Patents

Literature

283results about "Wood-turning machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

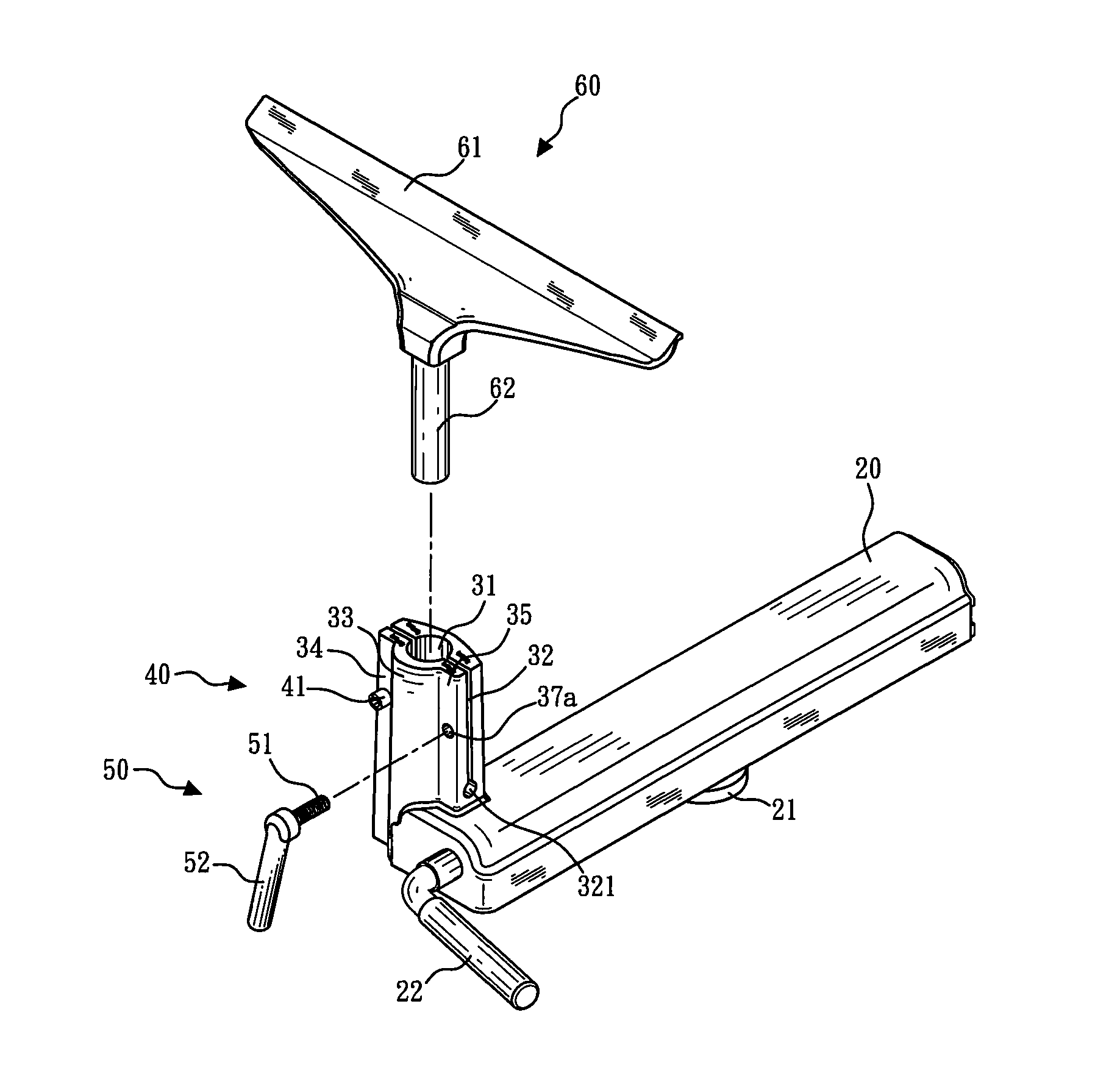

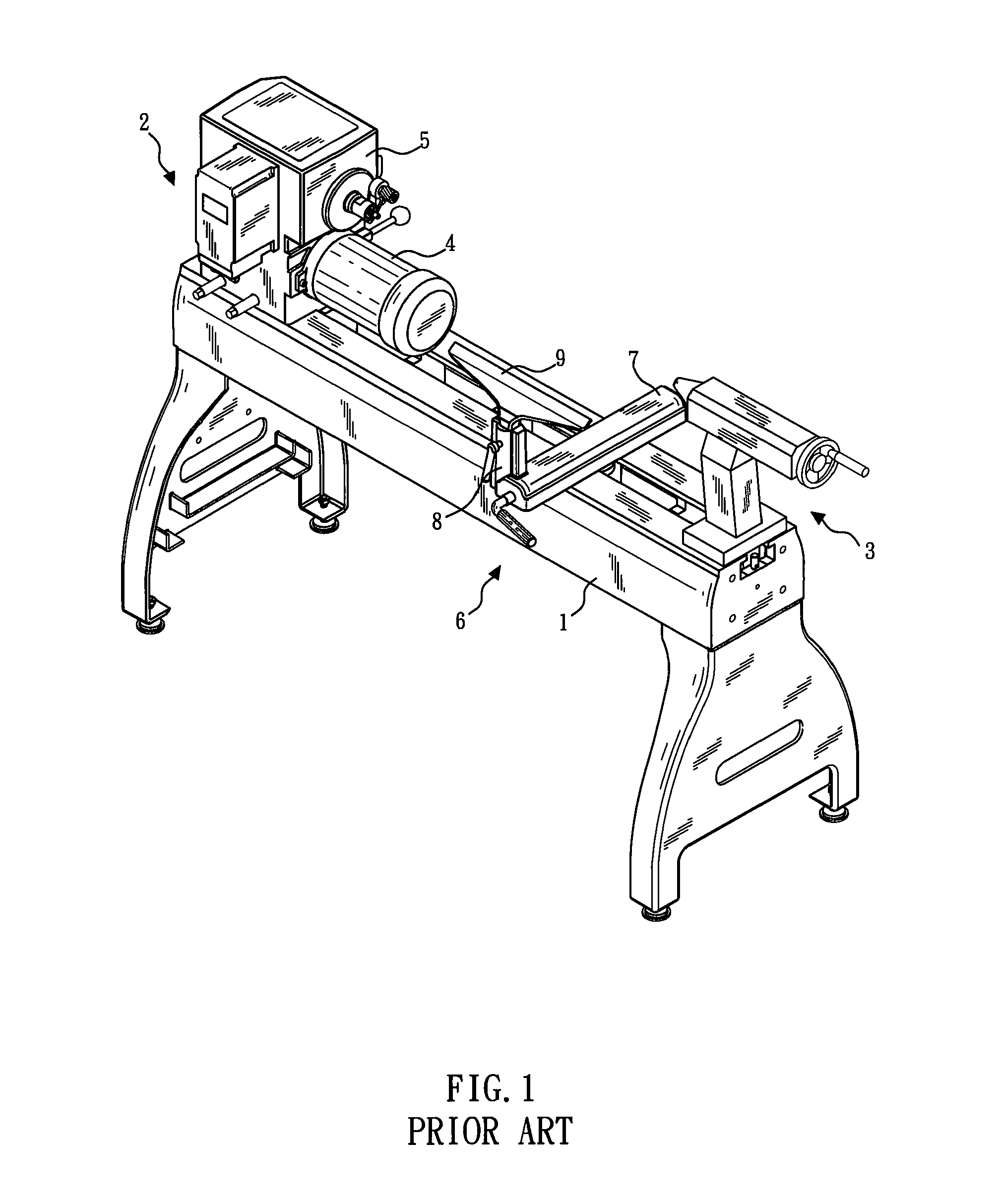

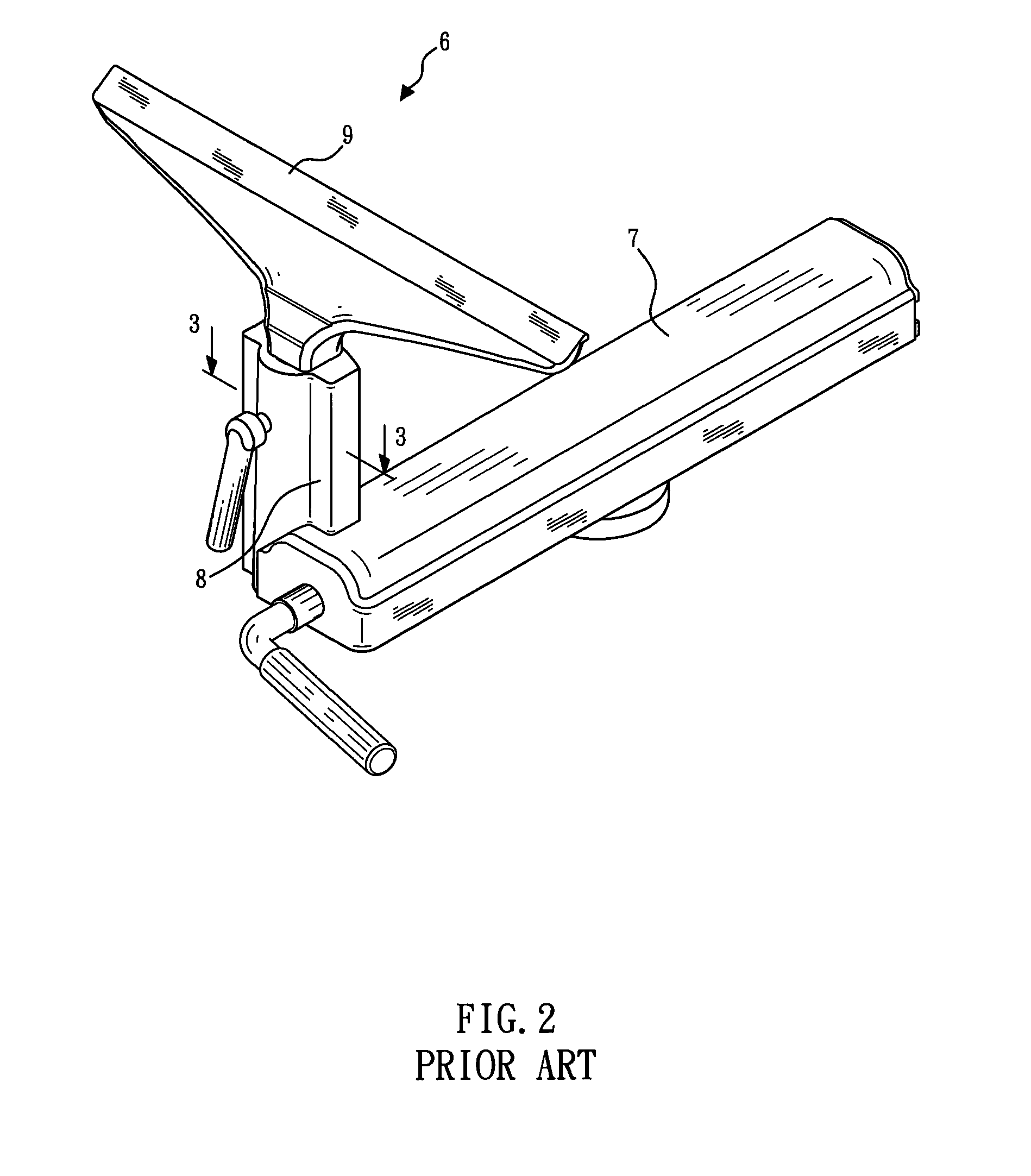

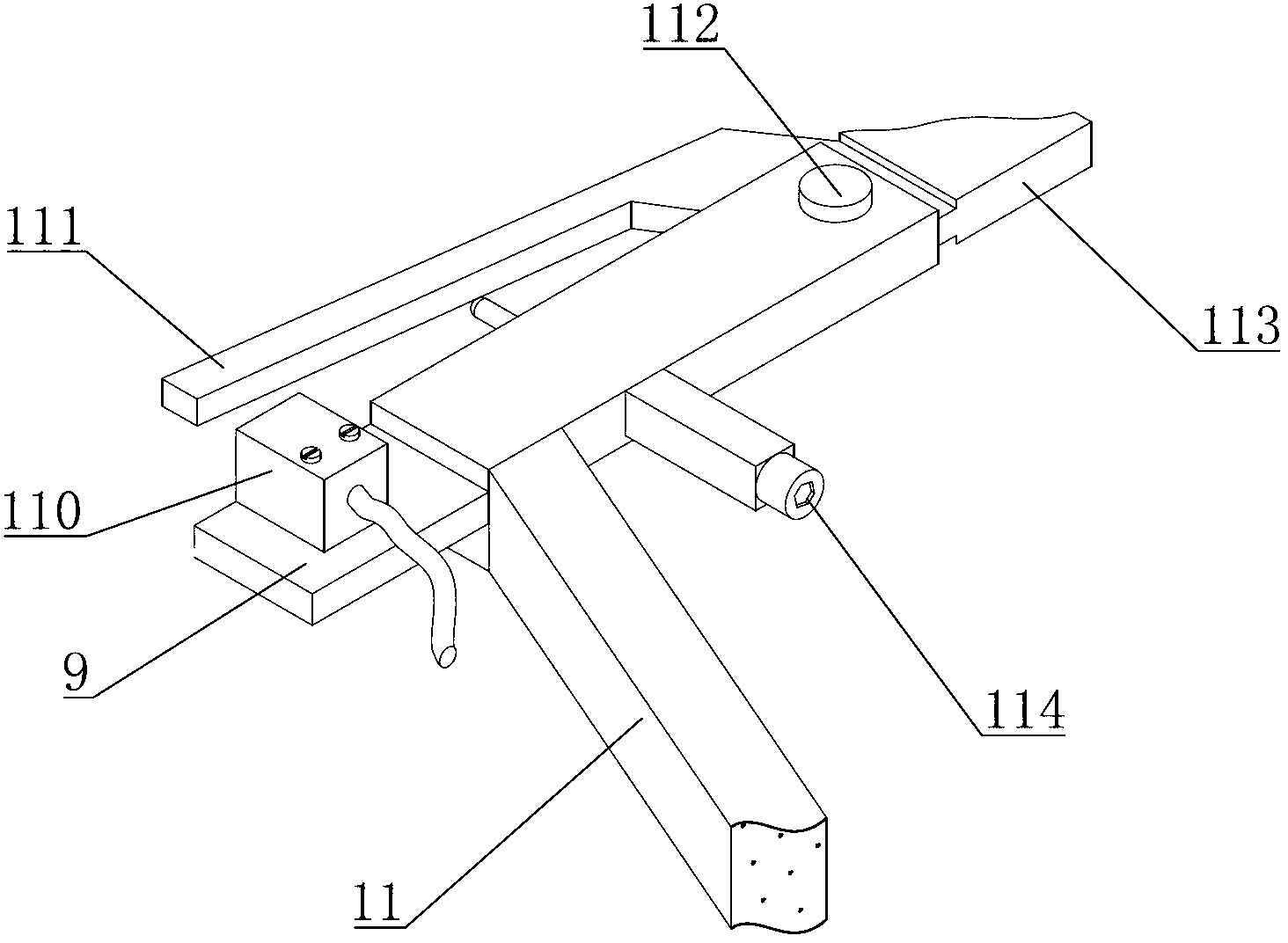

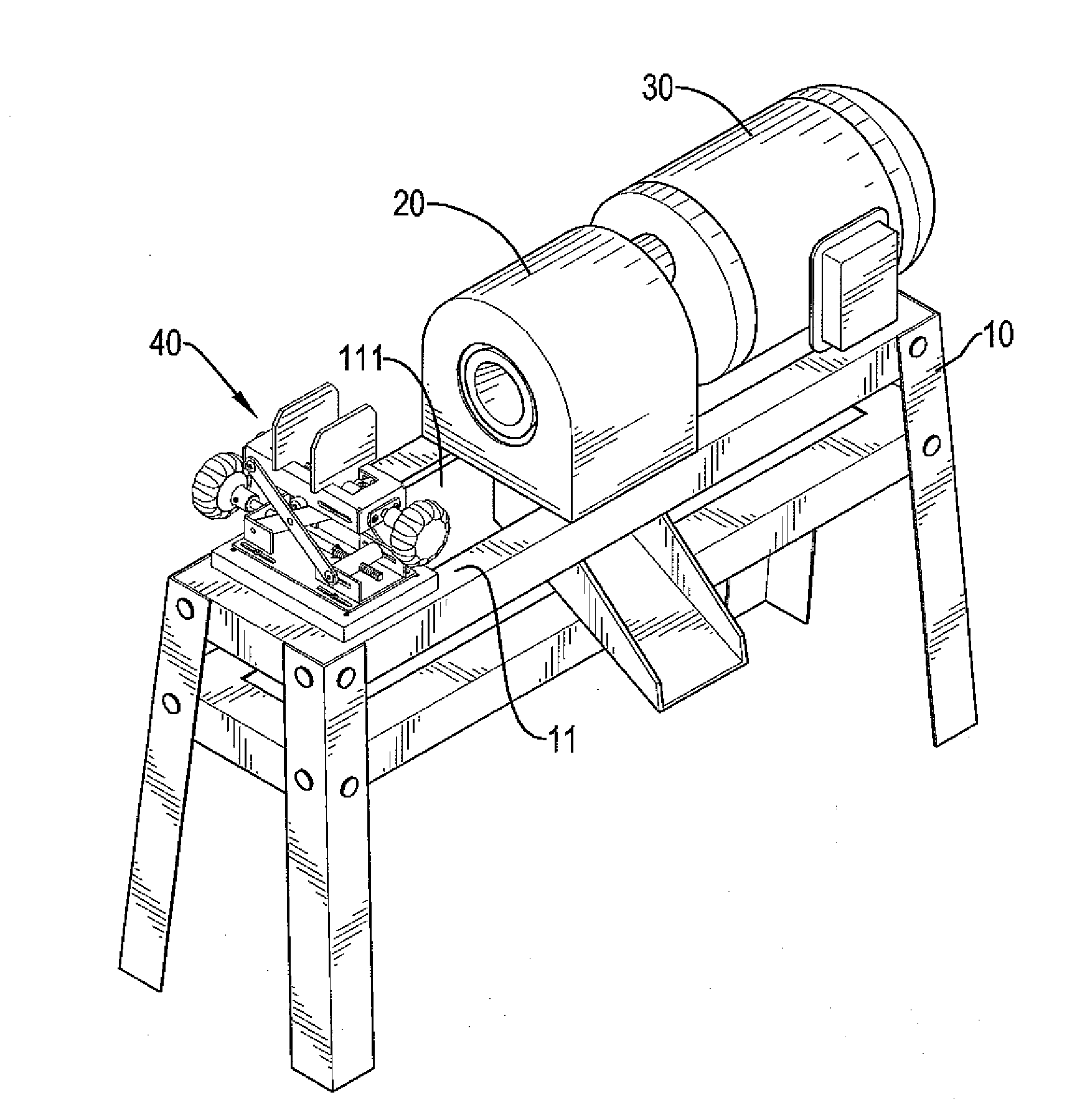

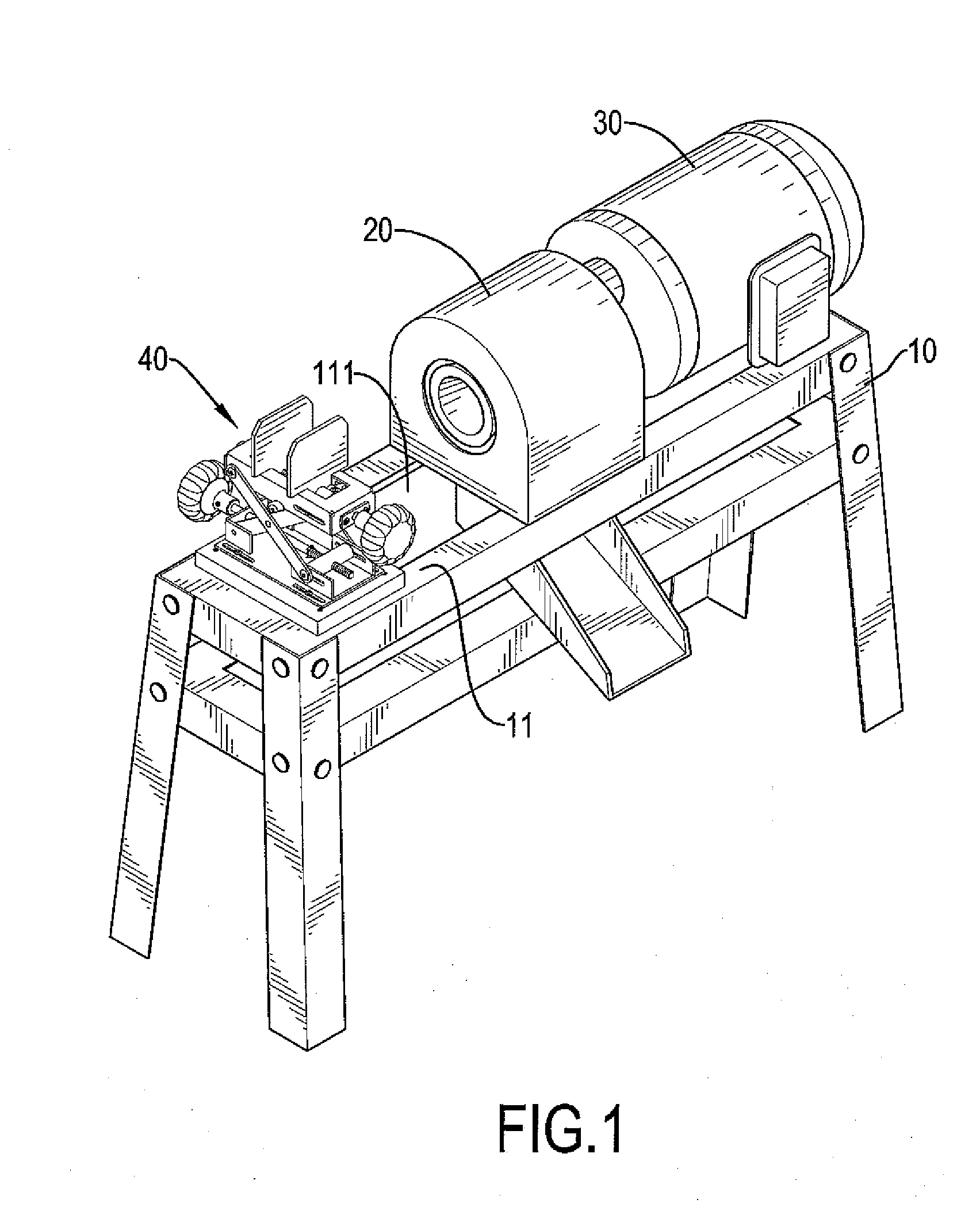

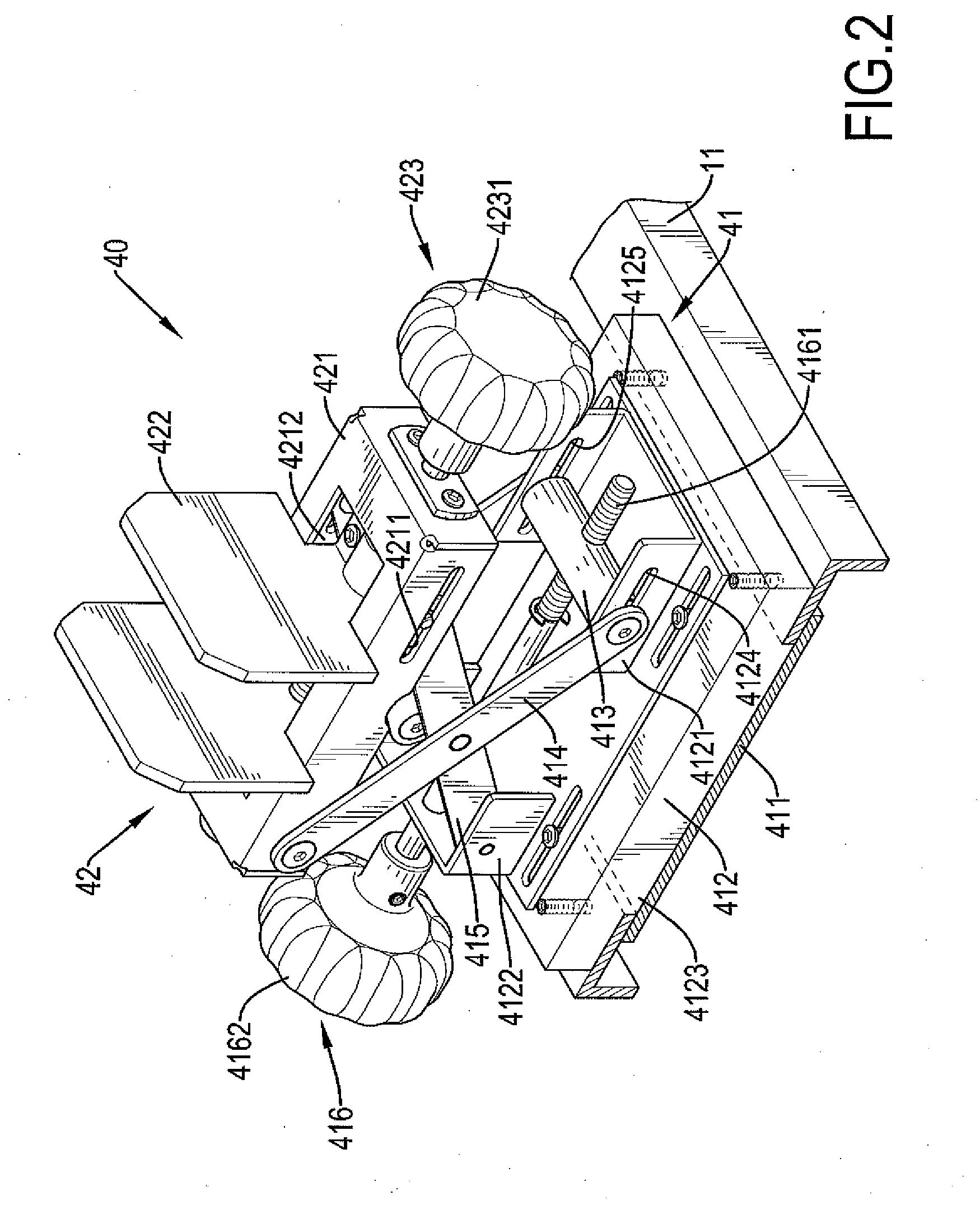

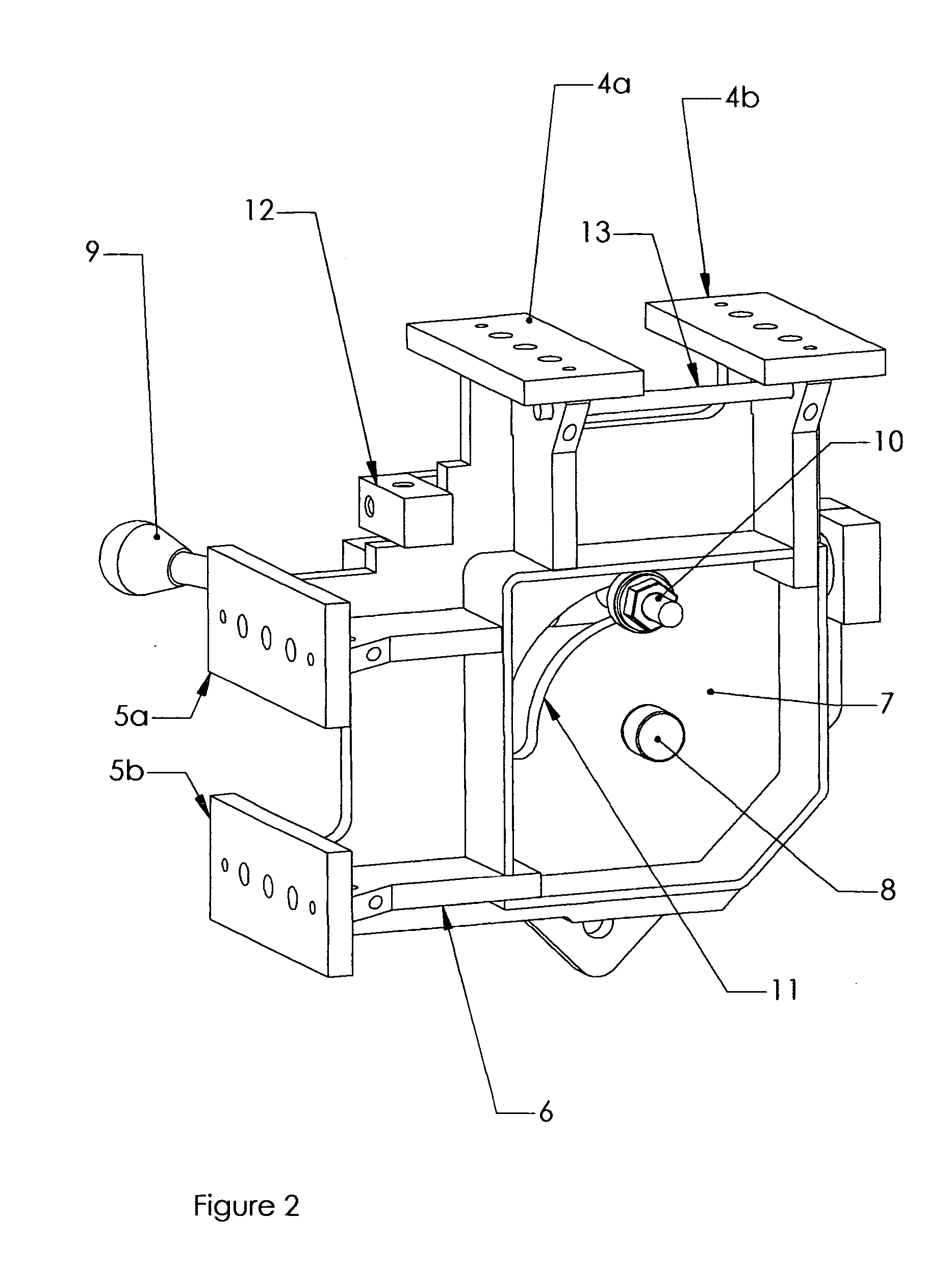

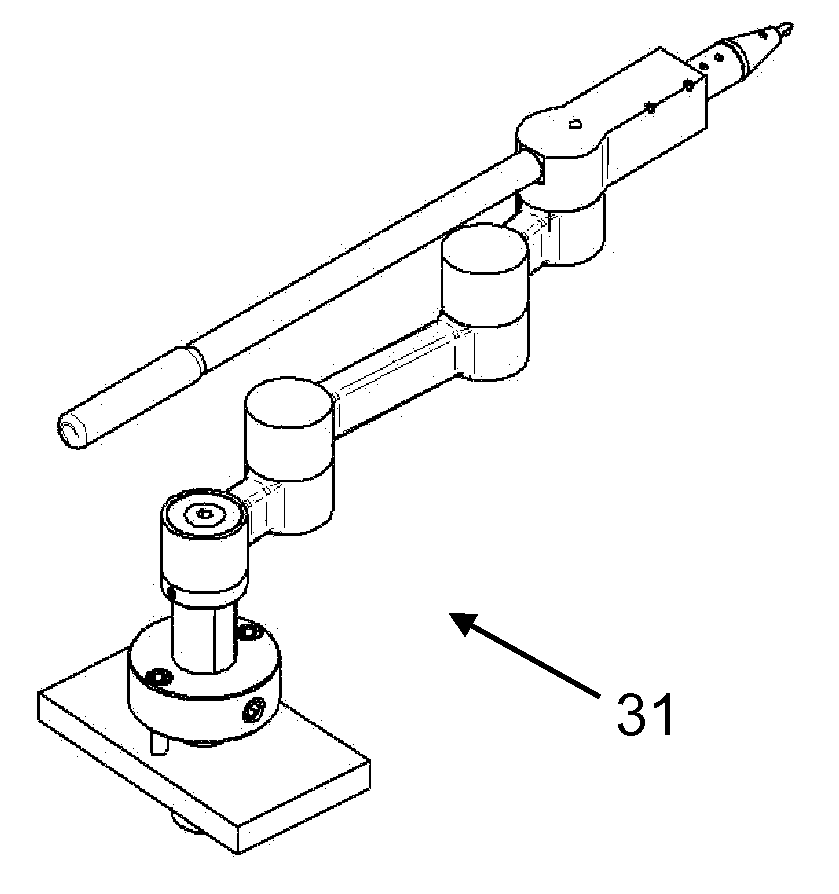

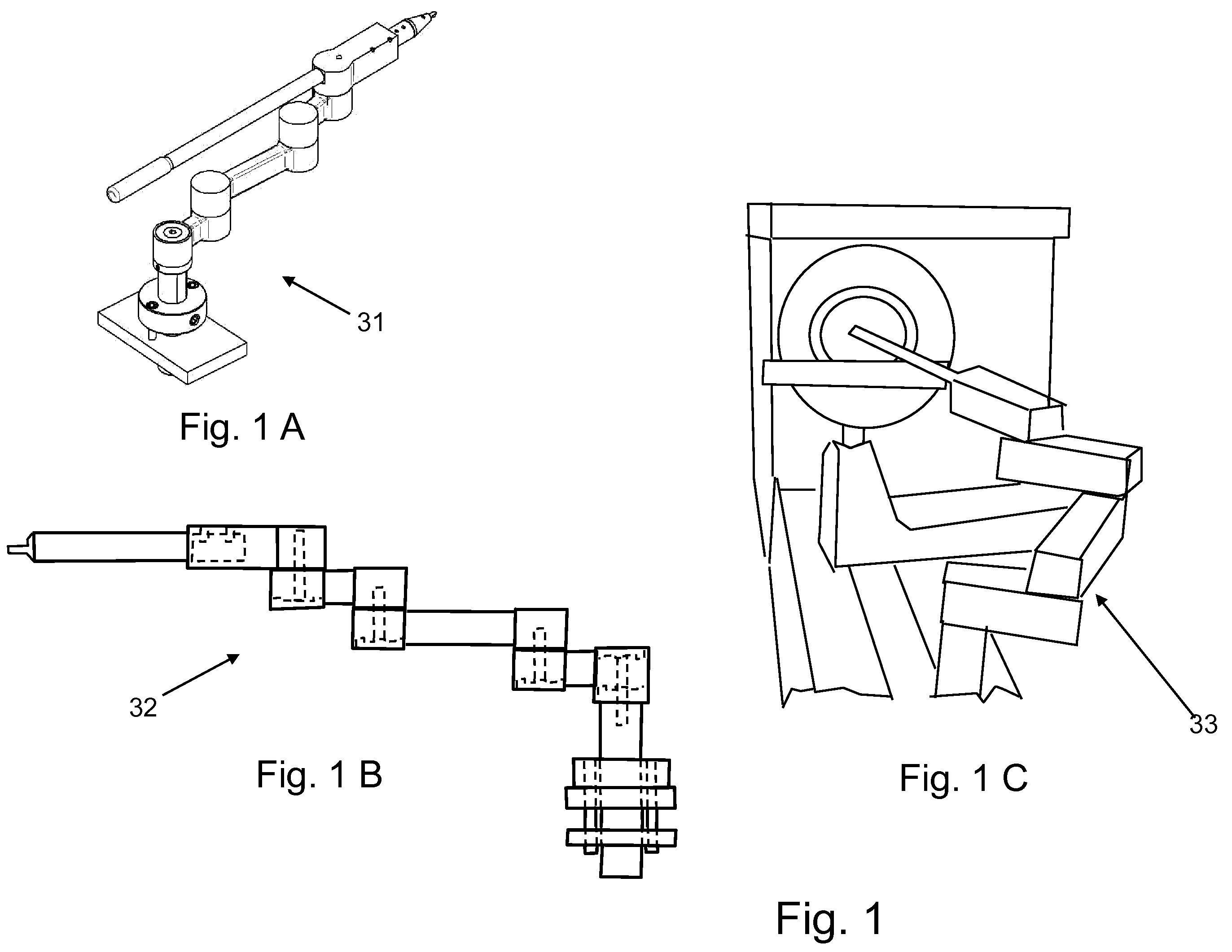

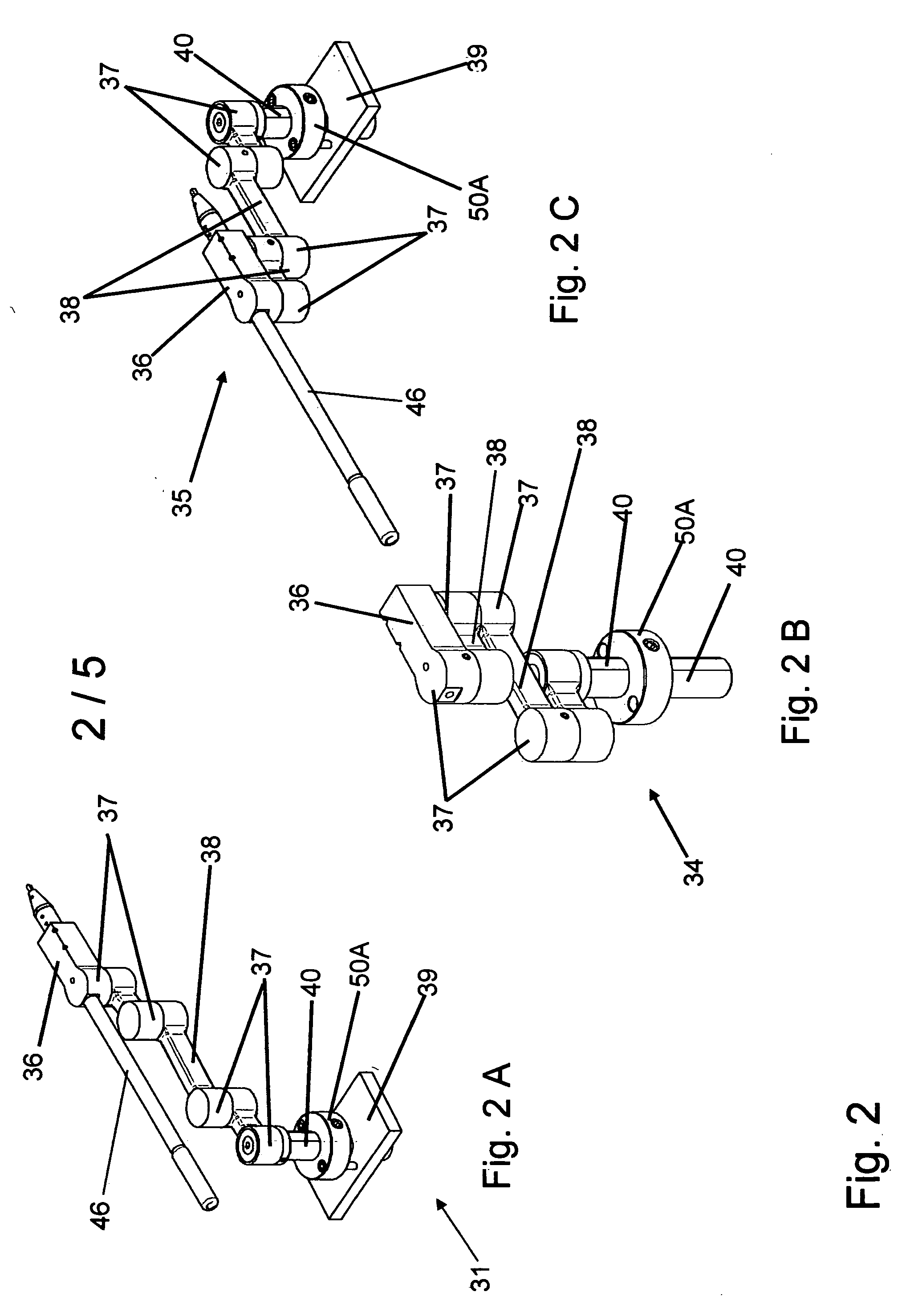

Toolrest mechanism for wood turning lathe

InactiveUS20130074988A1Unstable engagementImprove reliabilityWood-turning machinesEngineeringMechanical engineering

A toolrest mechanism for a wood turning lathe includes a banjo, a carriage, a first threaded element, a second threaded element and a toolrest. The carriage is divided into two clamping elements facing each other by a slot formed therebetween, and the clamping elements can be drawn together by operating the threaded elements, so as to adjust the carriage from an initial, release position toward a clamping position. The toolrest has a toolrest portion and a shaft. The shaft is allowed to move axially within the slot while the carriage is at the release position, and the shaft is disallowed to move axially within the slot while the carriage is at the clamping position.

Owner:CHOU CALVIN

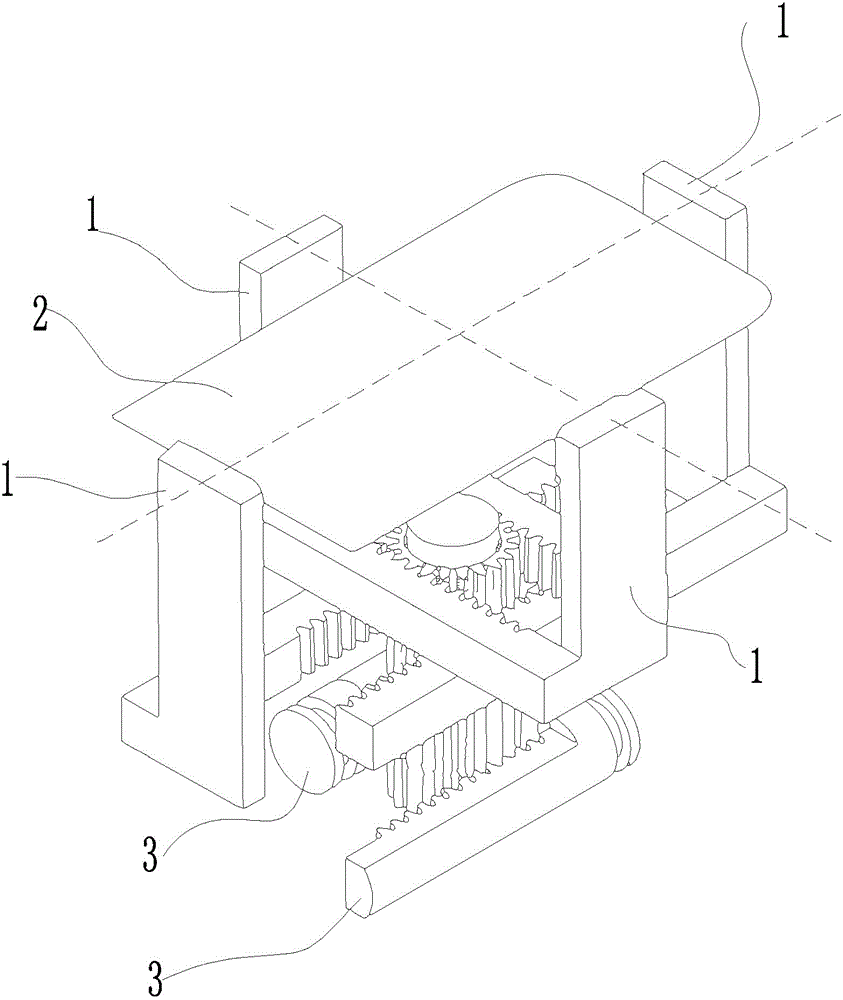

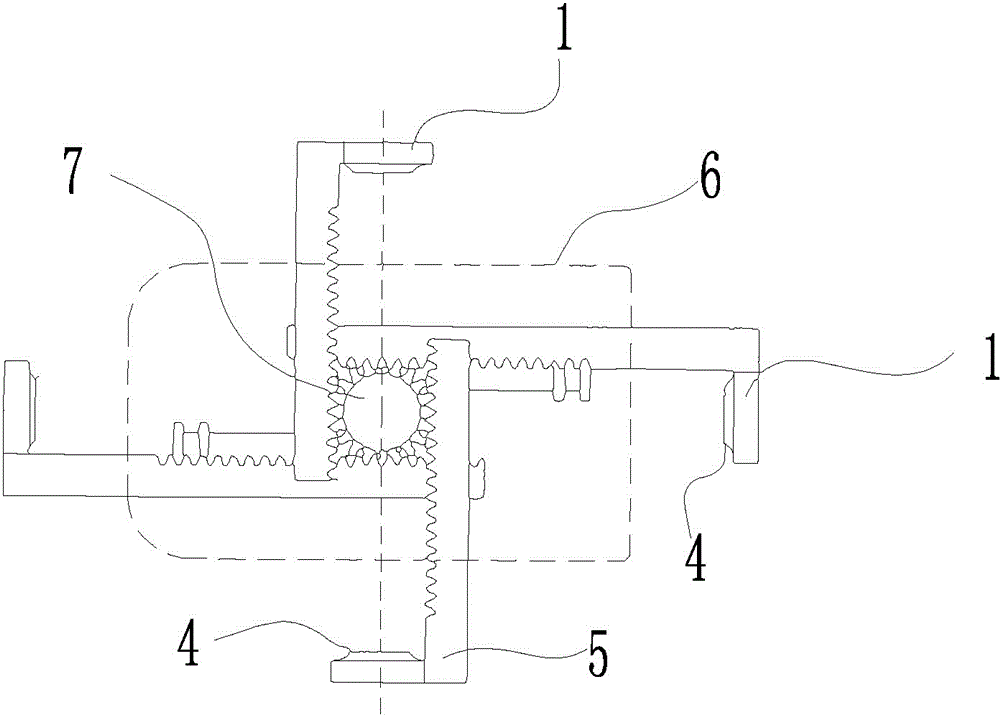

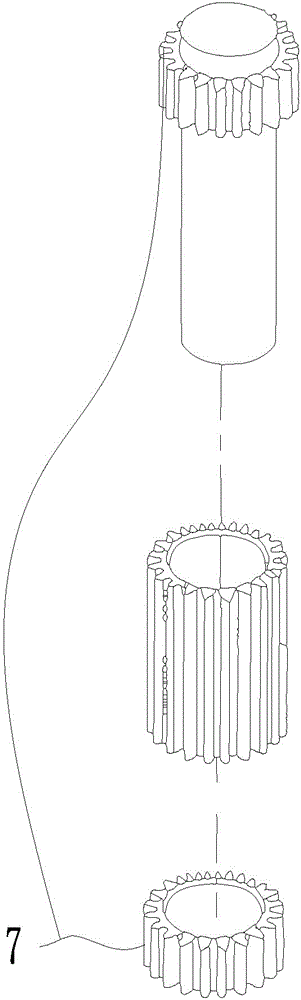

