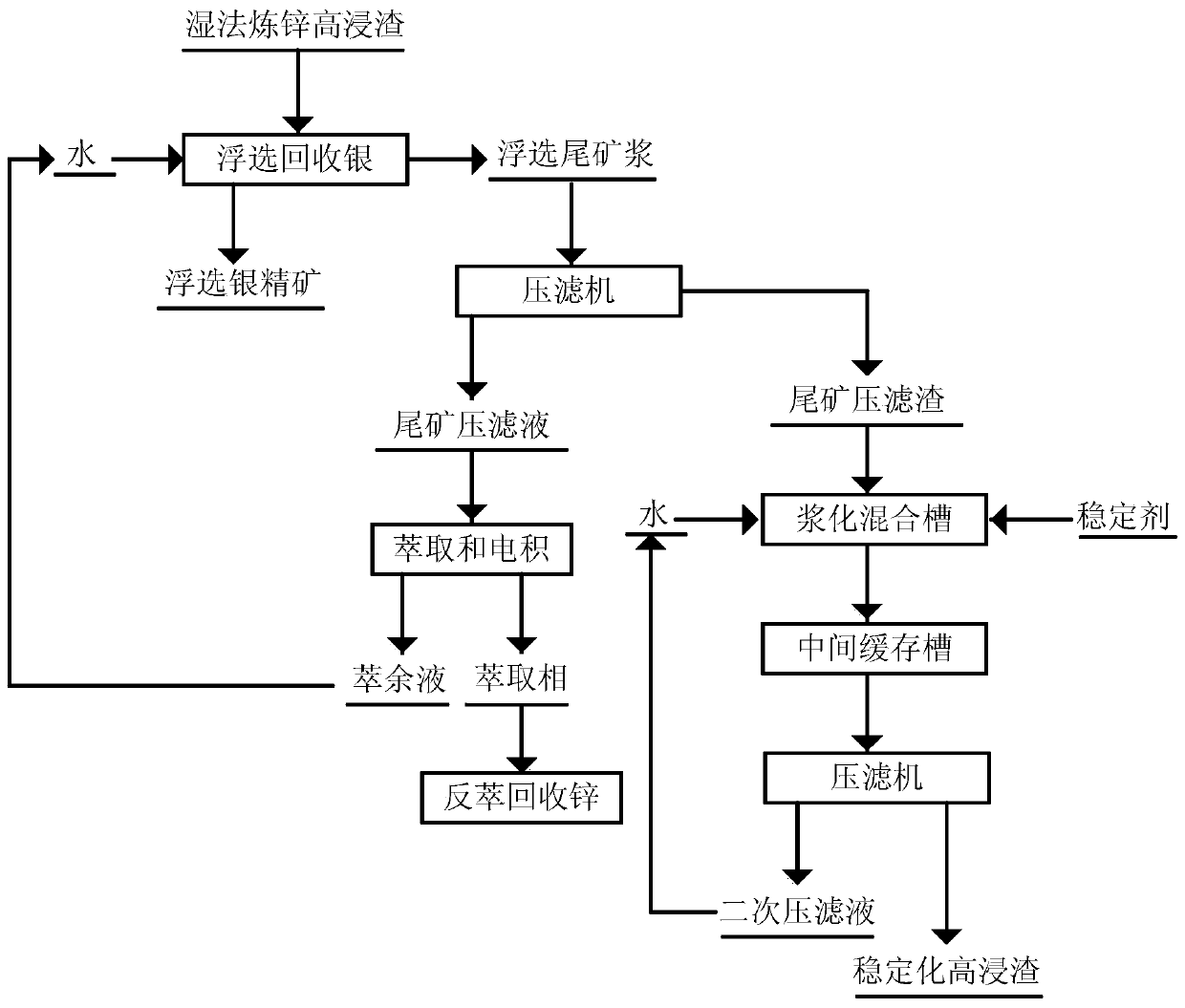

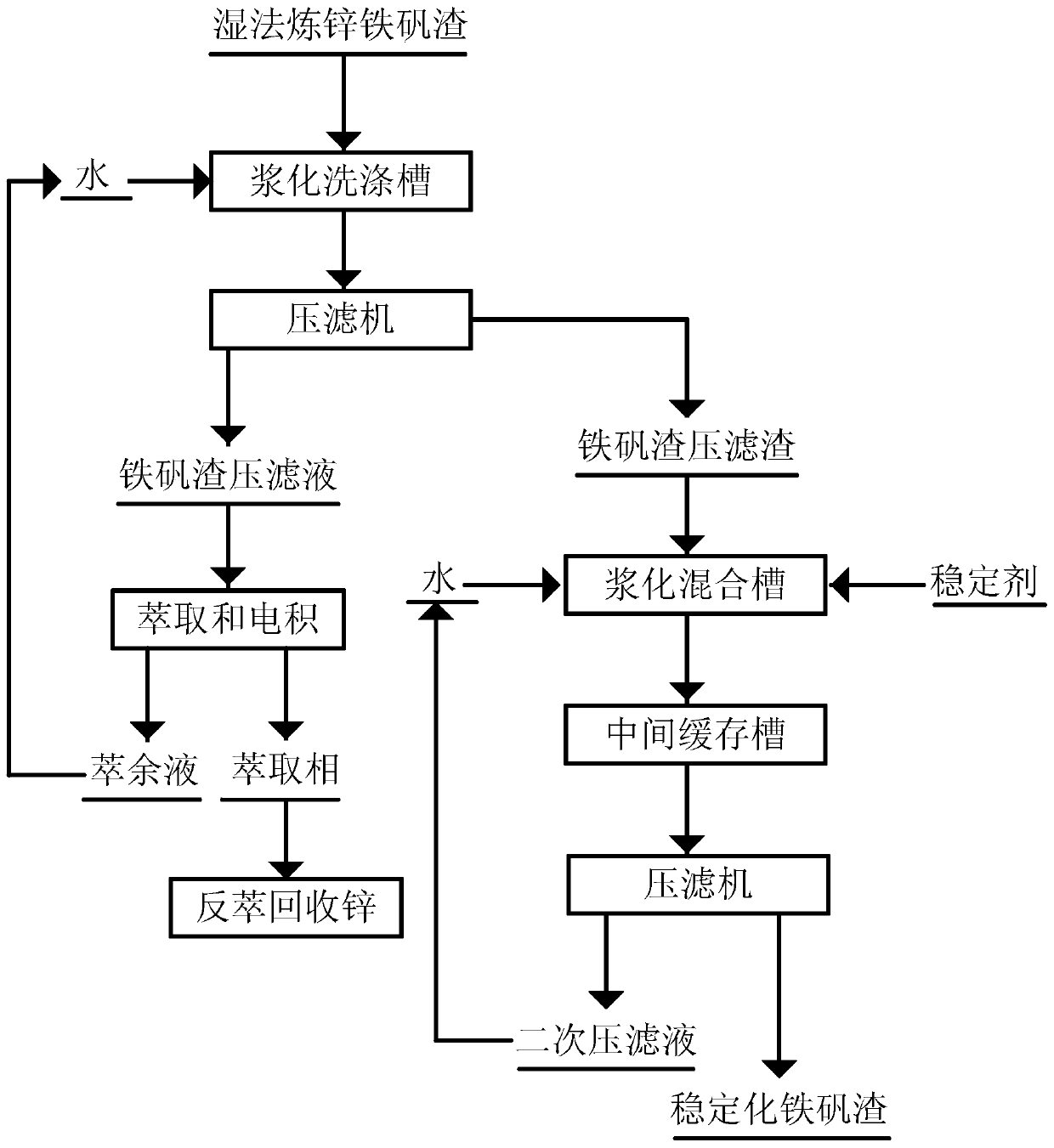

Comprehensive recycling and harmless disposal method for zinc hydrometallurgy high leaching residue

InactiveCN111041211ARelieve pressureAchieve recyclingPhotography auxillary processesProcess efficiency improvementEnvironmental engineeringHydrometallurgy

The invention discloses a comprehensive recycling and harmless disposal method for zinc hydrometallurgy high leaching residue. The method comprises the following steps that firstly, the zinc hydrometallurgy high leaching residue is floated for silver recycling, flotation tailing pulp is obtained, and after pressure filter, tailing pressure filter residue is obtained; secondly, water is added to the tailing pressure filter residue for stirring and slurry mixing, and a stabilizing agent is added for stirring to prepare adjusting slurry; and thirdly, the adjusting slurry is subjected to pressurefilter, secondary pressure filter liquid and secondary pressure filter residue are obtained, and the secondary pressure filter residue serves as stabilizing high leaching residue for landfill treatment. Through the method, silver is recycled firstly, meanwhile, floating achieves the effect of slurrying and washing of water soluble zinc, the high leaching residue subsequent stabilizing treatment pressure is reduced, consumption of a stabilizing reagent can be obviously reduced, the landfill amount of subsequent landfill treatment can be reduced, the subsequent treatment operation is obviously simplified, and the transport amount is smaller than mixed curing / stabilizing treatment operation in a paste mixing form.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

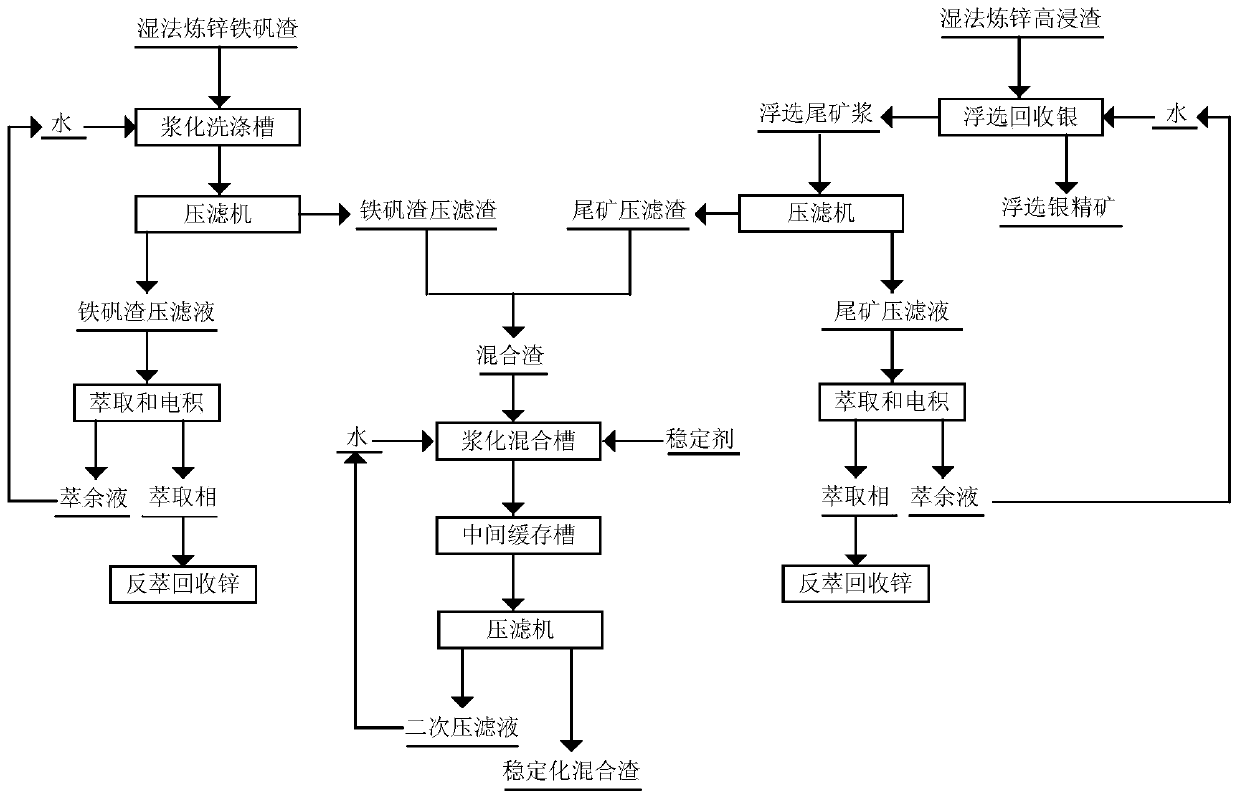

Comprehensive recovery and harmless treatment method for zinc hydrometallurgy iron vitriol slag and high leaching slag

