Cavity dynamic sealing structure

A dynamic sealing structure and cavity technology, applied in the direction of machines/engines, jet propulsion devices, layered products, etc., can solve the problems of inability to meet the needs of use, poor radial followability, etc., to improve the sealing performance and overall connectivity, The effect of uniform force and reduction of seal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

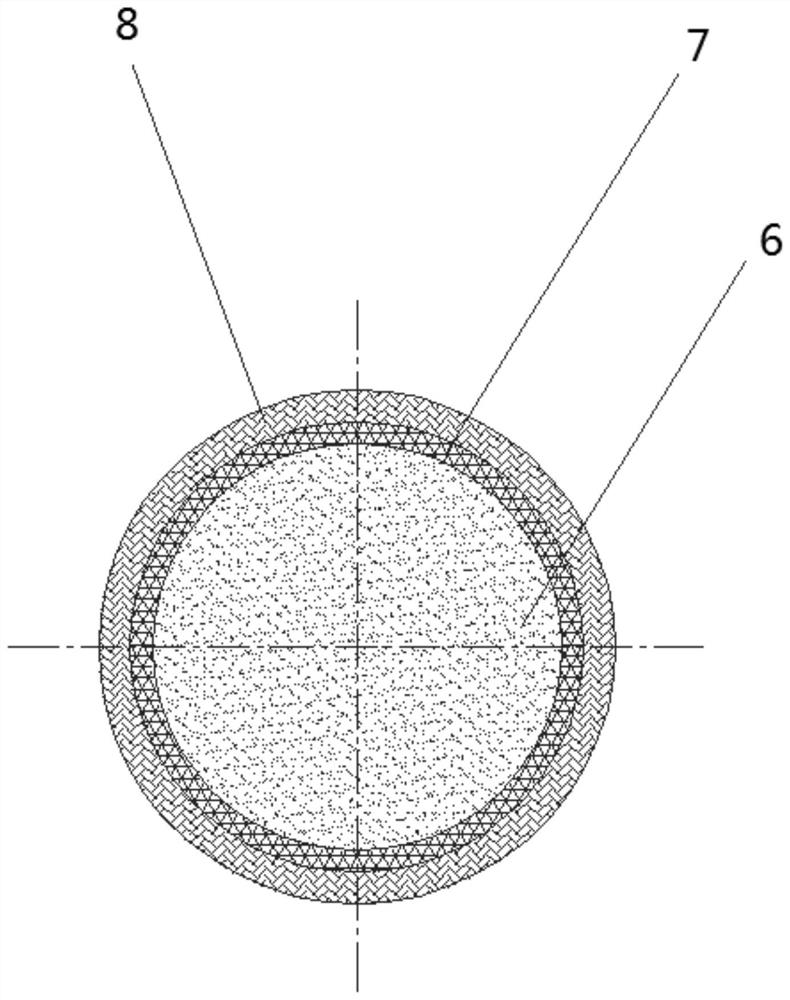

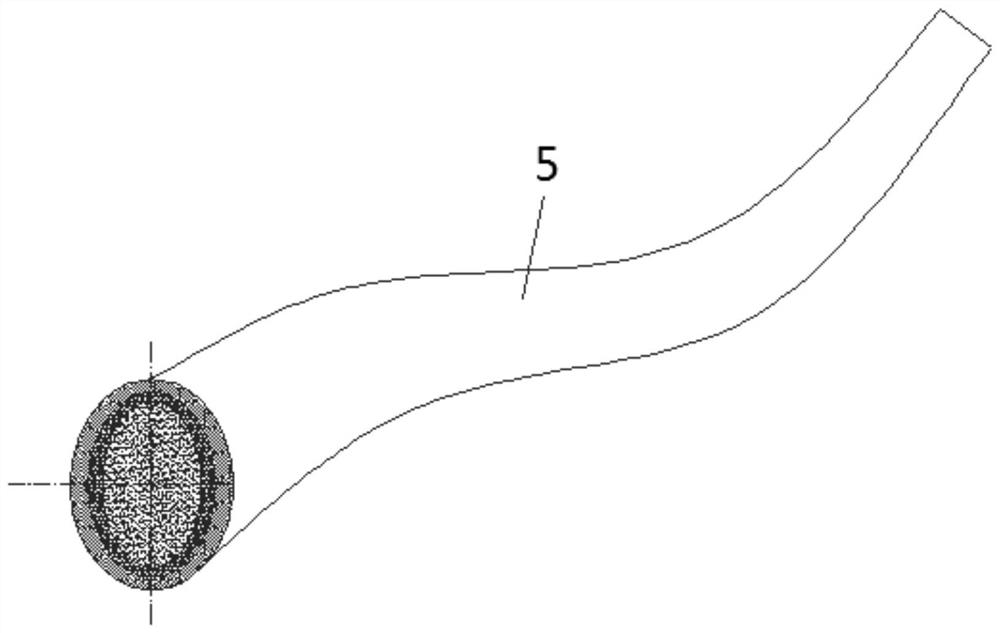

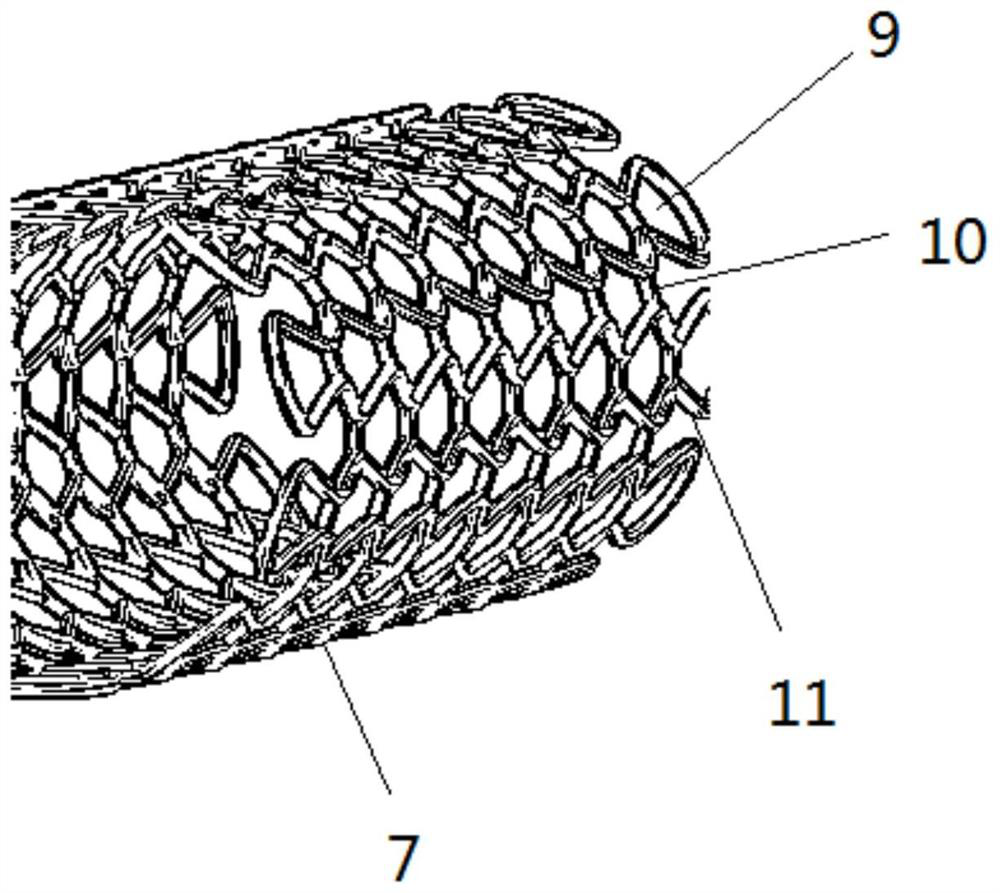

[0038] Such as figure 1 , 2 , 3 and 7 shows the first specific implementation of the cavity dynamic sealing structure, the dynamic sealing structure 5 is set in the sealing cavity 4 formed by the spherical shell 1, the fixed shell 2 and the baffle plate 3, the spherical shell 1 During the working process, it swings back and forth (swing angle ≤ 20° / s), and the medium in the inner cavity of the spherical shell 1 is high temperature and high pressure (temperature ≤ 1000K, pressure ≤ 1MPa) gas; the fixed shell 2 and the baffle 3 are fixedly connected, and they are still when working ; The spherical shell 1 cooperates with the fixed shell 2 and the baffle plate 3 in a radial clearance to form a sealed cavity 4, and the dynamic sealing structure 5 is arranged in the sealed cavity 4, relatively fixed with the fixed shell 2 and the baffle plate 3, and The spherical shell 1, the fixed shell 2 and the baffle plate 3 are in elastic contact state. When the dynamic sealing structure 5 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com