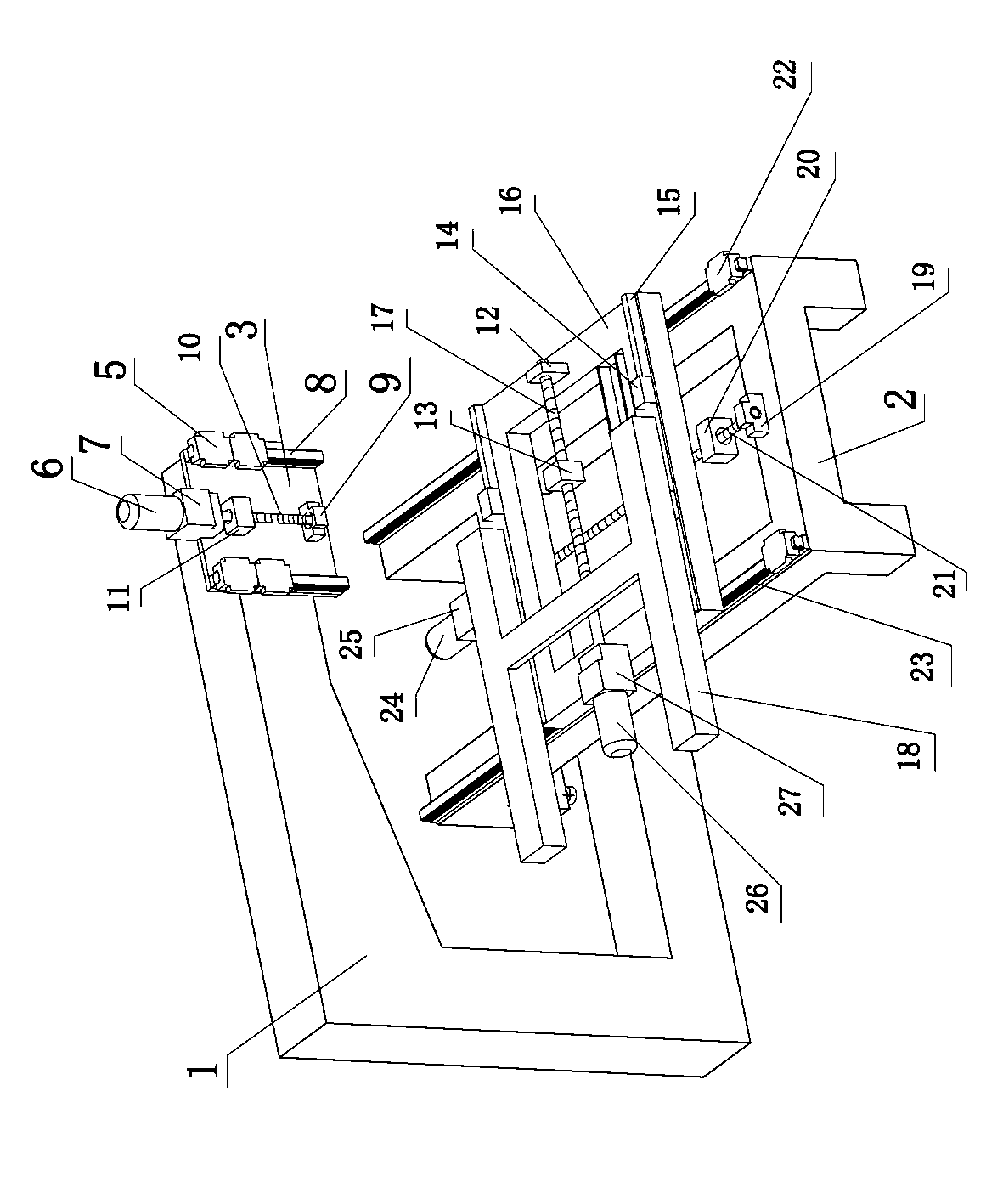

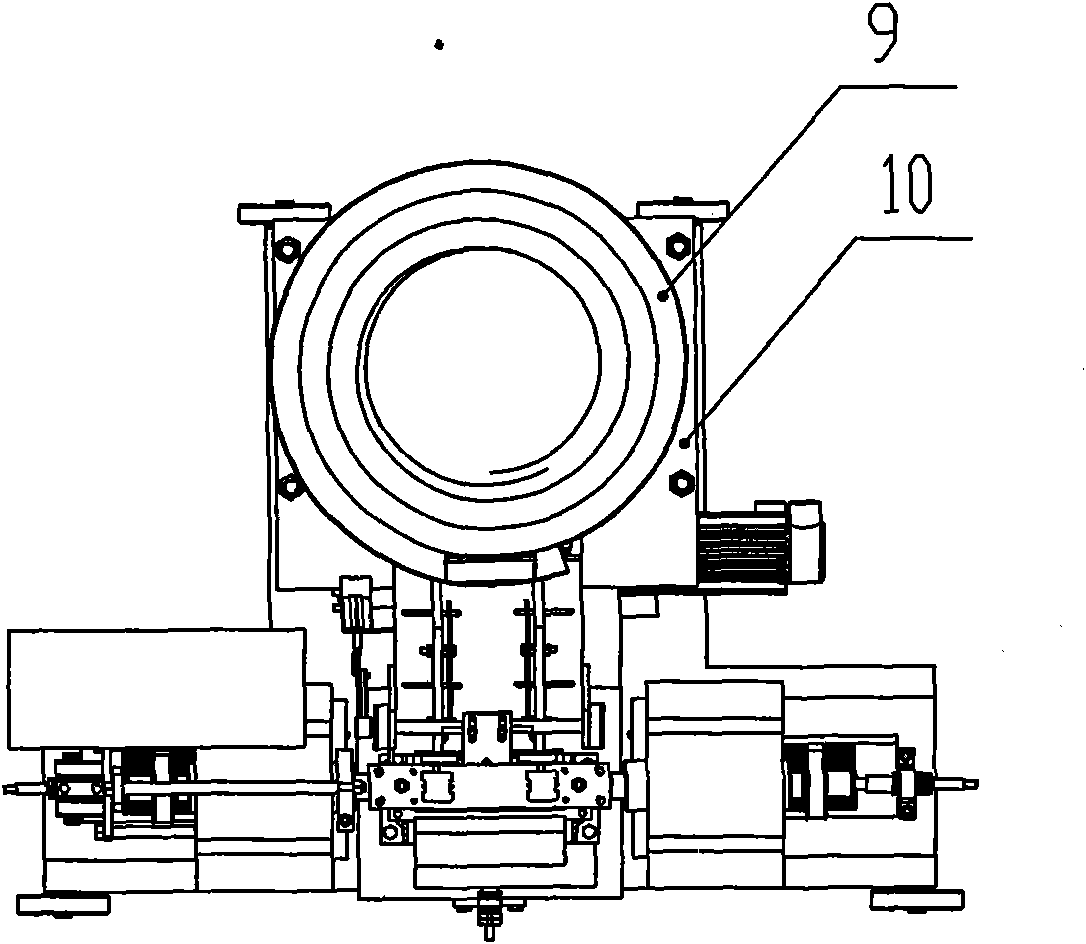

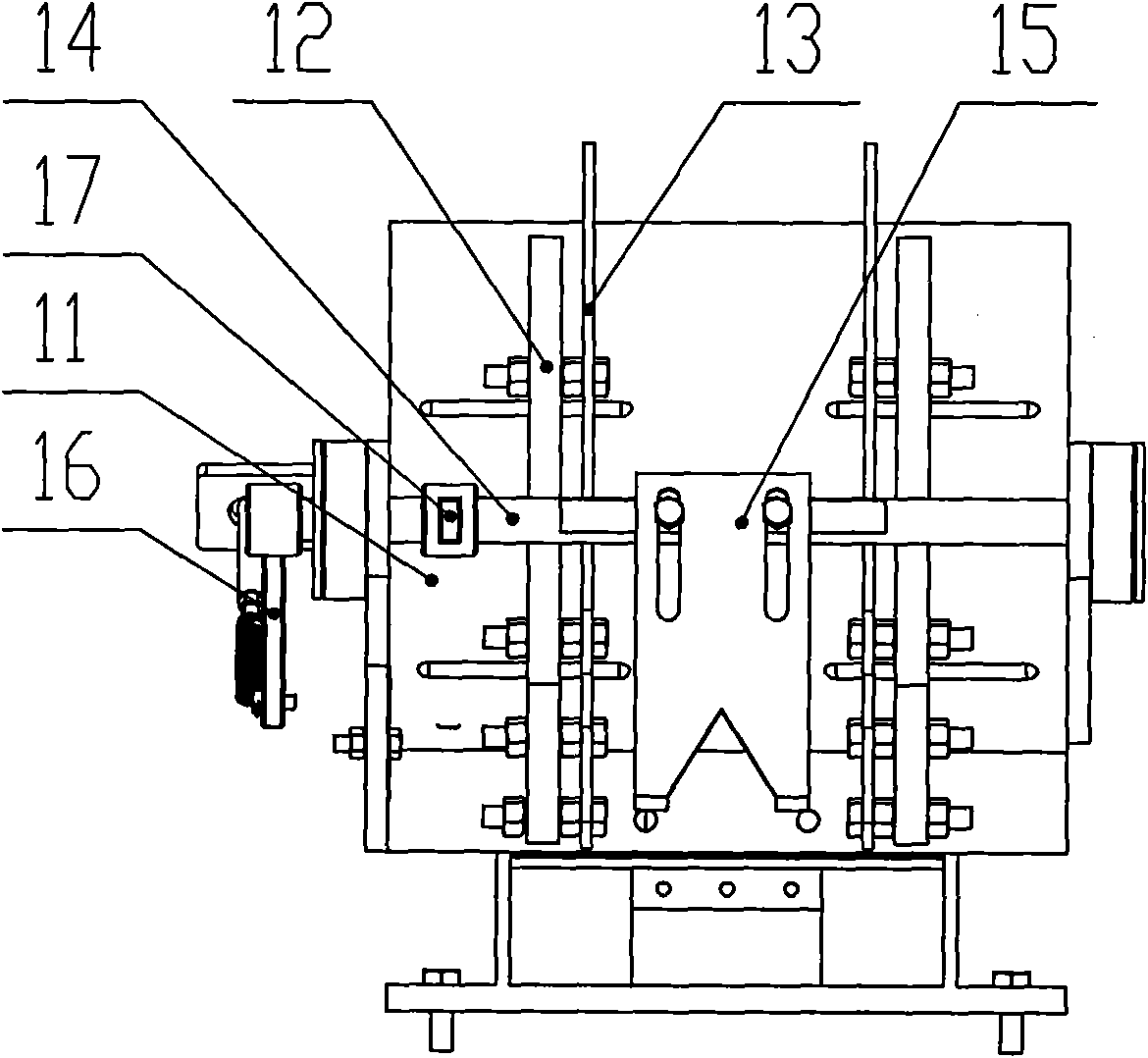

Door body clamping device

PendingCN104441077AAchieve clampingEasy to operateDrilling machinesProfiling/shaping machinesGear wheelElectric machinery

The invention relates to a door plate processing instrument, and particularly relates to a door body clamping device. The door body clamping device comprises a motor, four pressing plates in all, and a gear shaft, wherein the four resisting plates are used for pressing against a door body; one side of each pressing plate toward the adjacent side edge is a resisting surface; a rack of which the length direction is perpendicular to the resisting surface of each pressing plate is fixedly arranged below the pressing plate; the gear shaft is arranged below the door body; the racks which are respectively connected with the pressing plates with opposite positions are respectively arranged at two opposite sides of the gear shaft; the resisting plates and the racks form clamping function members; the clamping function members take the gear shaft as the center point and are in point symmetry distribution; the racks are meshed with the gear shaft; and the motor is fixedly connected with the lower end of the gear shaft or the motor is connected with the gear shaft through a transmission mechanism. The defect that the clamping device in the prior art cannot clamp from four surfaces is overcome; and the door body clamping device capable of automatically resetting is provided.