InactiveCN111041210ARelieve pressureAchieve recyclingPhotography auxillary processesProcess efficiency improvementSlagHydrometallurgy

The invention discloses a comprehensive recovery and harmless treatment method for zinc hydrometallurgy iron vitriol slag and high leaching slag. The method comprises the following steps of (1) addingwater into the zinc hydrometallurgy iron vitriol slag for slurrying and washing, and performing filter pressing on the obtained iron vitriol slag slurry to obtain iron vitriol slag filter-pressing slag; (2) performing flotation on the zinc hydrometallurgy high leaching slag to recover silver, and performing filter pressing on the obtained flotation tailings to obtain tailing filter-pressing slag;(3) mixing the iron vitriol filter-pressing slag and the tailing filter-pressing slag to prepare mixed slag, adding water, stirring and mixing slurry, and adding a stabilizer and stirring to prepareadjusting slurry; and (4) performing filter pressing on the adjusting slurry, and performing landfill treatment on the obtained secondary filter-pressing slag serving as stabilized mixed slag. According to the method disclosed by the invention, the recycling of the valuable element zinc is realized; the pressure of subsequent stabilization treatment of the iron vitriol slag is reduced, the consumption of a stabilizing reagent is obviously reduced, the subsequent treatment operation is simplified, and the transportation amount is smaller than that of mixed curing / stabilization treatment operation in a paste stirring form.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

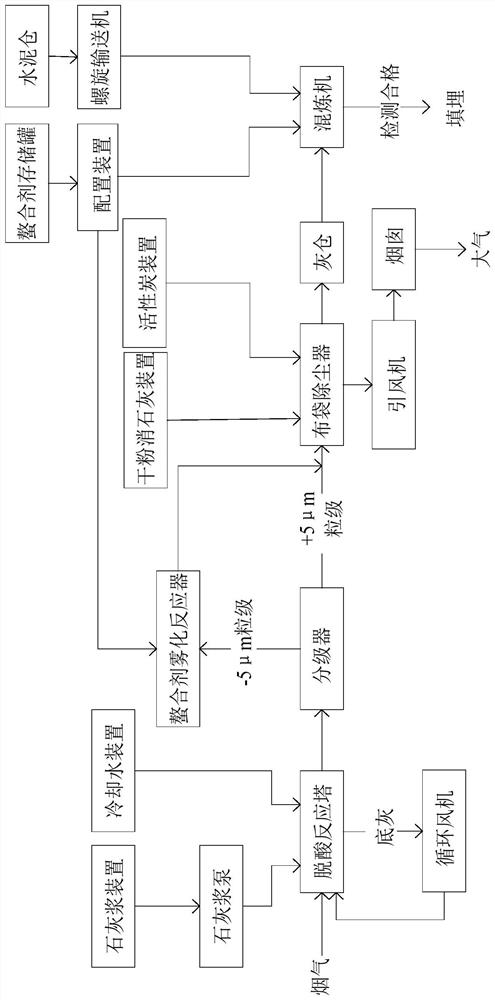

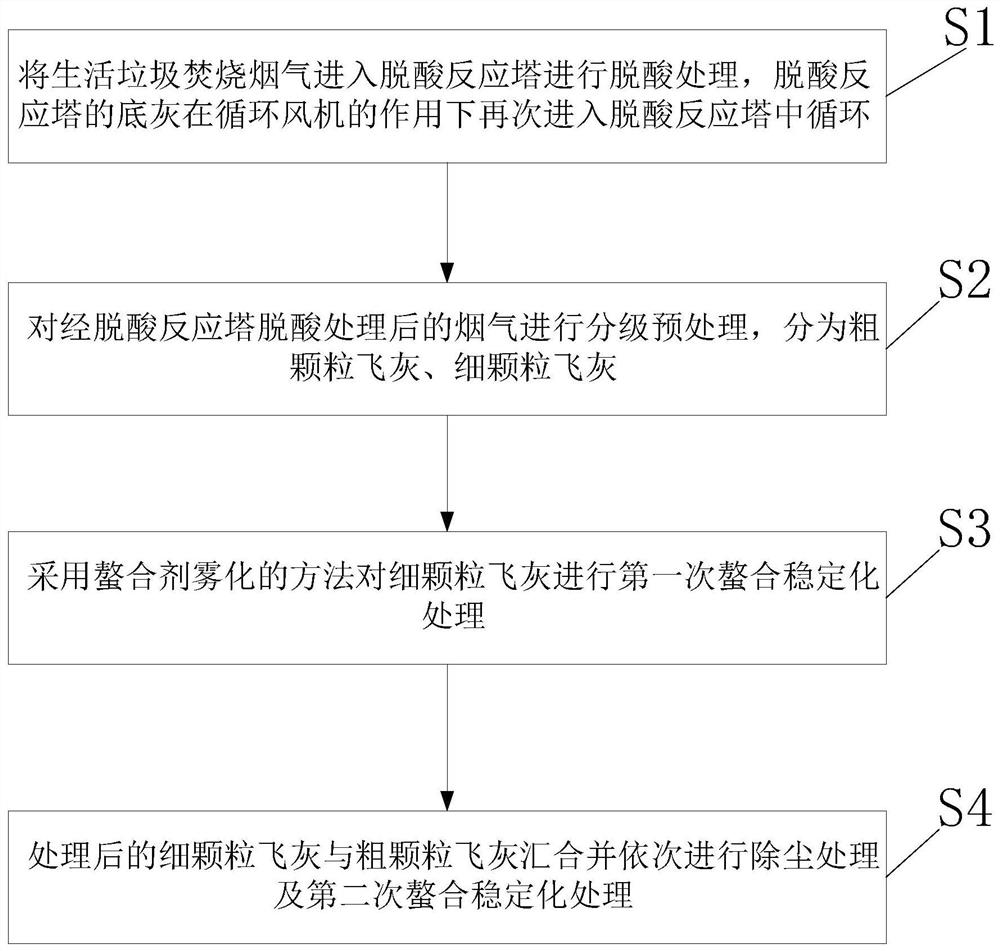

Household garbage incineration fly ash source reduction treatment system and method

PendingCN111905535AReduce fly ash productionReduce fly ash to landfillCombination devicesGas treatmentSource reductionFlue gas

The invention discloses a household garbage incineration fly ash source reduction treatment system and method, and the treatment system comprises a deacidification reaction tower, a classifier and a chelating agent atomization reactor which are sequentially communicated, the bottom of the deacidification reaction tower is connected with a circulating fan, and household garbage incineration flue gas enters the deacidification reaction tower for deacidification treatment; the bottom ash of the deacidification reaction tower enters the deacidification reaction tower again under the action of thecirculating fan to be circulated, the flue gas subjected to deacidification treatment is classified into fine-particle fly ash and coarse-particle fly ash through the classifier, and the fine-particlefly ash enters the chelating agent atomization reactor to be subjected to chelating stabilization treatment for the first time; and the treated fine-particle fly ash and the treated coarse-particle fly ash are converged and subjected to dust removal treatment and secondary chelating stabilization treatment in sequence. According to the method, the consumption of consumables in the flue gas purification process is reduced, the action efficiency of desulfurization and heavy metal fixing agents is improved, the fly ash yield and harmless treatment cost are reduced, and fly ash reduction and efficient stabilization treatment of heavy metals are realized.

Owner:北京首创环境科技有限公司

Harmless treatment method for recovering zinc and recovering slag through zinc hydro-metallurgy ammonium jarosite washing

InactiveCN111069232ARelieve pressureAchieve recyclingSolid waste disposalProcess efficiency improvementSlagEngineering

The invention relates to a harmless treatment method for recovering zinc and recovering slag through zinc hydro-metallurgy ammonium jarosite washing. The method comprises the following steps of (1) adding water to zinc hydro-metallurgy ammonium jarosite, carrying out slurry washing, and carrying out filter-pressing on the obtained ammonium jarosite slurry to obtain ammonium jarosite filter-pressing slag; (2) adding water into the ammonium jarosite filter-pressing slag, stirring and mixing, adding a stabilizer, and uniformly stirring and mixing to prepare a regulating slurry; (3) carrying out filter-pressing on the regulating slurry to obtain secondary filter-pressing slag as stabilized ammonium jarosite, and carrying out landfill treatment; and recycling the secondary press filtrate. According to the method, water-soluble zinc is recovered through slurry washing, recycling of valuable elements is achieved, the pressure of subsequent stabilization treatment of the ammonium jarosite is reduced, consumption of stabilization reagent is remarkably reduced, the landfill amount of subsequent landfill treatment is also reduced, and subsequent treatment operation is remarkably simplified.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

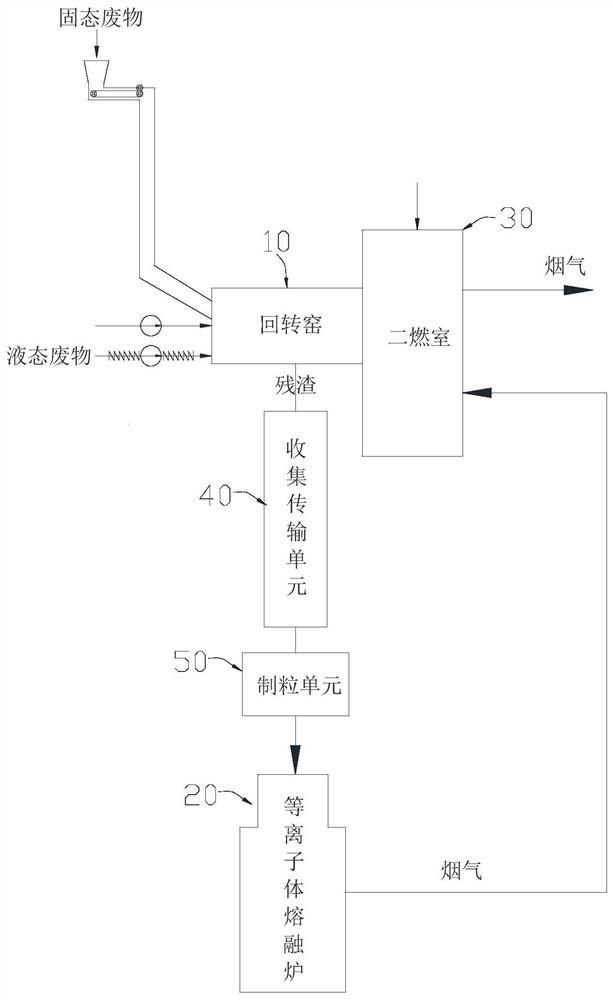

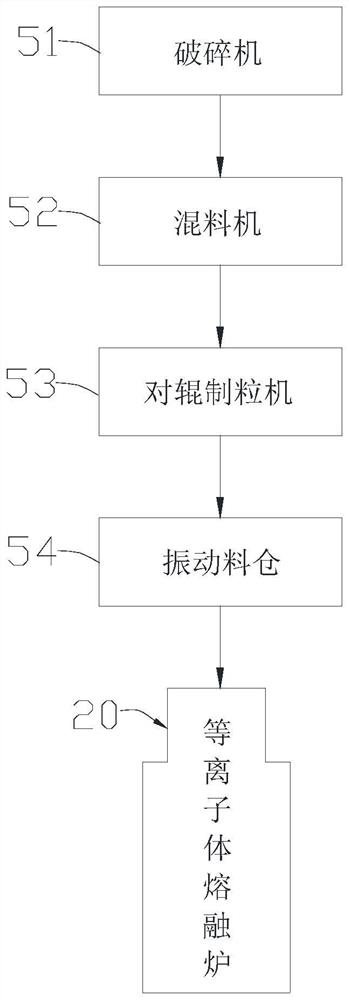

Hazardous waste incineration system and hazardous waste incineration method

ActiveCN112460603AAchieve recyclingReduce landfill volumeGranulation by pressingIncinerator apparatusCombustion chamberFuel treatment

The invention discloses a hazardous waste incineration system and a hazardous waste incineration method. The hazardous waste incineration system comprises a rotary kiln, a collecting and conveying unit, a plasma melting furnace and a secondary combustion chamber, wherein the rotary kiln is used for incinerating hazardous waste to form residues, the collecting and conveying unit is used for coolingand drying the residues, the plasma melting furnace is used for treating the residues to form glass bodies, and the secondary combustion chamber is used for carrying out secondary fuel treatment on smoke exhausted by the rotary kiln and the plasma melting furnace; and the collecting and conveying unit is connected between a discharging port of the rotary kiln and a feeding port of the plasma melting furnace, an exhaust port of the rotary kiln is connected with the secondary combustion chamber, and an exhaust port of the plasma melting furnace is connected with the secondary combustion chamber. According to the hazardous waste incineration system and the hazardous waste incineration method, the rotary kiln and the plasma melting furnace are combined to treat the hazardous waste, the landfill amount of an incineration project is reduced, land resources are saved, most of the glass bodies generated by the plasma melting furnace can be recycled and used as cement ingredients or building materials or heat preservation materials or craft product materials or the like, and recycling of part of the hazardous waste is achieved.

