Iron and zinc-containing dust sludge solid waste treatment method based on whole-process iron and steel enterprise

A disposal method and a whole-process technology, applied in the direction of improving process efficiency, etc., can solve problems such as the degree of corrosion and ash accumulation in waste heat boilers, excessive heavy metals in drainage, and heavy metal enrichment, etc., to achieve resource utilization, reduce heat loss, and improve water washing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

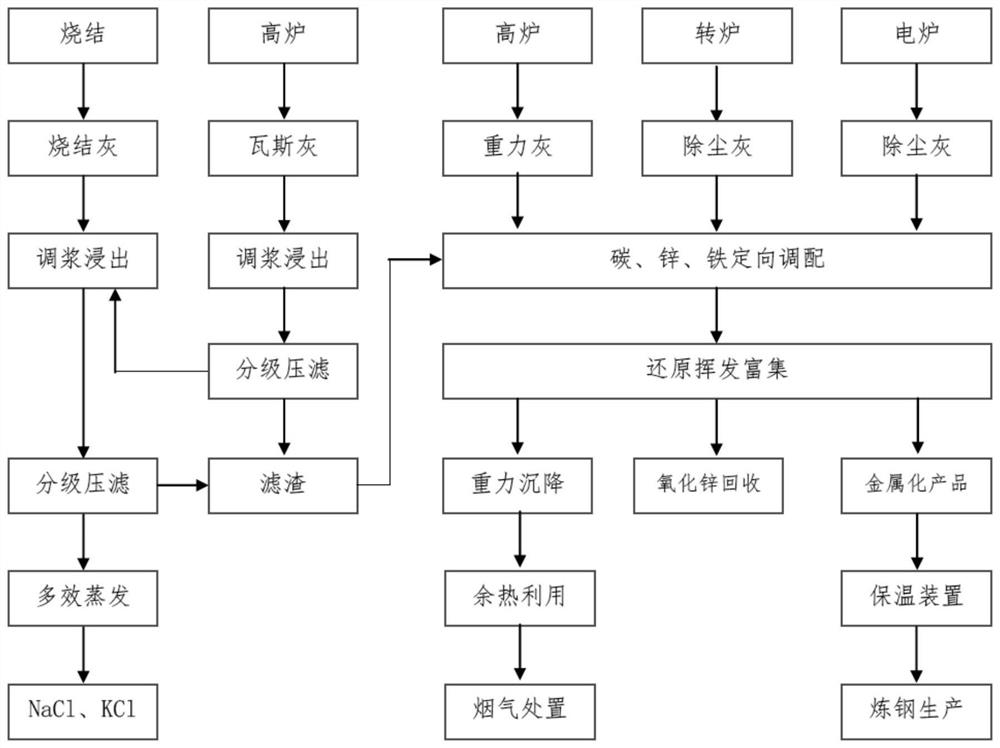

[0024] like figure 1 As shown, a method for solid waste disposal of iron-containing zinc-containing dust and sludge based on the whole process of iron and steel enterprises includes the following steps:

[0025] (1) washing the sintered ash produced by sintering and the gas ash of the blast furnace with water to reclaim the KCl and NaCl therein, and press-filtering the washed residue to obtain the filter residue;

[0026] (2) fully mixing the filter residue obtained in step (1) with the gravity ash of the blast furnace, the dedusting ash of the converter and the dedusting ash of the electric furnace, after adjusting the ratio of carbon, zinc and iron in the mixture, the mixture is subjected to reduction reaction;

[0027] (3) After the reduction reaction, the generated flue gas is sent to the waste heat boiler after being settled by gravity, and the steam generated by the waste heat boiler is used for heating; the flue gas after passing through the waste heat boiler is process...

Embodiment 2

[0033] A solid waste treatment method based on the whole process of iron and zinc-containing dust and sludge in iron and steel enterprises. After the gas ash produced in the blast furnace process of the iron and steel enterprise is fully stirred and leached, the leachate is sent to the sintered ash washing section produced in the sintering process, and the stirred slurry is passed through The solution rich in KCl and NaCl produced after graded filter press is sent to the multi-effect evaporation system to produce KCl and NaCl, and the filter residue produced after press filter is fully mixed with the gravity ash produced by the blast furnace, the dedusted ash produced by the converter, and the dedusted ash produced by the electric furnace , adjusting the water content of the mixture to 15%-25%, the carbon content to 15%-30%, the zinc content to 3%-15%, the iron content to 25%-50%, and the chlorine content to below 2%. After the iron-containing and zinc-containing raw materials ...

Embodiment 3

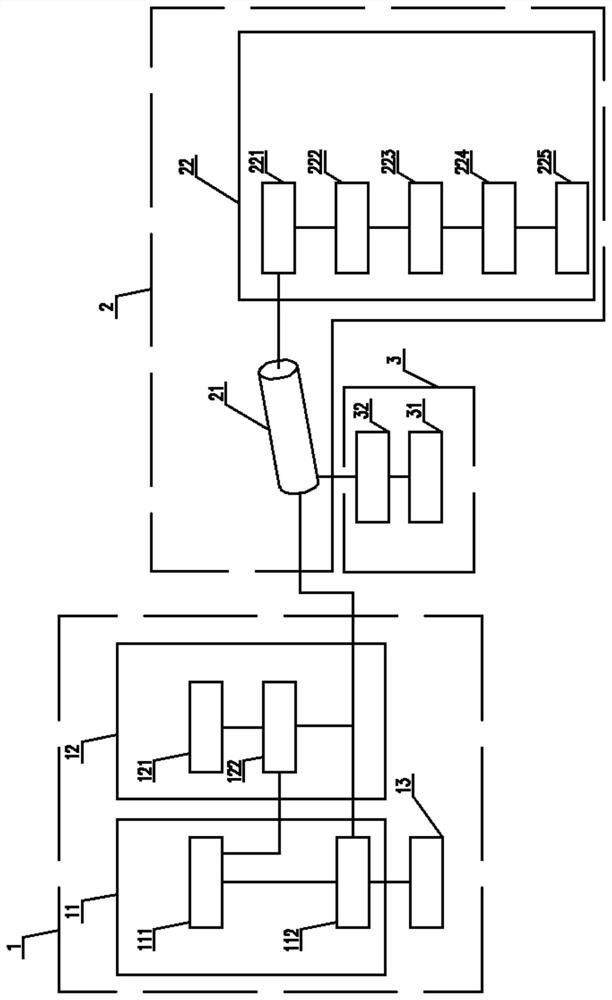

[0035] like figure 2 As shown, a iron and zinc-containing dust and sludge solid waste disposal system based on the whole process of iron and steel enterprises includes a water washing system 1, a zinc oxide recovery system 2 and a metallized product heat delivery system 3 connected in sequence, and the zinc oxide recovery system 2 It includes a reduction volatilization unit 21 and a flue gas treatment unit 22 connected in sequence.

[0036] The water washing system 1 includes a blast furnace gas ash water washing system 11 , a sintered ash water washing system 12 and an evaporation system 13 connected in sequence.

[0037] The blast furnace gas ash water washing system 11 includes a first pulping leaching unit 111 and a first graded filter press unit 112 connected in sequence, and the sintered ash water washing system 12 includes a second pulping leaching unit 121 and a second graded filter unit connected in sequence. Press filter unit 122, the effluent of the first graded f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com