Patents

Literature

59results about How to "Save clay resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pet used cat litter and preparation method thereof

The invention relates to pet cat litter and its preparation method, which comprises preparing organic base-material 20- 60%, clay 30-80%, binder 0-10%, water absorber 0-20%, surface adsorption substance0- 5%, crushing organic base-material to 30 screen mesh bulkload, processing clay to powder finer than 200 screen mesh, picking organic base material and clay proportionally to making cat litter base body, mixing and stirring the remaining material to making mixed covering material, placing cat litter base body in high-velocity rotating vibration machine, rotating making hydrosphere seeping to the surface of base body, then adding mixed covering material, vibrating slightly for mixing, then sifting and drying, sifting out powder. The inventive cat litter has good deodorant effect, good conglobation property after using, and waste cat litter can combust in favor of environment protection.

Owner:HANGZHOU LINAN KUROKAWA BENTONITE

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

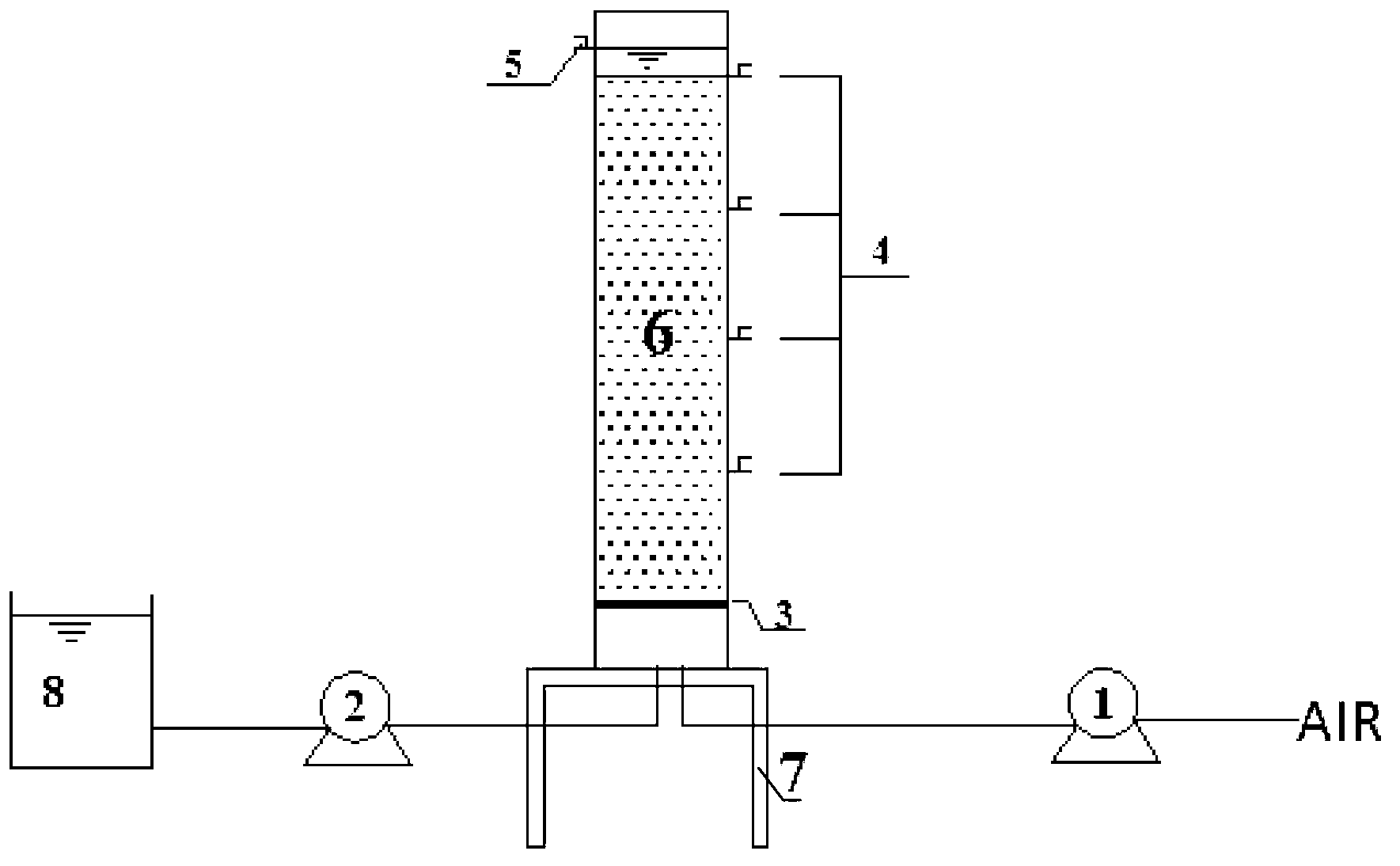

Method for preparing anti-hardening granular ceramic iron-carbon micro-electrolysis filler from industrial wastes

ActiveCN103253741ARealize the recycling of solid wasteSave clay resourcesTreatment using aerobic processesWater contaminantsElectrolysisChemical oxygen demand

The invention relates to a method for preparing anti-hardening granular ceramic iron-carbon micro-electrolysis filler from industrial wastes. The method comprises the steps of mixing iron powder, lignin, red mud and clay, which are used as raw materials, in a mass ratio of (4-5):(2-3):(1-3):3, then pelleting, and burning under a reducing atmosphere. The particle size of the prepared anti-hardening granular ceramic iron-carbon micro-electrolysis filler is 4-6mm. When used for sewage treatment, the anti-hardening granular ceramic iron-carbon micro-electrolysis filler can improve the biodegradability of wastewater in a short time and reduce the CODCr (Chemical Oxygen Demand Cr) and toxicity of the wastewater, and is difficult to be hardened in use, long in service cycle and simple to maintain. The industrial wastes are used as raw materials, so that energy resources are saved, and the treatment of wastes with processes of wastes against one another is realized.

Owner:SHANDONG UNIV

Method for mfg. energy-saving building brick using paper making mud

A technology for making energy-saving brick from paper-making mud includes such steps as proportionally mixing said mud with clay, shaping by brick maker, drying and calcining at 900-1050 deg. C. Its advantages are low energy consumption and high insulating performance of brick.

Owner:浙江中悦环保新材料股份有限公司

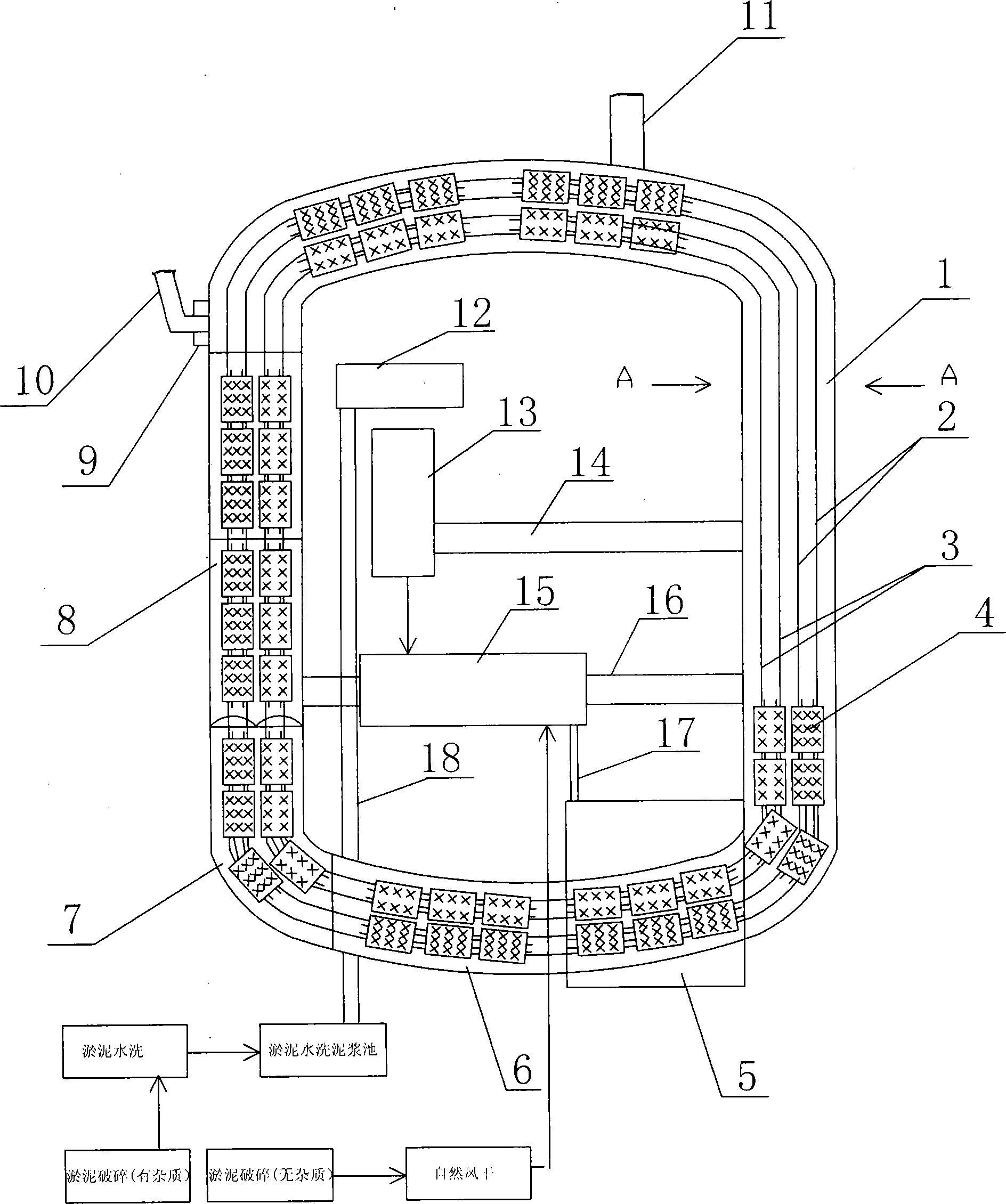

Method for baking clay ceramsite by using biological sludge of sewage treatment plant

The present invention relates to a method for baking clay ceramsite by using biological sludge produced by sewage plant. Its raw material composition contains (wt%) clay 71-89%, dried biological sludge of sewage plant 6-21%, limestone 3-8% and iron powder 2-6%. This invention uses the biological sludge produced by sewage plant as useful resource to bake high-quality ceramsite instead of partial clay, and can save firing expansion agent and mineralizing agent so that it possesses the extensive application.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing porcelain granule from waste paper-making sludge