Owner:CHONGQING OFAN DOOR IND

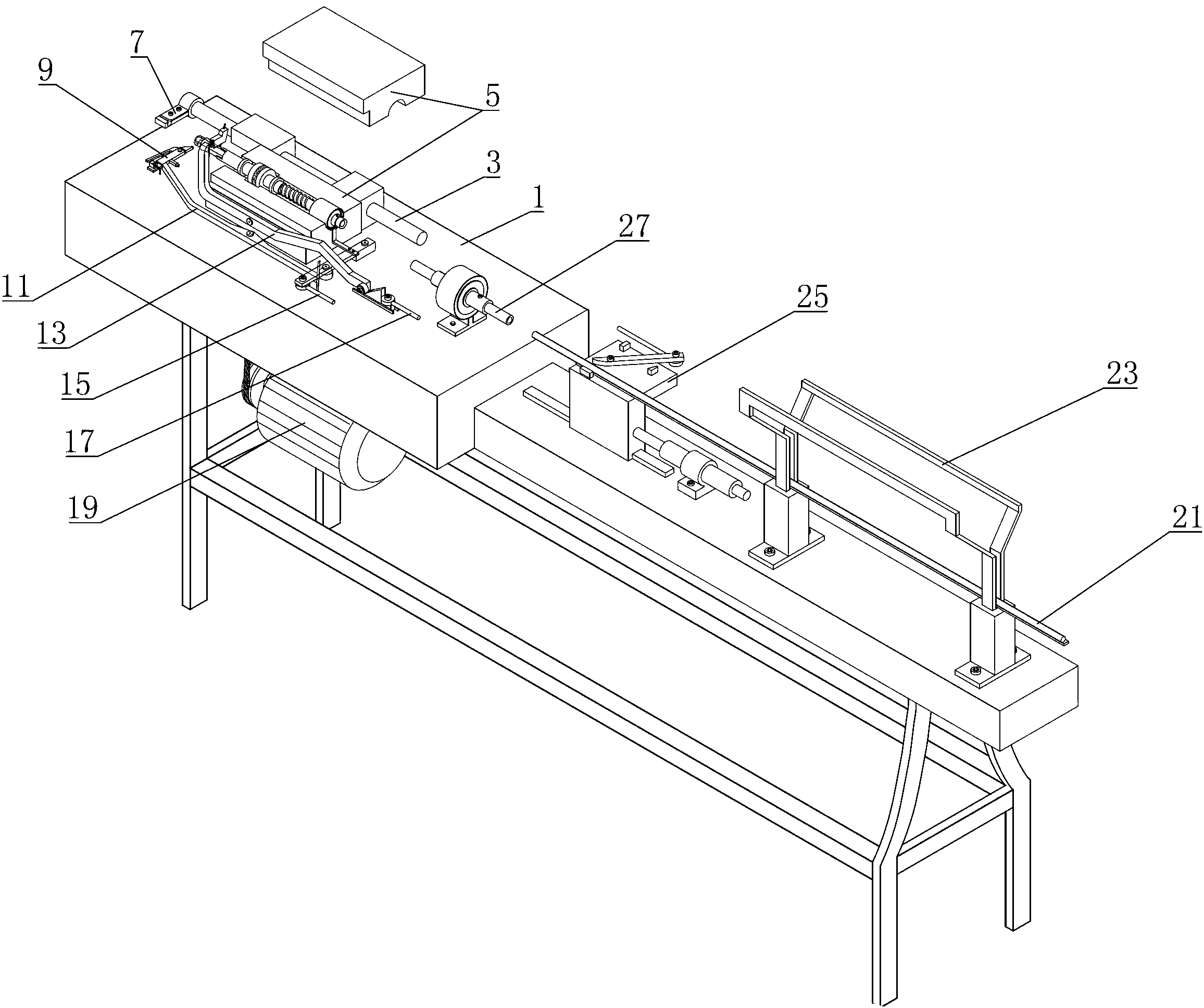

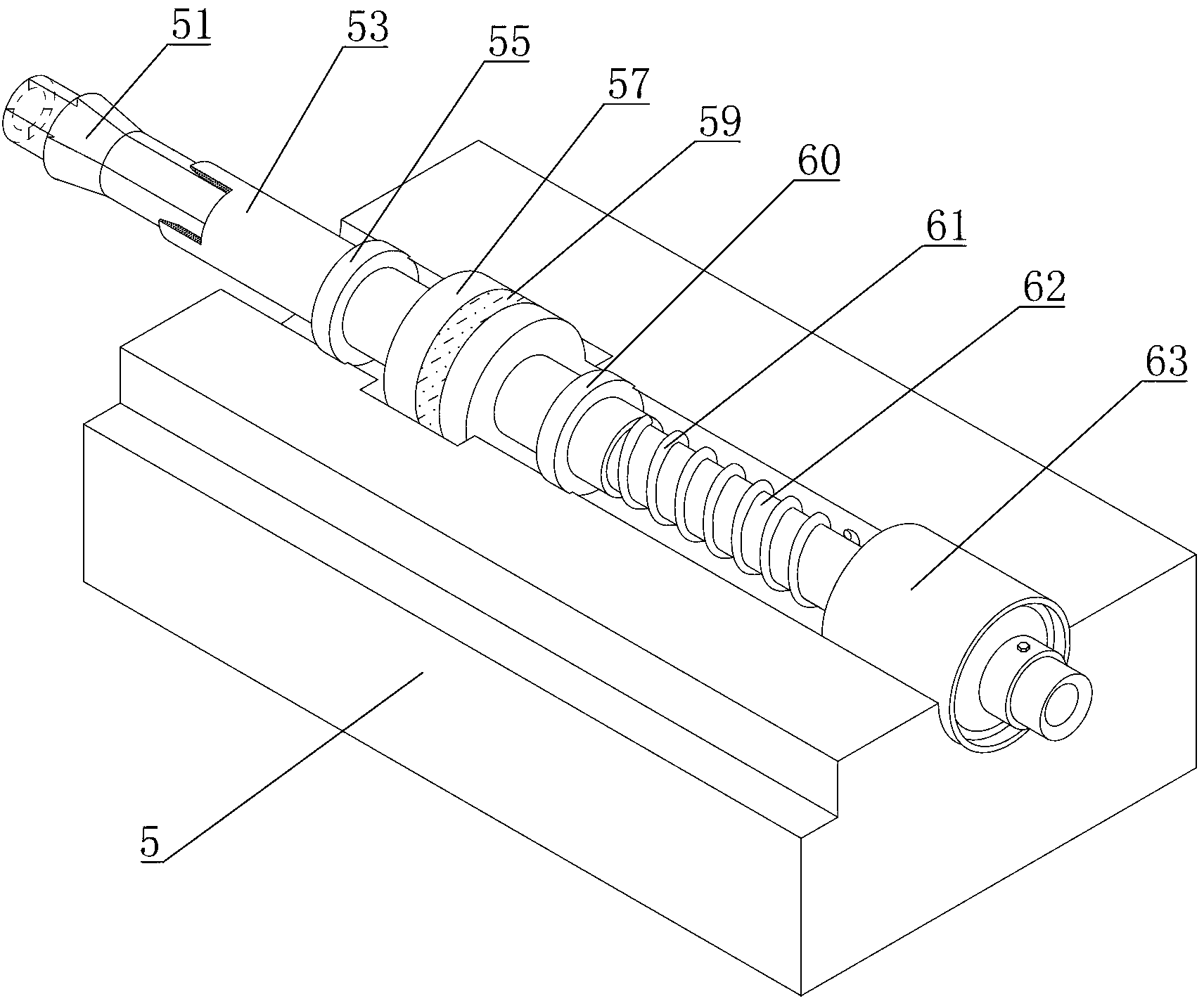

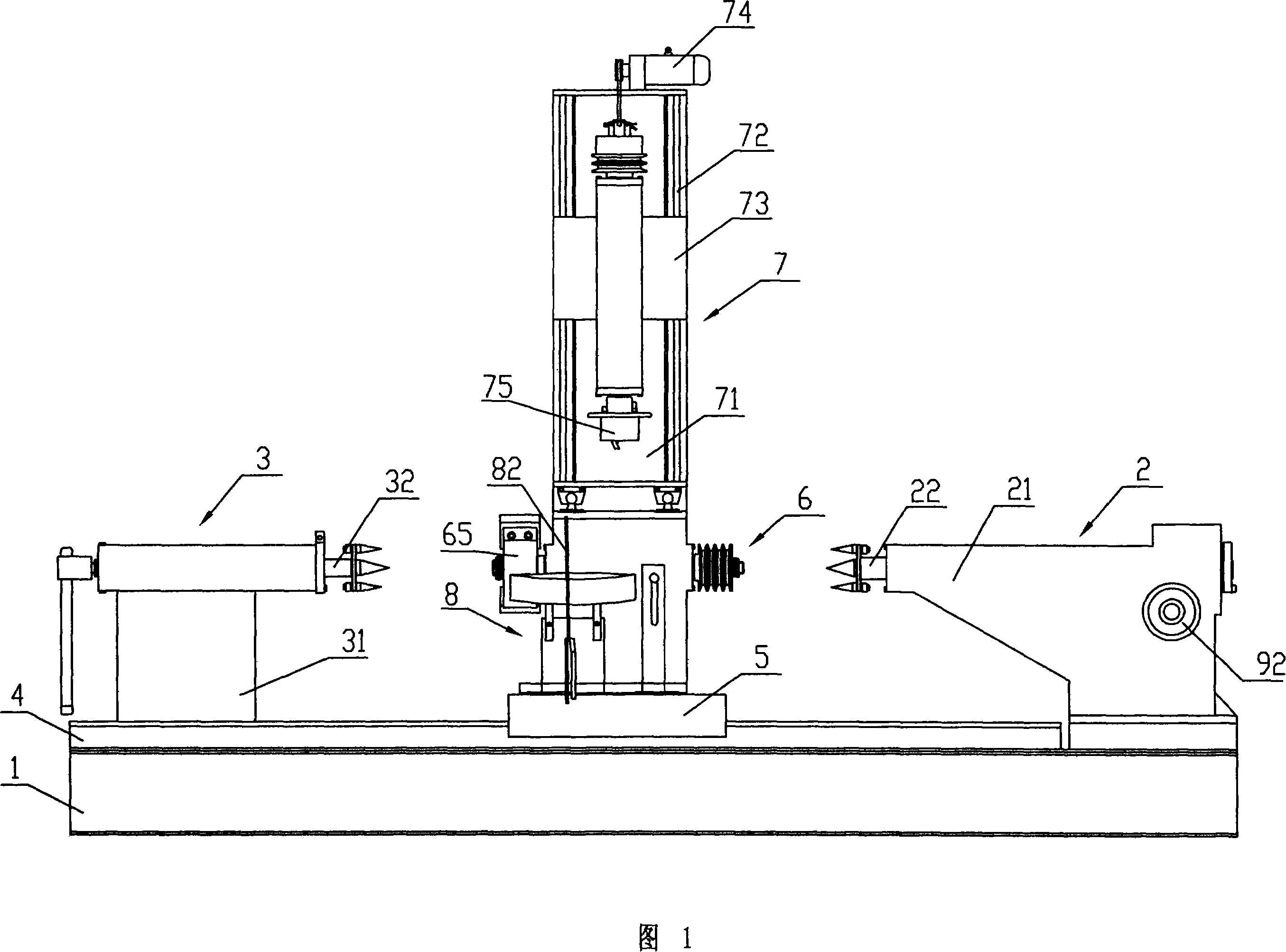

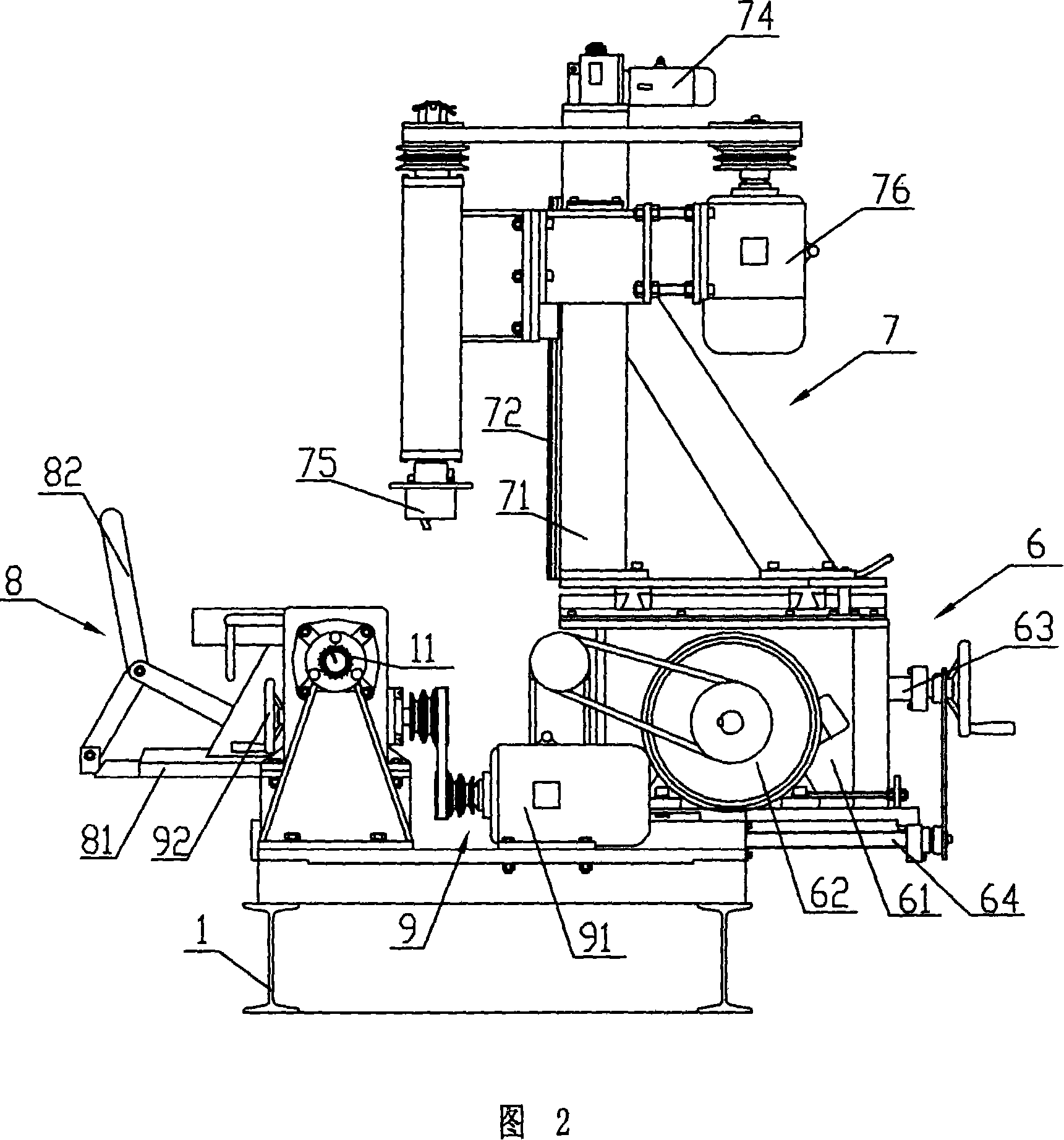

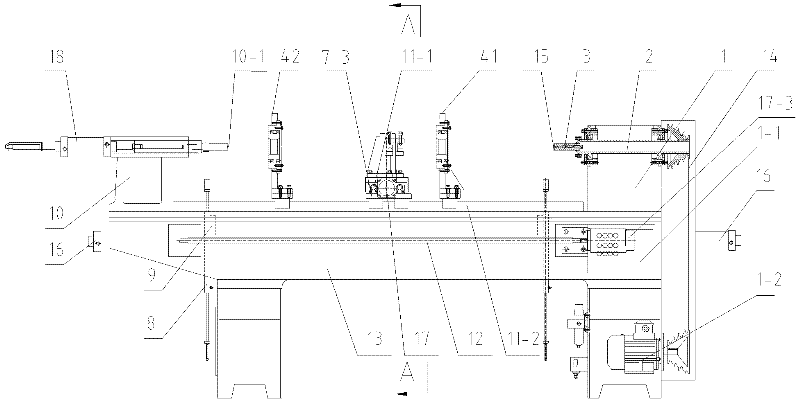

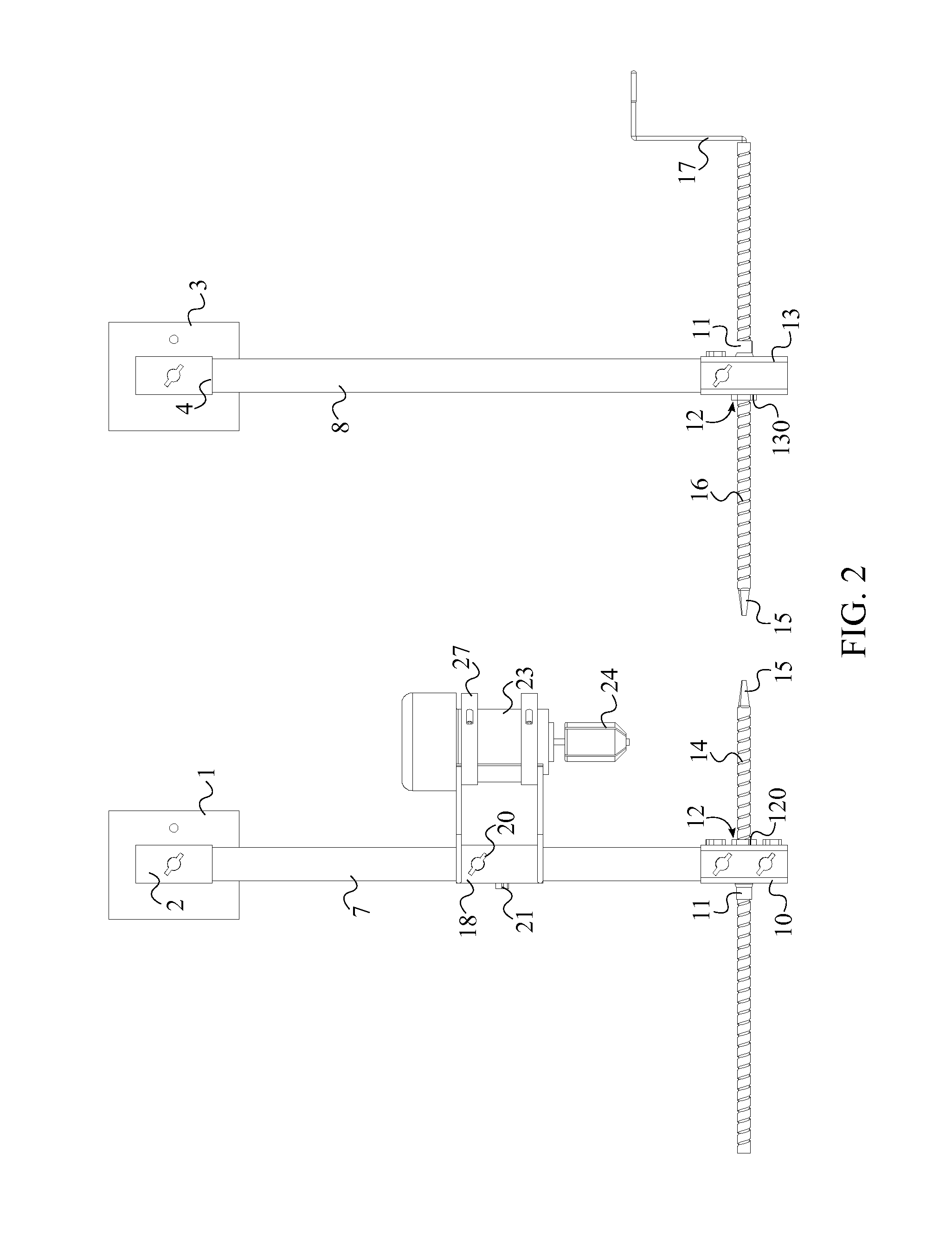

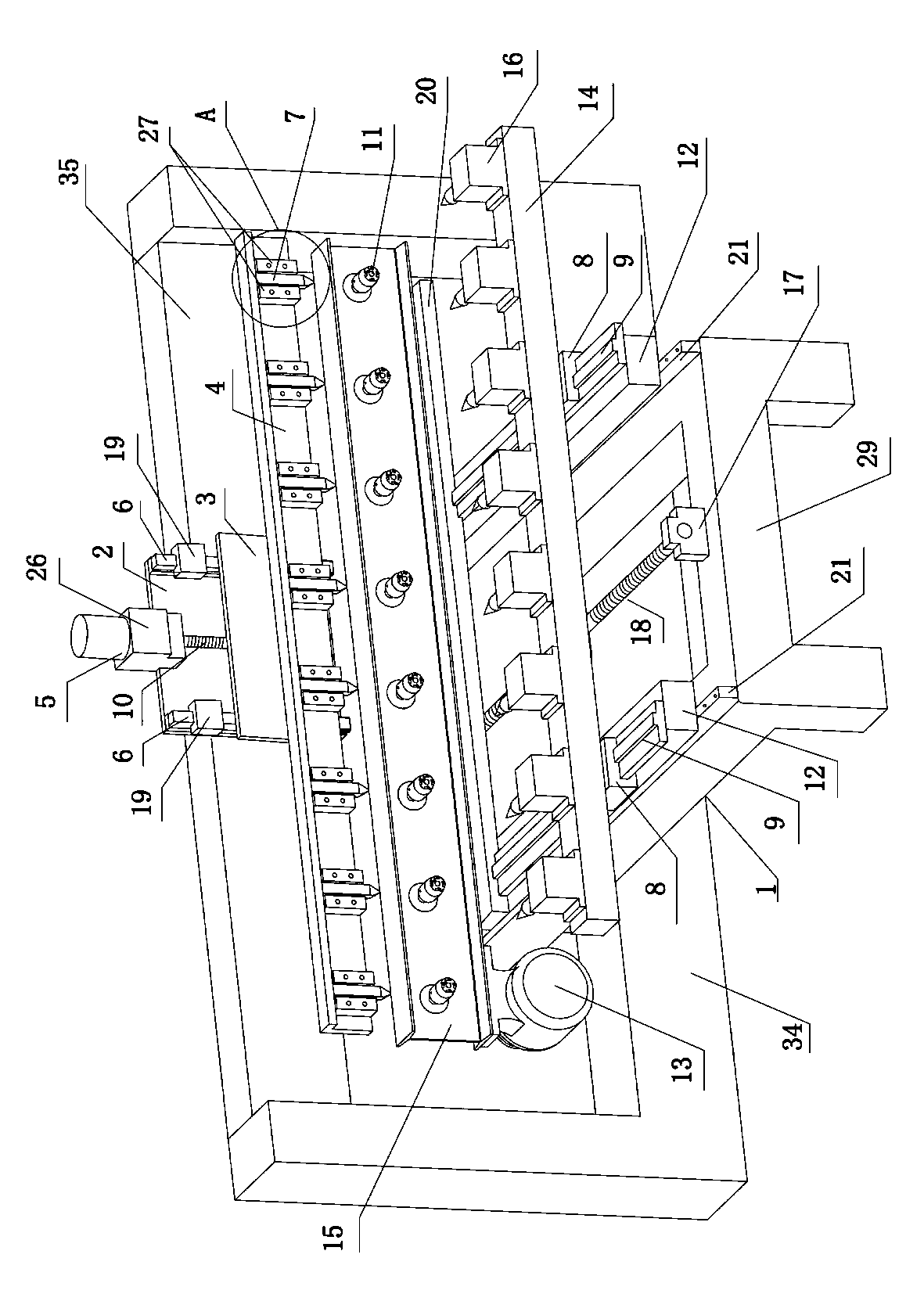

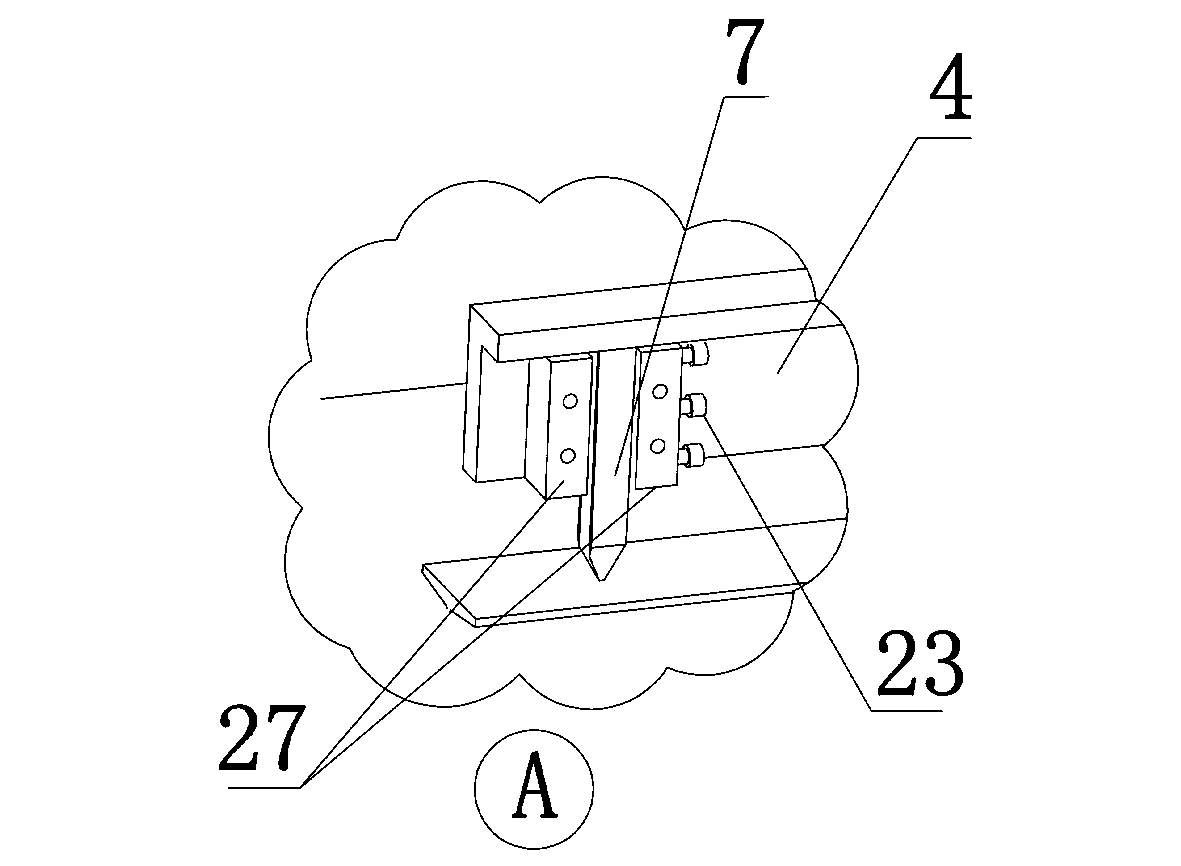

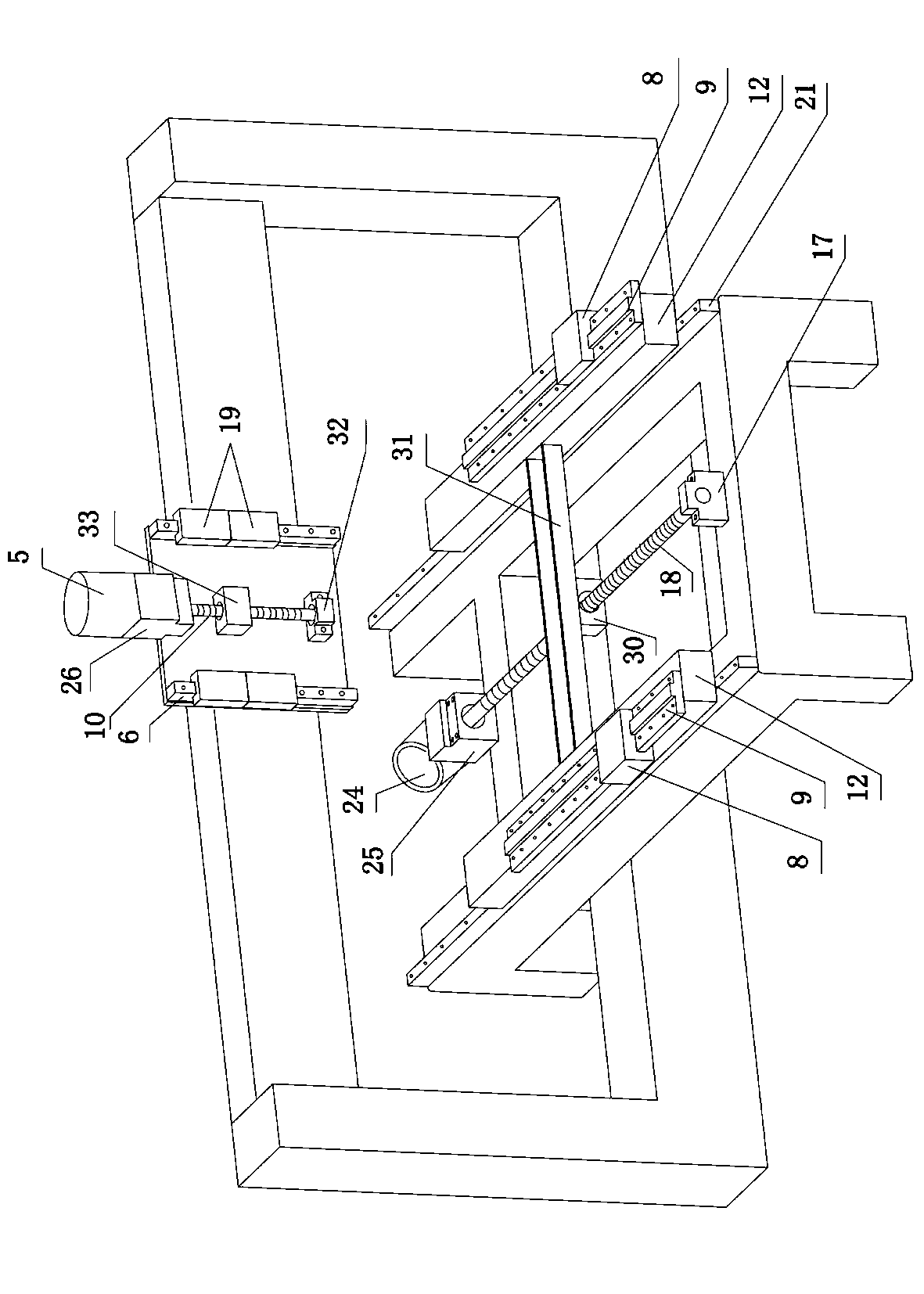

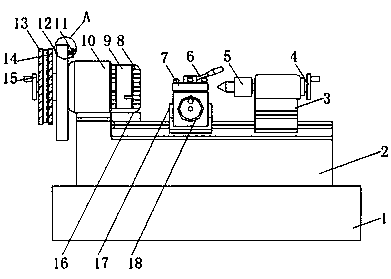

High-speed high-precision digital control automatic wood turning machine

InactiveCN103231421AShorten the timeRealize high-speed productionGolf teesWood-turning machinesProduction rateEngineering

The invention relates to a high-speed high-precision digital control automatic wood turning machine applied to batch production of golf tees and bamboo tees from thin bamboo wood bars. The wood turning machine comprises a machine frame, a motor, a machine head seat, a compressed air source and a full-automatic production digital control circuit, and is characterized by further comprising a mechanism mounted on the machine head seat and used for driving the thin bamboo wood bars to rotate, a mechanism for clamping and linearly pushing the bars, a mechanism for pushing a slide barrel and an amount stop lever to loosen a pawl head and an input amount stop head for working, a mechanism for quickly pushing a cutting knife in place and controlling the amount of feed, and a mechanism for moving a planer tool forwards and backwards, wherein the motor and the machine head seat are mounted on the machine frame; and the full-automatic production digital control circuit is provided with first to fourth hall sensors. A control method of the full-automatic production digital control circuit comprises first to fourth steps. The wood turning machine has the advantages of high production rate, sensitivity for response, accuracy for action, short bar cutting time, flexibility for bar clamping, stability for bar pushing, short consumption time and the like.