Owner:中广核工程有限公司 +3

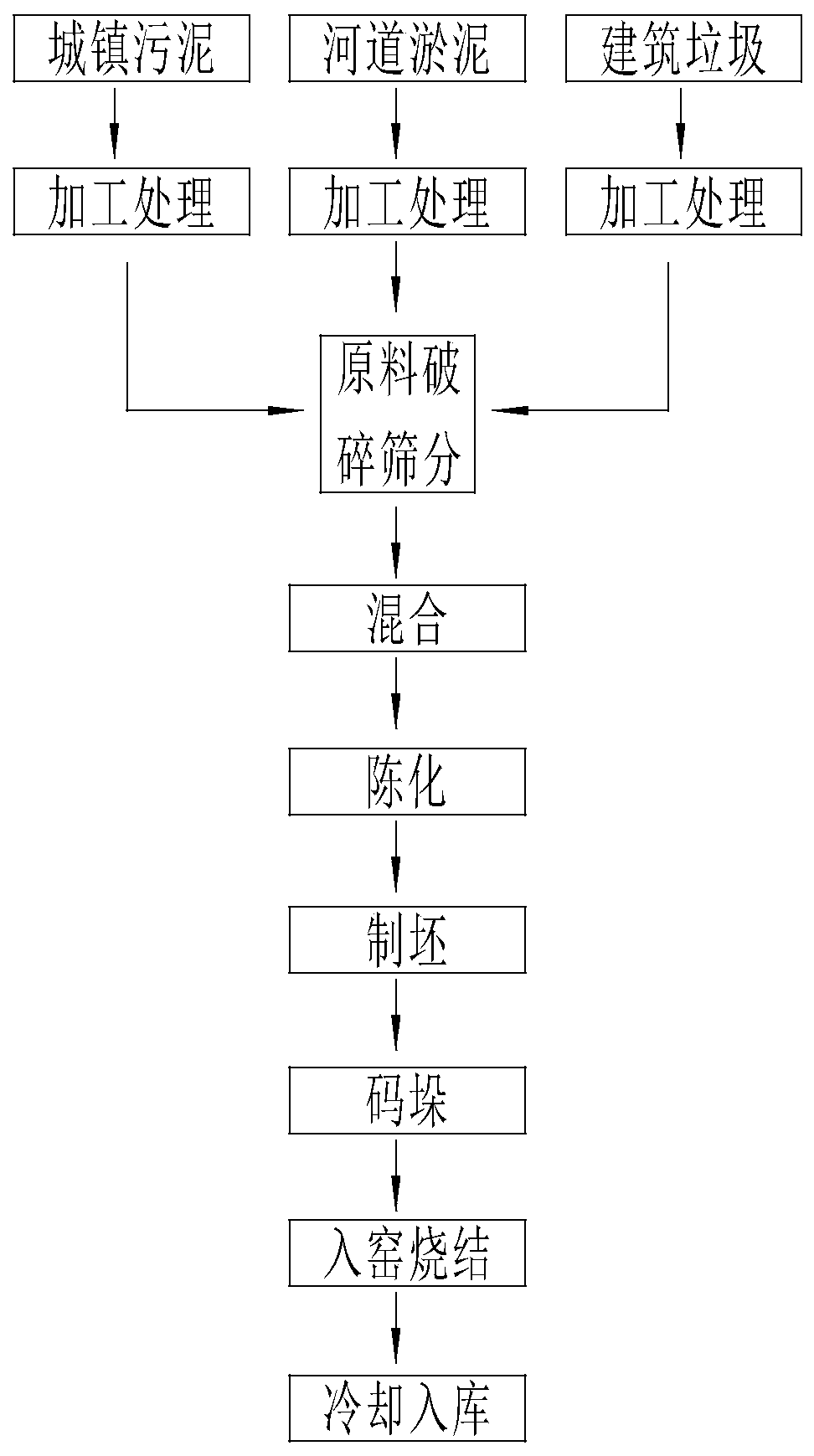

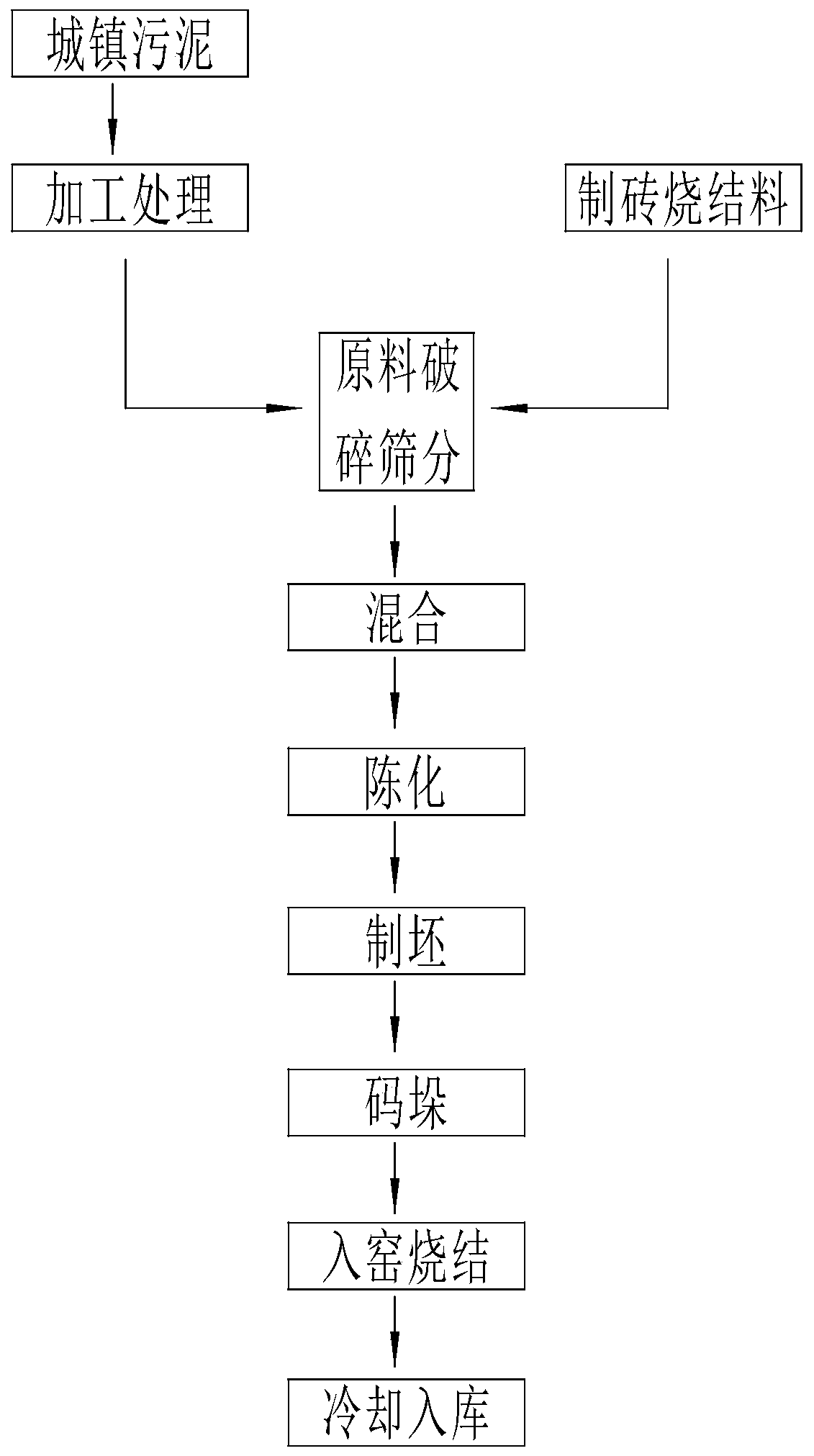

Solid waste building material comprehensive treatment and disposal process

InactiveCN110407557AReduce construction wasteReduce secondary pollutionCeramic materials productionClaywaresProcess equipmentLand resources

The invention relates to a solid waste building material comprehensive treatment and disposal process, which comprises the following process steps: respectively processing urban sludge, river sludge and construction waste, crushing and screening the raw materials, mixing, aging, making blanks, stacking the blanks, sintering in a kiln, cooling and warehousing; according to the invention, the treatment and disposal of the urban sludge, river sludge and construction waste are recombined and designed, toxic and harmful components in the sludge are solidified and subjected to combustion treatment,the possibility of secondary pollution of pollutants is completely reduced, and three new methods of solid waste treatment and disposal with only landfill are opened up. The reduced landfill volume can greatly reduce the demand for land resources, the original useless waste is changed into valuables, and the resource utilization of waste is realized. The process has the advantages of small equipment investment, large production capacity, low operation cost and high cost performance, and can realize centralized treatment of various solid wastes, realizes the integration of multiple wastes, multi-industry chain production, and finally realizes preparation of building materials from the solid wastes.

Owner:洛阳中新能再生能源有限公司

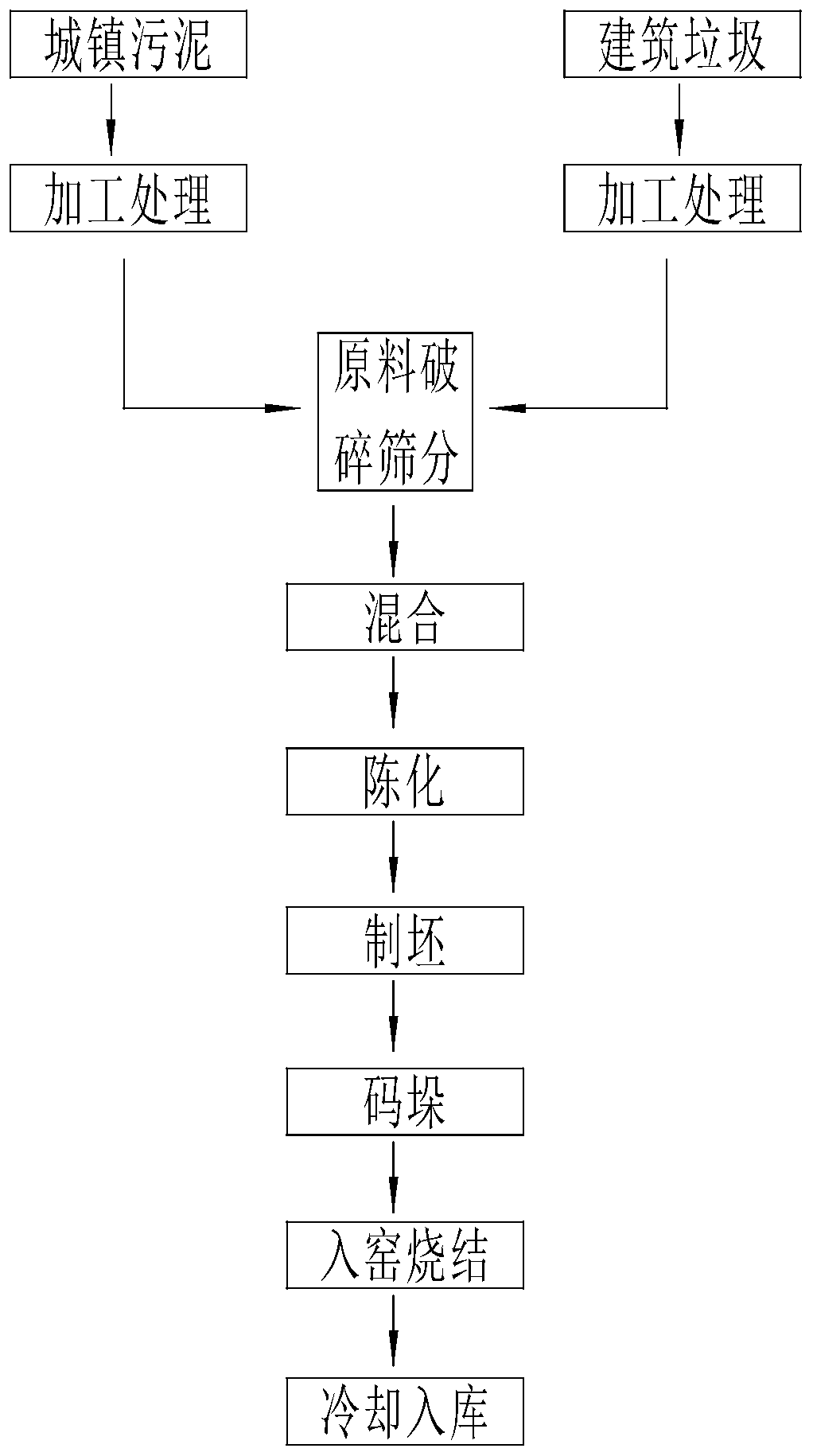

Comprehensive utilization process for making bricks from municipal sludge and construction waste