InactiveCN101386524ADifferent apertureDifferent porosityCeramic materials productionClaywaresSludgeCrushed stone

The invention provides a method for preparing porcelain granules by waste paper making sludge, which belongs to the technical field of solid waste treatment and disposal. The method comprises the following steps: mixing and milling, or mixing and granulating the waste paper making sludge, clay and pulverized fuel ash into spherical blank granules; and drying and sintering the spherical blank granules at a temperature of between 1,000 and 1,250 DEG C to produce a porcelain granule product. The method solves the problem of treating mass sludge produced by waste paper making, so that waste materials can be reasonably recycled, and the clay in fragmental stone chippings during the process of crushing construction aggregate can also be recycled, thereby solving the problems of occupying farmland, saving clay resource, and having certain significance for environmental protection. The method has the advantages of simple process and low cost, and is suitable for mass industrial production. The product produced by the method has high rate of finished products and wide application range. The light porcelain granules obtained by the porcelain granule preparation method have the advantages of standard dimension, easy graduation, and accord with national standard in pressure resistance and other indexes.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

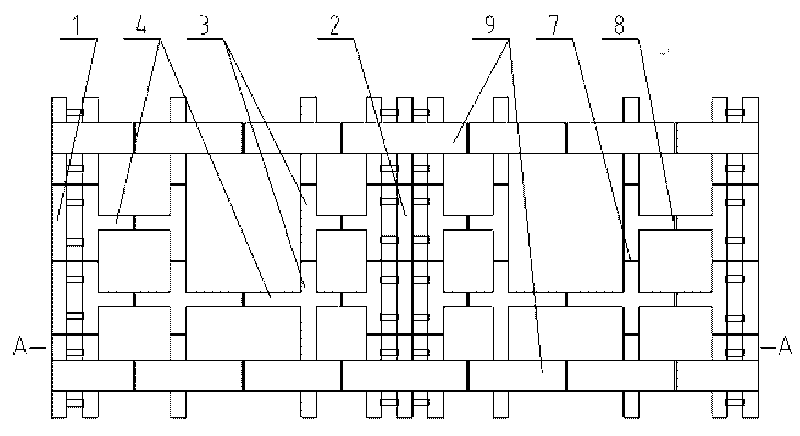

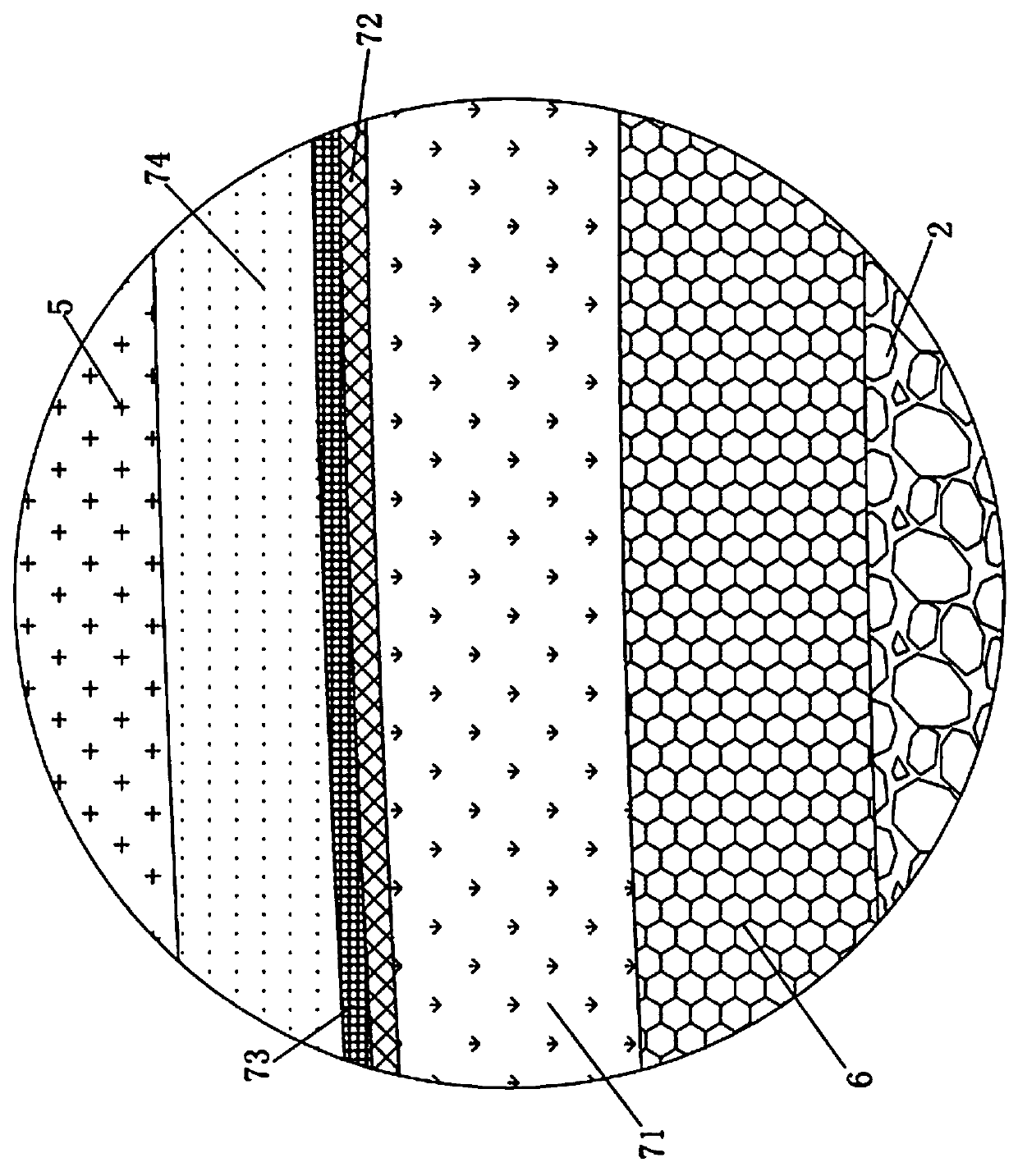

