Lining type anti-puncturing tire and method thereof

A technology for tires and inner linings, which is applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, and can solve problems such as complex structures and poor anti-puncture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

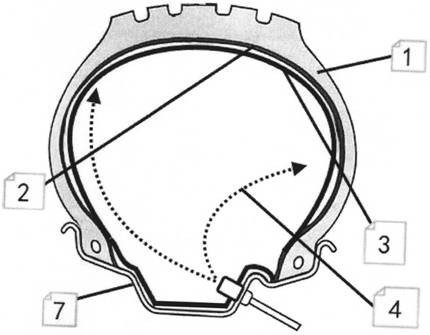

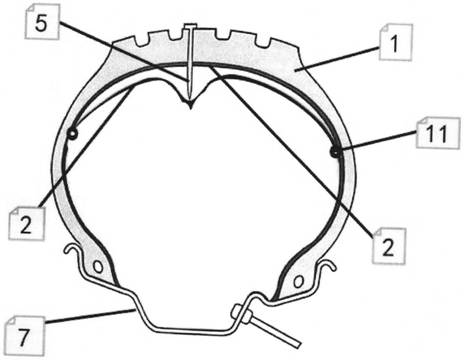

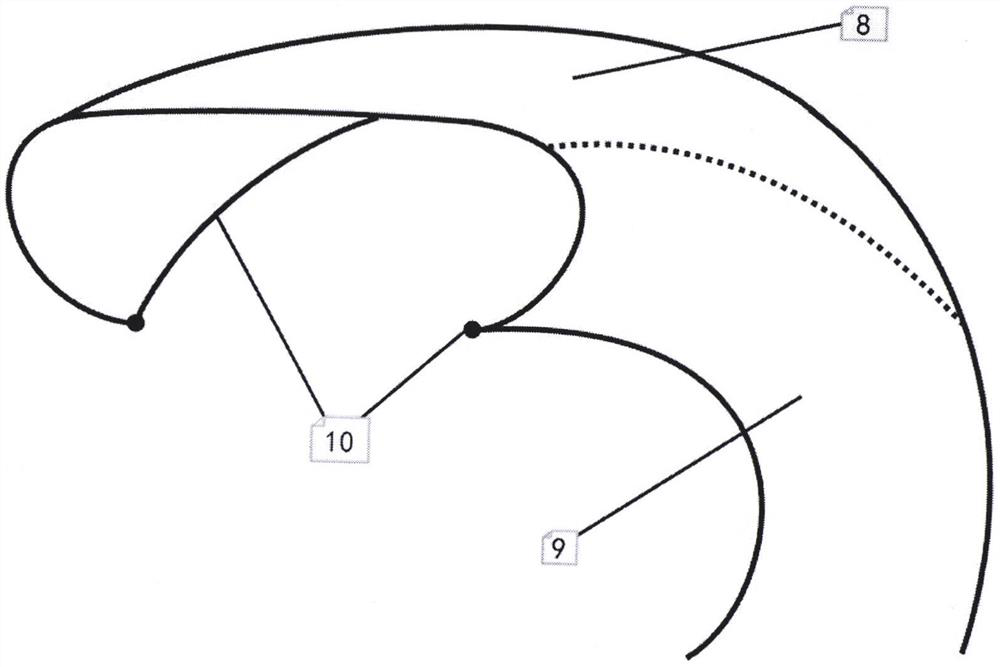

[0013] In the figure, the surface of the airtight layer 2 of the vacuum tire 1 is treated to a smooth surface, and at least one layer or more of the gas isolation layer 3 is arranged close to the inner layer 2. The size, area and shape of the isolation layer 3 basically match the inner liner of the tire when the tire is inflated under high pressure. The gas isolation layer is close to the airtight layer 2 but not mechanically combined with it. It can be easily separated from the inner liner 3 under the action of external force. When the vacuum tire 1 is inflated, the high-pressure gas 4 will press the gas isolation layer 3 tightly on the tire inner liner 2 and stick to the tire inner liner 2. When sharp When the object 5 pierces the inside of the tire from the tire outer side 6, the sharp object 5 first pierces the tire inner liner 2, and then partially lifts the gas insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com