Method for preparing anti-hardening granular ceramic iron-carbon micro-electrolysis filler from industrial wastes

An iron-carbon micro-electrolysis and anti-hardening technology, which is applied in chemical instruments and methods, water pollutants, aerobic process treatment, etc., can solve the problems of wasting resources and energy, achieve energy saving, extensive treatment and pretreatment, and reduce maintenance problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

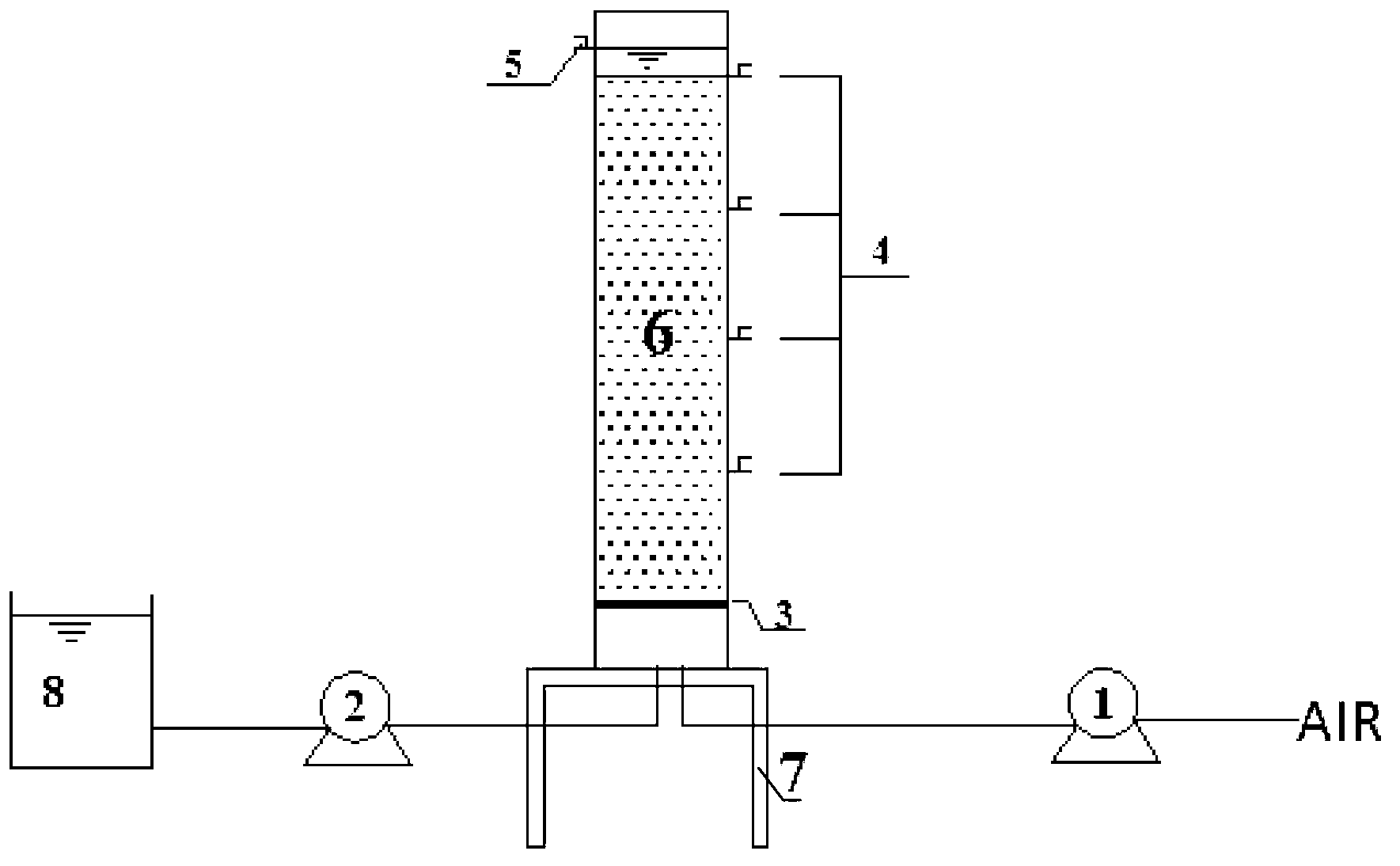

Image

Examples

Embodiment 1

[0032] According to the ratio of mass parts, pulverize 40 parts of iron powder, 20 parts of lignin, 30 parts of red mud, and 30 parts of clay, mix the dried raw materials evenly in a mixer, and place the raw materials in a disc-type ball forming machine , Spray the binder diluent (diluted 6 times after boiled with 0.5wt% polyvinyl alcohol and 1.5wt% sodium carboxymethylcellulose aqueous solution) during the rolling process, so that the raw material is rolled into a ball shape. After the raw meal balls are dried for 24 hours, they are fired in a tube furnace with a nitrogen protection device. Firing method: put the raw material balls into the furnace, pass nitrogen gas, wait for 15 minutes after the temperature rises to 300°C, then raise the temperature to 800°C and stay for 25 minutes, close the tube furnace, take out the filler after cooling .

[0033]The performance parameters of the obtained filler are as follows: particle size: 4mm; bulk density: 870kg / m 3 ;Water Absorpt...

Embodiment 2

[0035] According to the ratio of mass parts, pulverize 45 parts of iron powder, 25 parts of lignin, 25 parts of red mud, and 30 parts of clay, mix the dried raw materials evenly in a mixer, and place the raw materials in a disc-type ball forming machine , in the process of rolling, spray through binding agent diluent (same embodiment 1), be that raw material is rolled into ball shape. After the raw meal balls are dried for 24 hours, they are fired in a tube furnace with a nitrogen protection device. The specific method of firing is as follows. Put the raw material balls into the furnace, feed nitrogen, set the temperature to 350°C, wait for 20 minutes after the temperature rises to 300°C, then raise the temperature to 900°C and stay for 30 minutes, close the tube type Furnace, after cooling, take out the stuffing.

[0036] The performance parameters of the obtained filler are as follows: particle size: 5mm; bulk density: 870kg / m 3 ;Water Absorption: 12%.

[0037] Example of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com