InactiveCN110395992AReduce secondary pollutionReduce demandSpecific water treatment objectivesBiofuelsBrickCombustion

The invention relates to a comprehensive utilization process for making bricks from municipal sludge and construction waste. The process flow comprises the following steps: separately processing municipal sludge and construction waste, crushing and screening the raw materials, carrying out mixing, carrying out ageing, making blanks, carrying out stacking, carrying out sintering in a kiln, and carrying out cooling and warehousing. Through recombination and redesigning of treatment and disposal of the municipal sludge and the construction waste, toxic and harmful components in the sludge are subjected to solidification and combustion treatment, so that possibility of secondary pollution of pollutants is thoroughly reduced. The invention develops a new way of treating and disposing two solidwastes which are treated only by landfill before, so that the landfill amount is reduced, demands on land resources can be greatly reduced, original useless wastes are changed into valuables, and resource utilization of the wastes is realized.

Owner:洛阳中新能再生能源有限公司

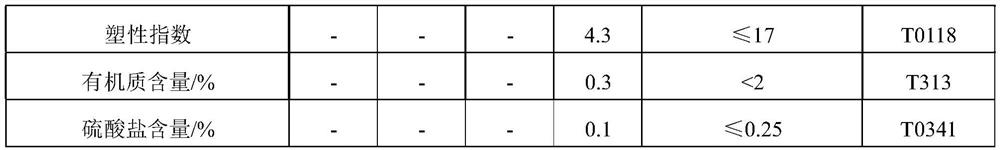

Cement stabilized macadam mixture doped with waste incineration slag

InactiveCN112142395AImprove resource utilizationReduce landfill volumeIncinerationEnvironmental engineering

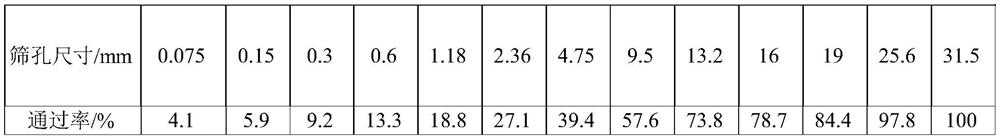

The invention discloses a cement stabilized macadam mixture doped with waste incineration slag. The cement stabilized macadam mixture is prepared by the following steps: preparing 0-2.36 mm waste incineration slag, cement, fly ash, an excitant and water according to a mass percentage ratio of 32.6%: 6.5%:32.5%:7.8%:20.6%, mixing, pelletizing, curing to obtain 4.75-13.2 mm slag pellets, and uniformly mixing with 0-4.75 mm waste incineration slag, cement, aggregate and water to obtain the mixture. According to the invention, the slag pellet prepared by the invention meets the technical requirements of the existing highway pavement base specification on coarse aggregate, so that the condition that the waste incineration slag cannot be used as the coarse aggregate due to substandard crushing value is changed, the resource utilization rate of the waste incineration slag in the highway base is greatly improved, and the slag pellet conforms to the green ecological characteristic, and is suitable for base layer materials of heavy, medium and light traffic pavements of roads of two or less levels; and the the slag pellet is used for replacing part of coarse aggregate of the cement stabilized macadam mixture, so that the use of natural aggregate is reduced, and the environmental protection is promoted.

Owner:YANGZHOU UNIV

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

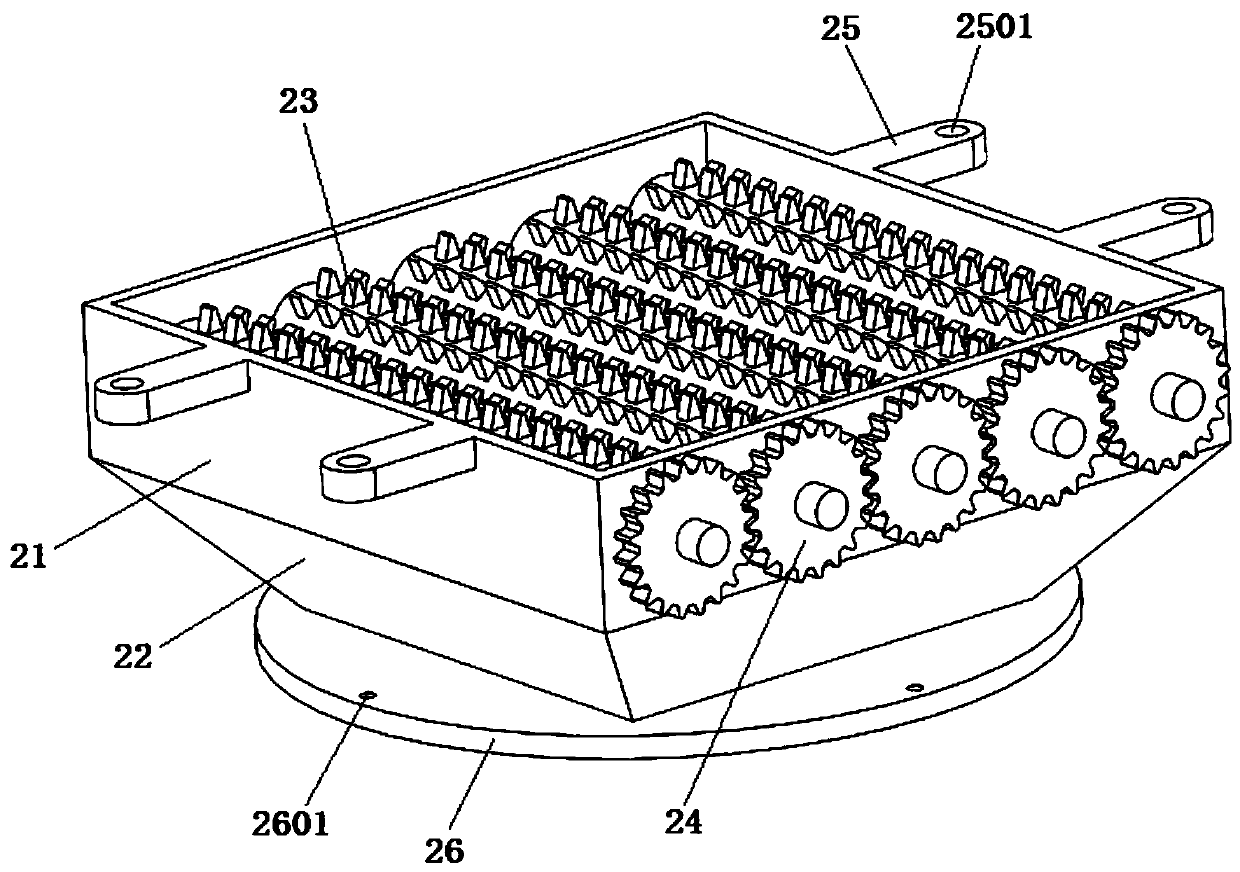

Air-cooled ash cooling device

InactiveCN106247349AReduce moisture contentReduce landfill volumeIncinerator apparatusWater contentEngineering

The invention relates to the technical field of hazardous waste treatment, specifically to an air-cooled ash cooling device. The air-cooled ash cooling device comprises an upper shell and a lower shell; the upper shell and the lower shell are welded into a whole; a guiding plate is installed at the feeding position of the upper shell body; a crushing device is installed at the discharging position of the lower shell; a cooling air inlet pipe and a bracket are installed in the lower shell; cooling plates are installed on the bracket; conveying devices below the guiding plate are installed on the cooling plates; and stirring bars are installed on the conveying devices. According to the air-cooled ash cooling device, traditional water-cooled ash cooling is replaced with air-cooled ash cooling, the water content of ash is reduced, the landfill size is recued, structure is simple, installation is convenient, flowing of the ash can be guided, and the phenomenon that the semisolid ash is solidified and adhered to the cooling plate due to stacking on the conveying devices is avoided.

Owner:CBMI CONSTR

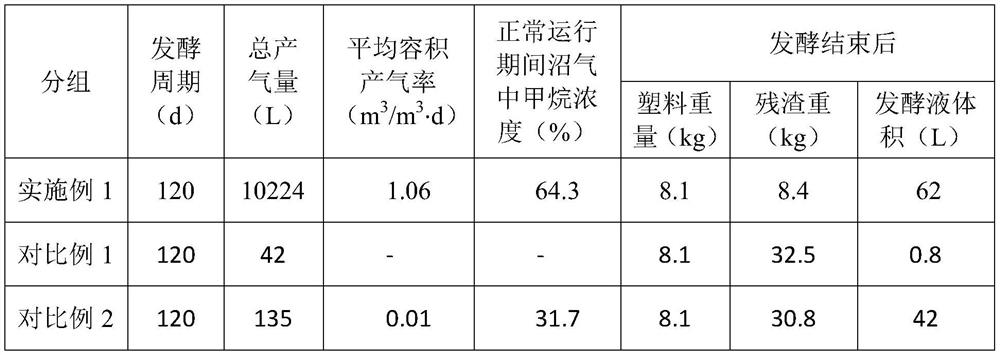

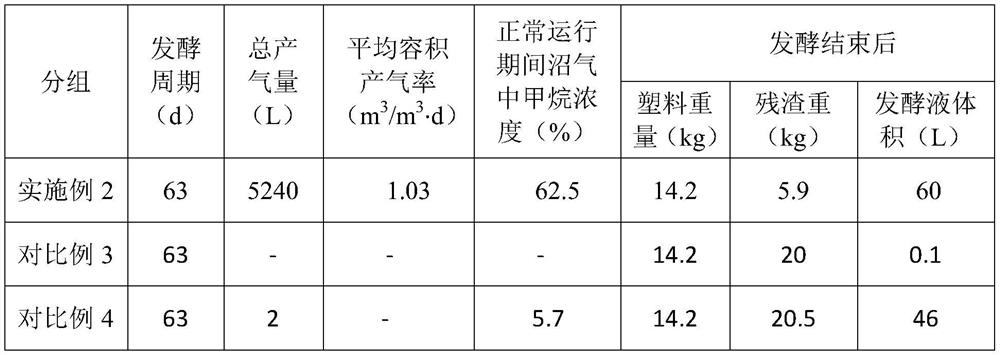

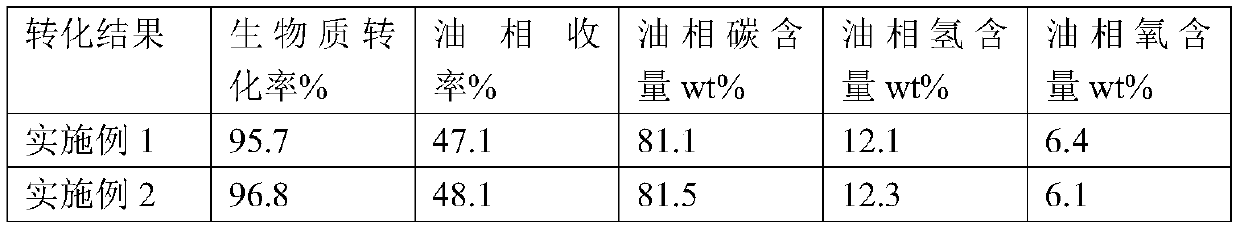

A treatment method for rapid reduction of domestic waste and energy recovery

ActiveCN108838196BRapid reductionAchieve reductionWaste processingSolid waste disposalProcess engineeringEnergy recovery

The invention discloses a treatment method for rapid reduction of household garbage and energy recovery, which includes breaking bags of domestic garbage after rough sorting, putting it into a sequencing batch type anaerobic dry fermentation tank for anaerobic fermentation, and returning leachate , treatment of residues and other steps. The invention can realize the reduction of domestic garbage and energy recovery in a low-cost, fast and efficient manner, not only realizes the innovation of the process route, but also greatly improves the treatment efficiency and greatly reduces the treatment cost.