Owner:杨洪

Lathes

The present invention therefore provides in one aspect a lathe including:a headstock comprising a lathe spindle;a tailstock; anda lathe bed wherein the lathe bed is mounted to be rotatable in a horizontal plane about a vertical axis.In a second aspect of the invention there is provided a lathe including:a headstock comprising a lathe spindle passing through a hollow column and within the hollow column means adapted to safely connect a vacuum to the interior of the lathe spindle;a tailstock; anda lathe bed wherein the lathe bed is mounted to be rotatable in a horizontal plane about a vertical axis.In a third aspect of the invention there is provided a lathe including:a headstock comprising a lathe spindle passing through a hollow column and within the hollow column means adapted to safely connect a vacuum to the interior of the lathe spindle;a lathe bed wherein the bed is mounted to be rotatable in a horizontal plane about a vertical axis; anda tailstock adapted to rotate 360° through its normal central location to permit alignment with the headstock spindle axis regardless of angular location of the lathe bed about its vertical axis.

Owner:CADDAYE ROBERT JOHN +1

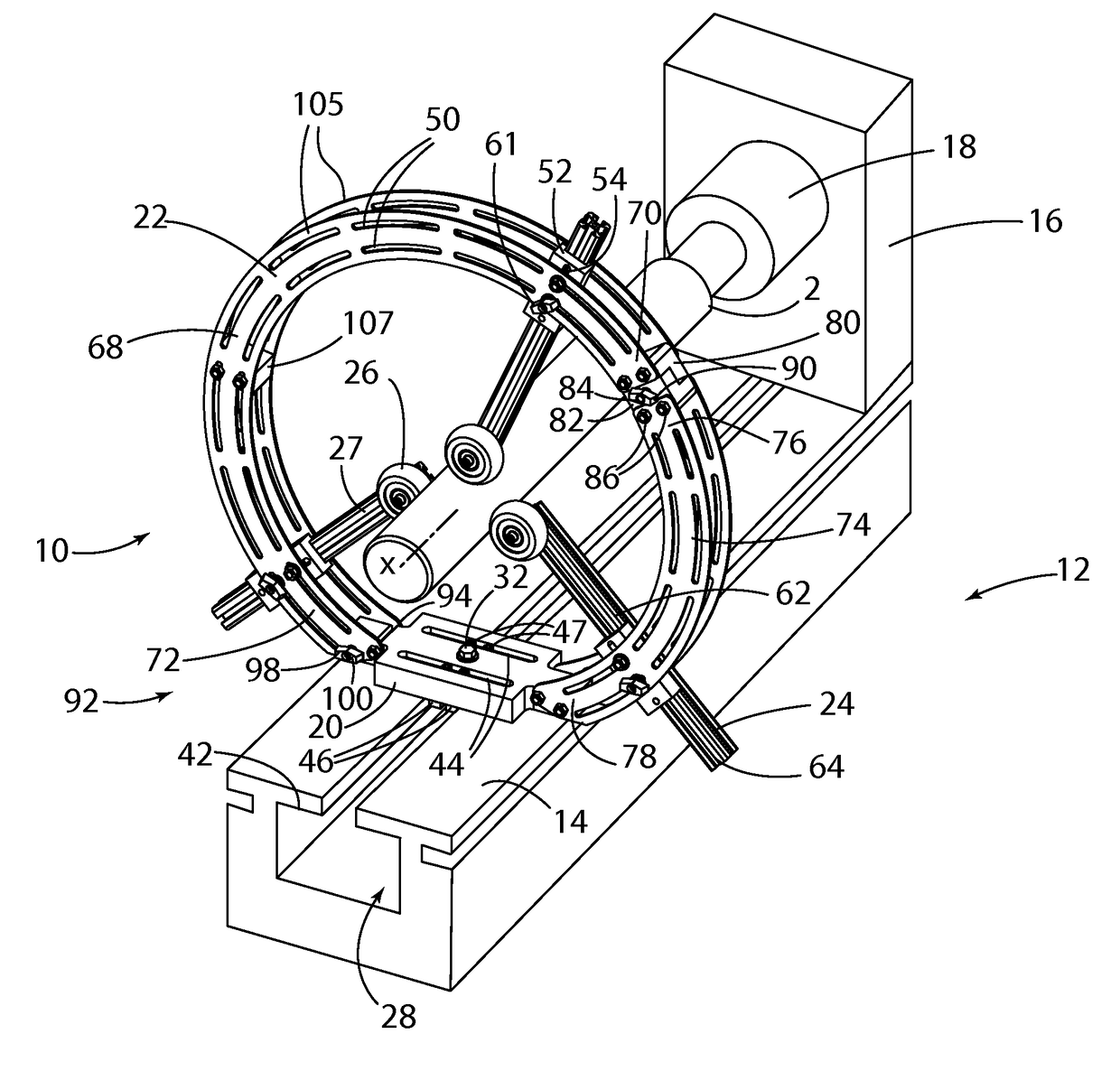

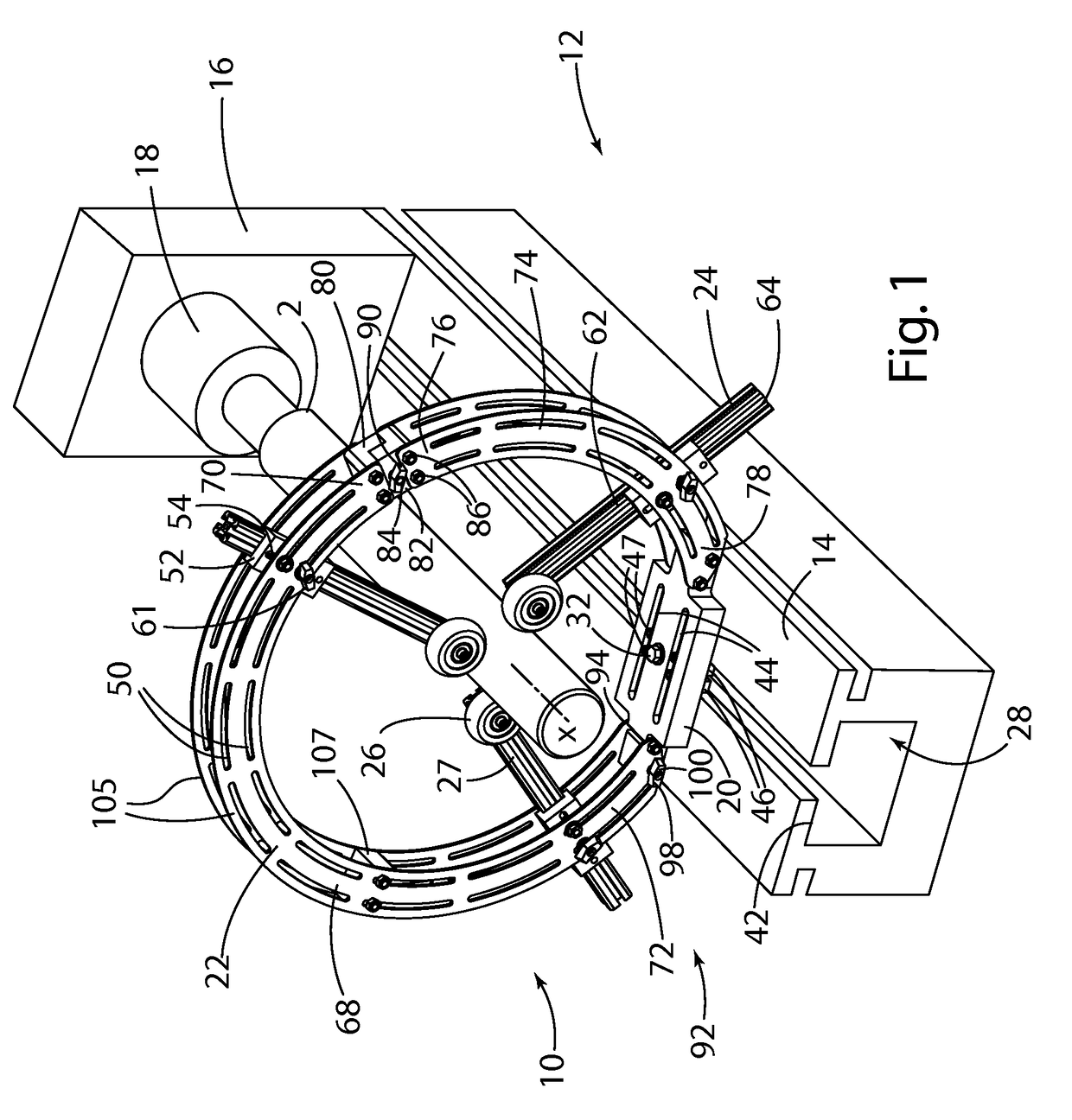

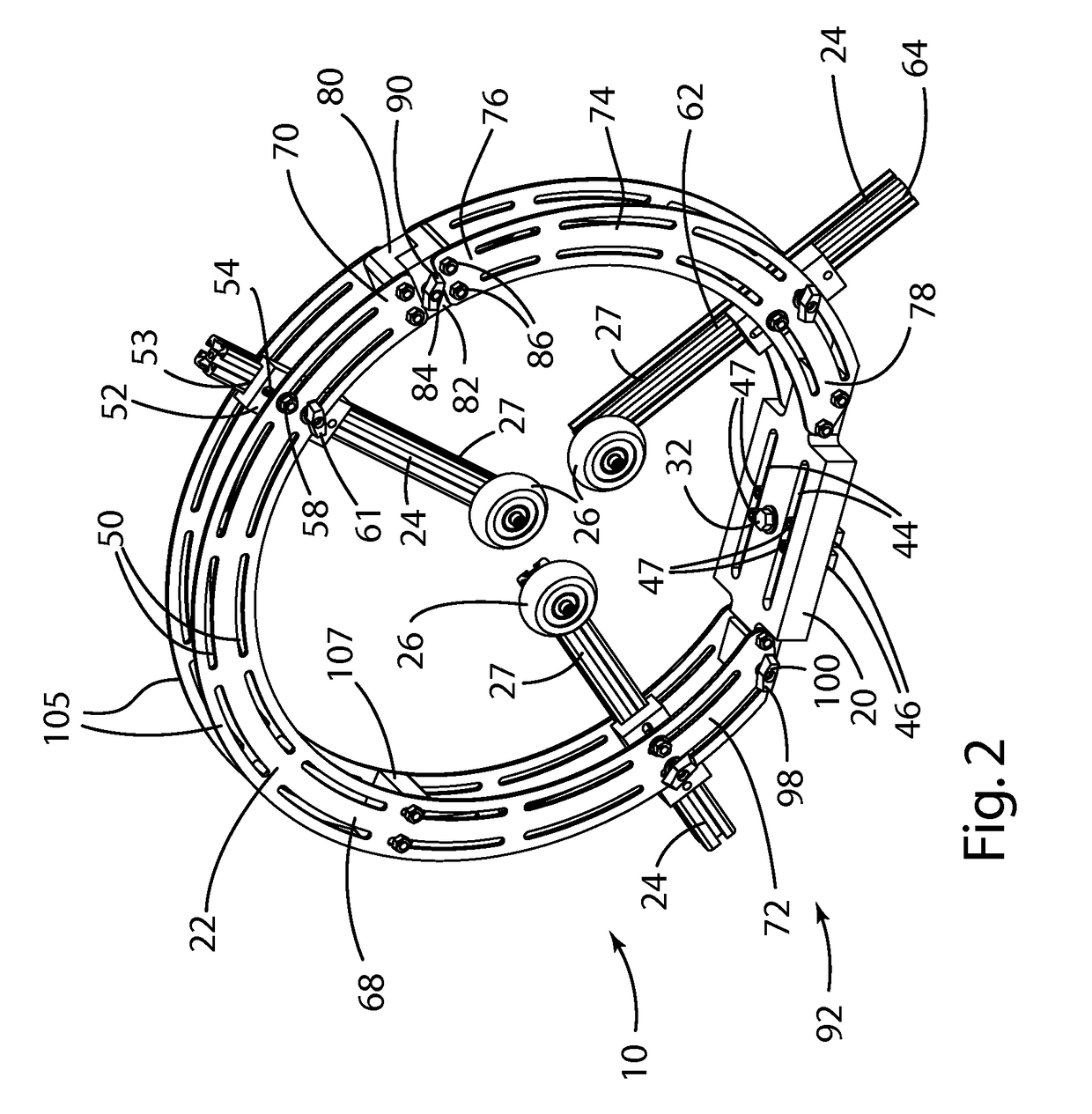

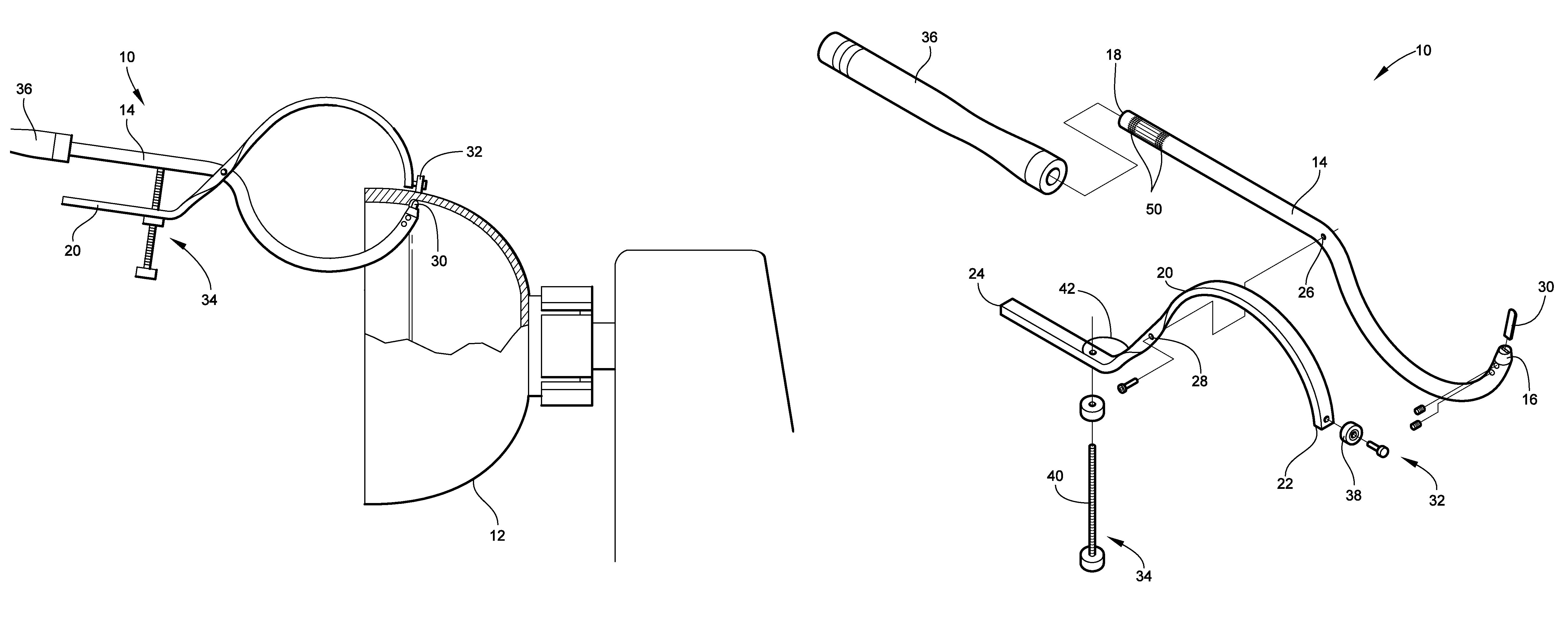

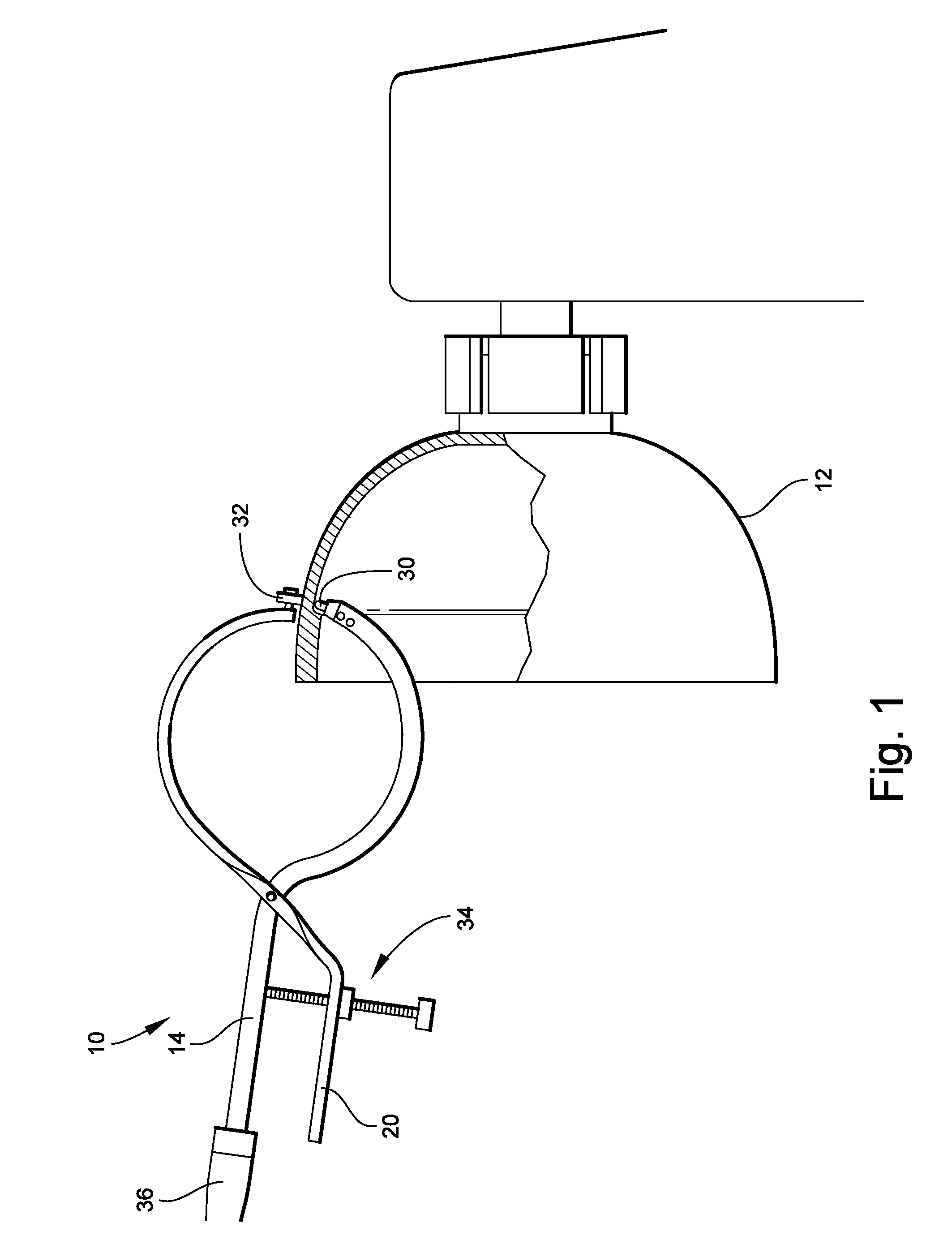

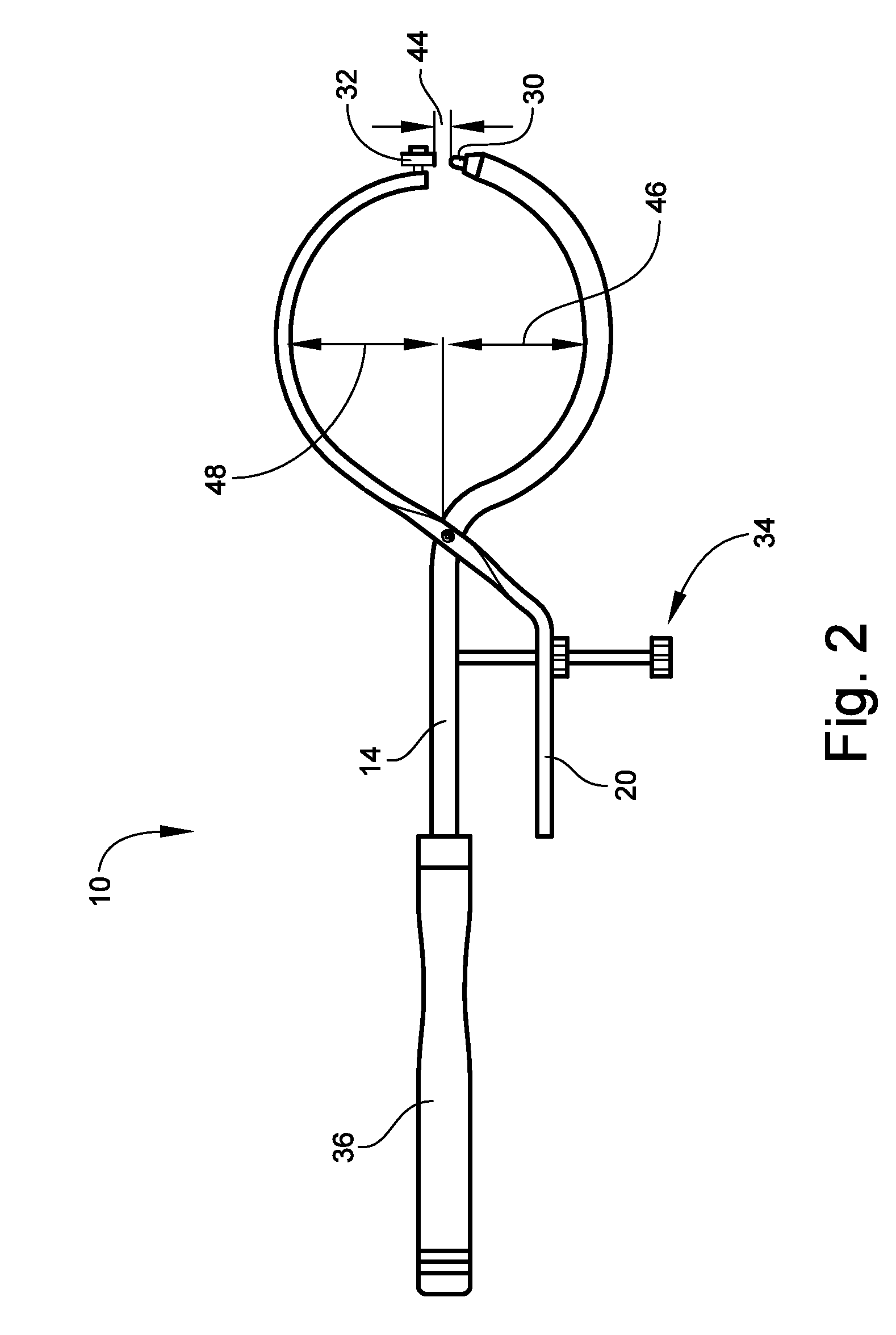

Lathe work piece support tool

A work piece support rest is provided for turning a work piece on a rotating lathe having a lathe bed, headstock, and a headstock spindle, where the work piece is attached to the headstock spindle. The support rest includes an adjustable base releasably attached to the slotted way of the bed via a locking plate and a pair of laterally adjustable way spacers moveable within a laterally extending slot that engage each side of the slotted way. A multi-piece outer ring is releasably attached to the adjustable base. A plurality of roller slides are releasably and adjustably attached to the outer ring, such that each of the roller slides extends radially inwardly and has a roller disposed at an inward distal end thereof for supporting the work piece.

Owner:CARTER PRODS

Carpentry machine tool used for log processing

InactiveCN101058196AImprove processing efficiencyEasy to stackProfiling/shaping machinesWood-turning machinesCircular discEngineering

The invention relates to a woodworking tool machine for original wood processing that comprises the vertical track base with both ends sticking the original wood and driving its motor tail base and support tail base, sliding base between them and being able to move along the vertical track, horizontal milling and cutting device for the original wood with vertical milling device installed on the horizontal milling base. The woodworking machine is not only able to process original wood with high efficiency, but also be able to vertical concave slot, horizontal concave slot and vertical sawing seam processing on the wood. It is multifunctional, with convenience for wood transportation, usage and storage.

