Novel environment-friendly durable impermeable and impermeable structure based on solid waste, and impermeable barrier material

A barrier material and a new type of technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problem of lack of special specifications for the structure of the anti-seepage layer, and achieve the effect of reducing pollution risks and blocking leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

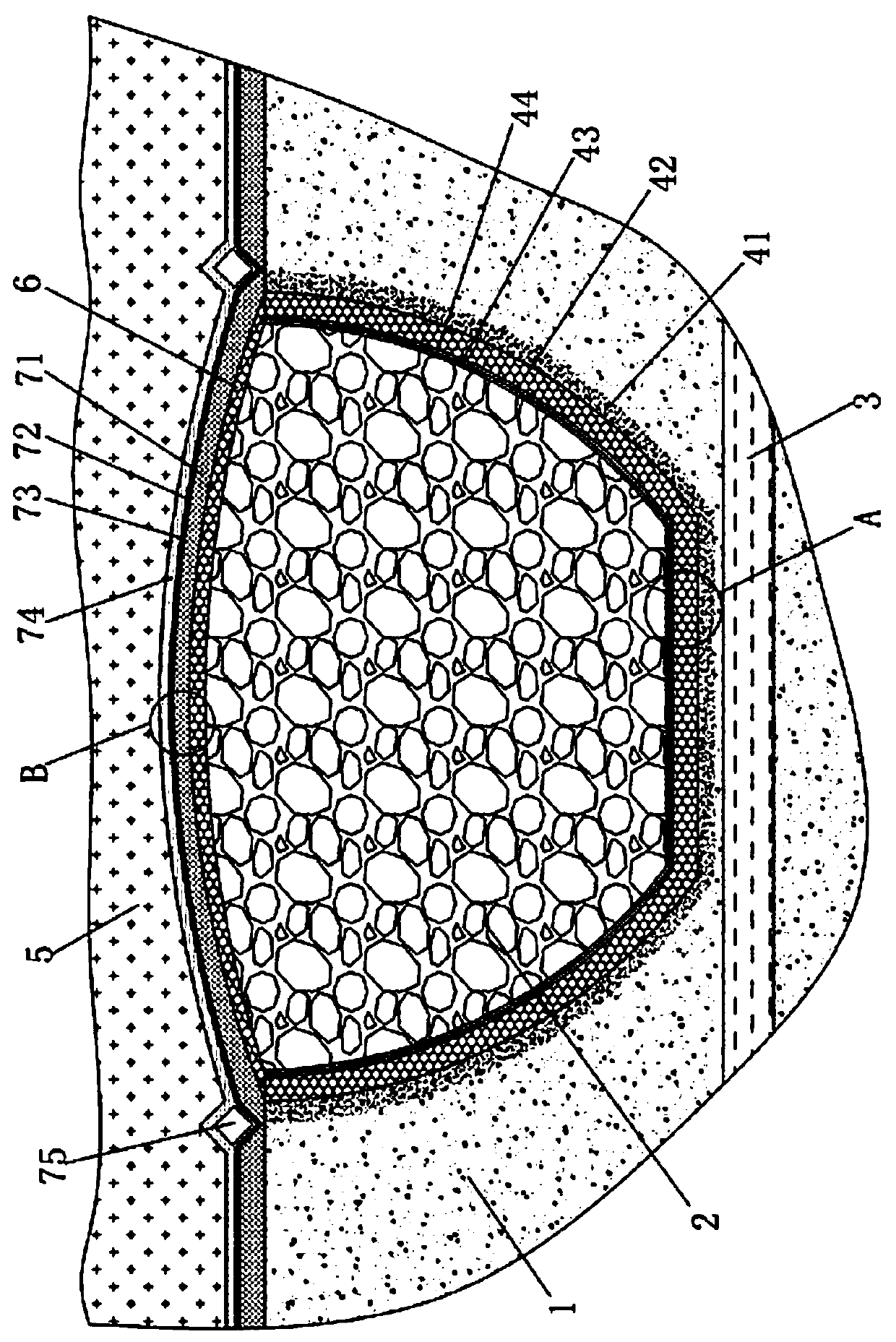

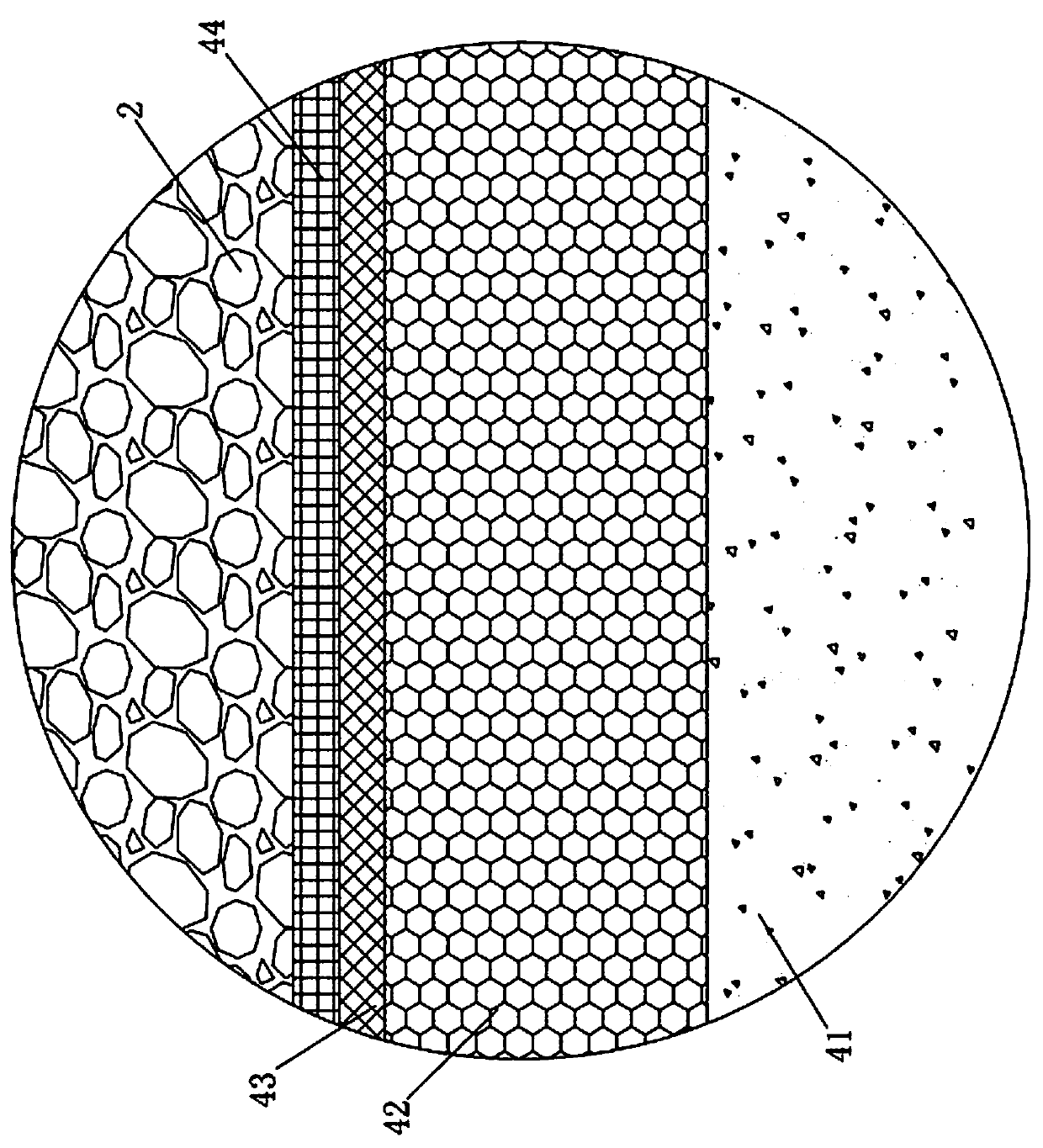

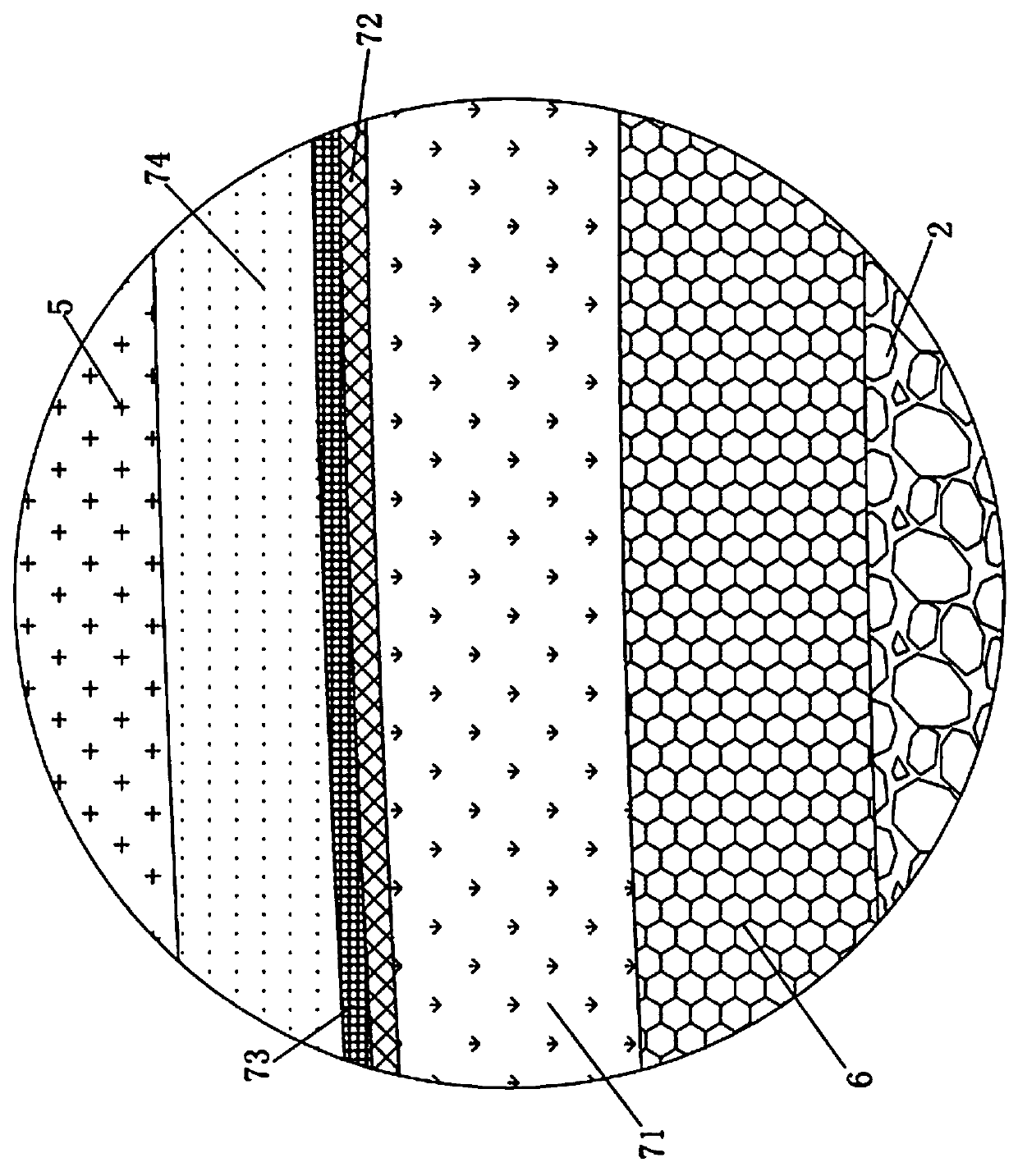

[0034] Embodiment one: see Figure 1-3 , a new environment-friendly and durable anti-seepage and anti-seepage structure based on solid waste, including a base layer, an anti-seepage layer and a closure cover layer. The anti-seepage barrier substrate, HDPE film and geotextile made by pouring the seepage barrier material, pour the anti-seepage barrier material on the base layer according to the potential and extend to the edge of the pit mouth to form the anti-seepage barrier substrate, in the anti-seepage barrier lining Lay HDPE film and geotextile on the bottom in turn, fill the mine pit with industrial solid waste and compact it