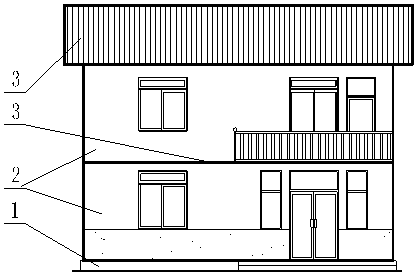

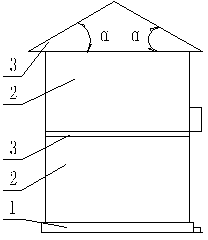

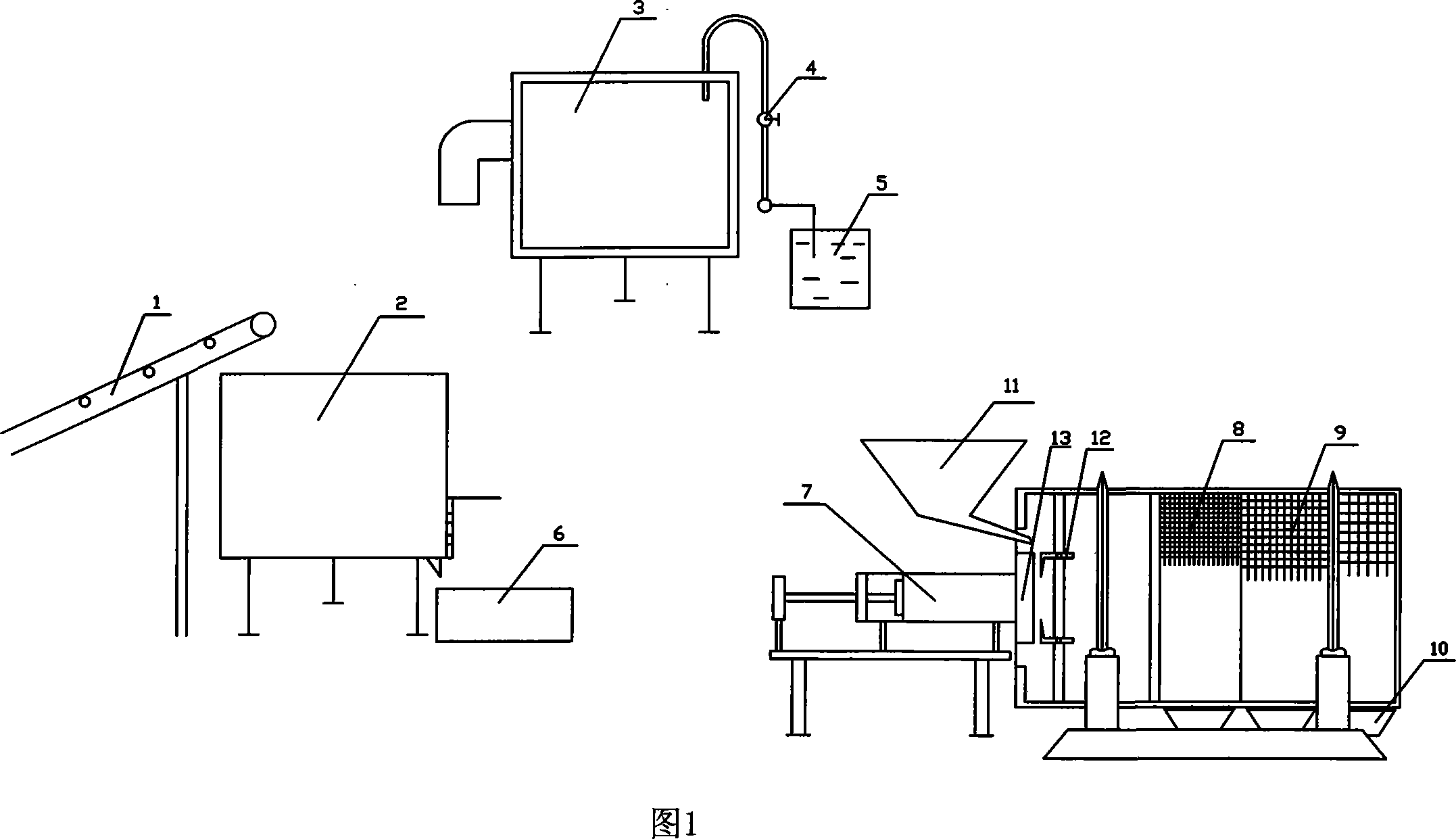

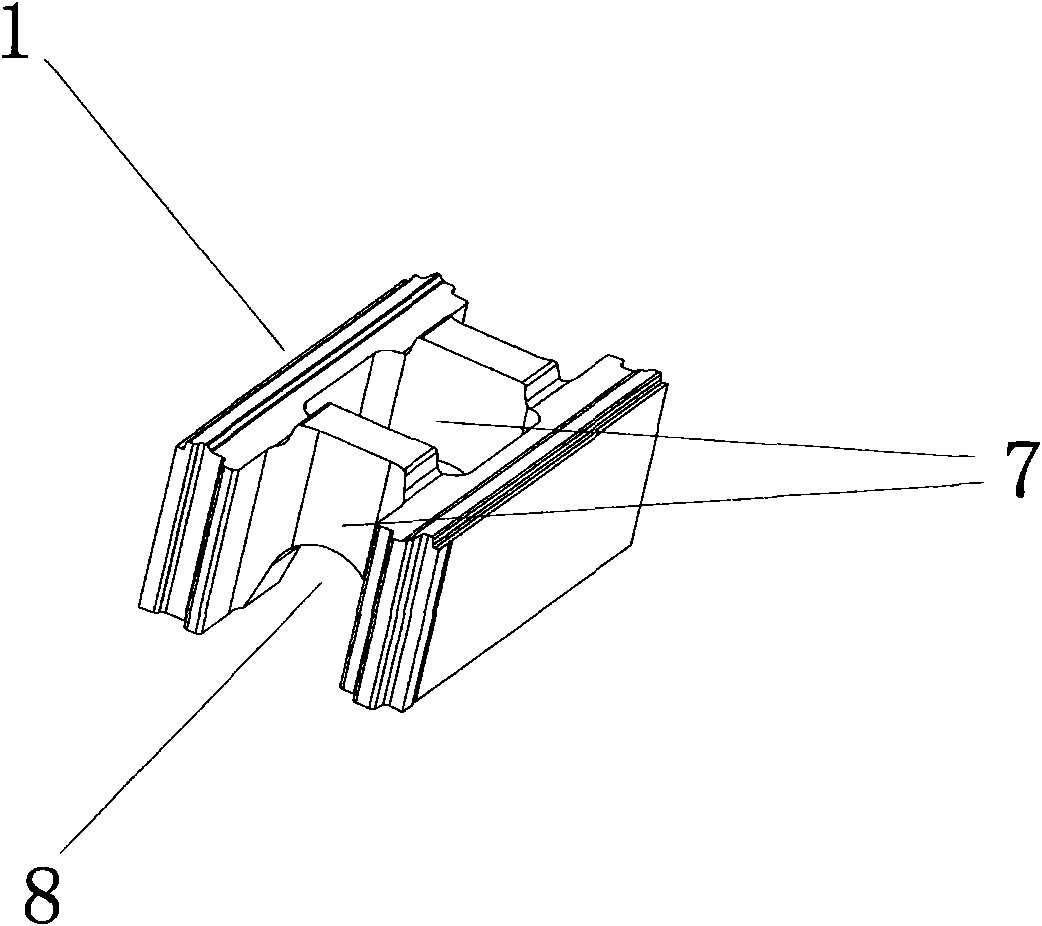

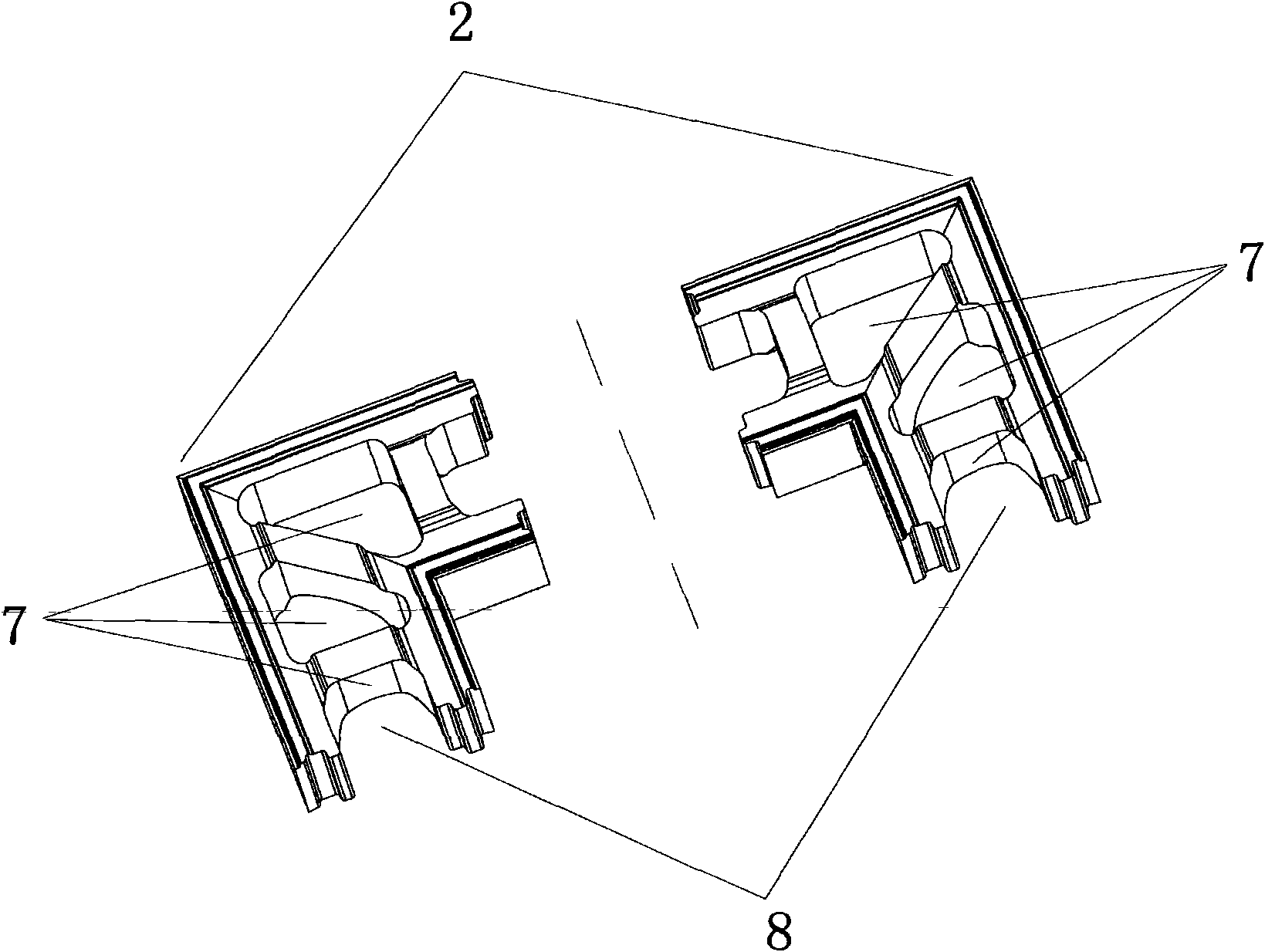

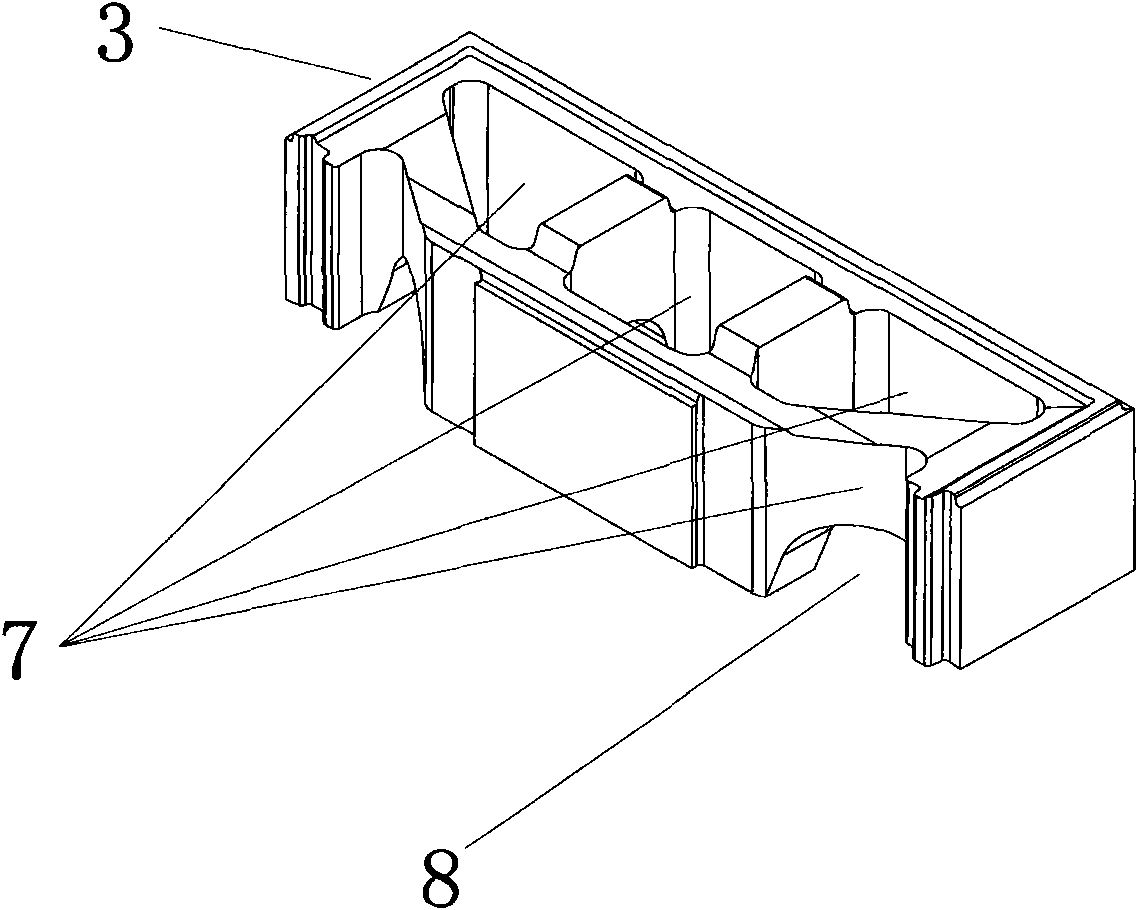

Steel structured wide-bay energy-saving residential building with gypsum walls and on-site layering and sectioning manufacturing method

ActiveCN101691784ASave clay resourcesSolve rust and fire protection problemsWallsDwelling buildingGypsumMesh grid

The invention discloses a steel structured wide-bay energy-saving residential building with gypsum walls and an on-site layering and sectioning manufacturing method. A steel grid framework is adopted as an outer wall or a skeleton of separation load-bearing walls, and is spliced by preformed steel members on site, and the steel members are connected by high strength bolts on site; after a section of steel grid framework in the height of the steel members is spliced, a wall pouring template is adopted to surround the section of steel grid framework; then gypsum slurry is poured into a cavity of the steel members surrounded by the template in an on-site pouring mode to fill the gypsum slurry into the cavity of the steel members and completely cover the constructed steel grid framework; and the steps are repeated to manufacture the steel structured wide-bay energy-saving residential building with the gypsum walls. The building has the advantages of high construction efficiency, good energy-saving effect, good rust and fire resistance, wide bay and flexible room division.