Owner:BIOGAS SCI RES INST MIN OF AGRI

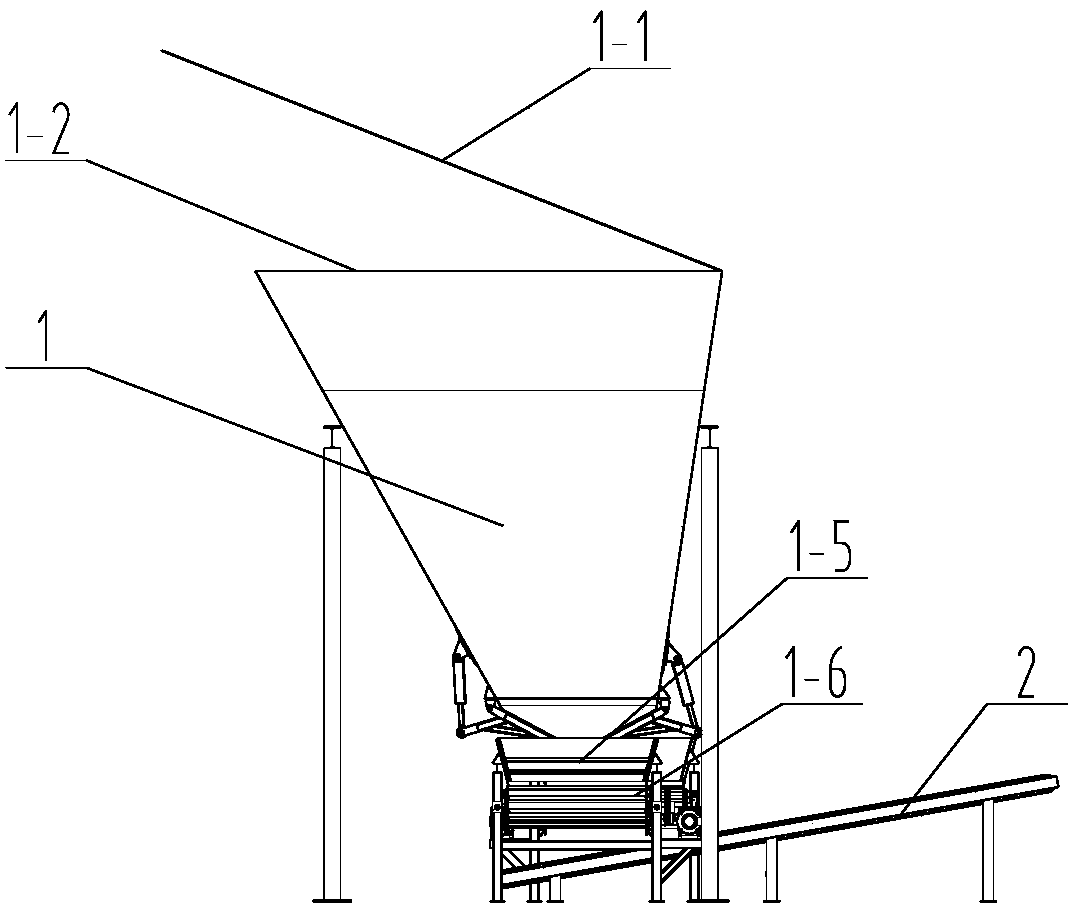

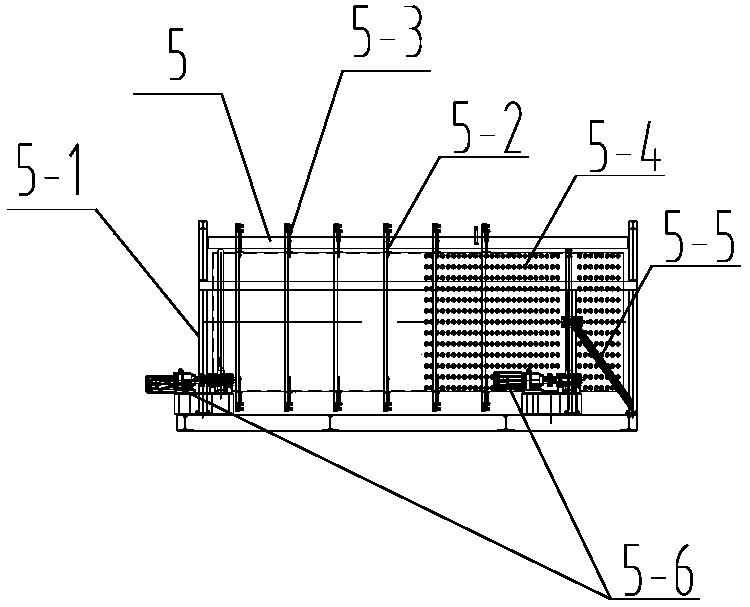

A concrete mixing plant using construction waste as raw material

ActiveCN105619617BMeet production needsRealize secondary useDischarging apparatusCement mixing apparatusControl systemBucket elevator

The invention discloses a concrete mixing station made of building waste. The concrete mixing station comprises an aggregate feeding system, a weighing system, a lifting system, a mixer system and a control system. The aggregate feeding system comprises a primary pulverizer, a double-deck vibrating screening machine, a conveying unit, a secondary pulverizer and a receiving water tank. The weighing system is a belt weigher. The lifting system is a bucket lifter. The conveying unit comprises a first conveying belt, a second conveying belt and a third conveying belt. The concrete mixing station is made of the building waste, and secondary utilization of the building waste is achieved; not only is the burying amount of the building waste decreased, but also environmental pollution is relieved, and raw materials can be provided for concrete production, so that the large-scale production requirement for concrete is met.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

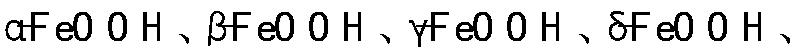

Novel application of waste agents

ActiveCN110404538AReduce recycling costsReduce landfill volumeHydrogenHydrogen/synthetic gas productionCatalytic effectOrganic matter

The invention discloses novel application of waste agents. The novel application involves the application of a FeOOH waste agent, a Fe21.333O32 waste agent, a ferric oxide waste agent and a Ni-Mo waste agent used as a hydro-liquefaction catalyst and a CO shift catalyst in an organic matter conversion process. The waste agents are used as idle resources, the price of the waste agents is farther lower than the price of fresh catalysts, so that the production cost is reduced, but a catalytic effect of the waste agents used as the hydro-liquefaction catalyst or the CO shift catalyst is comparableto a general catalyst effect.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

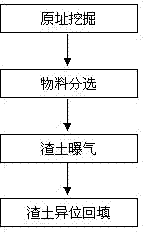

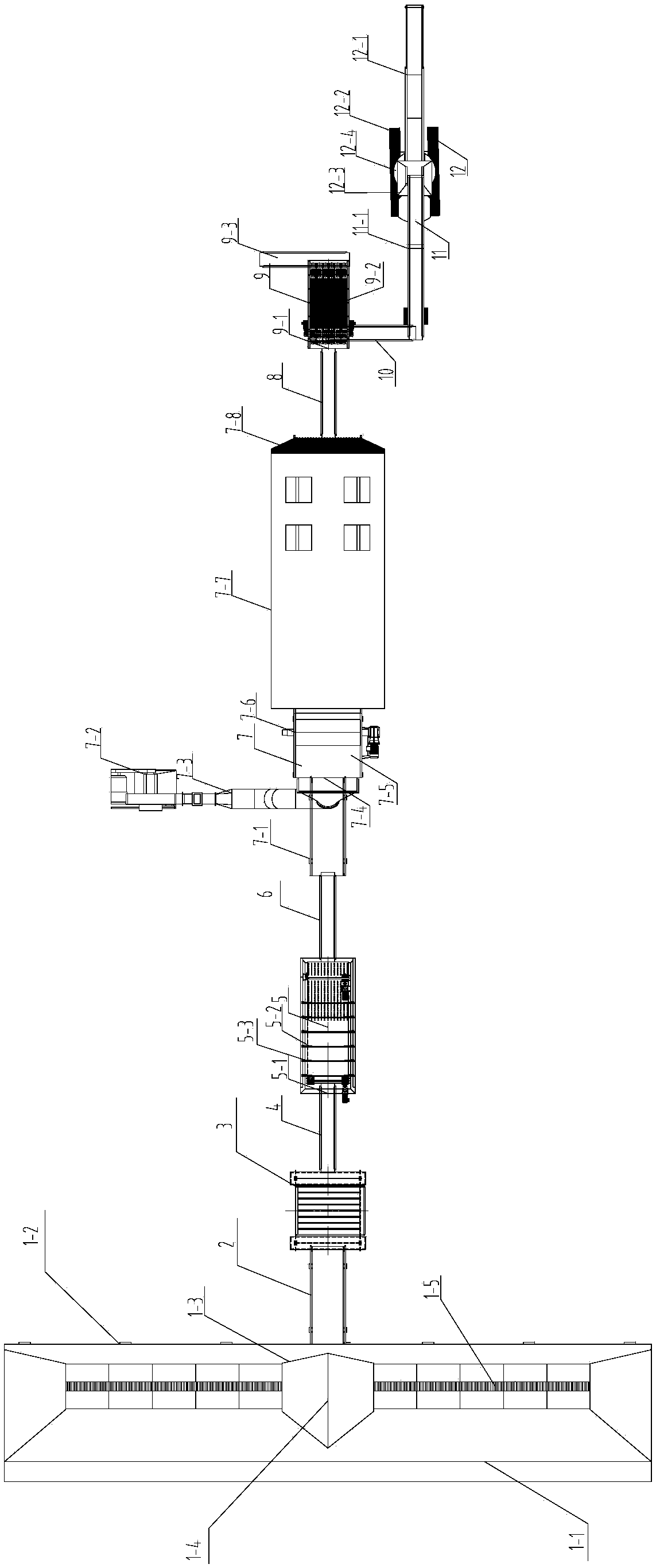

On-site ectopic enhanced aerobic stabilization method for household garbage landfill

ActiveCN103230927BImprove site utilization efficiencyImprove sanitationSolid waste disposalEnvironmental engineeringDomestic waste

The invention discloses an on-site ectopic enhanced aerobic stabilization method for a household garbage landfill, and belongs to environmental engineering. According to the method, the staged stepwise excavation is adopted, and the operation can be performed synchronously or in stages, so that the operation progress is guaranteed and the operation efficiency is improved; the material sorting is performed on excavated stale garbage, so that the resource utilization and the safe treatment of the garbage can be realized; and therefore, the landfill amount of the stale garbage is reduced, the space utilization efficiency of the household garbage landfill is improved, the oxidation rate of sorted muck is improved in a natural drying or forced ventilation mode, and the muck stabilization time is shortened. The sorted muck is subjected to backward stepwise backfill, so that the stability of the landfill is improved, the stabilization rate of the stale garbage is accelerated, the sanitary environment of the landfill is improved, and the requirement on special equipment is low; and the method is applicable to fast stabilization and restoration engineering for the simple household garbage landfill.