Owner:杜明干

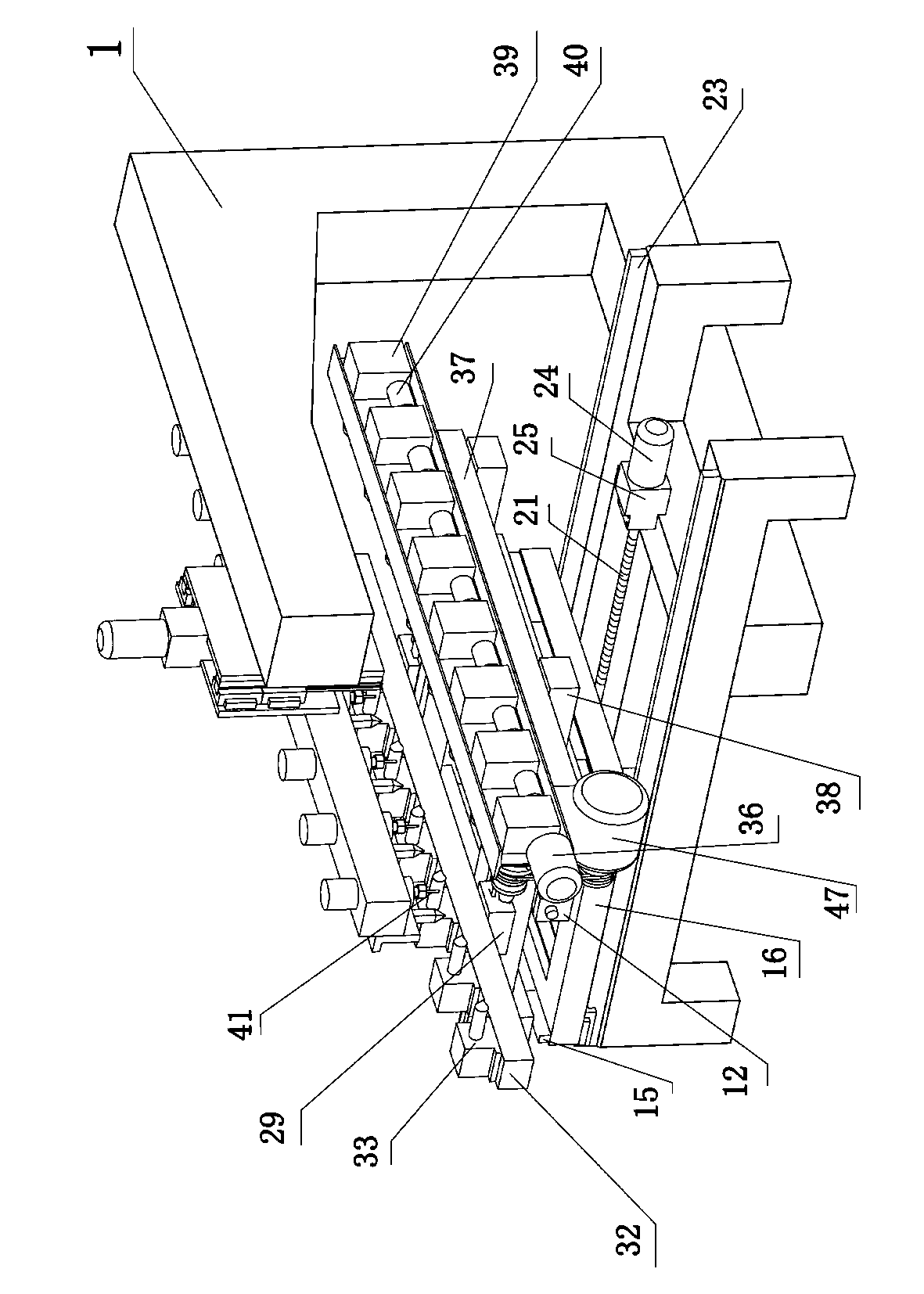

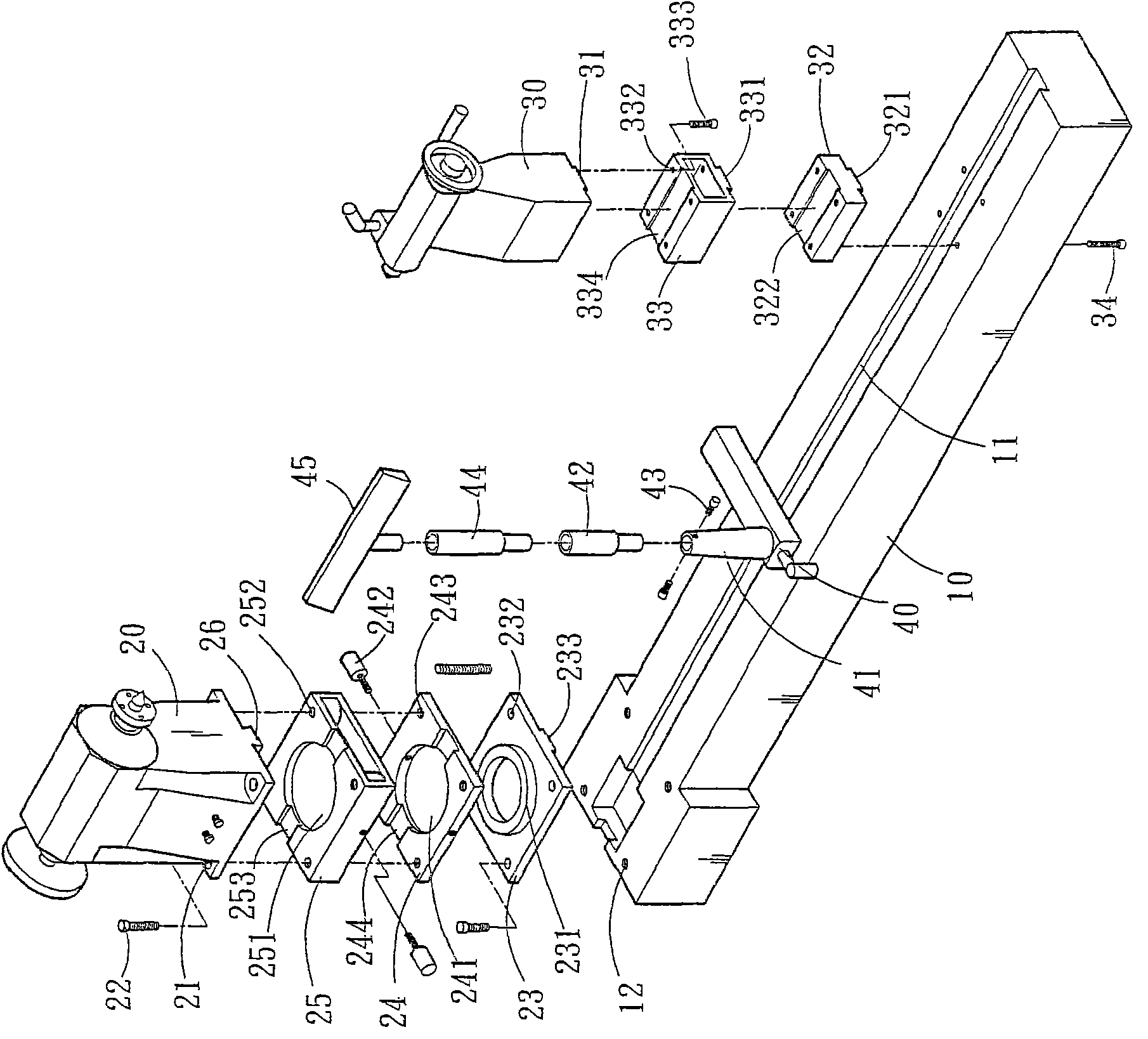

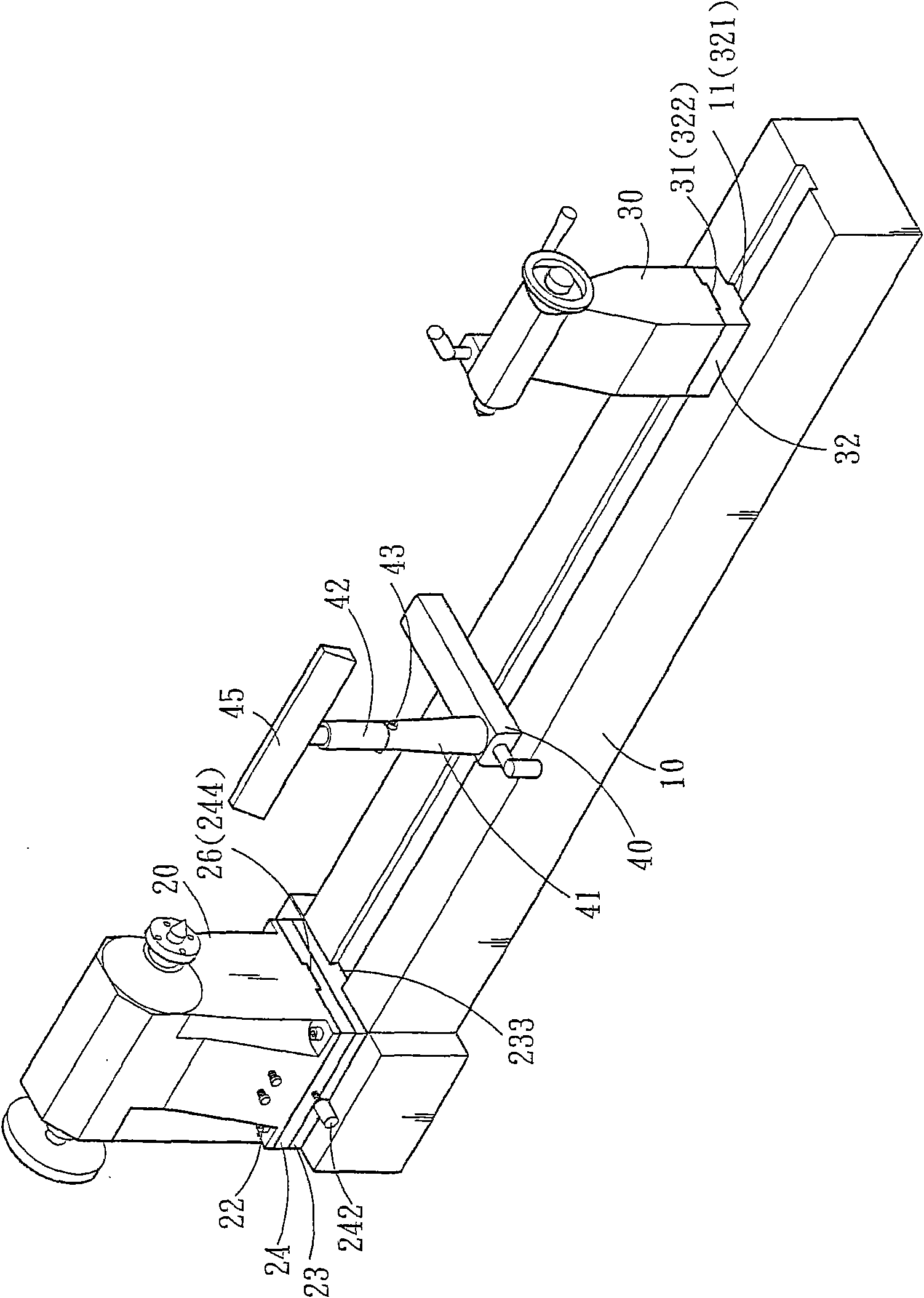

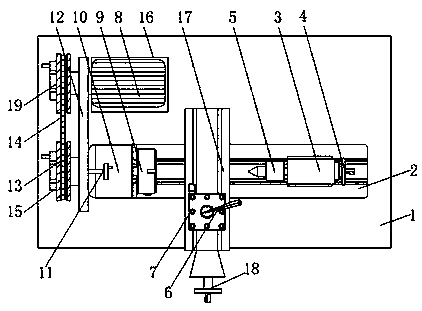

Numerical control wood working lathe and carving integrated machine

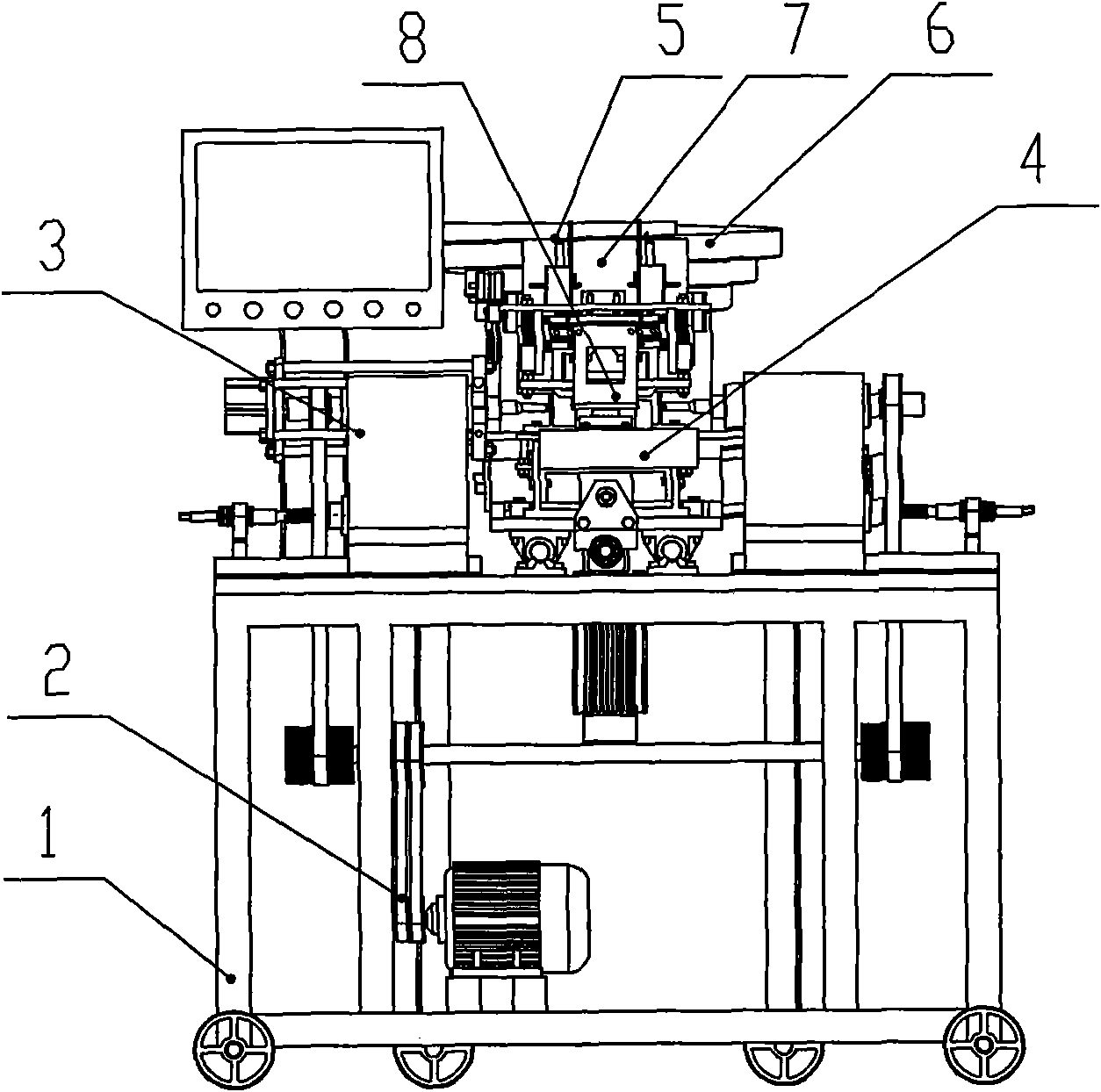

ActiveCN102699961AImprove machining accuracyReduce labor costsWood-turning machinesModel makingNumerical controlElectric machinery

The invention relates to a numerical control wood working lathe and carving integrated machine, and belongs to the technical field of wood-working machinery. The numerical control wood working lathe and carving integrated machine comprise a machine frame, a cross beam, a vertical driving mechanism, a cutter device, a horizontal driving mechanism, a vertical driving mechanism and a workpiece clamping driving mechanism. The cross beam is arranged on the upper part of the machine frame, and the vertical driving mechanism is arranged on the cross beam. The vertical driving mechanism comprises a first driving motor, a first motor fixing seat, a first block, a vertical guide rail, a first screw rod, a first connecting block, a vertical guide rail mounting board and a vertical planker. The cutter device comprises a cutter frame, a lathe tool frame, a carving cutter, a lathe tool, a lathe tool fixing plate, an adjusting screw and a motor. The vertical driving mechanism comprises a vertical worktable, a vertical guide rail, a fourth sliding block, a third driving motor, a third motor fixing seat, a third screw rod, a third connecting block and a third bearing supporting block. The horizontal driving mechanism comprises a horizontal worktable, a horizontal guide rail, a third sliding block, a second driving motor, a second motor fixing seat, a second screw rod, a second connecting block and a second bearing supporting block.

Owner:NANTONG OUKE CNC EQUIP CO LTD

a woodworking machine

InactiveCN102259355AEasy to processGuaranteed balance and stabilityWood-turning machinesElectric machineryEngineering

The invention relates to a woodworking machine tool, which belongs to the field of woodworking machinery and equipment, and comprises an interconnected headstock, a spindle, a chuck, a tool holder, a tool holder, a turning tool, a sliding plate, a feeding cylinder, a feeding rack, a tailstock, and a bed Body, guide rail, lead screw, stepping motor, wherein, the number of said tool holders is more than two, which are respectively arranged on the sliding plate; on the sliding plate; the number of the turning tool is the same as the number of the tool holder, the turning tool is arranged in a direction perpendicular to the axis of the lathe, and the tip of the turning tool is along the axis of the lathe The parallel directions are misaligned with each other. Compared with the prior art, the present invention has a novel structure and simple operation, effectively overcomes the defects of single knife and single knife holder for wood production and processing, greatly improves the processing efficiency, increases the smoothness of the finished product, and correspondingly reduces the economic cost. The invention is suitable for popularization and application in wood processing related fields.

Owner:陆卫斌

Optimized planer feeder system and method

ActiveUS7171278B2Promote recoveryImprove throughputSawing apparatusMulti-purpose machinesEngineeringMechanical engineering

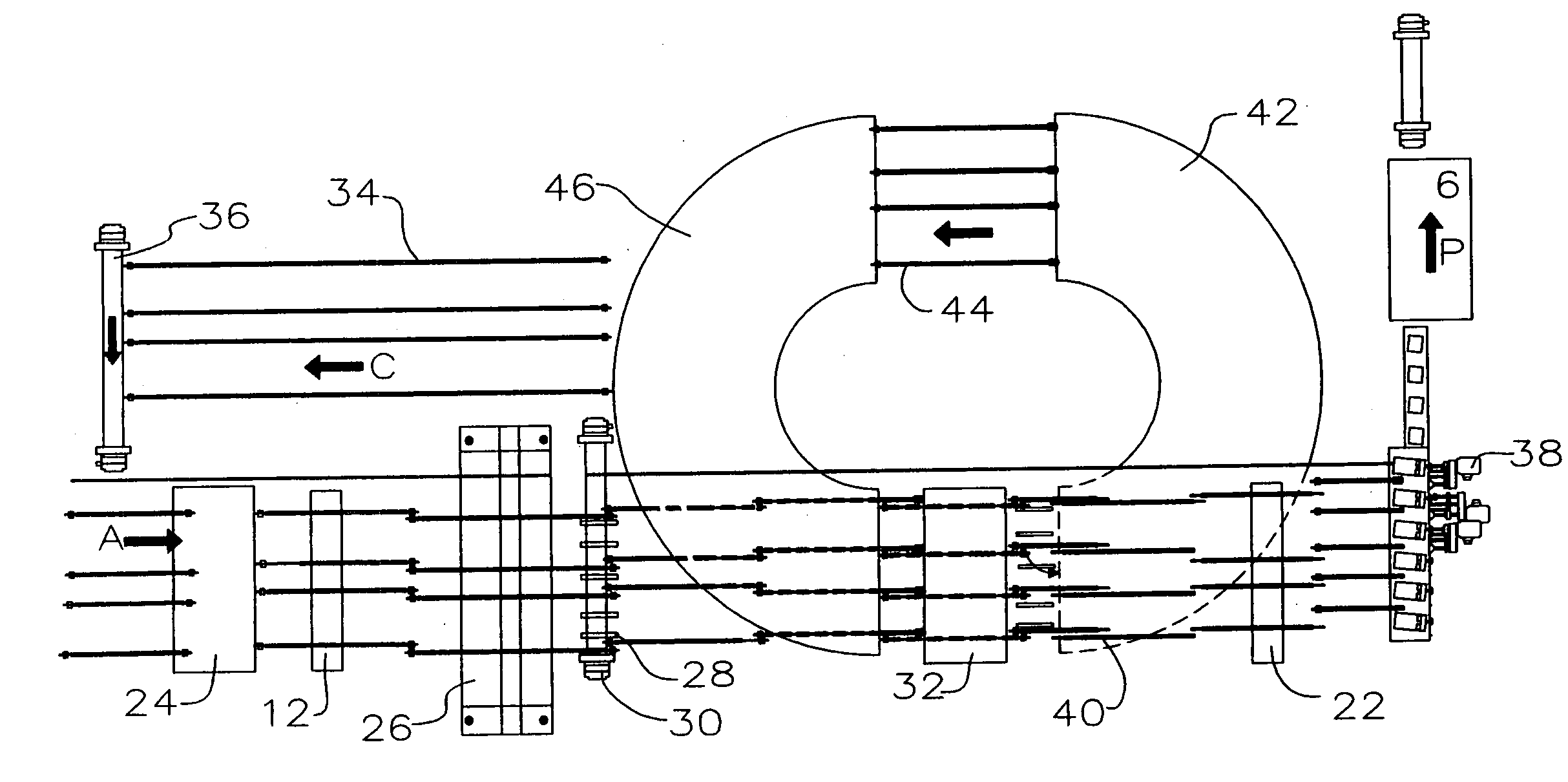

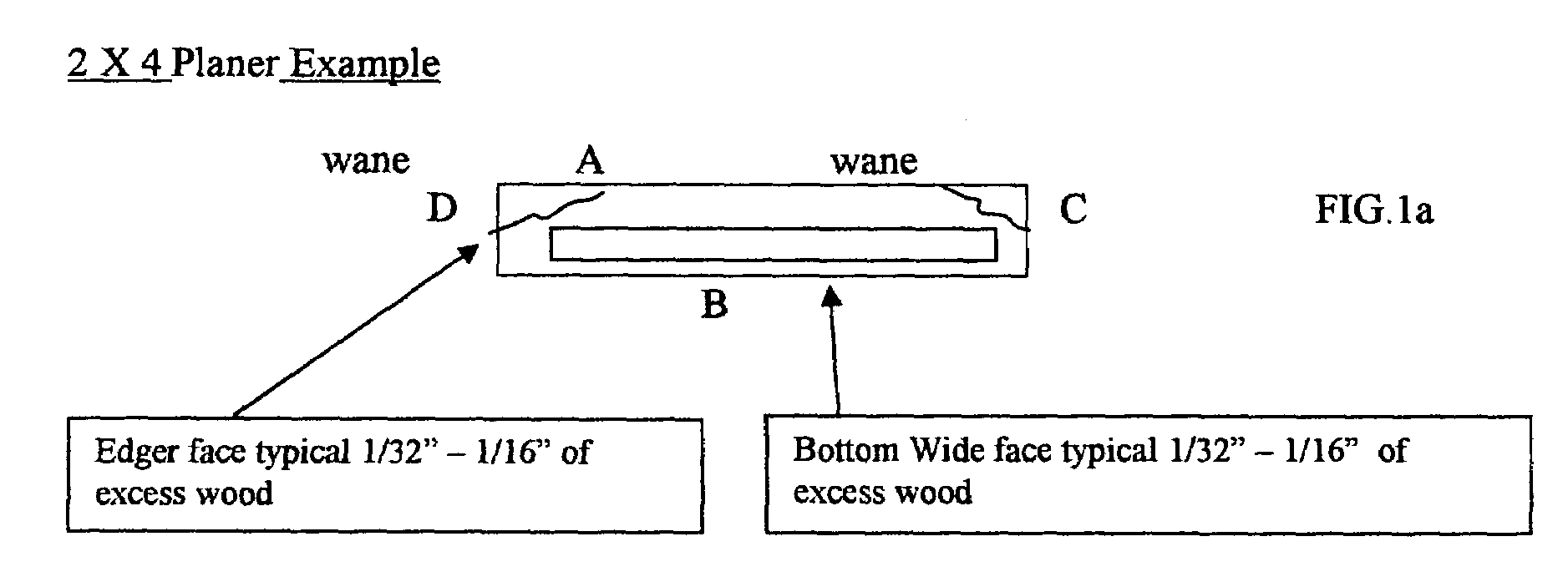

An apparatus for optimizing orientation of a workpiece in a planermill for feeding of the workpiece into a planer includes an infeed to the planer, a workpiece turner for selectively turning the workpiece end-for-end upstream of the planer on the infeed a workpiece flipper for selectively flipping the workpiece one hundred eighty degrees about a longitudinal axis of the workpiece upstream of the planer on the infeed, a scanner on the infeed upstream of the workpiece turner and workpiece flipper for detecting defects on the workpiece, a processor cooperating with the scanner, the workpiece turner and the workpiece flipper for optimizing the orientation of the workpiece relative to status and actively translatable cutterheads in the planer.

Owner:USNRKOCKUMS CANCAR

Numerical control machine tool for machining wooden handle

The invention discloses a numerical control machine tool for machining a wooden handle, which comprises a frame, a motor and a numerical control system. A clamping device is mounted on a frame, a machining mechanism is arranged in the clamping device, a feeding assembly is arranged at the upper end of the machining mechanism and comprises a vibratory conveying device, a discharging device and a feeding device which are sequentially arranged from top to bottom, the machining mechanism comprises an X-axis feeding device, a Z-axis feeding device, a turning tool rest and a forming tool rest, and chip removal devices are arranged on the turning tool rest and the forming tool rest. By the aid of the numerical control machine tool, conveying, feeding, clamping, machining, discharging, circulatory machining and waste collecting procedures are integrated, automation degree and production efficiency are improved, the labor intensity of workers is relieved, production is increased while consumption is reduced, and product quality is improved.

