A kind of method that reclaims precious metal platinum in tdi tar residue

A precious metal and residue technology, applied in the material field, can solve problems such as high operational risk, complex technology, and potential safety hazards, and achieve the effects of low environmental pollution risk, high digestion efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

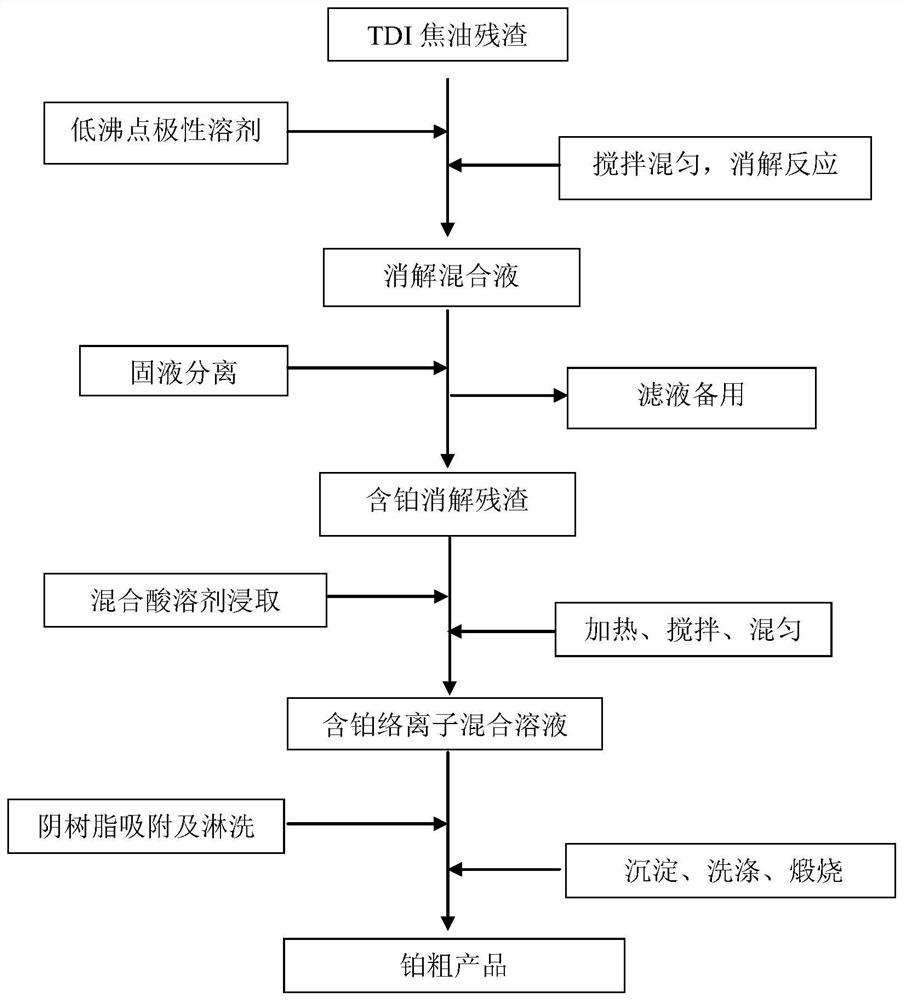

[0033] The TDI tar residue solid raw material is mechanically ground into a TDI tar residue powder with a particle size of 80-200 mesh; weigh an appropriate amount of the ground TDI tar residue powder and place it in a high-temperature and high-pressure reactor with a stirring device. : 5~10 (mass:volume ratio, kilogram:liter) add methanol solvent, mix and stir evenly, obtain the solid-liquid mixture 1 containing TDI tar residue. The high-temperature and high-pressure reactor containing the solid-liquid mixture 1 is heated from room temperature to 230-250°C, the pressure is maintained at 4-5MPa, and the holding time is 15-120min for digestion reaction to obtain the digested solid-liquid mixture 2. Turn off the switch of the high temperature and high pressure reactor, depressurize and cool to normal temperature and pressure.

[0034] The solid-liquid separation of the digested solid-liquid mixture 2 is carried out to obtain the digested filtrate and the digested solid residue c...

Embodiment approach 2

[0037] The TDI tar residue solid raw material is mechanically ground into a TDI tar residue powder with a particle size of 80-200 mesh; weigh an appropriate amount of the ground TDI tar residue powder and place it in a high-temperature and high-pressure reactor with a stirring device. : 5~10 (mass:volume ratio, kilogram:liter) add ethanol solvent, mix and stir evenly, obtain the solid-liquid mixture 1 that contains TDI tar residue. The high-temperature and high-pressure reactor containing the solid-liquid mixture 1 is heated from room temperature to 240-260°C, the pressure is maintained at 4-6MPa, and the digestion time is 15-120min to carry out the digestion reaction to obtain the digested solid-liquid mixture 2. Turn off the switch of the high temperature and high pressure reactor, depressurize and cool to normal temperature and pressure.

[0038] The solid-liquid separation of the digested solid-liquid mixture 2 is carried out to obtain the digested filtrate and the digeste...

Embodiment approach 3

[0041] The TDI tar residue solid raw material is mechanically ground into a TDI tar residue powder with a particle size of 80-200 mesh; weigh an appropriate amount of the ground TDI tar residue powder and place it in a high-temperature and high-pressure reactor with a stirring device. :1~20 (mass:volume ratio, kilogram:liter) add isopropanol solvent, mix and stir evenly, obtain the solid-liquid mixture 1 containing TDI tar residue. The high-temperature and high-pressure reactor containing the solid-liquid mixture 1 is heated from room temperature to 240-260°C, the pressure is maintained at 2-12MPa, and the holding time is 15-120min to carry out the digestion reaction to obtain the digested solid-liquid mixture 2. Turn off the switch of the high temperature and high pressure reactor, depressurize and cool to normal temperature and pressure.

[0042] The solid-liquid separation of the digested solid-liquid mixture 2 is carried out to obtain the digested filtrate and the digested...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com