Owner:GUIZHOU UNIV +3

Method for preparing light porous sintering material by red mud and plant residues

The invention relates to a method for preparing a light porous sintering material by red mud and plant residues. The method comprises the following steps: by using the red mud with the water content being less than or equal to 65wt% and the plant residues with the water content being less than 70wt%, preparing and mixing materials; rolling and mixing; moulding; and sintering to obtain the light porous sintering material. The method which utilizes waste red mud and plant residues wide in source and large in output can produce serial products such as water permeable paving products, filtering products, products for sound absorbing materials, catalytic products, light panels or heat-insulating and sound-proofing bricks which are wide in purpose and high in value with low cost. The method has industrial competitiveness and good investment economical benefit. Meanwhile, not only are a lot of clay resources and non-renewable fuel coal as building materials and chemical product raw materials saved to realize industrial emission reduction of Co2, but also the pollution of waste pollutants red mud and plant residues to water, soil and air can be effectively solved, and secondary disasters are prevented.

Owner:长沙紫宸科技开发有限公司

Method for preparing cement clinker by using oil shale waste residues

The invention discloses a method for preparing cement clinker by using oil shale waste residues. The method comprises the following steps of: 1, mixing the following components according to the following proportions: 81 to 84 percent of limestone, 12 to 15 percent of shale waste residues, 1 to 2 percent of iron tailings sand and 2 to 4 percent of moulding sand; and 2, grinding the mixture obtained in the step 1 to obtain raw materials which is screened by a 80um square-hole sieve of which the screen residue is less than 5 percent, calcining the raw materials at temperature of between 1,350 and 1,450 DEG C for 15 to 20 minutes, and cooling to obtain the cement clinker. The method is used for preparing the cement clinker by using the oil shale waste residues replacing clay, so that a large quantity of clay resources are saved, and the production cost of the cement is reduced; furthermore, the doped quantity of the oil shale waste residues is large and up to 13 percent, so that the oil shale waste residues are used fully; therefore, the economic benefit is increased, wastes are turned into treasures, a large quantity of stacked residues are avoided, the land occupied amount is reduced, and the environment pollution is reduced.

Owner:FUSHUN MINING IND GROUP

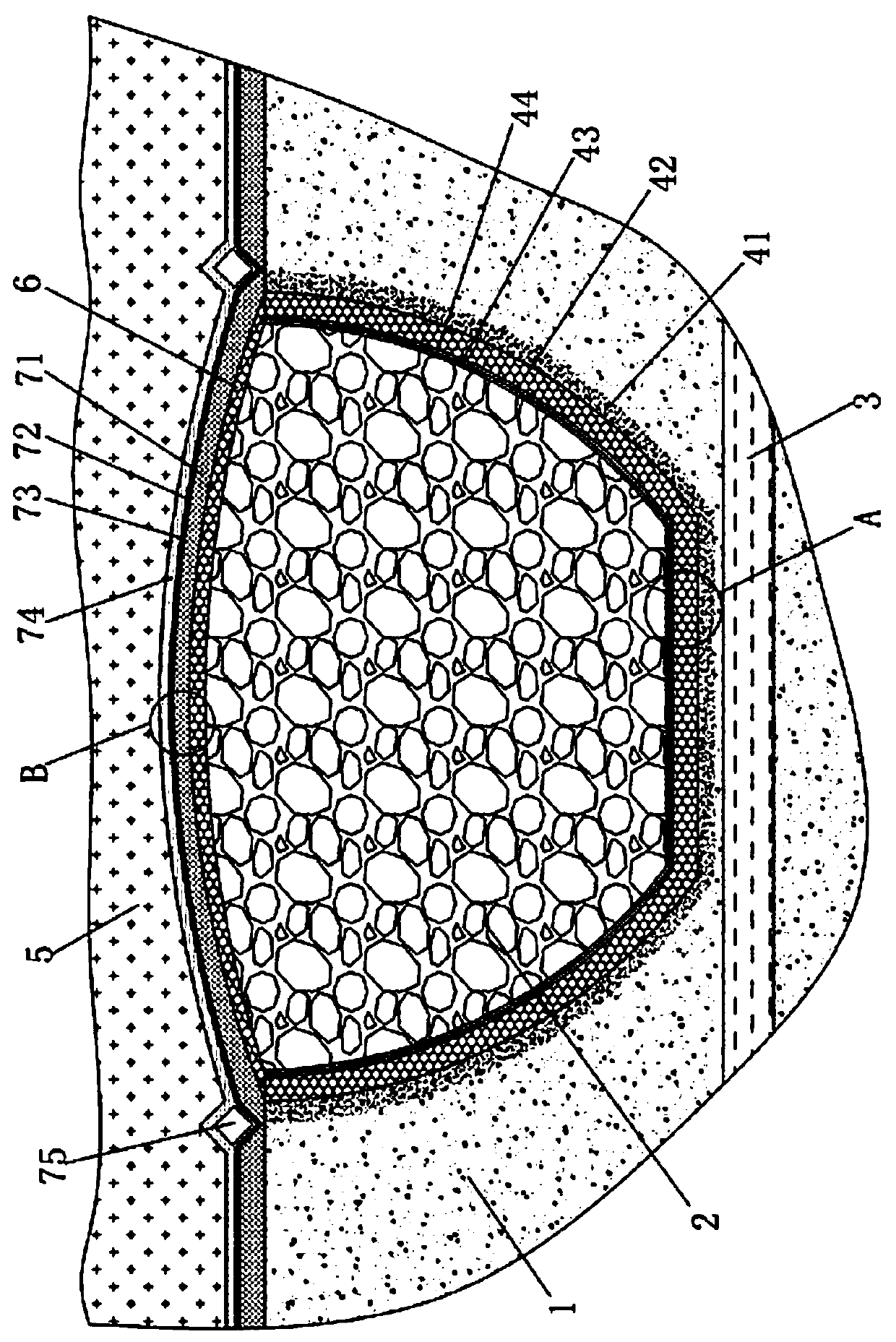

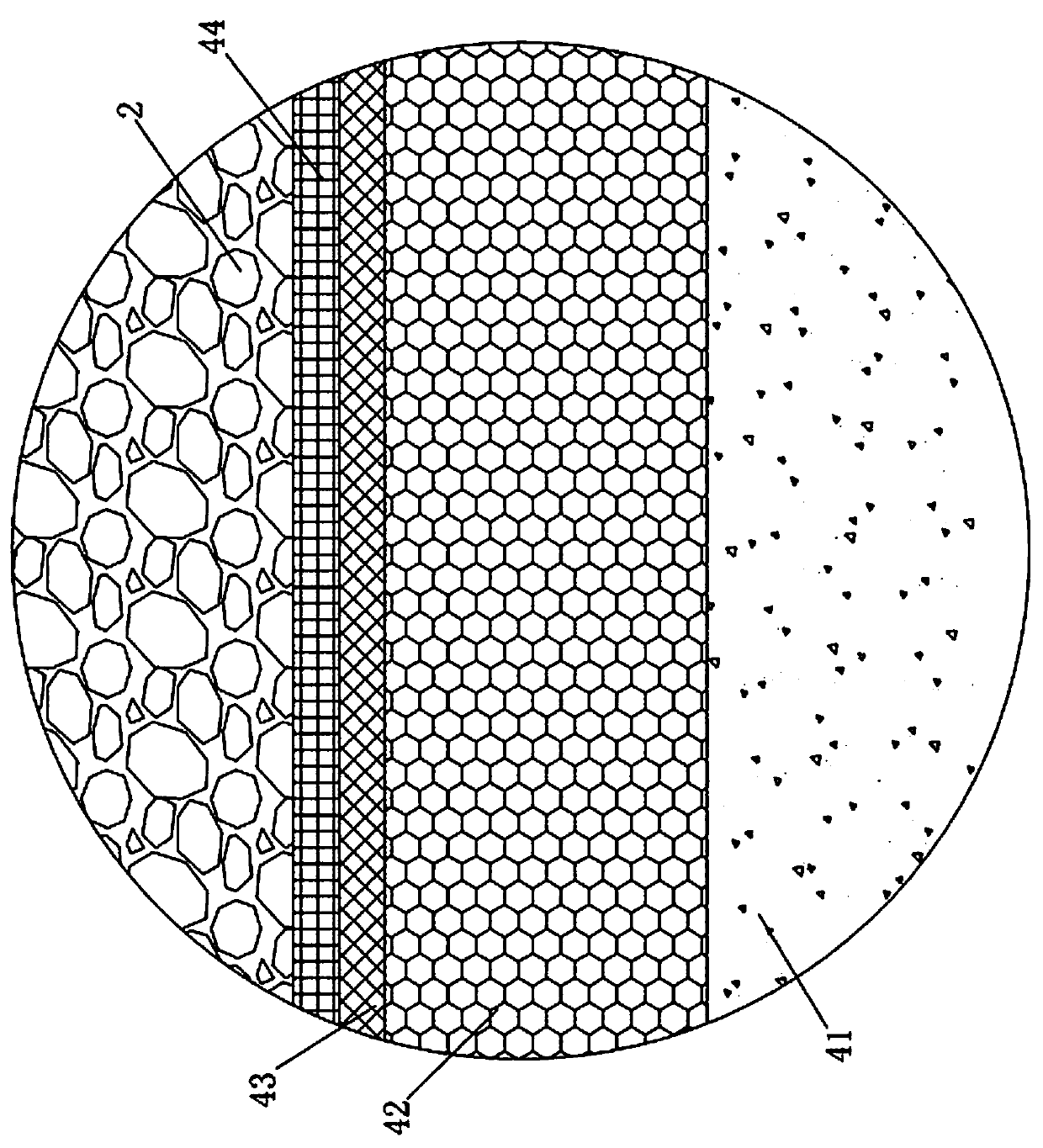

Novel environment-friendly durable impermeable and impermeable structure based on solid waste, and impermeable barrier material