Owner:黄山市继林机械制造有限公司

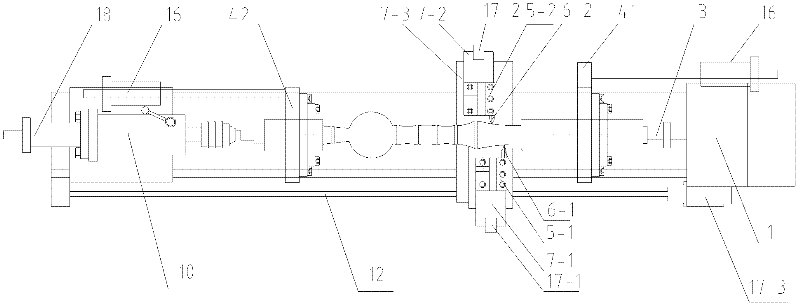

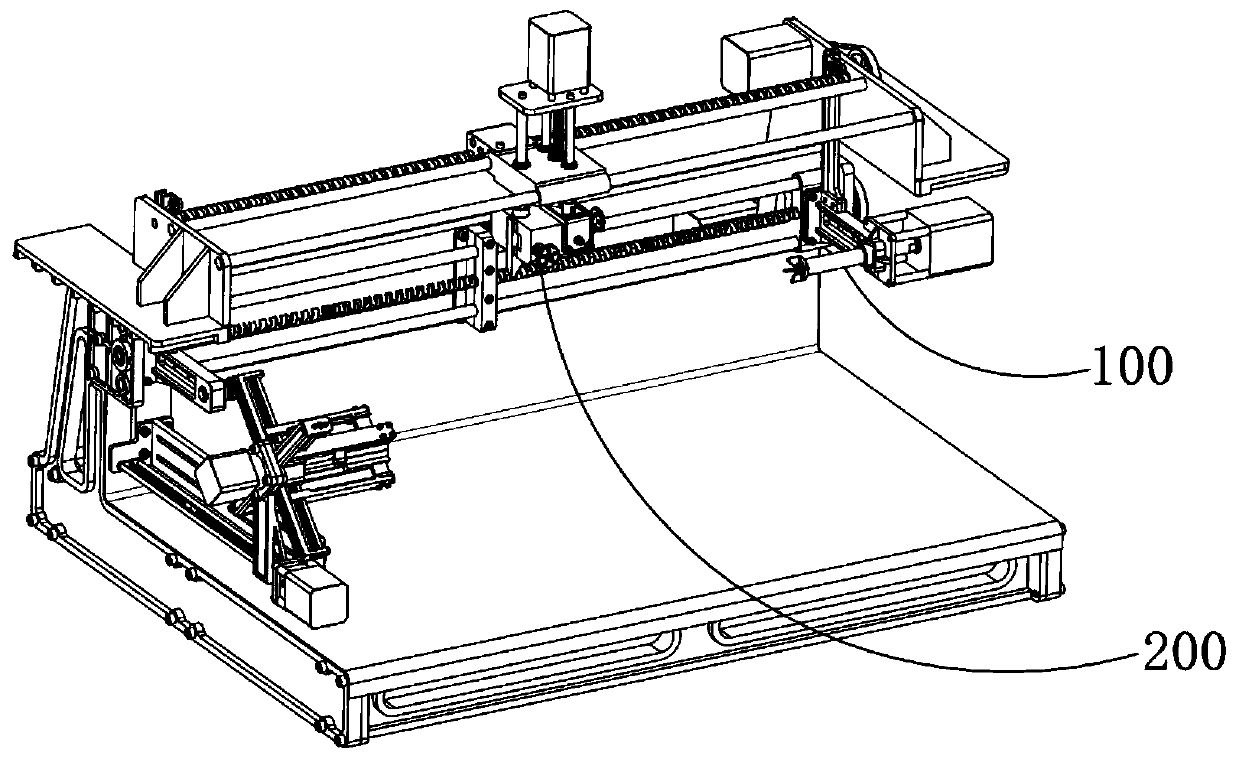

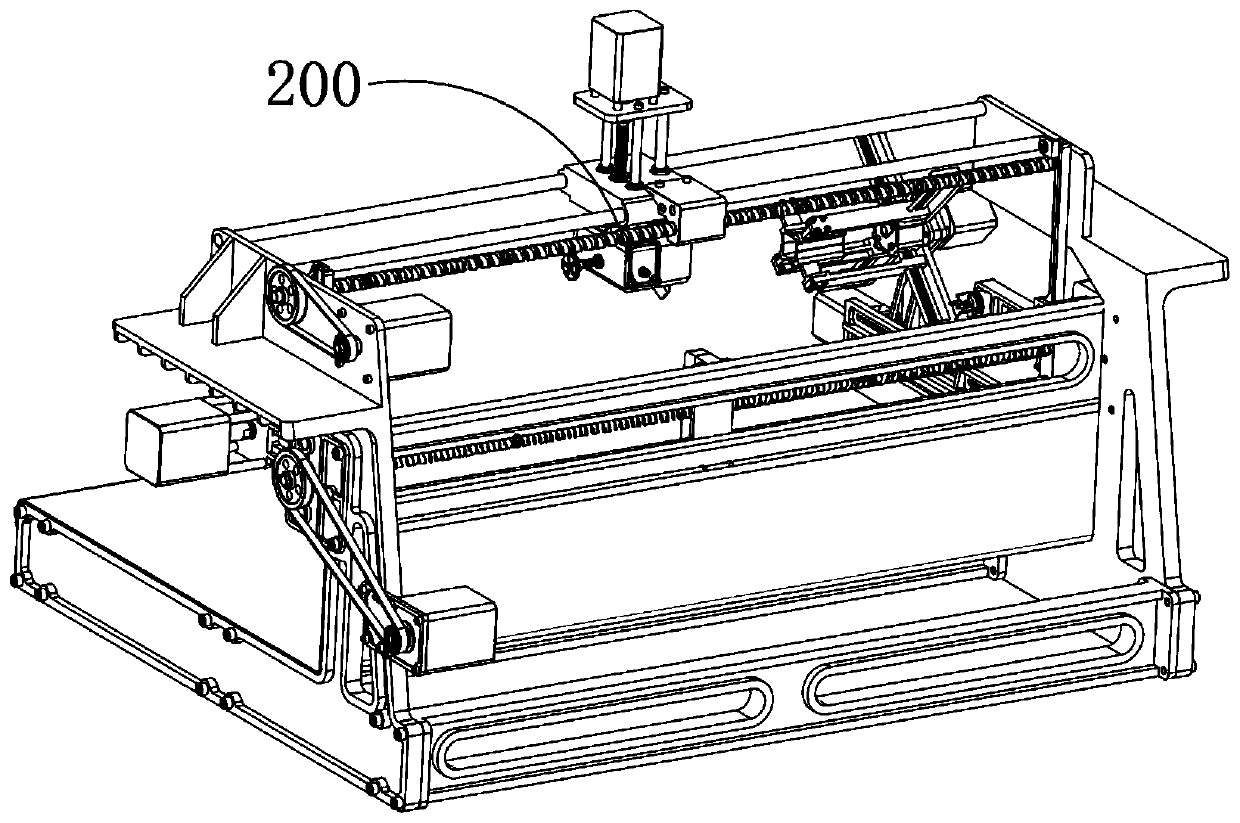

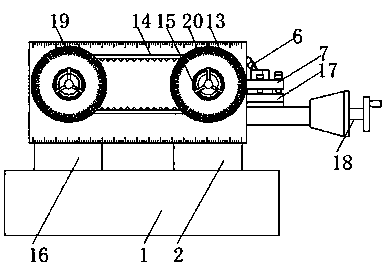

High-precision multi-shaft automatic turning process of wood

ActiveCN109866289ARealize self-centering clampingIngenious structureWood-turning machinesMotor driveEngineering

The invention provides a high-precision multi-shaft automatic turning process of wood. The high-precision multi-shaft automatic turning process comprises the steps that firstly, one end of a rodlike wood workpiece is inserted between clamping corner blocks of a self-centering feeding mechanism, the clamping corner blocks are close to each other and do synchronous movement, and the rodlike wood workpiece is subjected to self-centering clamping; then a feeding motor drives a first supporting frame to slide close to a first sliding block along a feeding guide rod until the wood workpiece clampedby the clamping corner blocks is conveyed into the space between a first tip and a second tip, and the rodlike wood workpiece and the two clamping ends of a clamping mechanism are coaxial; then the clamping mechanism is started to operate, and the two ends of the rodlike wood workpiece are clamped; then the feeding motor is started to rotate reversely, a clamping motor is started to rotate reversely, and the self-centering feeding mechanism is reset; and finally, a spindle motor drives the rodlike wood workpiece to rotate at high speed, a transverse driving mechanism and a lifting driving mechanism cooperate to drive a turning tool to carry out feeding in the transverse direction and the longitudinal direction, and the rotary rodlike wood workpiece is cut through the turning tool.

Owner:惠民县创大木业有限公司

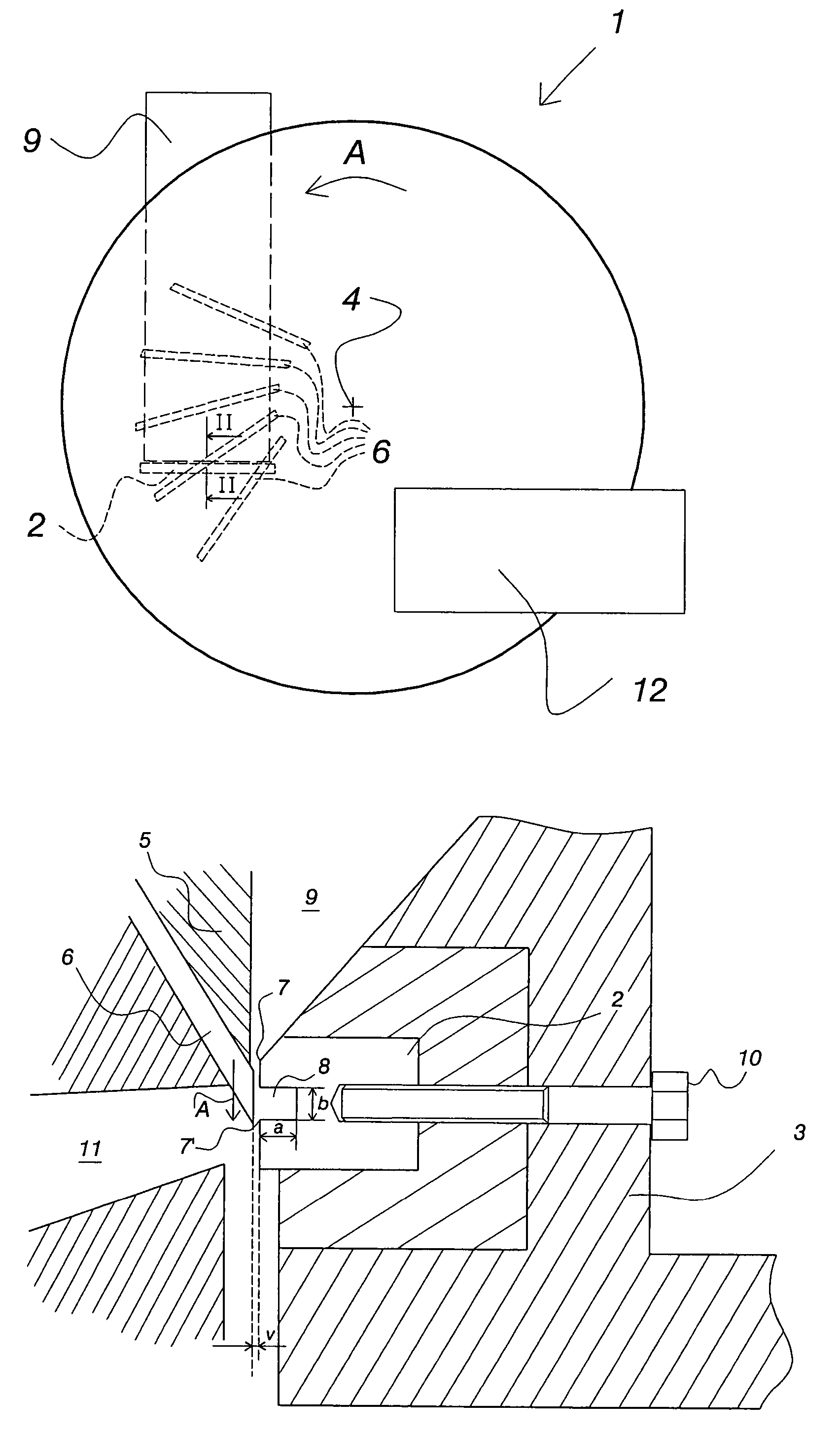

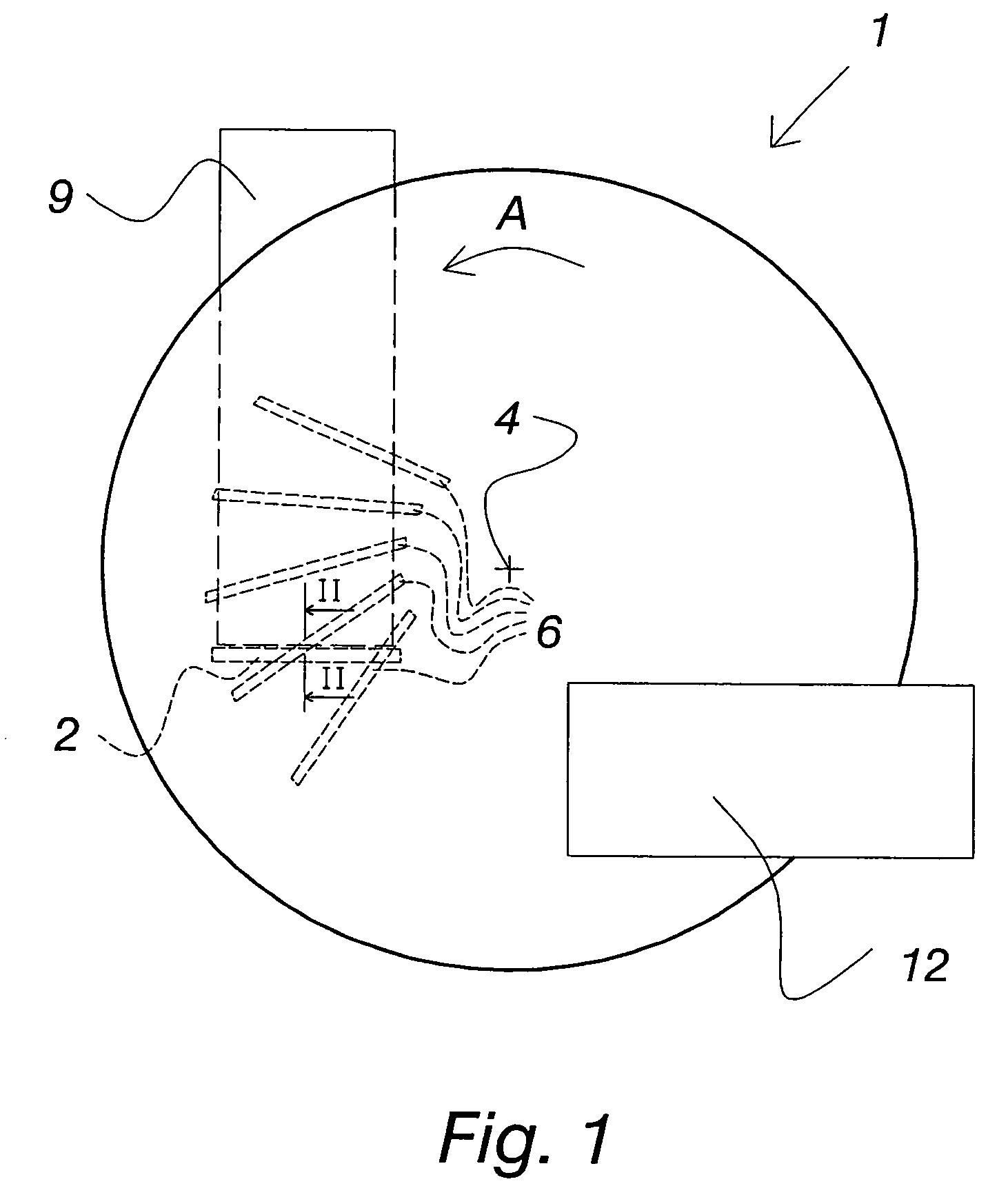

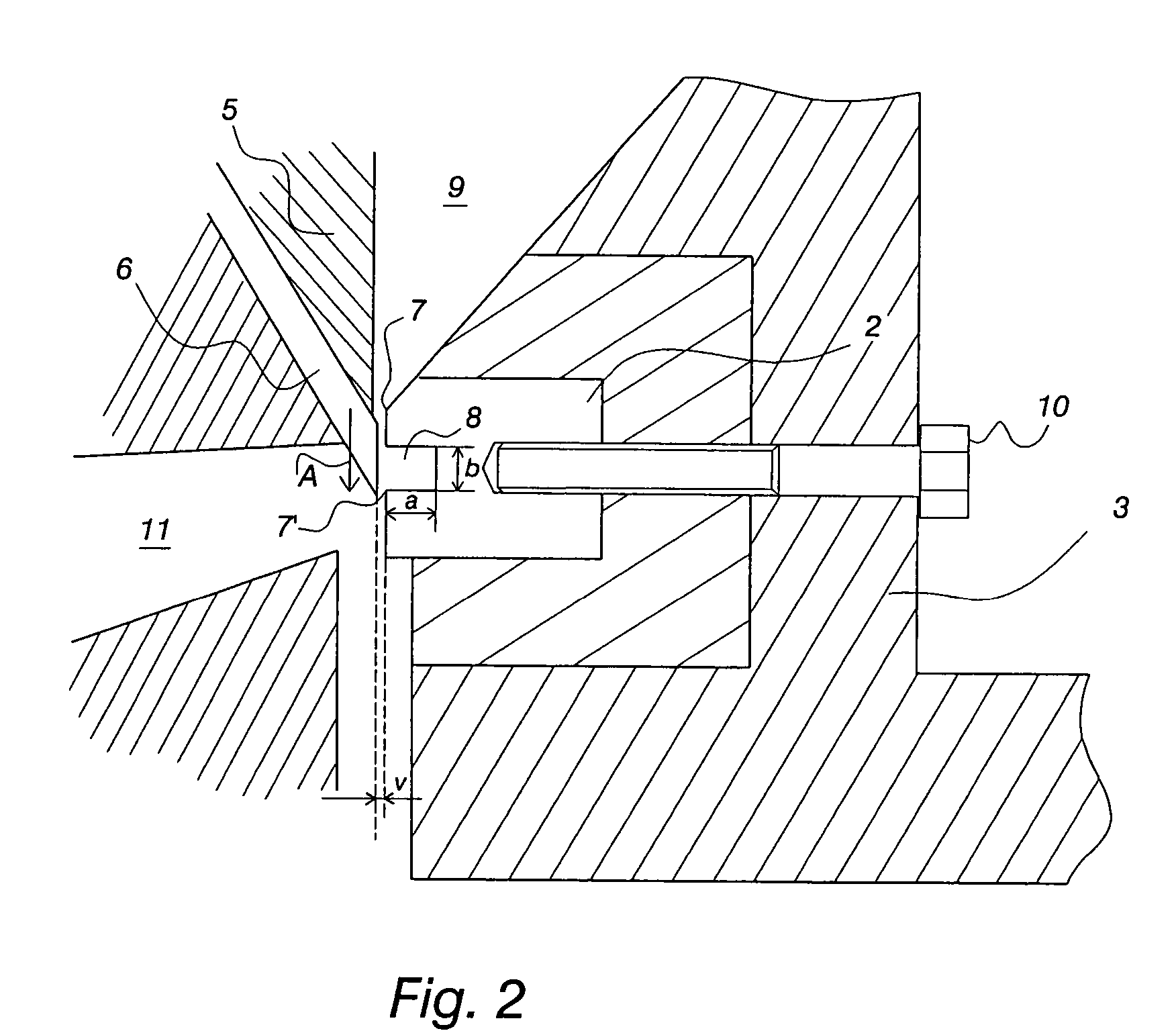

Chipper bed knife

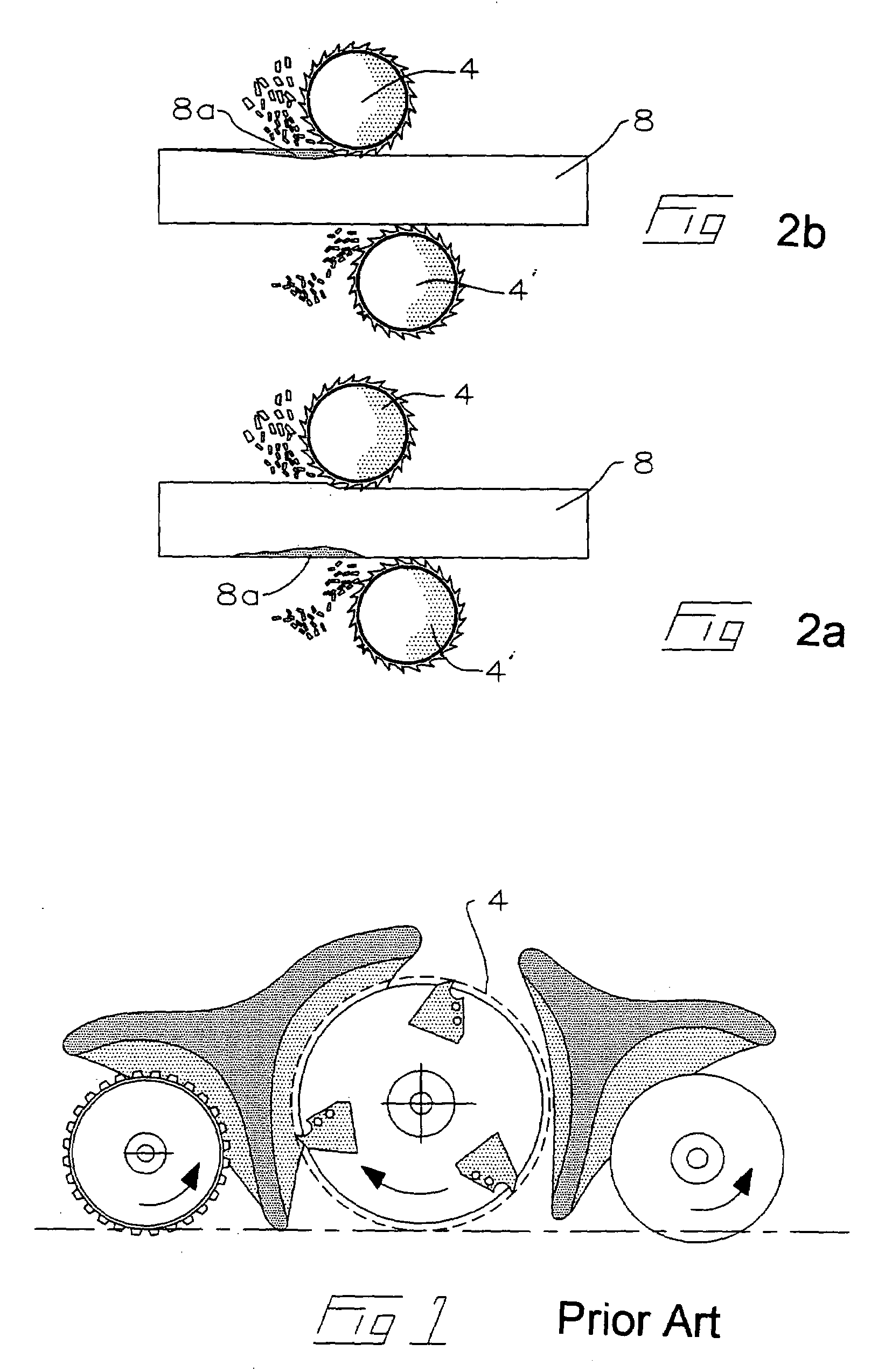

InactiveUS7267146B2Easy to replaceMulti-purpose machinesWood-turning machinesStructural engineeringMechanical engineering

The invention relates to a chipper (1) bed knife (2) attached detachably to the chipper frame (3), the chipper (1) having a chipper disc (5) supported on its shaft (4), which shaft is fitted rotatably to the chipper frame (3), the chipper disc (5) comprising a number of knives (6) arranged to pass the knife edge (7) of the bed knife (2) at a distance corresponding to the required knife clearance (v), when the chipper disc (5) is rotating. The bed knife (2) also has a second knife edge (7′), the said knife edges (7, 7′) being arranged at a distance from each other in the direction of movement (A) of the chipper disc (5) knives (6). A groove (8) is formed in the bed knife (2) between the said knife edges (7, 7′).