Owner:武汉致衡环境安全工程技术有限公司

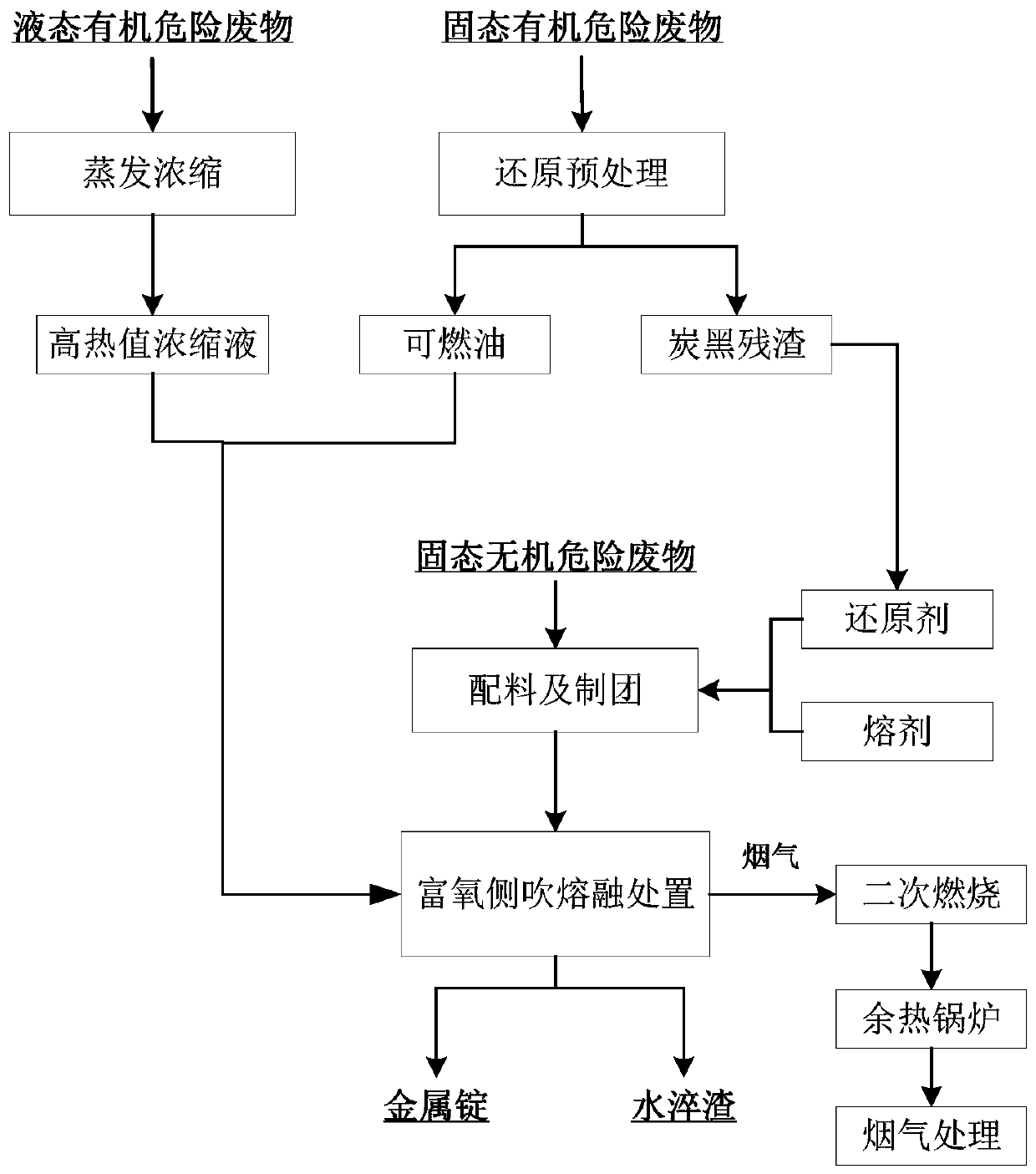

A melting disposal method for hazardous waste

ActiveCN108380642BEasy to handleReduce productionWaste processingTransportation and packagingWaste treatmentQuenching

The invention discloses a hazardous waste melting disposal method, which belongs to the field of hazardous waste treatment. The invention can simultaneously process solid organic hazardous waste, liquid organic hazardous waste and solid inorganic hazardous waste. The main steps of the present invention include: reducing and pretreating solid organic hazardous waste, concentrating and pretreating liquid organic hazardous waste, batching, mixing, and forming solid inorganic hazardous waste, flux, and reducing agent to obtain agglomerate materials, and The bulk material and the intermediate product obtained in the pretreatment step are transferred to an oxygen-enriched side-blowing melting treatment furnace for melting treatment, and the crude metal ingot and vitreous water-quenched slag products are obtained from the melting treatment. The flue gas generated by melting treatment is subjected to secondary combustion, heat energy recovery, and flue gas purification to meet the standard discharge. The invention has a wide application range of raw materials and can completely realize the safe disposal and recycling of hazardous wastes.

Owner:ZHEJIANG SHENLIAN ENVIRONMENTAL PROTECTION GRP CO LTD

Comprehensive utilization process of city sludge in sintering brick making

The invention discloses a comprehensive utilization process of city sludge in sintering brick making. The process comprises the following procedure steps: processing city sludge, and performing raw material crushing and screening with a brick making sintering material; performing mixing; performing aging; manufacturing blanks; performing piling; performing sintering in a kiln; and performing cooling and warehouse storage. As city sludge treatment is recombined and designed, the city sludge is firstly converted into a regenerated fuel, the regenerated sludge fuel is combined with the building material sintering industry and is used as one of raw materials of sintered building materials, finally the sludge can be treated and converted into sintered bricks, a novel mode is created in additionto a landfill treatment mode of city solid wastes, the landfill amount can be reduced, demands on land resources can be greatly reduced, original wastes can be turned into wealth, and resource utilization of wastes can be achieved.

Owner:洛阳中新能再生能源有限公司

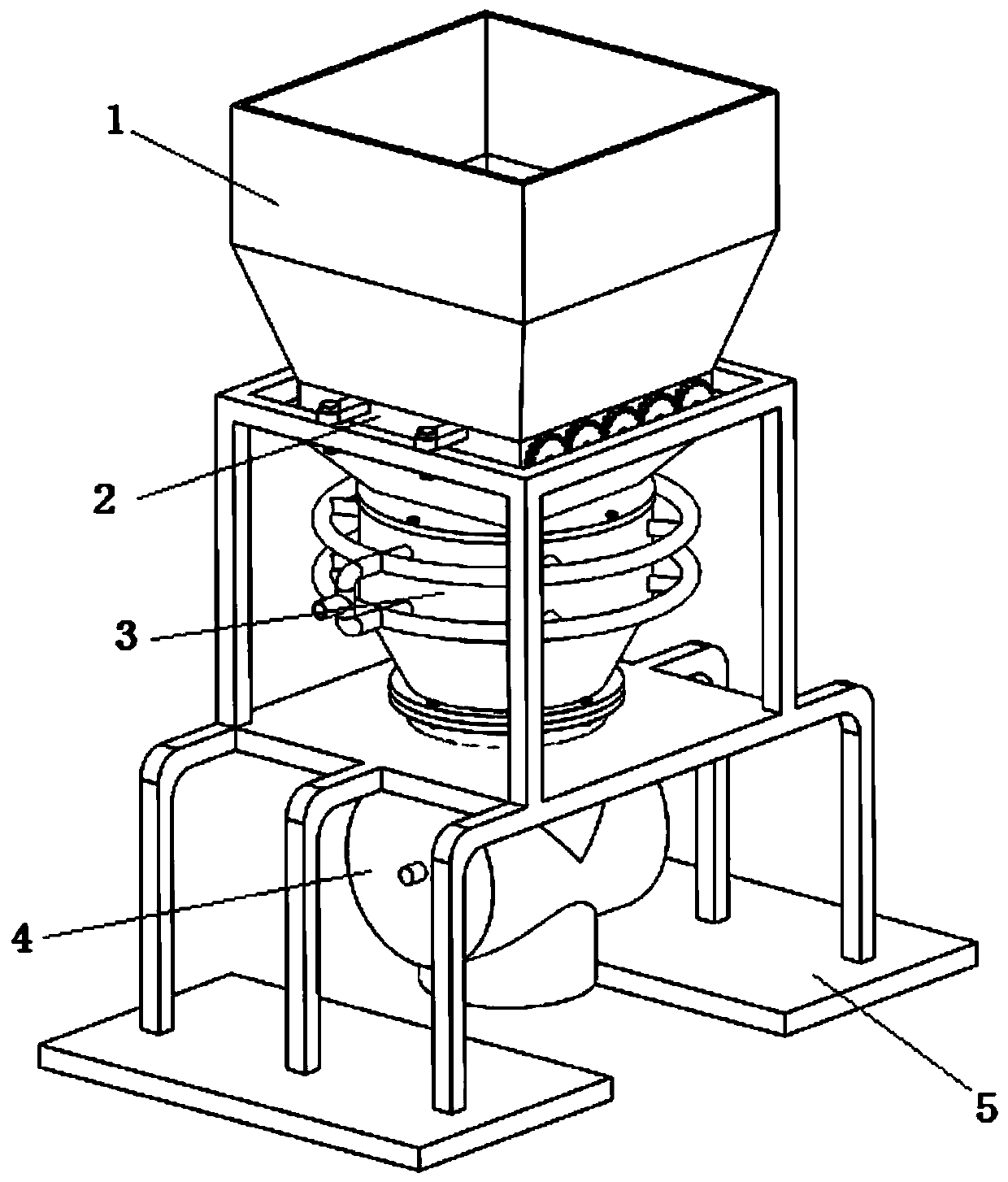

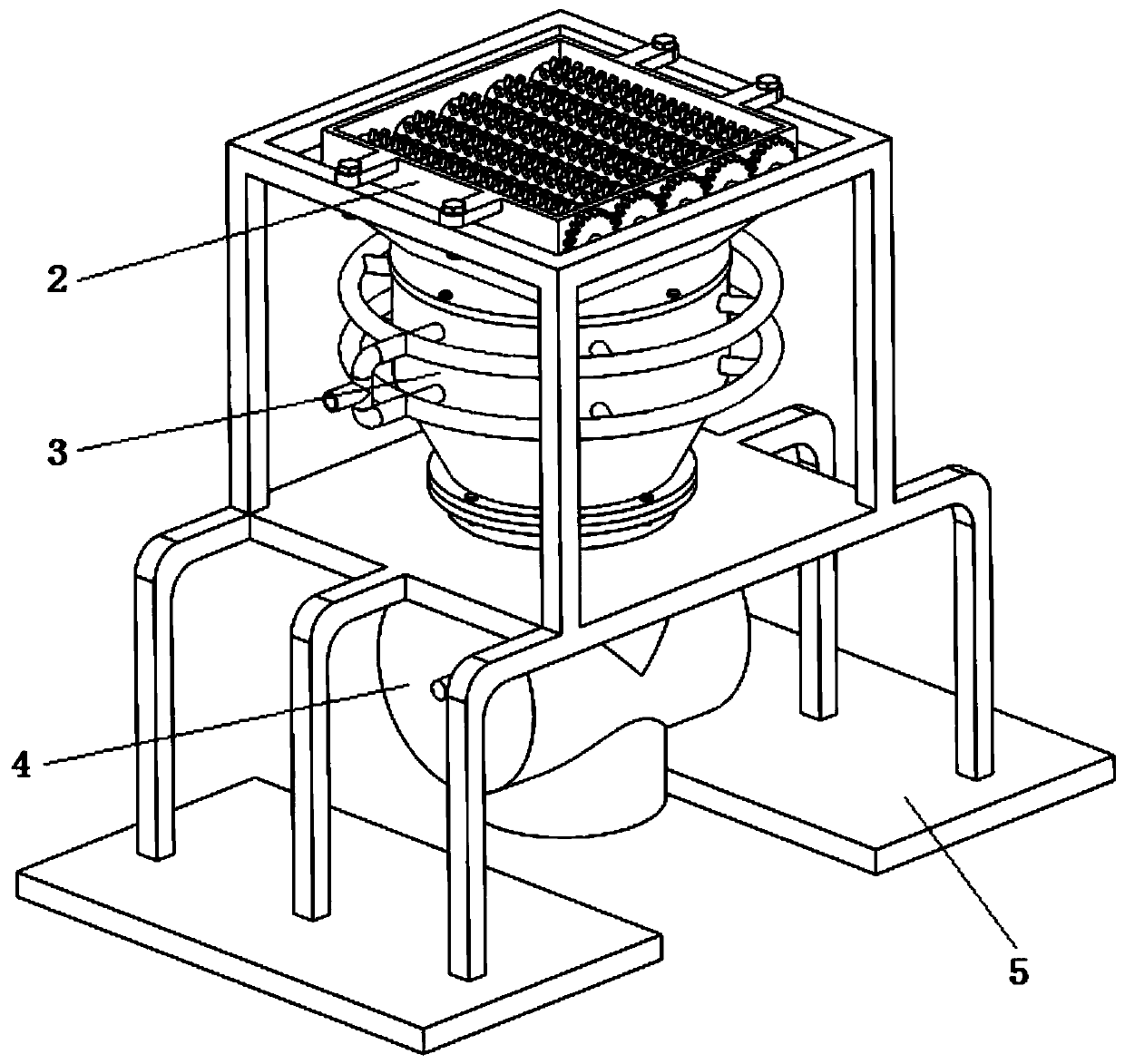

Hazardous waste treatment equipment

ActiveCN108758650BImprove processing efficiencySimple structureIncinerator apparatusFixed bearingCombustion chamber