until the pit mouth and form an arched surface, and pour impermeable barrier materials on the arched surface according to the potential to form a closure cover layer. The field cover layer is connected to the upper edge of the anti-seepage barrier substrate, and the matrix soil layer for vegetation greening is laid on the field closure cover layer.

...

Embodiment 2

[0051] Embodiment two, see Figure 4 , the anti-seepage and anti-seepage structure is slightly different from Example 1. The difference is that the anti-seepage structure omits the groundwater collection flow channel. This structure is used to landfill Class I industrial solid waste. Proceed as follows:

[0052] (1) Select a suitable mine pit as a Class I industrial solid waste landfill, use a mechanical rammer to compact the bottom and edges of the pit after manually leveling the pit, and use a compaction coefficient of 0.93 as the base layer;

[0053] (2) The formula of the impermeable barrier material used: by weight percentage, 80% of fly ash,

[0054] 8% desulfurized gypsum and 12% activator quicklime were weighed separately;

[0055] Mix the above materials evenly to obtain gelling material powder; respectively pour the gelling material powder and water (water-binder ratio 0.25) into a mixer and mix to obtain an impermeable barrier material;

[0056] (3) Pour the conf...

Embodiment 3

[0060] Embodiment 3 is slightly different from Embodiment 1, and the difference lies in: the preparation method of the impermeable barrier material used:

[0061] (1) In terms of weight percentage, measure according to the ratio of 70% fly ash, 15% blast furnace slag, 8% desulfurized gypsum, and 7% cement clinker; mix all raw materials evenly to obtain cementitious material powder;

[0062] (2) Measure water according to the weight ratio of water-binder ratio of 0.3, pour the cementitious material powder and water into the mixer for mixing, pour the mixed anti-seepage material on the bottom and edge of the base layer, and pour in the order of "Z" (Construction site temperature > 5°C), pouring thickness is 40cm, vibrate after pouring;

[0063] (3) Curing starts 16 hours after pouring, using watering for natural curing, covering the surface of the material with tarpaulin and plastic cloth, and curing lasts for 30 days to obtain an impermeable barrier material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com