PendingCN109989430ARealize the harmless disposal of solid wasteBarrier leakProtective foundationSlagSoil horizon

The invention relates to a novel environment-friendly durable impermeable and impermeable structure based on solid waste, and an impermeable barrier material. The impermeable and impermeable structurecomprises a foundation layer, an anti-seepage layer and a sealing field cover layer; an impermeable barrier material is poured on a base layer according to potential to form an impermeable barrier substrate; an HDPE film and geotextile are laid on the substrate, a mine pit is filled with industrial solid waste and compacted, and an arch-shaped surface is formed at a mine pit opening; an impermeable barrier material is poured on the arch-shaped surface according to the potential to form a field sealing cover layer, the field sealing cover layer is connected with the upper edge of the impermeable barrier substrate, and a matrix soil layer is laid on the field sealing cover layer. According to the invention, solid wastes such as fly ash, desulfurized gypsum, blast furnace slag and the like are utilized to prepare the impermeable barrier material; industrial solid waste is buried in a waste mine pit for storage, harmless treatment is achieved, the impermeable barrier material can effectively block leakage of a solid waste leaching solution, the risk of underground water pollution is reduced, and the mine pit is designed according to the standard of a solid waste resource storage, so that further comprehensive utilization is facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

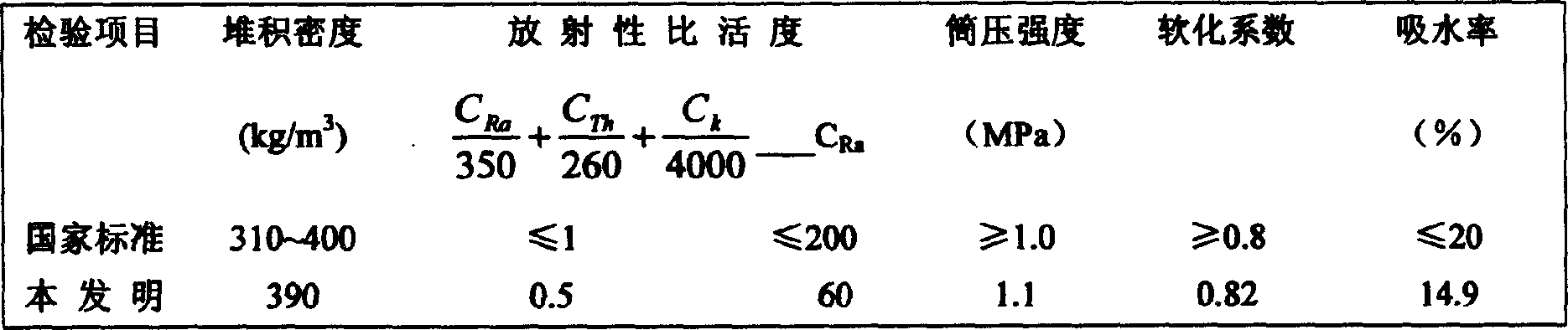

High-strength ceramsite prepared by utilizing Yellow River silt and sludge as adhesive and preparation method of high-strength ceramsite

ActiveCN107459364AReduce manufacturing costSolve processing problemsCeramic materials productionCeramicwareSludgeAdhesive

The invention discloses a method for preparing high-strength ceramsite prepared by utilizing Yellow River silt and sludge as an adhesive. The method comprises the following steps: by taking Yellow River silt, sludge and fly ash as main raw materials, mixing the various raw materials in proportions, granulating, drying, roasting, and cooling, thereby obtaining the high-strength ceramsite. According to the method disclosed by the invention, the high-strength aggregate which is high in physical strength, high in chemical stability, low in bulk density and large in specific surface area and can be applied to the fields of buildings, water treatment, garden art and the like is obtained, and the ceramsite production cost is greatly reduced. Meanwhile, the consumption of scarce resources is reduced, the treatment problem of local Yellow River silt and industrial solid wastes is solved, and the high-strength ceramsite has excellent market prospects.

Owner:山东京泰再生资源有限公司

Porcelain grey tile without carburization and sintering method thereof

InactiveCN102826833ASave clay resourcesNo crackingCeramic materials productionClaywaresMulti materialDrying time

A porcelain grey tile without carburization and a sintering method thereof. Bauxite, purple sand, clay, and gas stove coal cinder are mixed, added with water to prepare a green body, and then the porcelain grey tile without carburization is sintered under a certain temperature condition. According to the invention, a mixture of multiple materials is used instead of pure clay for sintering, which saves clay resources; the green body does not crack when a lot of water is lost within a short period, which greatly shortens the drying time of the green body; during high temperature sintering, carbon particles are generated in raw coal reactions of generator gas and gas stove coal cinder, and colorize the inner and outer sides of the green body, which omits the colorization and color preservation processes in the prior art, shortens the process flow, increases the sintering efficiency, and saves energy.

Owner:HENAN YANSHI CLASSICAL GARDENS

Mildew-proof and corrosion-resistant composite nano calcium silicate brick and production method thereof

The invention discloses a mildew-proof and corrosion-resistant composite nano calcium silicate brick, which is prepared by mixing an ethylene-vinyl acetate copolymer with a compounded plasticizer composed of diisodecyl phthalate, [beta]-diketone and ammonium polyphosphate. The brick is improved in mechanical performance and meanwhile is enhanced in anti-aging performance and processability and can enhance flexibility of cables. The ammonium polyphosphate has the effect of a condensed phase and is mixed with magnesium hydroxide to achieve excellent flame-retarding effect. In addition, the sintered brick is high in strength, is strong in bearing capability, is low in density, is low in heat conductivity coefficient and can satisfy use requirement, is wide in application range and is good in market prospect. The sintered brick can reduce environment pollution of industrial solid waste discharge, is low in cost and less in pollution, is less in damage on human body, is good in abrasion resistance, is strong in anti-aging performance and also achieves economic and social benefit of turning waste into resources.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

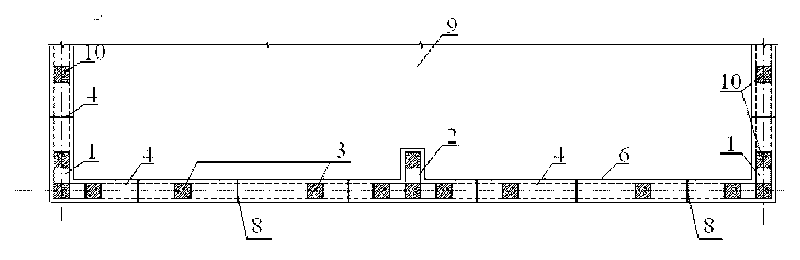

Energy-saving domestic architecture with cast-in-place industrial gypsum bearing wall and manufacturing method thereof

ActiveCN103306501AAvoid steamIncrease loading capacityWallsBuilding material handlingReinforced concreteThermal insulation

The invention discloses an energy-saving domestic architecture with a cast-in-place industrial gypsum bearing wall and a manufacturing method thereof. The method comprises the following steps: pouring industrial gypsum slurry into a wall body template in the field to manufacture the gypsum bearing wall of the domestic architecture; afterwards, performing pouring for gypsum / concrete compound building floor or house cover on the gypsum bearing wall, after the completion of the pouring, erecting a bottom template of the building floor or the house cover in advance; and arranging prefabricated industrial gypsum molded cases onto the bottom template at equal intervals, and performing concrete pouring after bars are arranged among the industrial gypsum molded cases and at the upper parts thereof, so as to manufacture the gypsum / concrete compound building floor or house cover on the gypsum bearing wall body. Due to the adoption of the method, the construction cost is low, no reinforced concrete structure is required for the wall body support, the structure is reliable, the construction is easy, the thermal insulation performance is good and the energy saving effect is obvious. The domestic architecture is particularly suitable for low-storey and small-bay domestic architectures in rural.

Owner:GUIZHOU UNIV +4

Method for producing brick by using shale and feldspathic sandstone

InactiveCN101450851AHigh strengthThe characteristics of high strength, in addition, the weight of the fired brick of the present invention is highSolid waste managementWood-turning machinesSocial benefitsBrick

The invention discloses a method for manufacturing bricks by utilization of shale and sandstone, which comprises: mixing the shale, the sandstone, coal refuse and coal dust according to the ratio of 20-25:65-70:10-15:0.25-0.3 by weight portion; adding 15 to 20 weight portions of water into the mixture to be stirred and manufactured into green bricks; placing the green bricks into a kiln for sintering after drying the green bricks, wherein the sintering temperature is between 950 and 1,050 DEG C, and the sintering time is between 20 and 24 hours; and drawing the bricks out of the kiln after performing heat preservation for 5 to 6 hours. The sintered bricks have the advantages of weather resistance, alkali resistance, high strength and light weight. The method changes waste into valuable, saves farmlands, protects land resources, and has good social benefit and economic benefit.

Owner:冯玉存

Pet used cat litter and preparation method thereof

The invention relates to a cat litter for pets and a preparation method thereof. % Prepare the materials, pulverize the organic base material into granules finer than 30 meshes, process the clay into fine powders finer than 200 meshes, take the organic base material and clay in proportion to process the cat litter matrix, and then mix and stir the remaining materials to cover the surface. To mix the material, put the cat litter matrix into a high-speed rotary vibrating machine to rotate and vibrate to make the water vapor in the matrix seep out and adhere to the surface of the matrix, then add the surface to cover the mixed material, and then sieve and dry after a little vibration and mixing. The granules are sieved to remove powder and packaged for storage. It has good deodorizing effect, good particle agglomeration after use, will not cause the consolidation of pellets to break when cleaning waste cat litter, easy to clean, waste cat litter can be burned, which is beneficial to environmental protection, and the product and production cost are low. Cat litter for pets and preparation method thereof.