Owner:ANDRIZ OY

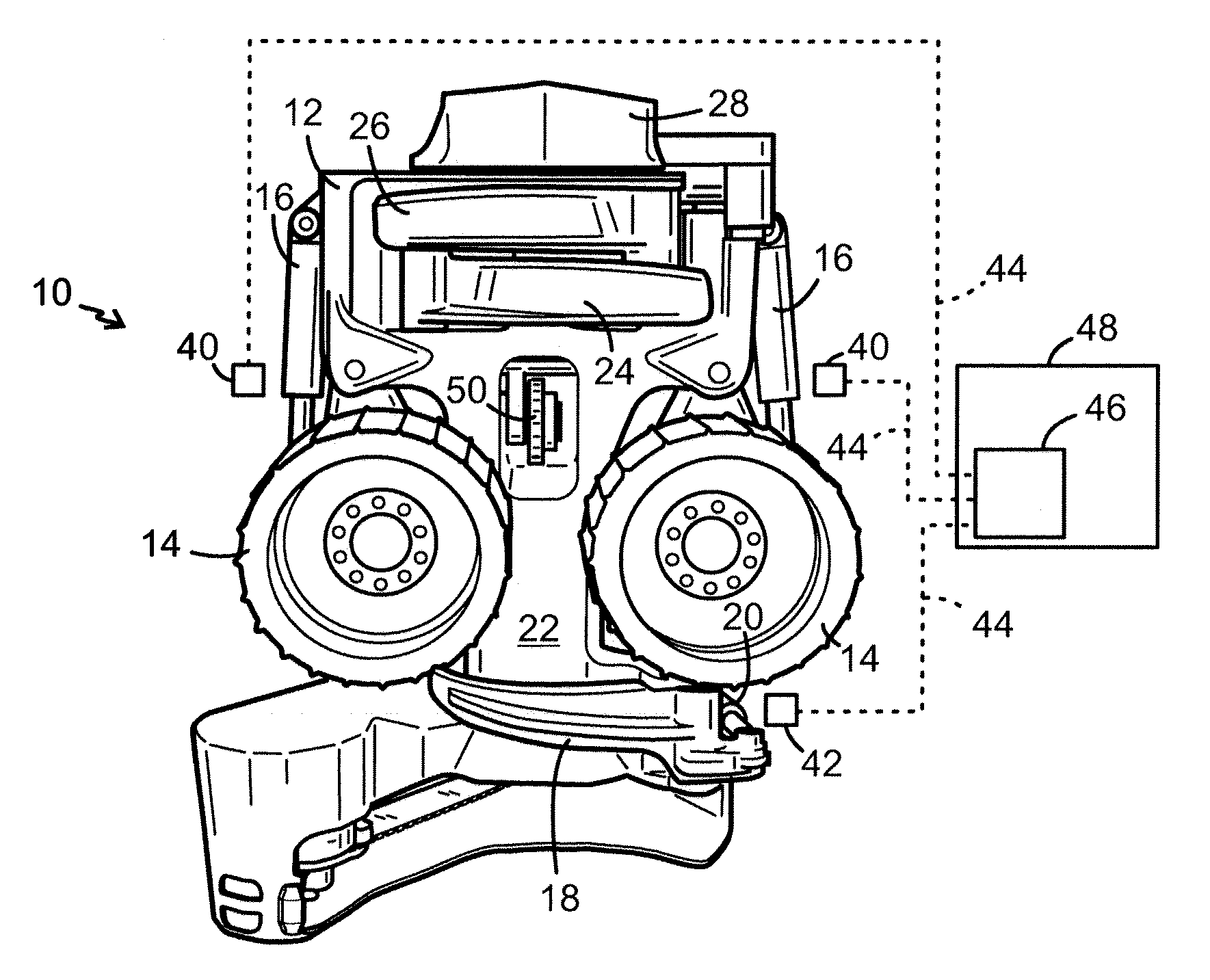

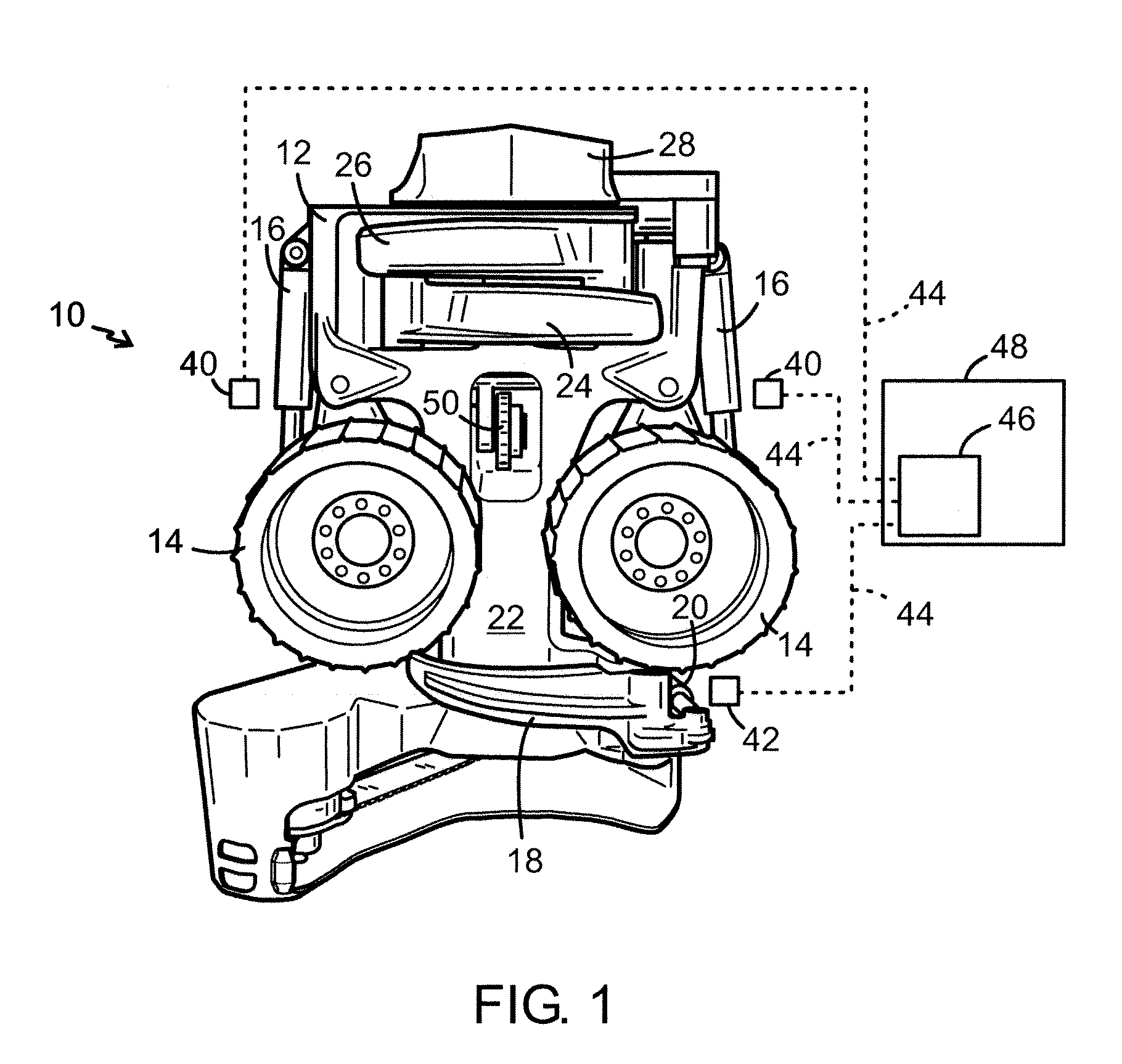

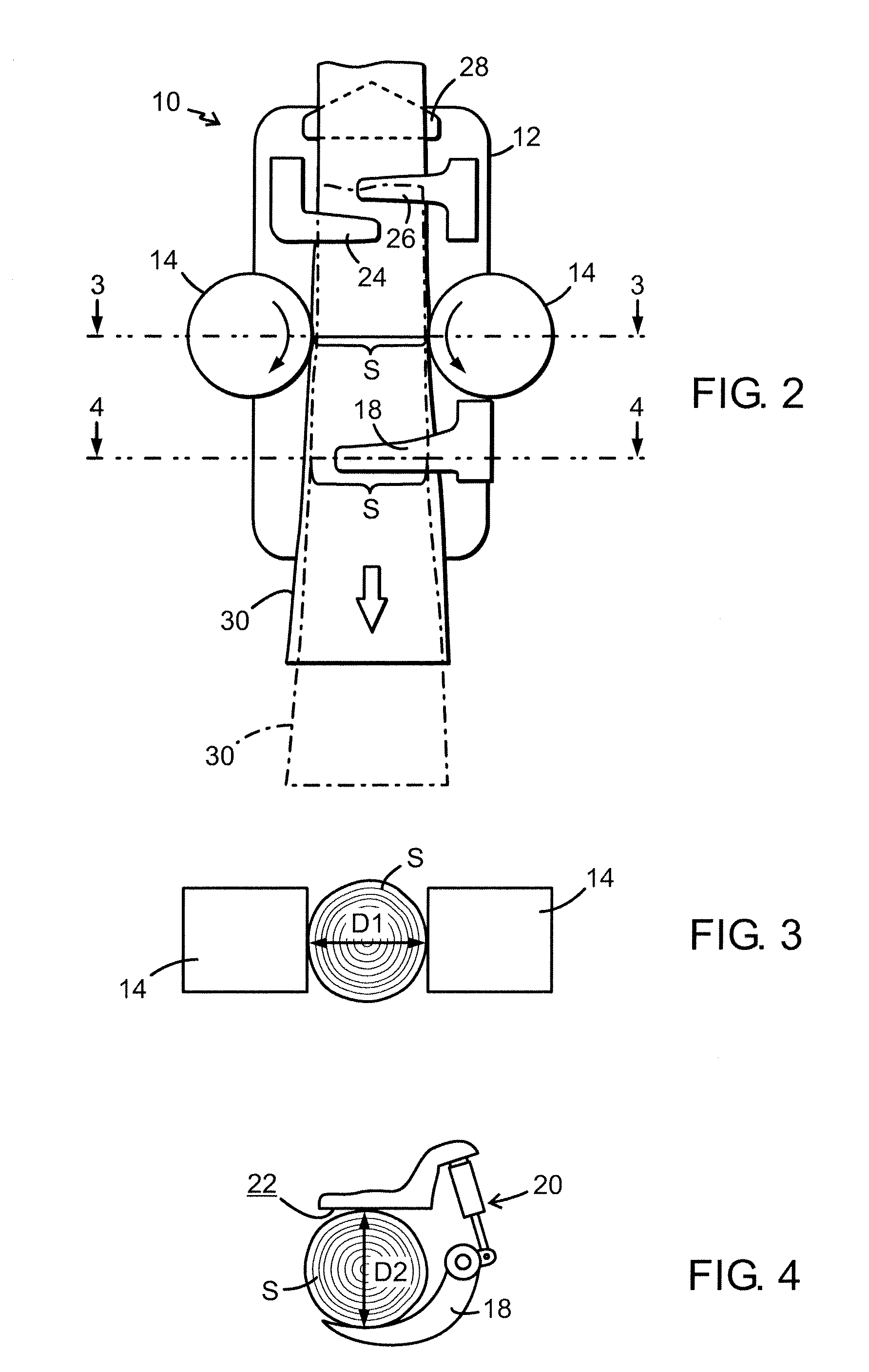

Determination of thickness of a tree trunk

Method and device for the determination of a thickness of a cross-section (S) of a tree trunk (30) received in a harvesting assembly (10) comprising a pair of opposite feed wheels (14) engaging with the tree trunk and a delimbing knife (18) abutting against the tree trunk. The mutual position of the feed wheels is detected as a measure of a transverse dimension (D1) of the cross-section of the tree trunk. The position of the delimbing knife (18) in relation to an abutment surface (22) of the tree trunk opposite thereto is detected as a measure of an additional transverse dimension (D2) of the cross-section (S) of the tree trunk, which additional transverse dimension forms an essentially right angle with the first-mentioned transverse dimension. The thickness of the cross-section (S) of the tree trunk is calculated based on the two measures of the transverse dimensions (D1, D2).

Owner:LOG MAX

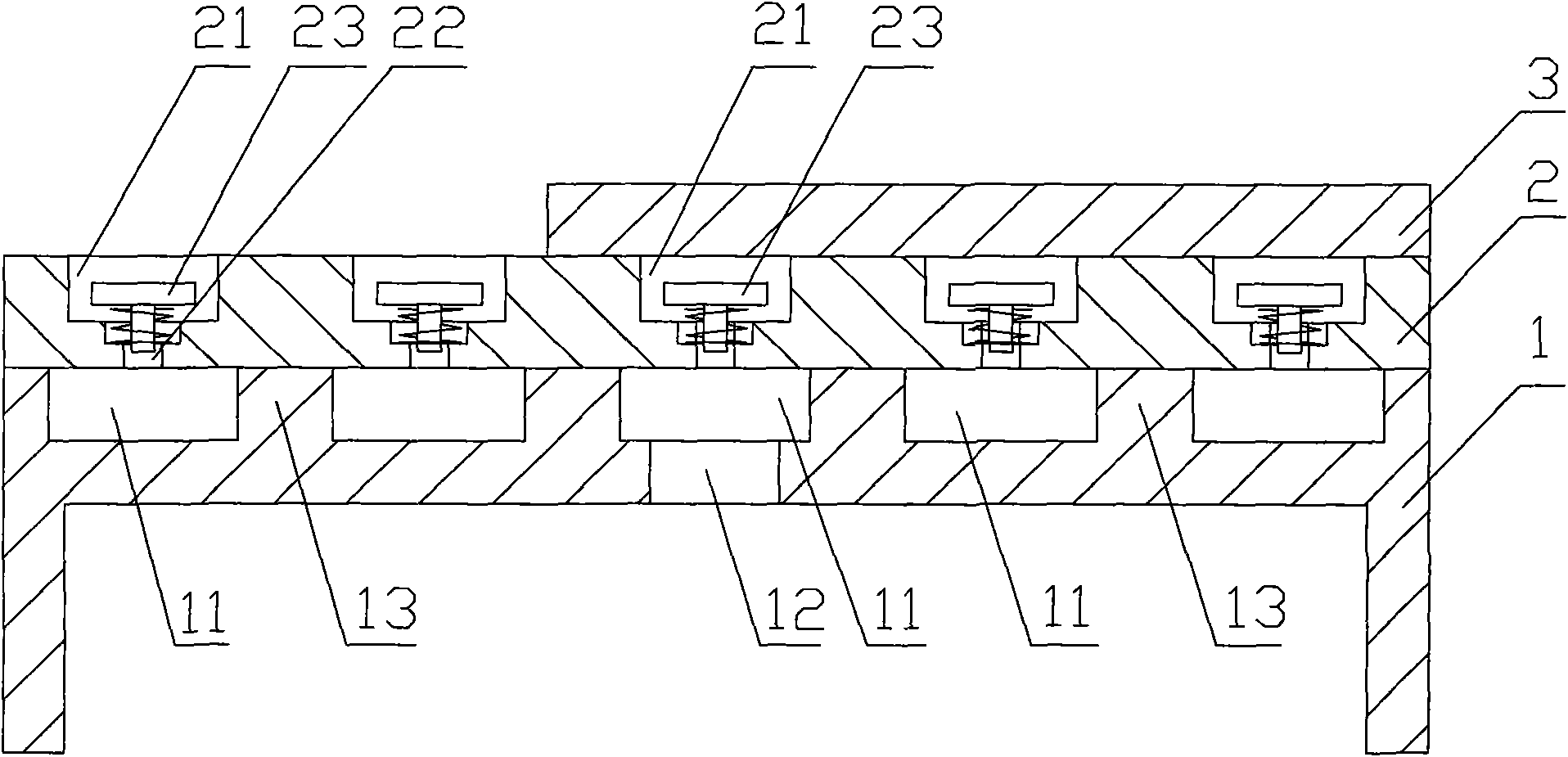

Automatic vacuum-adsorption working table

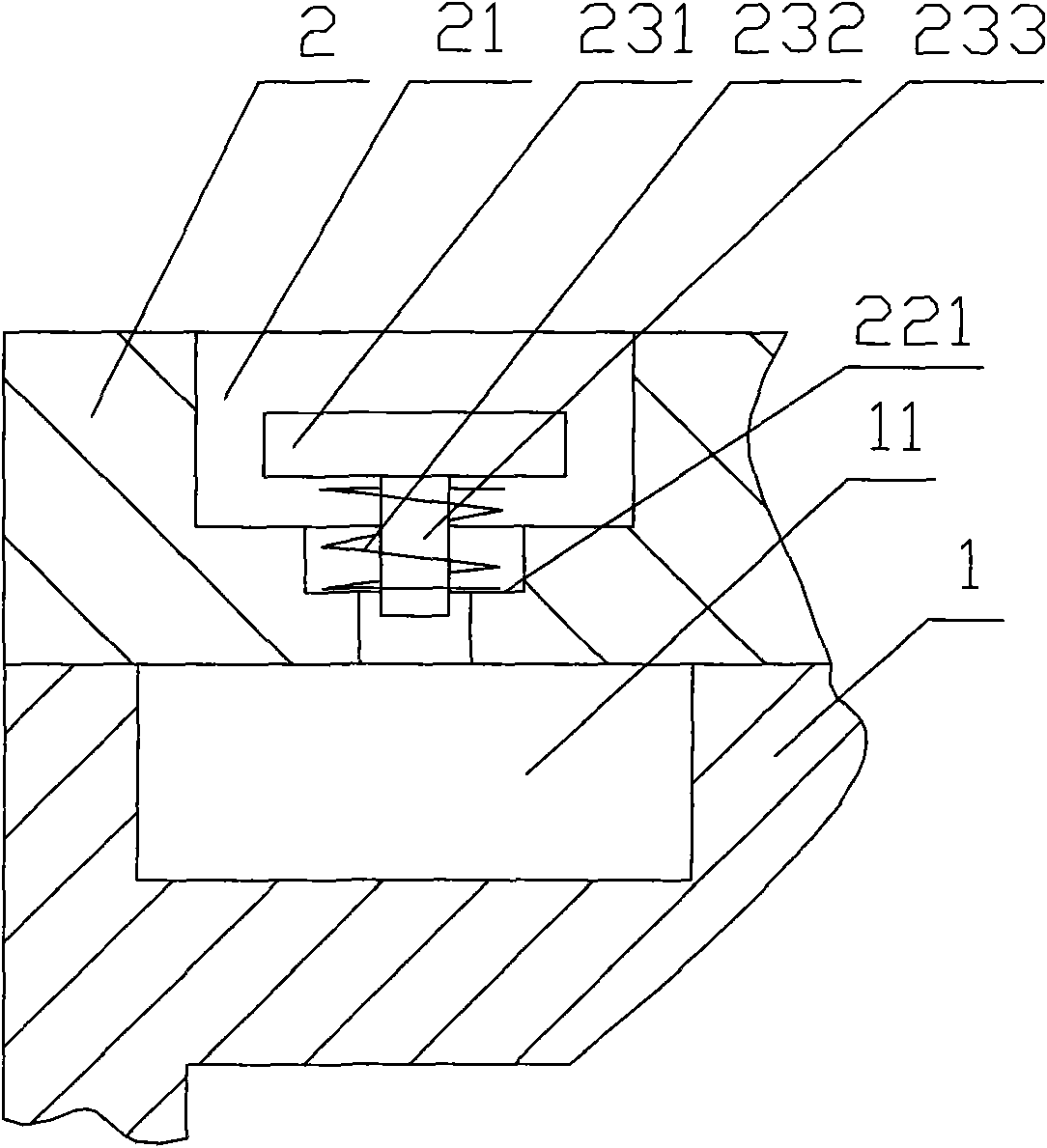

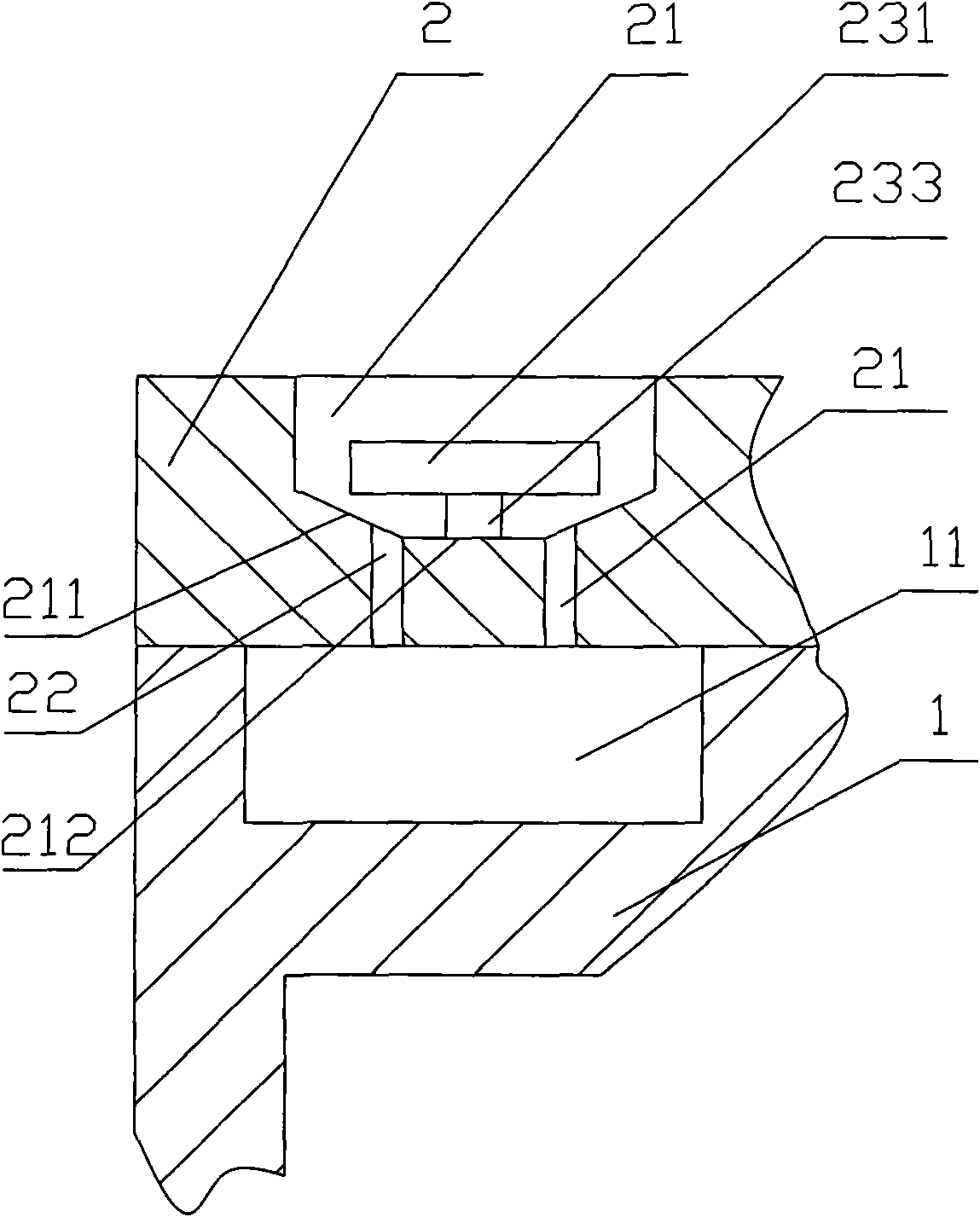

ActiveCN101870125AGuaranteed adsorption effectGuaranteed vacuumWood-turning machinesAtmospheric airPulp and paper industry

The invention discloses an automatic vacuum-adsorption working table. The working table comprises a vacuum working table (1) and an adsorption working table (2), wherein a vacuum groove (11) is formed on the vacuum working table (1) and communicated with a suction hole (12); the adsorption working table (2) and the vacuum working table (1) are overlapped up and down, and the edges thereof are in sealed connection; the adsorption working table (2) is provided with a plurality of adsorption grooves (21) which are communicated with the vacuum groove (11); and an automatic closing device (23) is arranged in each of the adsorption grooves (21). An automatic adsorption device is arranged in each of the adsorption grooves of the adsorption working table, as a result, when the working table is used, the adsorption holes which are not covered by wood plates can be automatically closed under the action of atmospheric pressure, which ensures the vacuum degree in the adsorption grooves and the vacuum groove and the adsorption capability of the adsorption working table to the wood plates.

Owner:杨岚

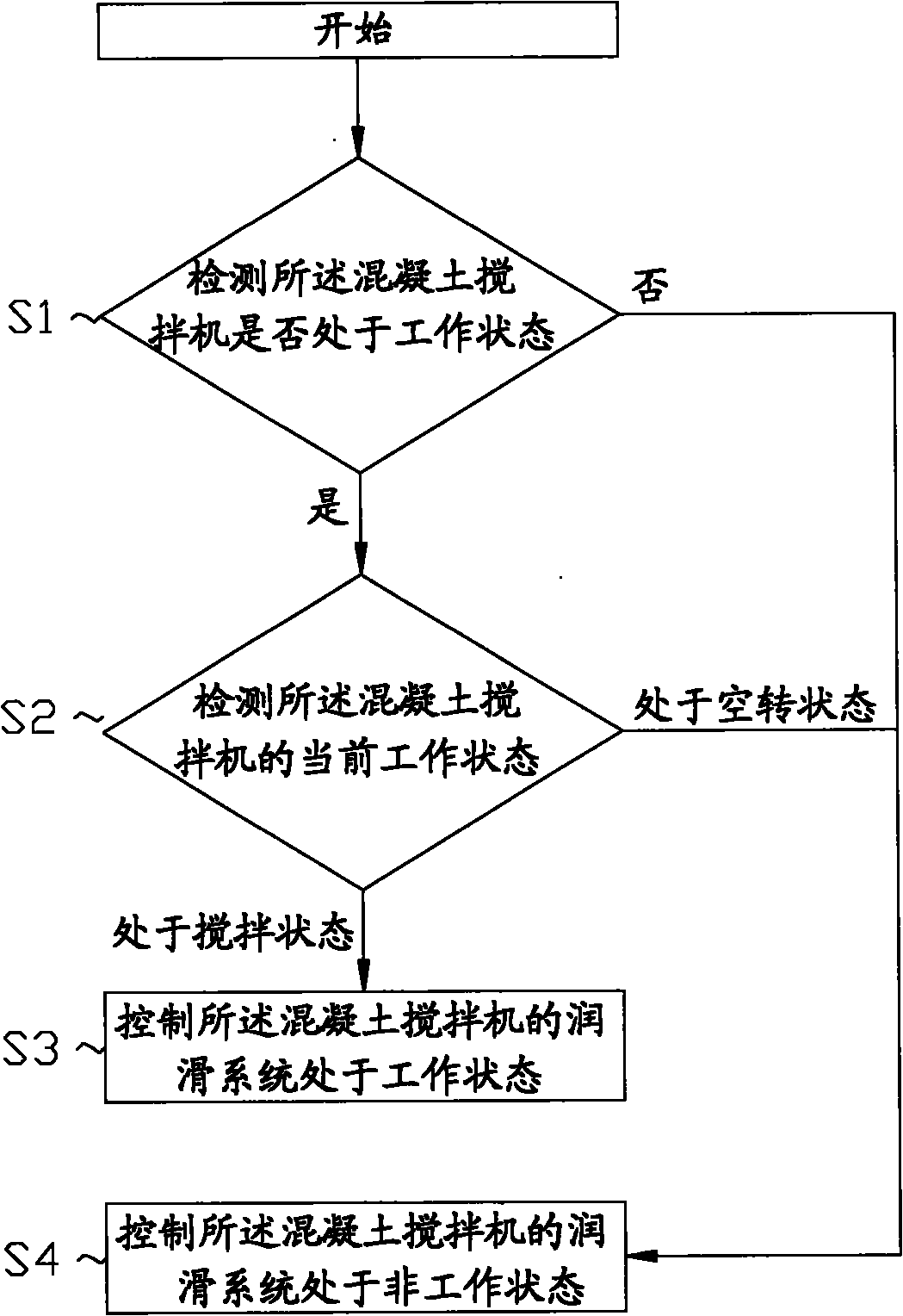

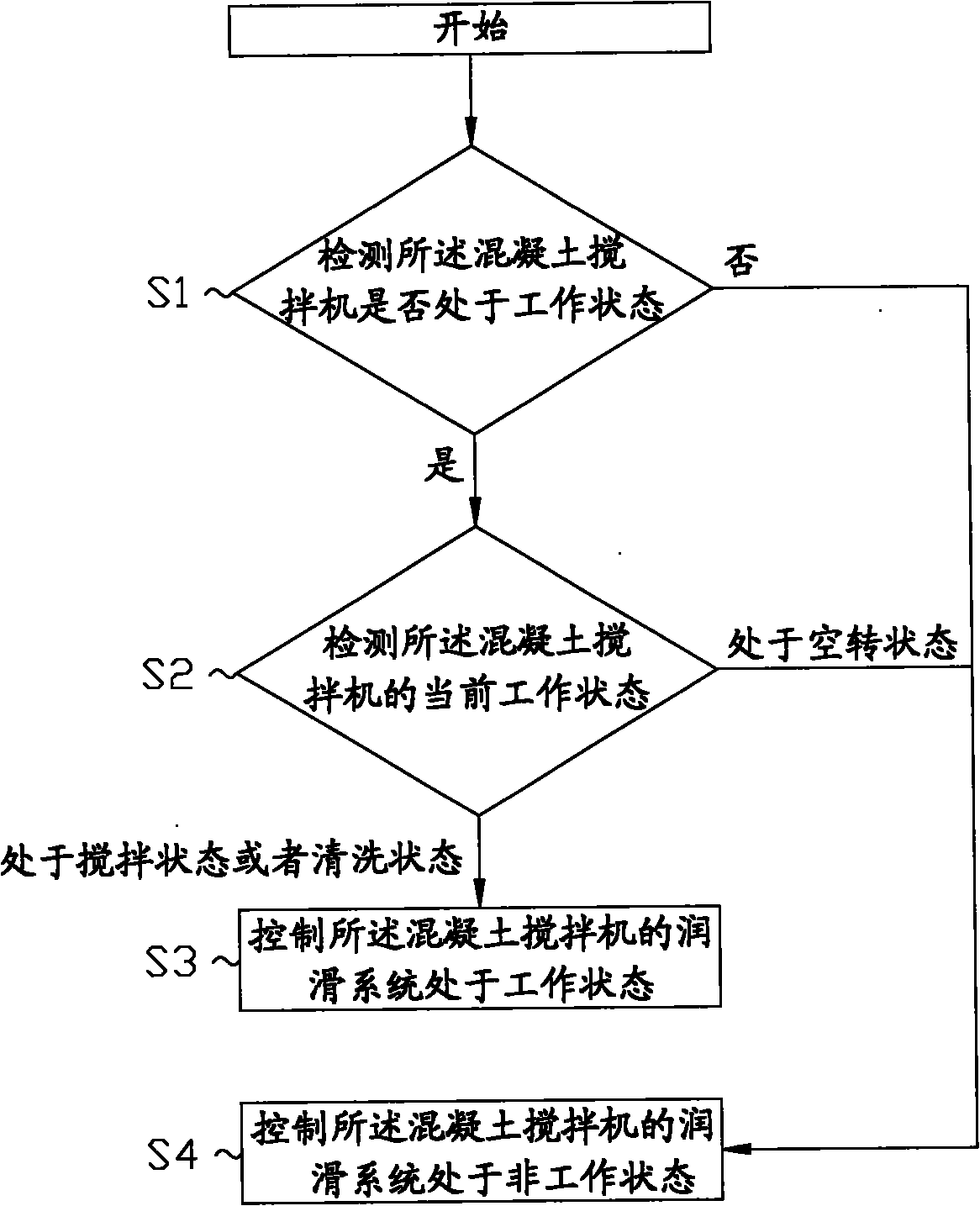

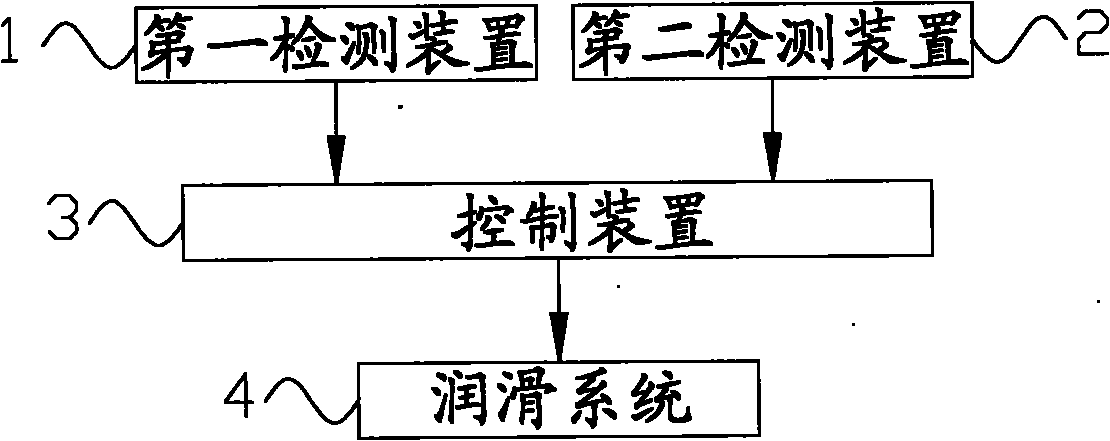

Concrete mixer and lubrication oil supply control system and method thereof

The invention discloses a lubricating oil supply control method, which is used for a concrete mixer and controlling the work of a lubricating system according to the work state of the concrete mixer; when the concrete mixer is in a mixing state, the lubricating oil supply control method is used for controlling the lubricating system of the concrete mixer to be in the work state; and when the concrete mixer is in an idle state, the lubricating oil supply control method is used for controlling the lubricating system of the concrete mixer to be in the non-work state. The lubricating oil supply control method not only ensures the requirements of the concrete mixer on the lubricating performance and the sealing performance, but also avoids the waste of lubricating oil caused by the lubricationwhen lubricating oil supply is not required and reduces the using cost. The invention also discloses a lubricating oil supply control system and the concrete mixer comprising the lubricating oil supply control system.