The invention discloses hazardous waste disposal equipment. The hazardous waste disposal equipment comprises a rotary kiln, a rolling device, a cooling device, a discharge device and a fixed bearing device which are arranged in sequence. The rolling device, the cooling device and the discharge device are all mounted at a discharge port of the rotary kiln through the fixed bearing device. The rolling device comprises a rolling hopper. The rolling hopper comprises a square hopper and a trapezoidal discharge port. The cooling device comprises a cylindrical hopper and a circular-truncated-cone-shaped hopper which are integrally formed. The discharge device comprises a first barrel-shaped hopper and a second barrel-shaped hopper. The first barrel-shaped hopper and the second barrel-shaped hopper communicate and are perpendicular to each other. Through the hazardous waste disposal equipment, hazardous waste is incinerated in the rotary kiln; gas gets into a secondary combustion chamber to conduct treatment; waste residues fall into the rolling device to be rolled; the cooling device implements air cooling through a cooling air inlet pipe and conducts cooling and dehumidification on the waste residues at maximum efficiency; the landfill volume is reduced, and the cost is lowered.

Owner:内蒙古新蒙西环境资源发展有限公司

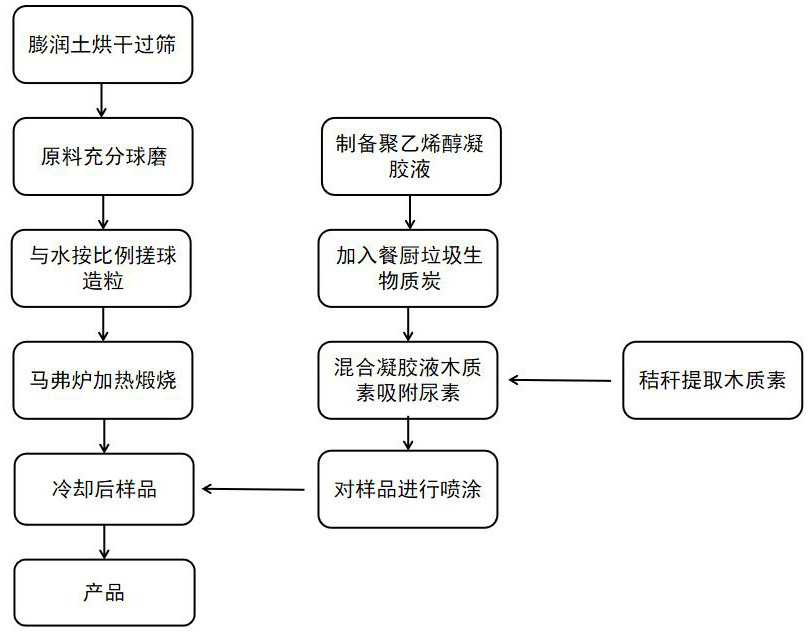

Method for preparing slow-release nutrient soil based on kitchen waste

PendingCN112679274AReduce manufacturing costReduce landfill volumeSolid/semi-solid fertilisersLayered/coated fertilisersEnvironmental engineeringOrganic matter

The invention provides a method for preparing slow-release nutrient soil based on kitchen waste, and the method comprises the following steps: by using kitchen waste as a basic raw material, grinding the kitchen waste into powder by using N, P, K, organic matters and other nutrient components required by various crops after mixing the kitchen waste and potassium phosphate rich in P and K elements, carrying out ball milling by a ball mill, and after performing sufficient mixing to obtain the slow-release nutrient soil, performing granulating by taking water as an adhesive, and performing calcining at high temperature to prepare nutrient soil particles which are rich in various plant growth nutrient elements and have a slow release function. The method has the comprehensive advantages that the preparation process is simple, industrial production is easy, the environment is protected, and resource reutilization of the kitchen waste is achieved, the kitchen waste is subjected to reduction and resource treatment, the environment is effectively improved, and the preparation cost of the nutrient soil is reduced.

Owner:HEILONGJIANG UNIV

Construction method of a waste incineration ash pile

The invention discloses a construction method for an incinerated garbage ash pile, and belongs to the technical fields of solid waste resource utilization and foundation treatment. The construction method is used for solving the problem of waste utilization of incinerated garbage ash and is characterized by comprising the following steps that a, a steel pipe 2 provided with a concrete precast piletip 1 sinks into a foundation 3 so that a pile hole can be formed; b, bacteria liquid, medium sand and the incinerated garbage ash are uniformly mixed at first and then added with a 0.05 mol / L calcium chloride solution to be mixed into a mixture; c, the mixture is poured into the steel pipe 2 sinking into the foundation in advance, and a grouting pipe 4 and a grout extracting pipe 5 are buried inthe mixture 6 in the mixture filling process; d, after the pile hole is filled with the mixture 6, the steel pipe 2 is pulled out; e, liquid in pores of the mixture in the pile hole is completely extracted through the grout extracting pipe 5, then, consolidating fluid is injected through the grouting pipe 4 till the pores of the mixture in the whole pile hole is full of the consolidating fluid, and still standing is conducted for 6-24 h; and f, the step e is repeated for 4-6 times, and construction of the incinerated garbage ash pile is completed.

Owner:NANJING FORESTRY UNIV

A method and system for in-situ resource processing of stock garbage

ActiveCN108787699BRealize high resource utilizationReduce landfill volumeSolid waste disposalDispersed particle separationOrganic manureEnvironmental engineering

The invention discloses a stock garbage in-situ resourceful treatment method and a stock garbage in-situ resourceful treatment system. The system comprises a garbage temporary storage area, a plate feeder, a first breaking device, a drum screen, an air separation device, a second breaking device, a first magnetic separation device, a tension and relaxation screen, an aerobic biological drying reactor, an organic fertilizer compressing and packing device, a second magnetic separation device, a liquid type drum screen, a dewatering device, a percolating liquid treatment system and a deodorization system; garbage in the garbage temporary storage area is transported to the plate feeder; the plate feeder is sequentially connected with the first breaking device and the drum screen; a first outlet of the drum screen is connected with the air separation device; a first outlet of the air separation device is connected with the second breaking device; a second outlet of the air separation deviceis sequentially connected with the second magnetic separation device, the liquid type drum screen and the dewatering device; an outlet of the dewatering device is connected with a first inlet of theaerobic biological drying reactor; a second outlet of the drum screen is connected with the first magnetic separation device and the tension and relaxation screen; an outlet of the tension and relaxation screen is connected with a second inlet of the aerobic biological drying reactor; an outlet of the aerobic biological drying reactor is connected with the organic fertilizer compressing and packing device; the aerobic biological drying reactor is further connected with the percolating liquid treatment system and the deodorization system; and the garbage temporary storage area is further connected with the percolating liquid treatment system. Production of secondary pollution can be completely prevented, and highly-resourceful utilization of the stock garbage can be achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