Owner:HANGZHOU LINAN KUROKAWA BENTONITE

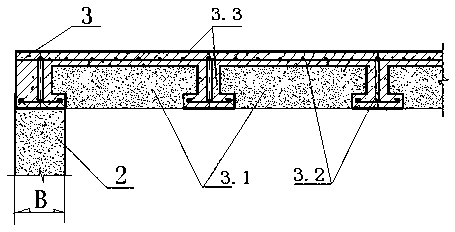

Process for manufacturing mud environment protection brick

InactiveCN101172841ASolve the problem of raw material sourceSave clay resourcesCeramic materials productionClaywaresBrickSlurry

The invention discloses a preparation method of environment-protection silt bricks, and the preparation method comprises the steps as follows: silt crashing, silt bathing, slurry tranportation, slurry depoisting, silt drying, slit performing, mud perform transportation, mud perform dying, brick sintering, brick heat preserving and product stacking. The invention solves the material origin of the brick production and saves the clay material, and the production cost is low.

Owner:陆振富

Production method for cold-foaming coal ash baking-free ceramicite

InactiveCN101113088ASave clay resourcesSimple processSolid waste managementCeramicwareExpanded clay aggregateSlurry

A production method of cold foaming fly ash unfired haydite has the following steps that: 1.the fly ash after being wheel grinded is sieved by sieve meshes with the size of 80-100 meshes. Then the fly ash, concrete and sodium silicate are mixed evenly by a blender according to a weight proportion of 1.5:1:0.2. At the same time a certain quantity of water-absorbing resin polyacrylic acid calcium, water and additive are added. The materials are blended evenly into slurry. The foaming agent is foamed by mechanical method and then is solid foamed through chemical way. The slurry is blended with the foam according to a volume proportion of 1:3-4. The evenly blended slurry is sent into pregelation groove after going through pregelation and setting, then squeezed, cut and molded by dry powder particle rotation. Compared with the prior art, the invention has following beneficial effects that clay resource is saved by adopting industrial waste materials such as fly ash, concrete and sodium silicate as main materials; processing technique is simplified by adopting the cold foaming technique and molding through extrusion, segment and dry powder particle rotation; the production cost is reduced and has good quality.

Owner:杨子江 +1

Grey tile and firing process thereof

InactiveCN110818390AImprove corrosion resistanceIncreased durabilityCeramic materials productionClaywaresCompressive resistanceSlag

The invention provides a grey tile and a firing process thereof, and relates to the technical field of building materials. The grey tile is made of the following raw materials: shale powder, lime powder, fly ash, caesious peat meal, black powder, and furnace slag. The grey tile has good corrosion resistance, durability and erosion resistance, has freezing resistance and impermeability, discoloration and peeling prevention, no radiation, aging resistance and no light pollution, has high compressive strength and strong disassembly resistance, and is relatively beautiful.

Owner:重庆市忠县古屋建材有限公司

Method for producing brick from oil sludge and coal gangue

InactiveCN101891452ASave clay resourcesEnergy savingCeramic materials productionClaywaresCoal gangueWaste treatment

The invention relates to a method for producing a brick from oil sludge and coal gangue as raw materials. The brick comprises the following components in percentage by weight: 10 to 20 percent of oilfield oil sludge, 10 to 30 percent of coal gangue, 40 to 65 percent of clay, 5 to 20 percent of water and 0.5 to 3 percent of modifying additive. The method comprises the following steps of: stirring the components uniformly in a stirring device to form a semi-finished brick blank, and drying and roasting the brick blank to form a finished product of the brick. By combining an internal combustion process for manufacturing the brick by sintering and making full use of heat values of the oil sludge and the coal gangue, the method reduces external fuels during roasting, saves a large amount of energy, meanwhile solves the treatment problem of the oil sludge and the coal gangue, and protects the environment. The brick manufacturing method is simple, has low cost, realizes reduced, harmless and recycling requirements of solid waste treatment, and has good market prospect and popularization value.

Owner:SHANDONG UNIV OF SCI & TECH

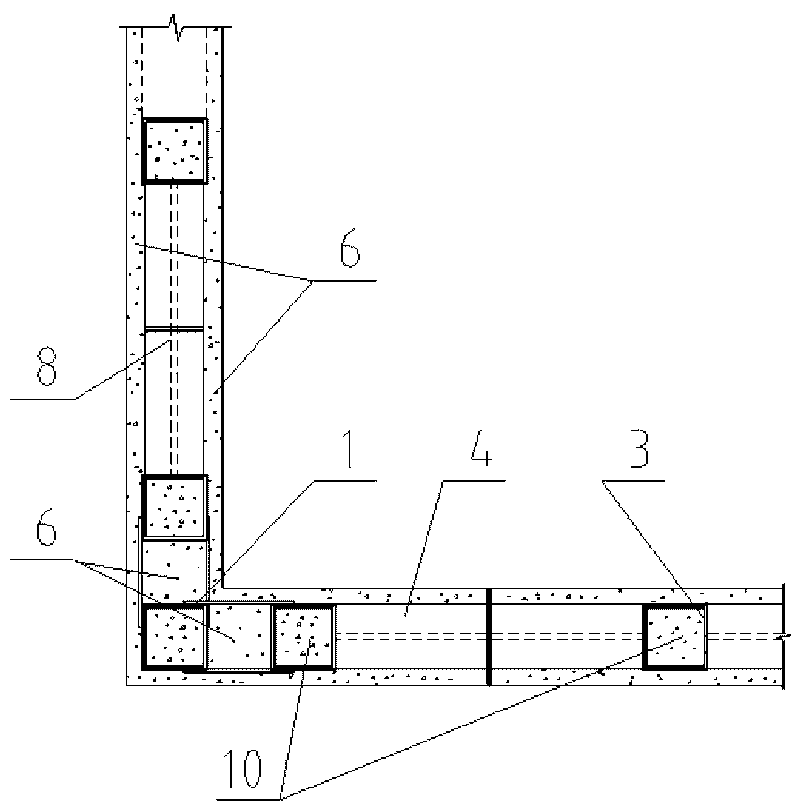

Integral rain inlet and construction method thereof

InactiveCN101949167BImprove stabilityImprove securitySewerage structuresBuilding material handlingGratingComputer module

The invention discloses an integral rain inlet and a construction method thereof. The rain inlet comprises a water-collecting pool, a grating opening and a grate, wherein the water-collecting pool is formed by a wall frame built by concrete modules and concretes solidified in the wall frame and fixedly connected with the grating opening; and the grating opening is rotatablely connected with the grate. All components of the rain inlet of the invention are connected together to form a whole, thereby improving the stability and safety of the rain inlet and avoiding the grating opening and the grate separating from the water-collecting pool. In addition, the water-collecting pool of the rain inlet of the invention can be integrated into a whole, thereby improving the intensity of the rain inlet.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

