A kind of resource treatment method of manganese slag solid waste and its application

A treatment method and resource recovery technology, applied in the field of resource recovery of manganese slag solid waste, can solve the problems of large floor area, debris flow disaster, waste of manganese resources, etc., achieve easy control of process flow, simple processing technology, and avoid secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

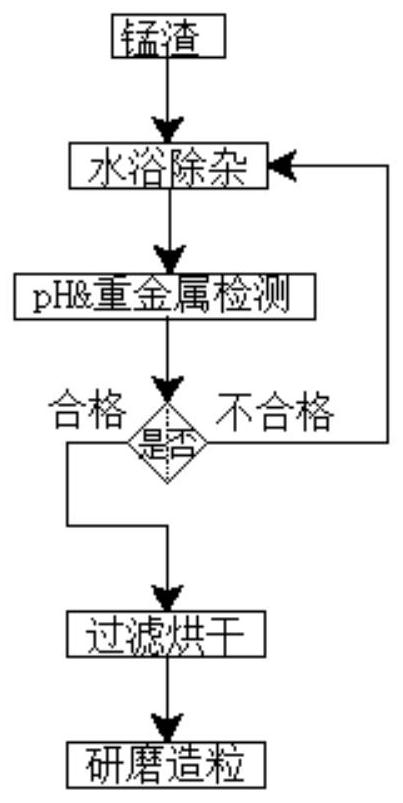

[0038] Embodiment 1 Manganese slag solid waste resource treatment

[0039] The first step: add deionized water, and prepare the manganese slag into a 10wt% concentration slurry;

[0040] Step 2: Use a 70°C water bath to stir, the stirring speed is about 800r / min, control the slurry to form a vortex, and the stirring time is 30min;

[0041] The third step: After filtering, the filter residue is immersed in water for 12 hours with a horizontal shaker;

[0042] Step 4: Use a vacuum circulating pump to filter the impurity-removed slurry, use a pH meter and an atomic absorption instrument to detect the pH value and the content of heavy metal ions such as arsenic, chromium, and lead in the water body, and strictly control the pH ≥ 6.8, and the arsenic , chromium, lead and other heavy metal ions content ≤ 0.1mg / L; if it still exceeds the standard, perform water bath purification again, if the test is qualified, enter the next step;

[0043] Step 5: Use a constant temperature dryer ...

Embodiment 2

[0046] Embodiment 2 Manganese slag solid waste resource treatment

[0047] The first step: add deionized water, and prepare manganese slag into 20wt% concentration slurry;

[0048] Step 2: Use 80°C water bath to stir, the stirring speed is about 800r / min, control the slurry to form a vortex, and the stirring time is 30min;

[0049] The third step: After filtering, the filter residue is immersed in water for 10 hours with a horizontal shaker;

[0050] Step 4: Use a vacuum circulating pump to filter the impurity-removed slurry, use a pH meter and an atomic absorption instrument to detect the pH value and the content of heavy metal ions such as arsenic, chromium, and lead in the water body, and strictly control the pH ≥ 6.8, and the arsenic , chromium, lead and other heavy metal ions content ≤ 0.1mg / L; if it still exceeds the standard, perform water bath purification again, if the test is qualified, enter the next step;

[0051] Step 5: Use a constant temperature dryer to dry f...

Embodiment 3

[0054] Embodiment 3 Manganese slag solid waste resource treatment

[0055] The first step: add deionized water, and prepare the manganese slag into a 10wt% concentration slurry;

[0056] Step 2: Use 80°C water bath to stir, the stirring speed is about 800r / min, control the slurry to form a vortex, and the stirring time is 30min;

[0057] The third step: After filtering, the filter residue is immersed in water for 10 hours with a horizontal shaker;

[0058] Step 4: Use a vacuum circulating pump to filter the impurity-removed slurry, use a pH meter and an atomic absorption instrument to detect the pH value and the content of heavy metal ions such as arsenic, chromium, and lead in the water body, and strictly control the pH ≥ 6.8, and the arsenic , chromium, lead and other heavy metal ions content ≤ 0.1mg / L; if it still exceeds the standard, perform water bath purification again, if the test is qualified, enter the next step;

[0059] Step 5: Use a constant temperature dryer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com