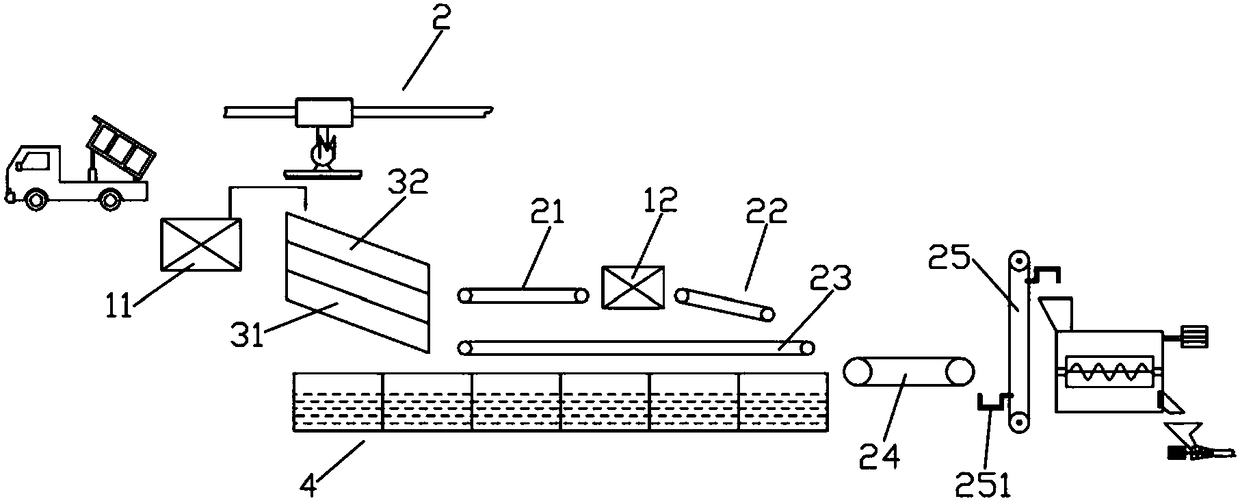

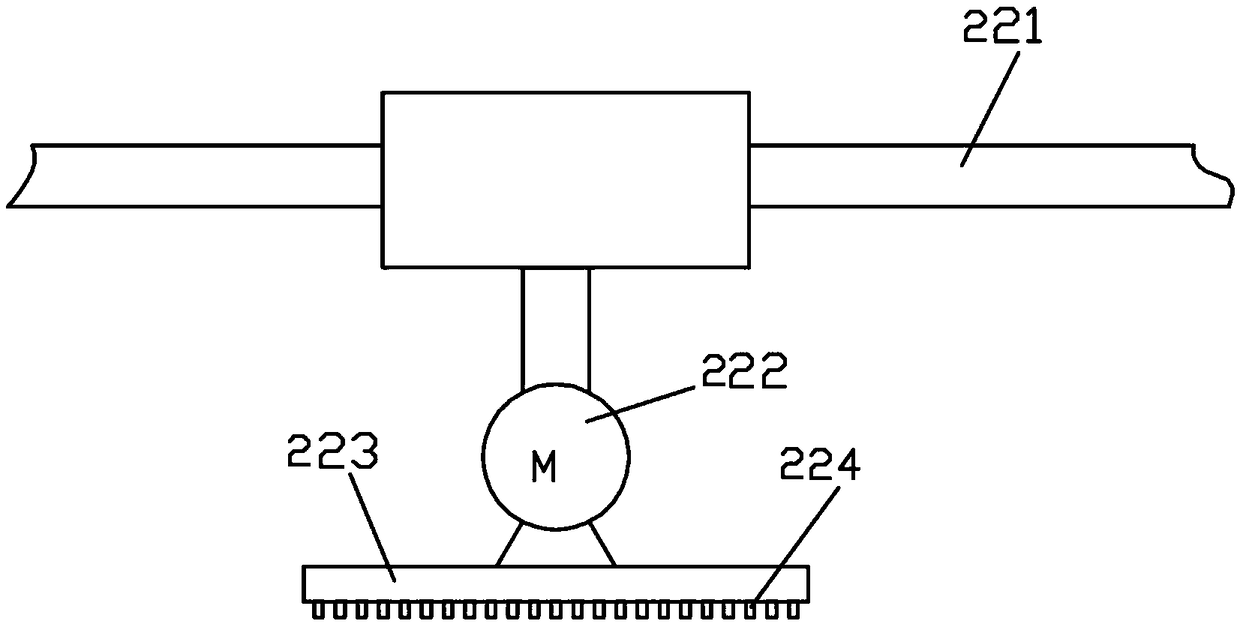

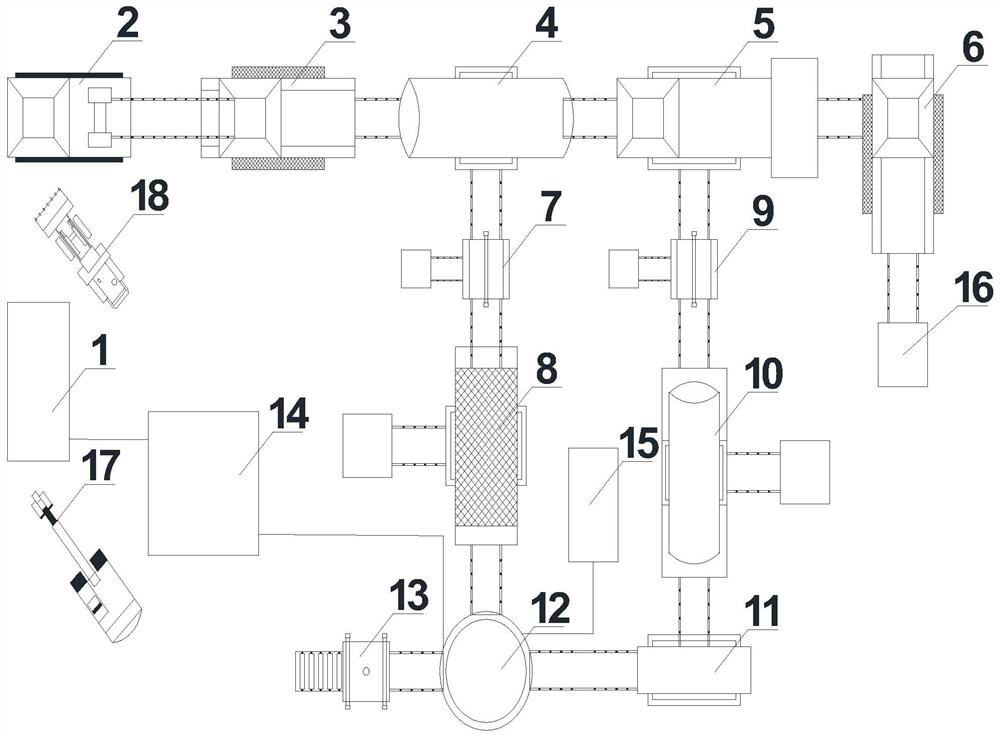

Integrated garbage treatment system for household garbage sanitary landfill

PendingCN107931300AReduce wasteIncrease usageLandfill technologiesSolid waste disposalDomestic wasteTreatment system

The invention discloses an integrated garbage treatment system for a household garbage sanitary landfill and belongs to the technical field of household garbage integrated treatment. The system comprises an unloading platform device, a large piece removal device, a bag breaking device, a winnowing device, a screening device and an automatic landfill device connected successively. The unloading platform is used for receiving household garbage materials input by the outside and conveying the same to the large piece removal device; the large piece removal device is used for removing large piece garbage in the household garbage materials and conveying residual materials to the bag breaking device; the bag breaking device is used for scattering wrappages in the household garbage materials and conveying the scattered household garbage materials to the winnowing device; the winnowing device is used for screening light materials in the household garbage materials and conveying the same to thescreening device; the screening device is used for screening lumps in the light materials and conveying the same to the automatic landfill device; and the automatic landfill device is used for conveying the collected lumps to a preset site for landfill.

Owner:源创环境科技有限公司

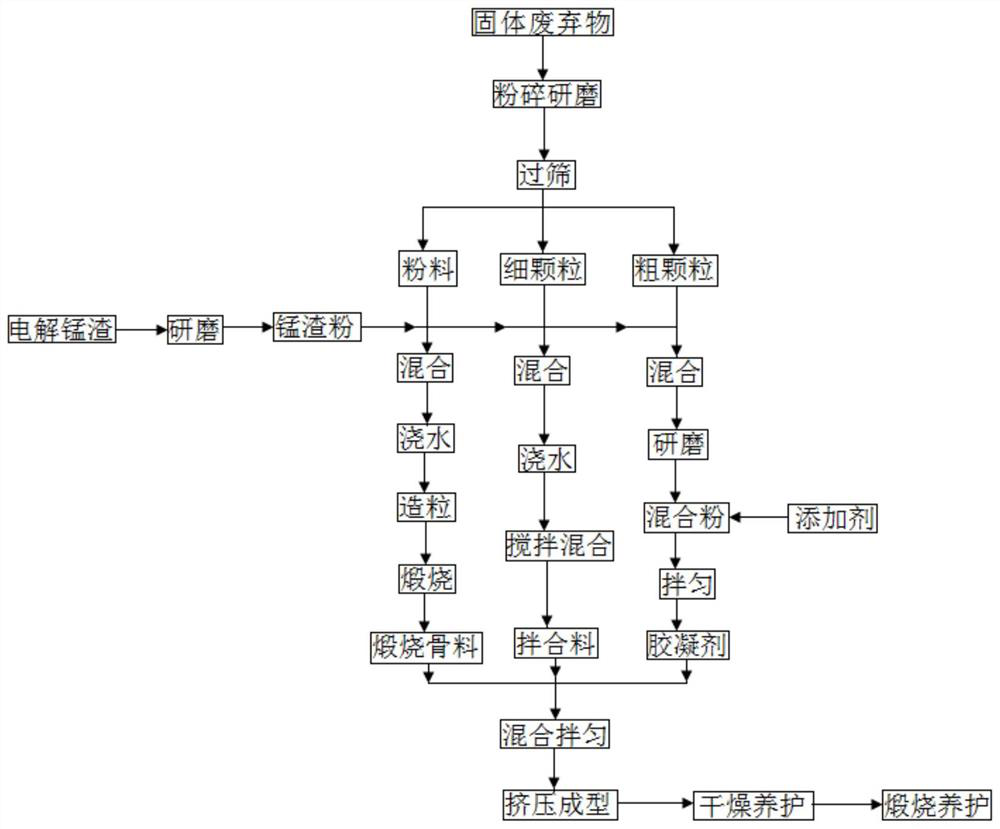

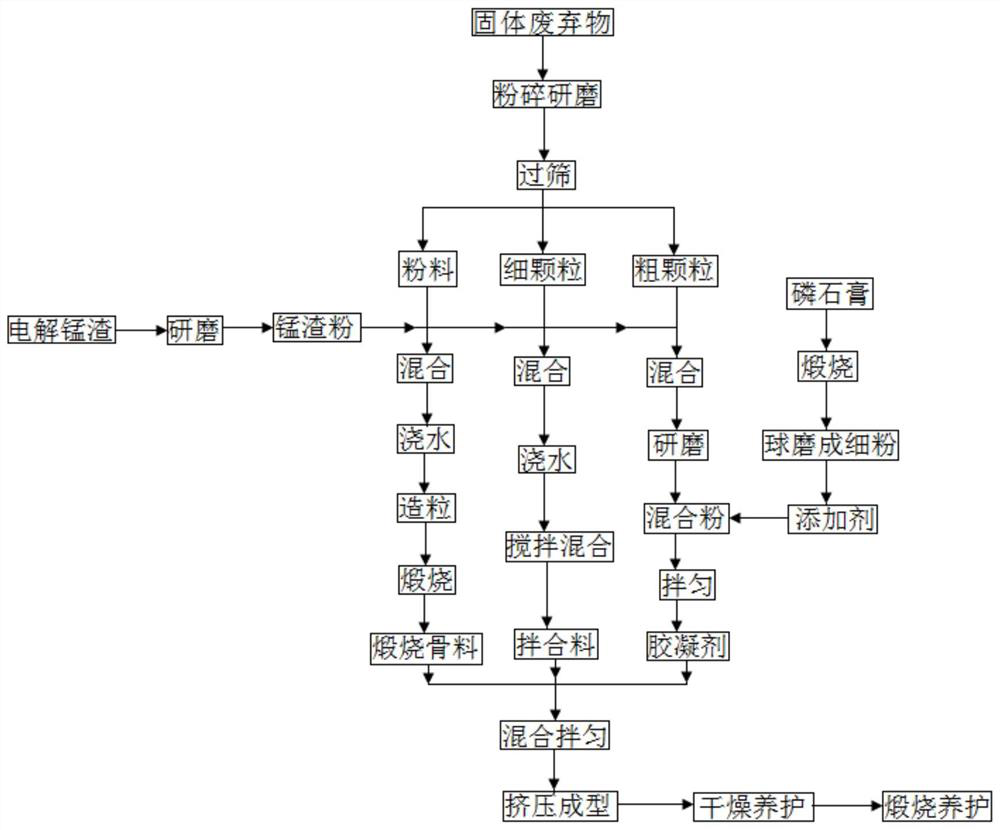

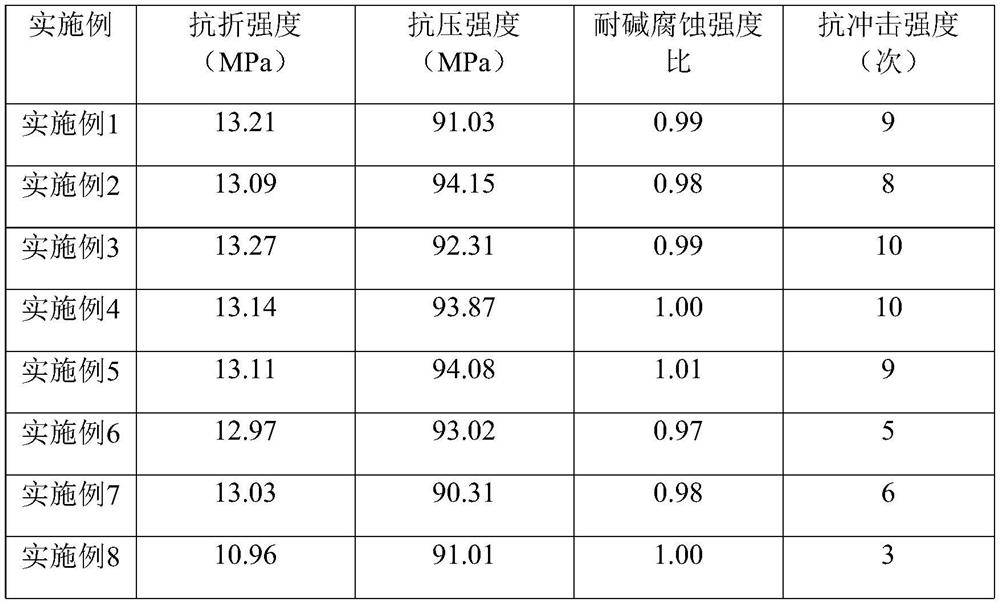

High-strength alkali-resistant composite brick based on waste reutilization and preparation method of high-strength alkali-resistant composite brick

ActiveCN114315317AReduce landfill volumeReduce stockpilesSolid waste managementCeramic materials productionBrickManganese

The invention relates to the technical field of building materials, in particular to a high-strength alkali-resistant composite brick based on waste reutilization and a preparation method of the high-strength alkali-resistant composite brick. Electrolytic manganese residues and solid waste generated by house demolition are selected as main raw materials, and silicon-calcium resources in the electrolytic manganese residues and the solid waste are fully utilized; solid waste is subjected to grinding and grading treatment, electrolytic manganese residues are ground to expose siliceous components, then manganese residue powder and powder are used for preparing calcined aggregate, the manganese residue powder and fine particles are mixed to form a mixture, the manganese residue powder and coarse particles are ground to form mixed powder, and an additive is added as a gelatinizing agent, so that the consumption of the electrolytic manganese residues and the solid waste is increased; the silicon components in the electrolytic manganese residues interact with materials with different silicon and calcium components in the solid waste, and calcined aggregate, a mixture and a gelling agent are formed respectively. And through extrusion forming, drying maintenance and calcination maintenance, the compression resistance and breaking strength of the composite brick are improved, and the alkali corrosion resistance is enhanced.

Owner:宜兴市隆昌耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com