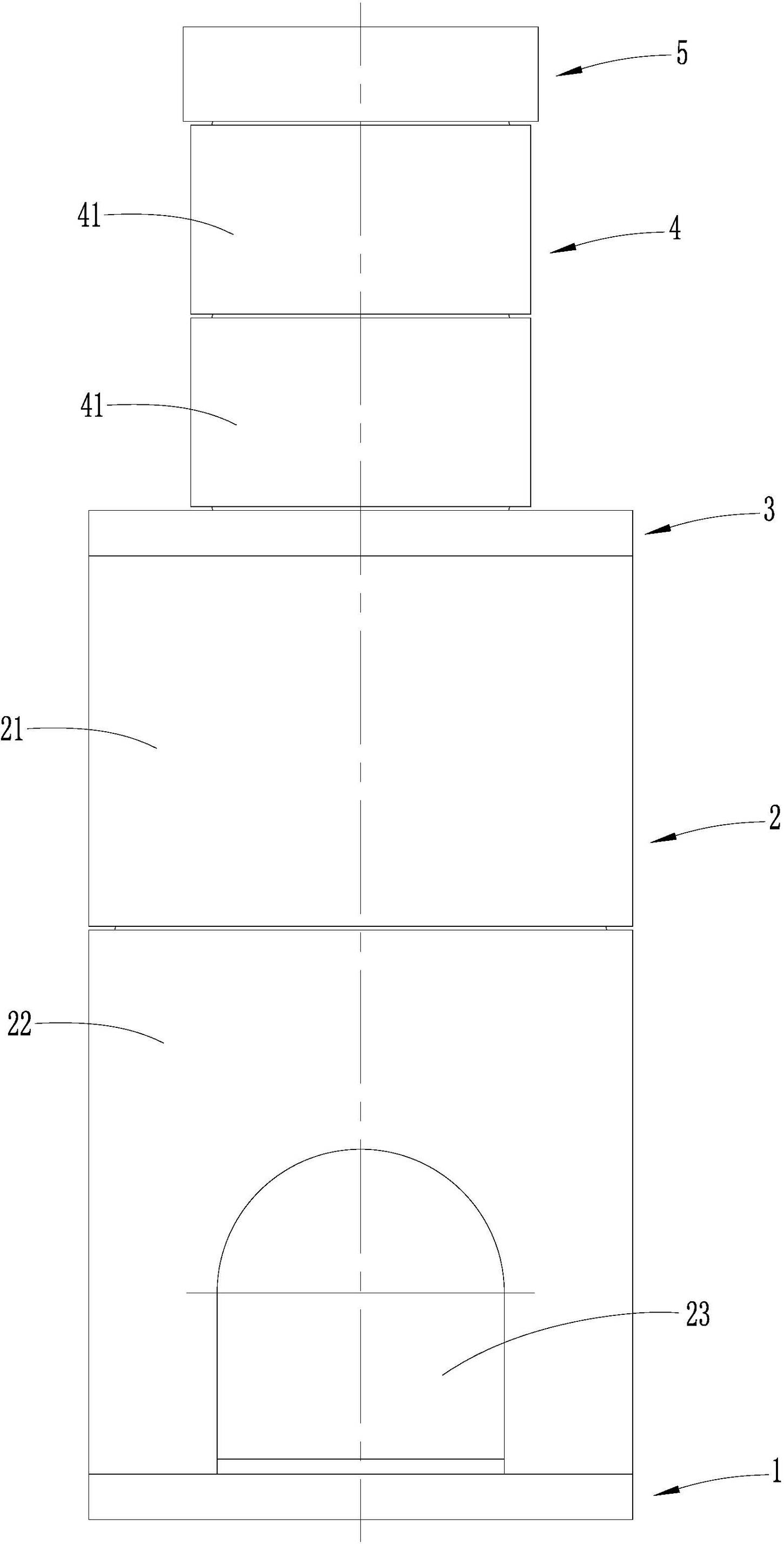

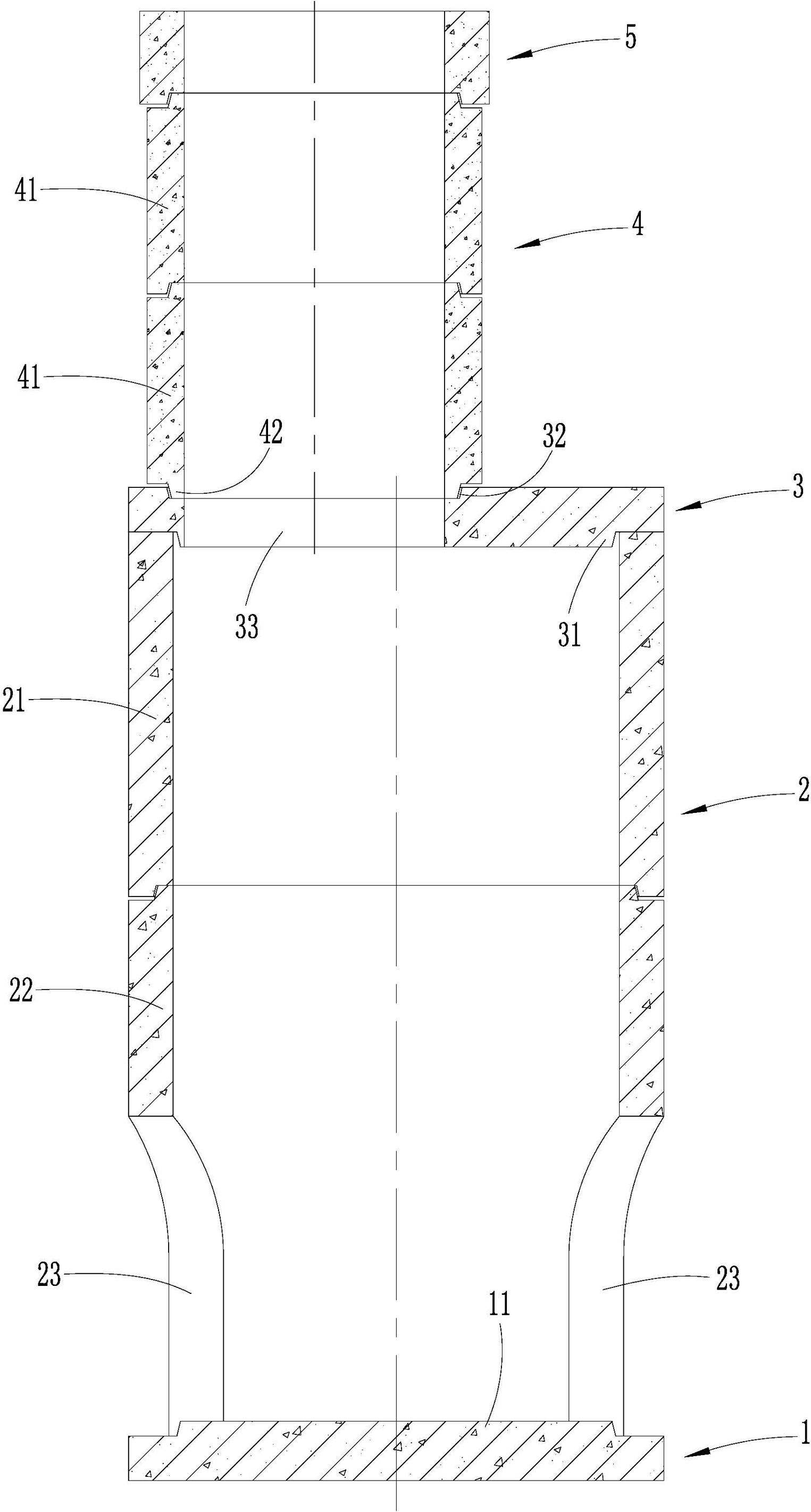

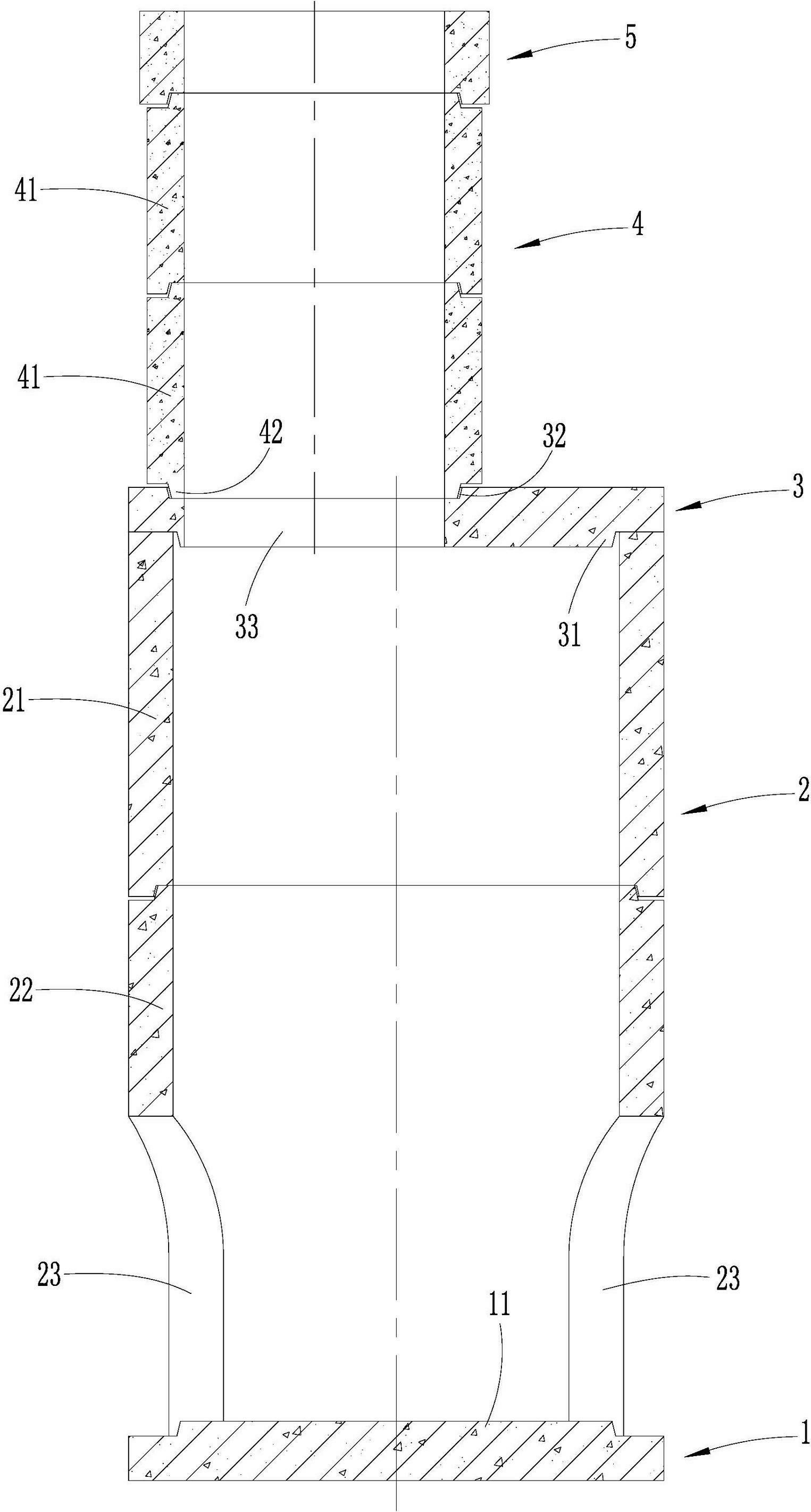

Assembly type manhole

InactiveCN102587419AImprove the quality of construction projectsHigh compressive strengthArtificial islandsUnderwater structuresReinforced concreteEngineering

An assembly type manhole comprises a bottom plate, a manhole chamber, a cover plate, a shaft, a manhole ring and a manhole cover which are sequentially connected from bottom to top and are reinforced concrete prefabricated parts, and at least two inverted U-shaped reserved holes are arranged at the lower end of the manhole chamber. A downwards extending first boss which is concentric with the cover plate and matches with an inner cavity of the manhole chamber is disposed on the lower surface of the cover plate, a step through hole is arranged at a position, which is close to the outer edge, of the cover plate, a first hole and a second hole are vertically communicated with each other to form the step through hole, the size of an opening of the first hole is larger than that of an opening of the second hole, and the central line of the step through hole is parallel to that of the cover plate; the upper end surface of the manhole chamber is a plane; a downwards extending second boss which matches with the first hole is arranged at the lower end of the manhole chamber; the cover plate is placed on the upper end surface of the manhole chamber, and the first boss is inserted into the inner cavity of the manhole chamber; and the second boss is inserted into the first hole. An upwards extending second boss which is concentric with the bottom plate and matches with the inner cavity of the manhole chamber is disposed on the upper surface of the bottom plate and is inserted into the inner cavity of the manhole chamber. By the aid of the assembly type manhole, construction efficiency is high, and clay resources are saved.

Owner:ANHUI FANGDA CEMENT PROD

Application of finished plastic inspection well in outdoor drainage system

InactiveCN102864833APrevent leakageAvoid secondary pollutionSewerage structuresEngineeringBuilding construction

The invention discloses application of a finished plastic inspection well in an outdoor drainage system. The application includes the steps of pit and foundation construction, inspection well connecting pipe mounting, shaft mounting, backfilling, well lid mounting, closed water test and the like. The application of the finished plastic inspection well in the outdoor drainage system is convenient to construct and good in construction quality.

Owner:成张佳宁

Calcium silicate graphene nano-base material for filtering and removing haze molecules and production method thereof

InactiveCN106178687AImprove flame retardant performanceImprove heat resistanceDeodrantsFiltration separationPorosityCalcium silicate

The invention discloses a calcium silicate graphene nano-base material for filtering and removing haze molecules. According to the material, the mechanical performance, aging resistance and processing performance can be improved due to combination of ethylene-vinyl acetate copolymer; ammonium polyphosphate has an effect in a condensed phase; a filter fibrous film is prepared from titanium dioxide and degradable polylactide chitosan, has double functions of adsorbing aerosol and volatile organic matters and has the advantages of degradability and environmental friendliness; since positive charges are carried in molecules, the chitosan can be used for adsorbing bacteria carrying negative charges, so that the chitosan has a sterilization function; and structurally, fibrous film layers with different diameters and porosities are prepared, and are combined with nano-graphene among layers, the porosity and specific surface area of a composite adsorbing film are improved, and the effect is reinforced.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Method for baking clay ceramsite by using biological sludge of sewage treatment plant

The present invention relates to a method for baking clay ceramsite by using biological sludge produced by sewage plant. Its raw material composition contains (wt%) clay 71-89%, dried biological sludge of sewage plant 6-21%, limestone 3-8% and iron powder 2-6%. This invention uses the biological sludge produced by sewage plant as useful resource to bake high-quality ceramsite instead of partial clay, and can save firing expansion agent and mineralizing agent so that it possesses the extensive application.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing cement clinker by using oil shale waste residues

ActiveCN102491701BAvoid bulk accumulationReduce manufacturing costClinker (waste)Process engineering

The invention discloses a method for preparing cement clinker by using oil shale waste residues. The method comprises the following steps of: 1, mixing the following components according to the following proportions: 81 to 84 percent of limestone, 12 to 15 percent of shale waste residues, 1 to 2 percent of iron tailings sand and 2 to 4 percent of moulding sand; and 2, grinding the mixture obtained in the step 1 to obtain raw materials which is screened by a 80um square-hole sieve of which the screen residue is less than 5 percent, calcining the raw materials at temperature of between 1,350 and 1,450 DEG C for 15 to 20 minutes, and cooling to obtain the cement clinker. The method is used for preparing the cement clinker by using the oil shale waste residues replacing clay, so that a large quantity of clay resources are saved, and the production cost of the cement is reduced; furthermore, the doped quantity of the oil shale waste residues is large and up to 13 percent, so that the oil shale waste residues are used fully; therefore, the economic benefit is increased, wastes are turned into treasures, a large quantity of stacked residues are avoided, the land occupied amount is reduced, and the environment pollution is reduced.

Owner:FUSHUN MINING IND GROUP

Alkaline residue processing method using slurry

InactiveCN103394500ACause secondary pollutionIncrease productivitySolid waste disposalWater dischargeFoundation engineering

The invention discloses an alkaline residue processing method using slurry, and the processing method comprises the following steps: the first step, a cofferdam is constructed, and an annular water seepage ditch is dug around the cofferdam; the second step, a water gun or a water cannon is arranged beside an alkaline residue pool, and water is injected into the alkaline residue pool to dilute alkaline residue in the alkaline residue pool into alkaline residue slurry; the third step, the alkaline residue slurry in the alkaline residue pool is conveyed into a mixer through a mud slurry pump; the fourth step, fly ash is put into a ash pool and is diluted with water into slurry, the slurry is conveyed into the mixer through a residue slurry pump to mix with the alkaline residue slurry, and the mixed slurry is conveyed into the cofferdam of the first step through a booster pump; and the fifth step, water content of the slurry in the cofferdam is reduced to design requirements of engineering soils through use of a strong drainage method, and the water discharged from the cofferdam into the annular water seepage ditch is pumped back to the ash pool or / and a mud pool for cycle use. The engineering soils prepared according to the alkaline residue processing method using the slurry, can be used for general-engineering backfill soil, building-foundation-engineering backfill soil, soft foundation treatment engineering soil and highway construction engineering soil.

Owner:顾建华 +3

Waste glass powder sintered bricks and production method thereof

The invention discloses waste glass powder sintered bricks and a production method thereof. The waste glass powder sintered bricks comprise, by weight, 20-25 parts of waste glass powder and other raw materials. According to the sintered bricks, by adopting the waste glass powder as the main raw material, clay resources are saved, the production cost is lowered, and the purpose of disposing the waste glass powder and preventing the waste glass powder from polluting the environment is achieved; under the synergistic effect of added antimonous oxide and chlorine in polyvinyl chloride resin, the flame retardancy of polyvinyl chloride is improved; through cooperation of a compound plasticizer composed of added dioctyl sebacate, dimethyl terephthalate, an antioxidant 616 and tetrabromophthalic anhydride and the polyvinyl chloride resin, the forward effect of the plasticizers is maximized, the usage quantity of the plasticizers is reduced while the low temperature resistance of the sintered bricks is improved, and flexibility is improved.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

Production method of cold-foaming fly ash unfired ceramsite

InactiveCN101113088BSave clay resourcesSimple processSolid waste managementCeramicwareExpanded clay aggregateSlurry

A production method of cold foaming fly ash unfired haydite has the following steps that: 1.the fly ash after being wheel grinded is sieved by sieve meshes with the size of 80-100 meshes. Then the fly ash, concrete and sodium silicate are mixed evenly by a blender according to a weight proportion of 1.5:1:0.2. At the same time a certain quantity of water-absorbing resin polyacrylic acid calcium, water and additive are added. The materials are blended evenly into slurry. The foaming agent is foamed by mechanical method and then is solid foamed through chemical way. The slurry is blended with the foam according to a volume proportion of 1:3-4. The evenly blended slurry is sent into pregelation groove after going through pregelation and setting, then squeezed, cut and molded by dry powder particle rotation. Compared with the prior art, the invention has following beneficial effects that clay resource is saved by adopting industrial waste materials such as fly ash, concrete and sodium silicate as main materials; processing technique is simplified by adopting the cold foaming technique and molding through extrusion, segment and dry powder particle rotation; the production cost is reduced and has good quality.

Owner:杨子江 +1

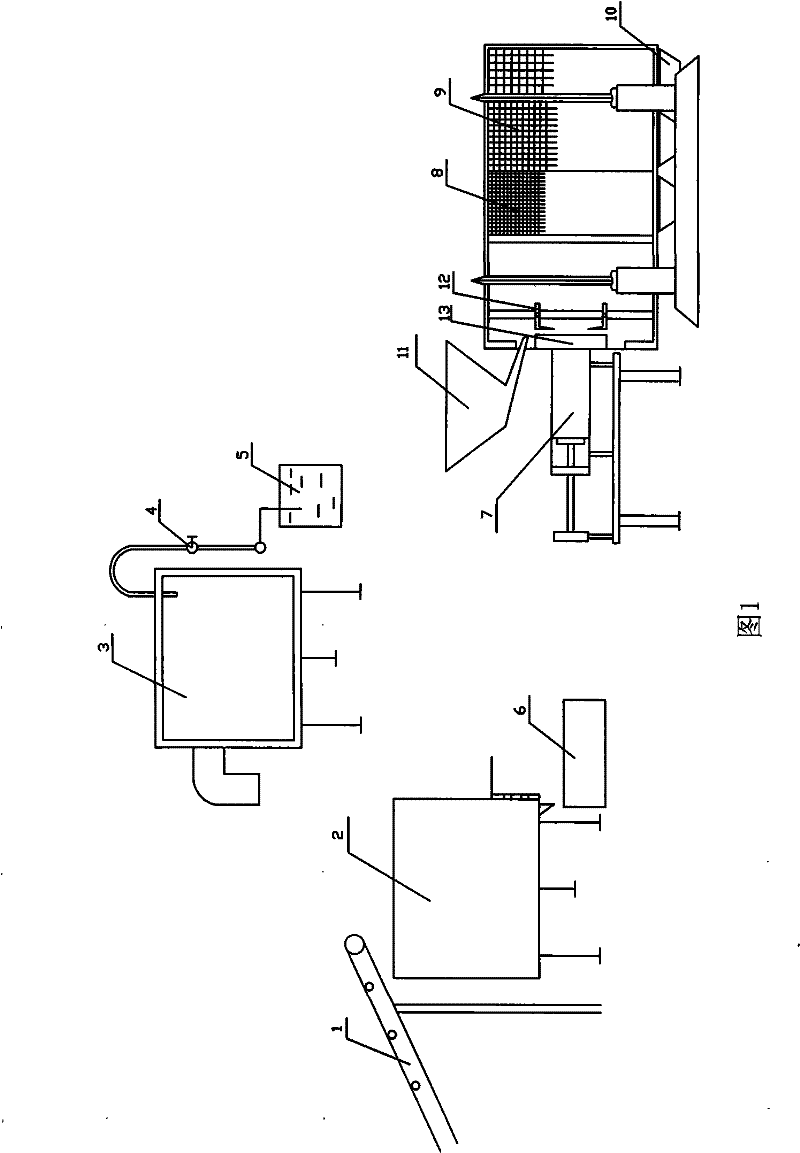

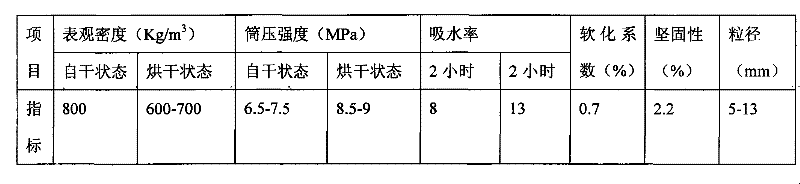

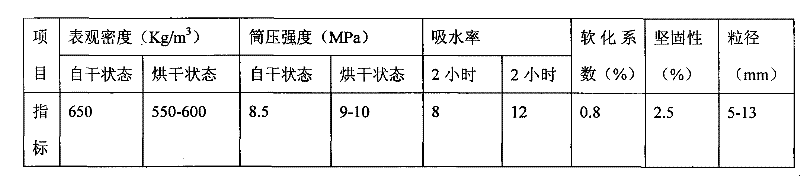

Riverway bottom mud ecological brick for riverway restoration work and preparing method thereof

The invention provides a riverway bottom mud ecological brick for riverway restoration work and a preparing method thereof. The ecological brick is mainly prepared from, by mass, 75-85% of dry bottommud, 5-10% of pulverized fuel ash, 5-10% of carbide slags and 2-5% of a pore forming agent. According to the riverway bottom mud ecological brick and the preparing method thereof, adopted raw materials including the heavy-metal-polluted riverway bottom mud, the pulverized fuel ash, the carbide slags, the pore-forming agent and rice hulls are all industrial or agricultural waste; meanwhile, the ecological brick is used for riverway restoration, the purpose of treating waste with waste is achieved, a new means of recycling the waste is put forward, and meanwhile, clay resources are saved.

Owner:WUXI MUNICIPAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com