Owner:SANY HEAVY IND CO LTD (CN)

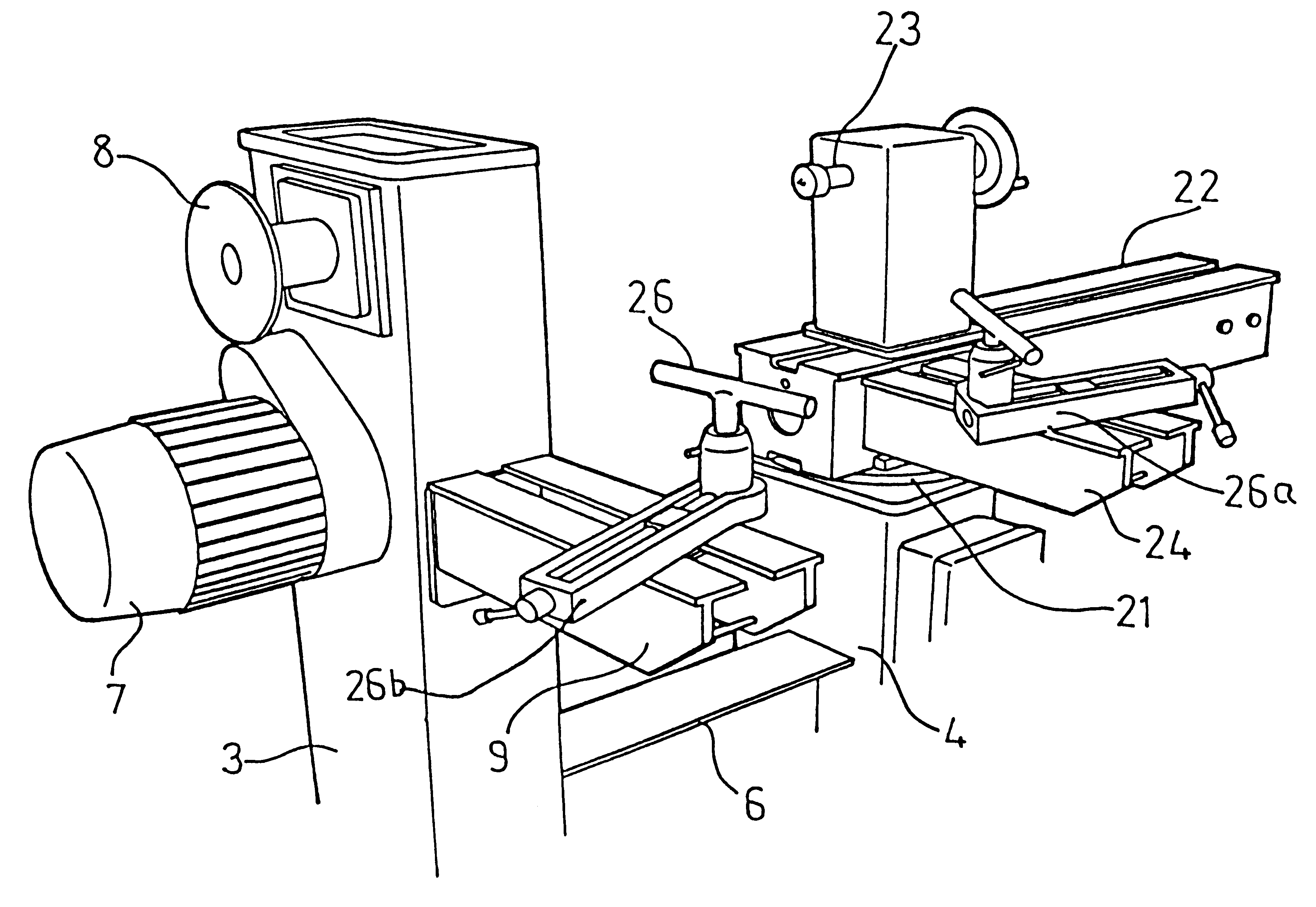

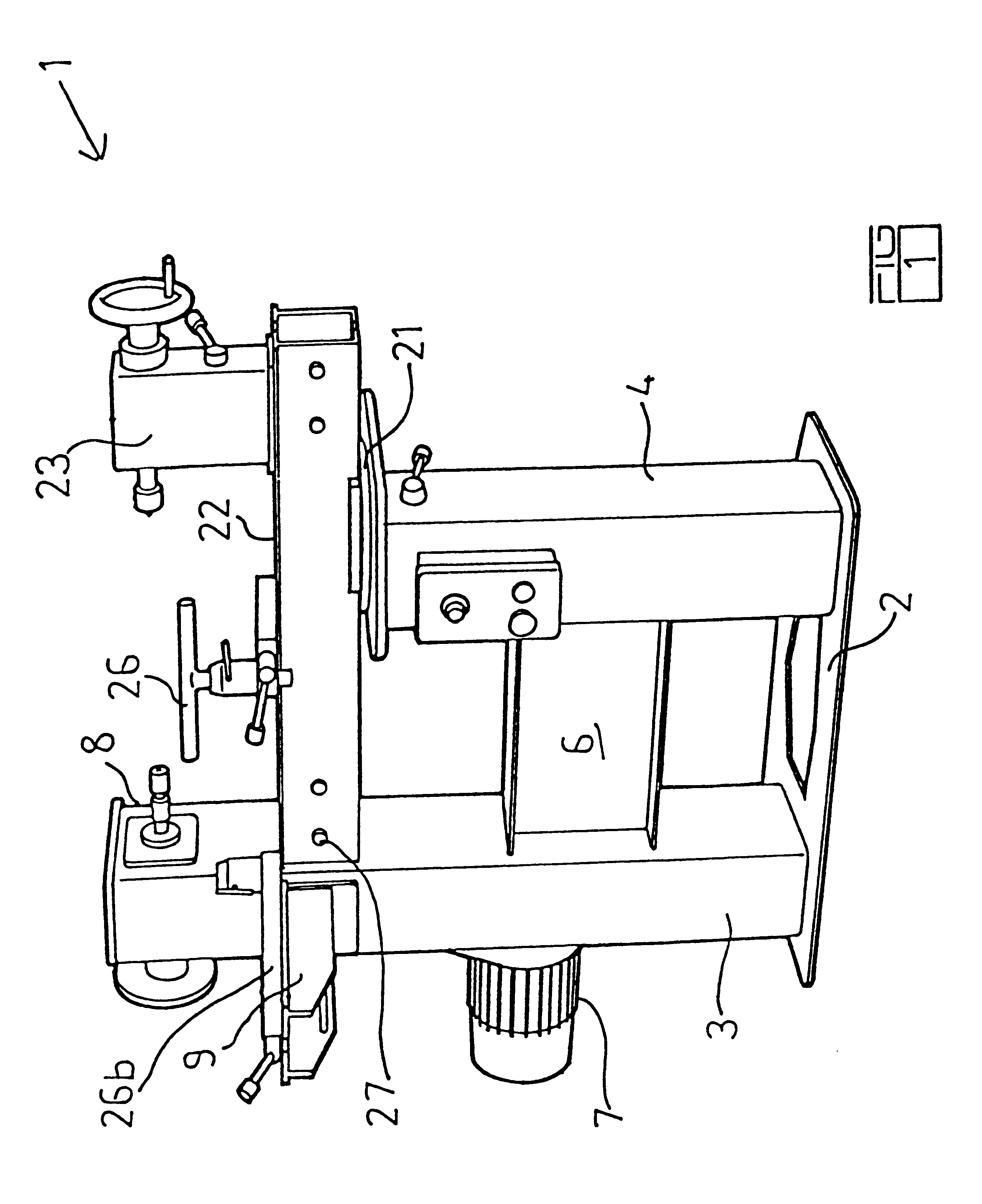

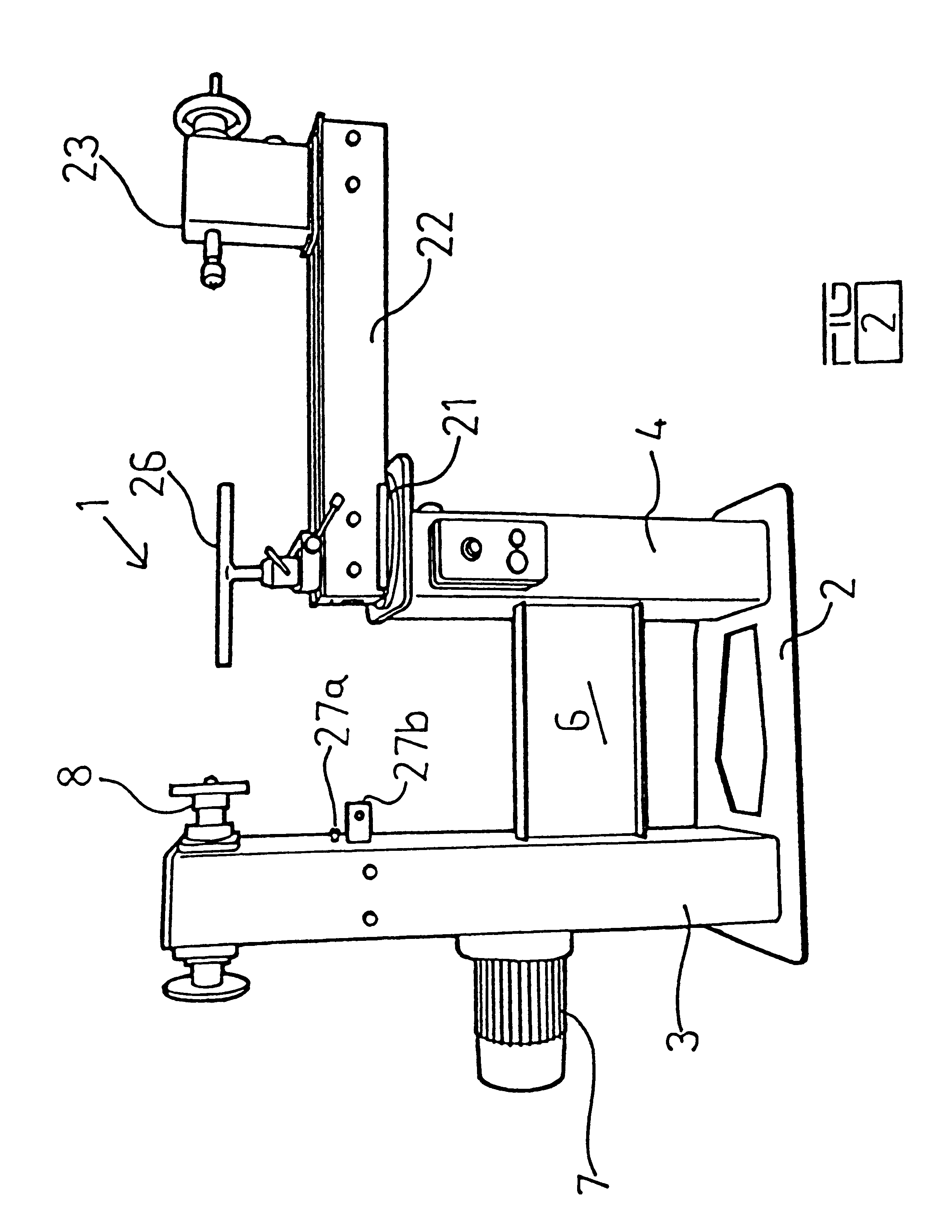

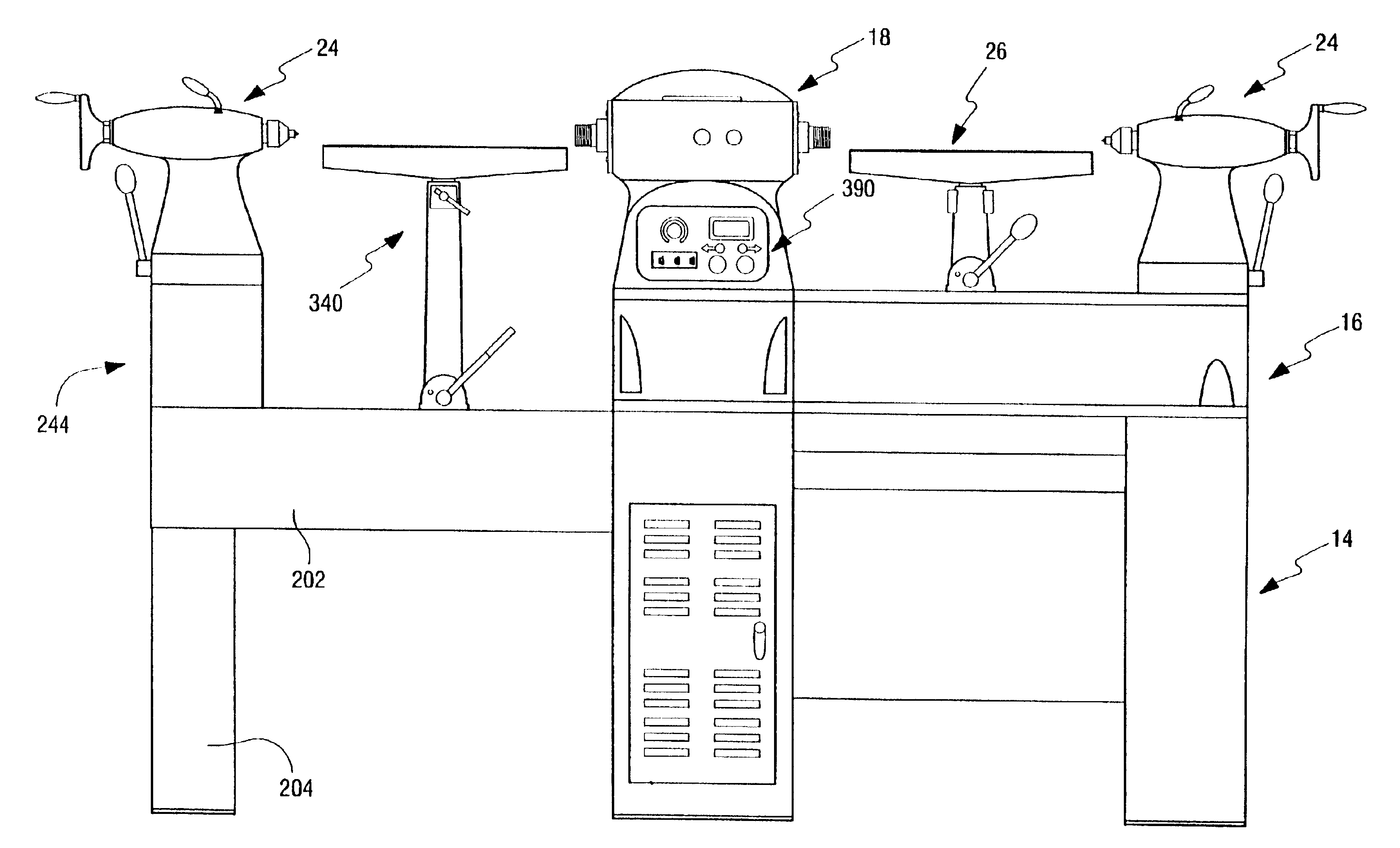

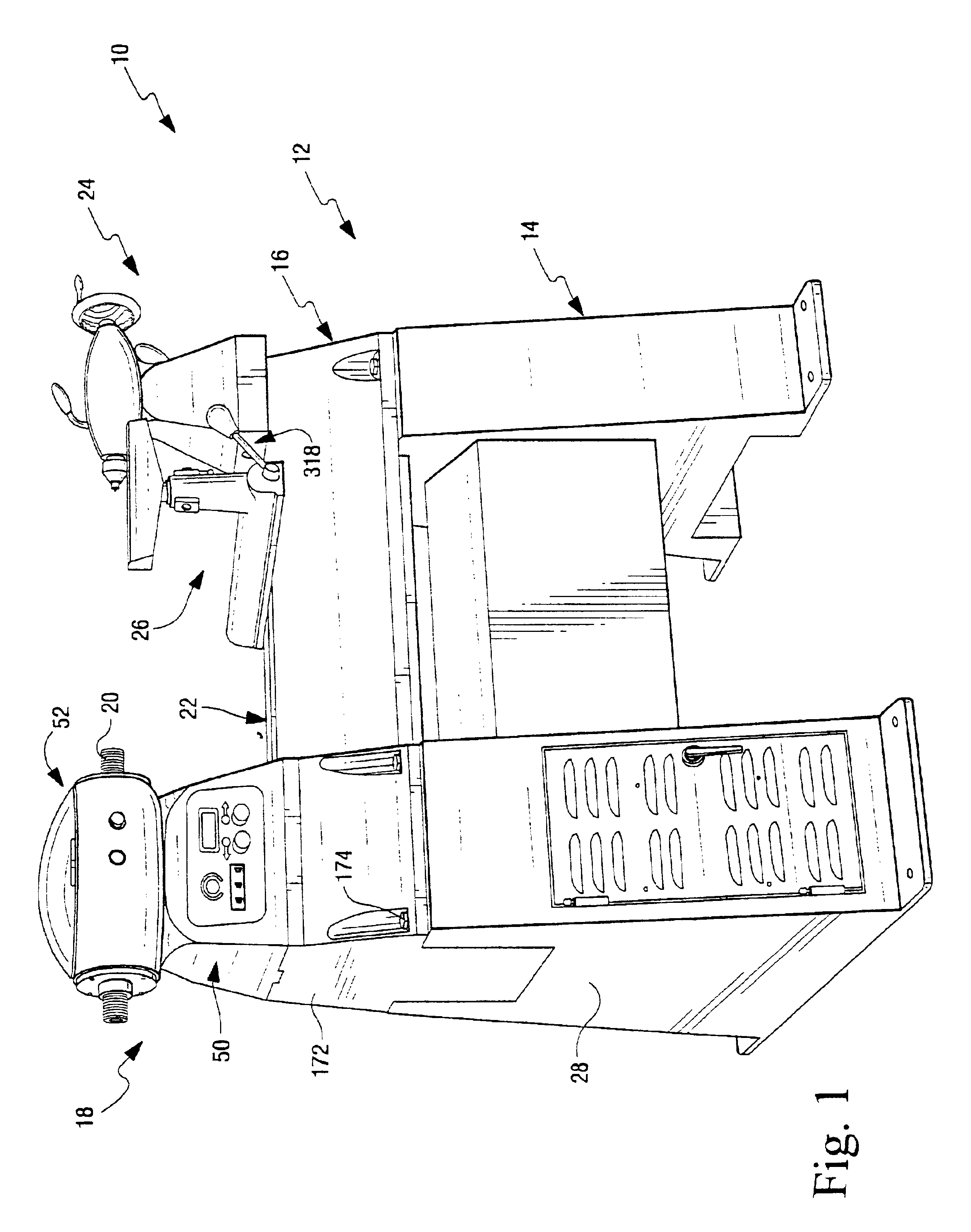

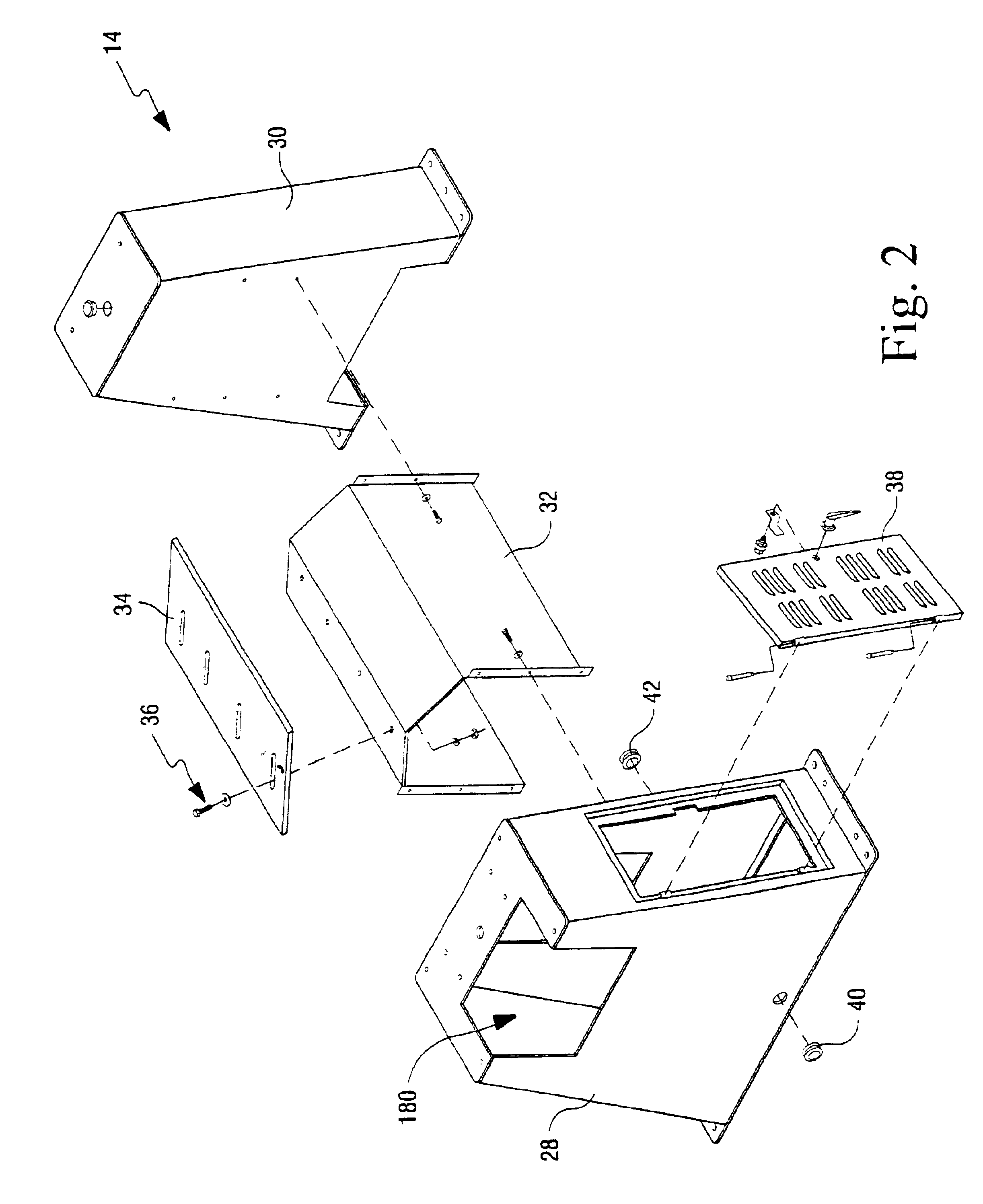

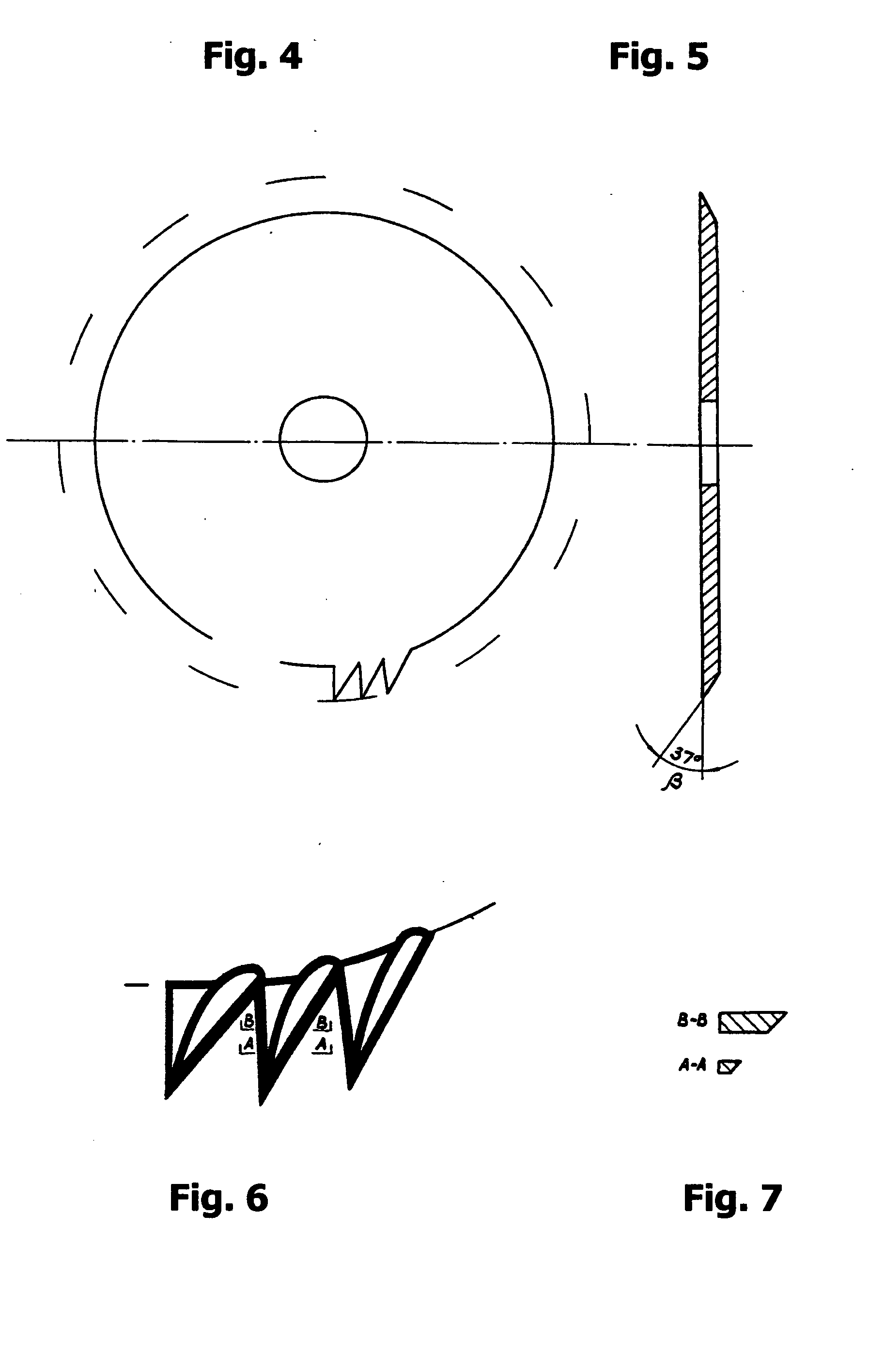

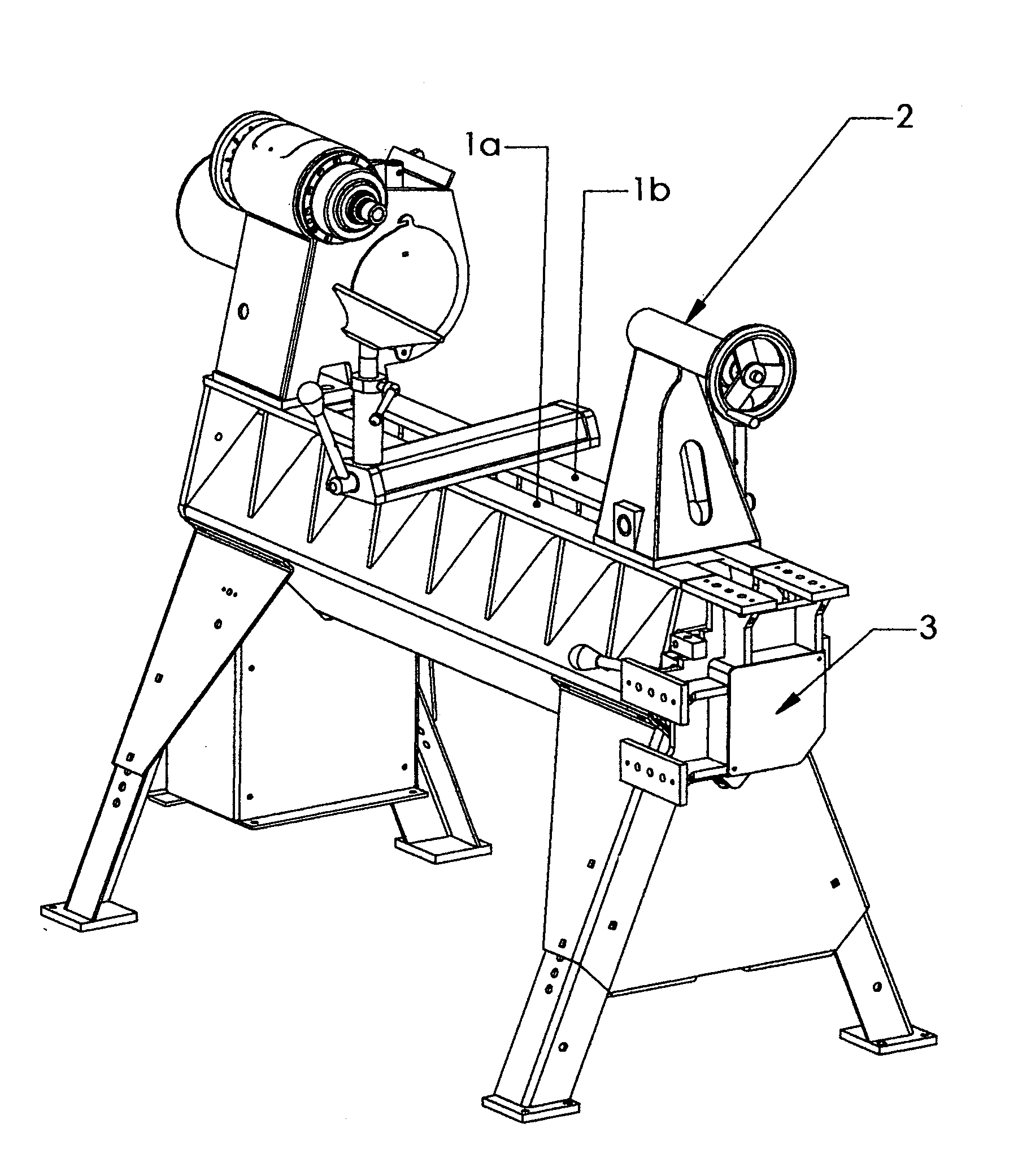

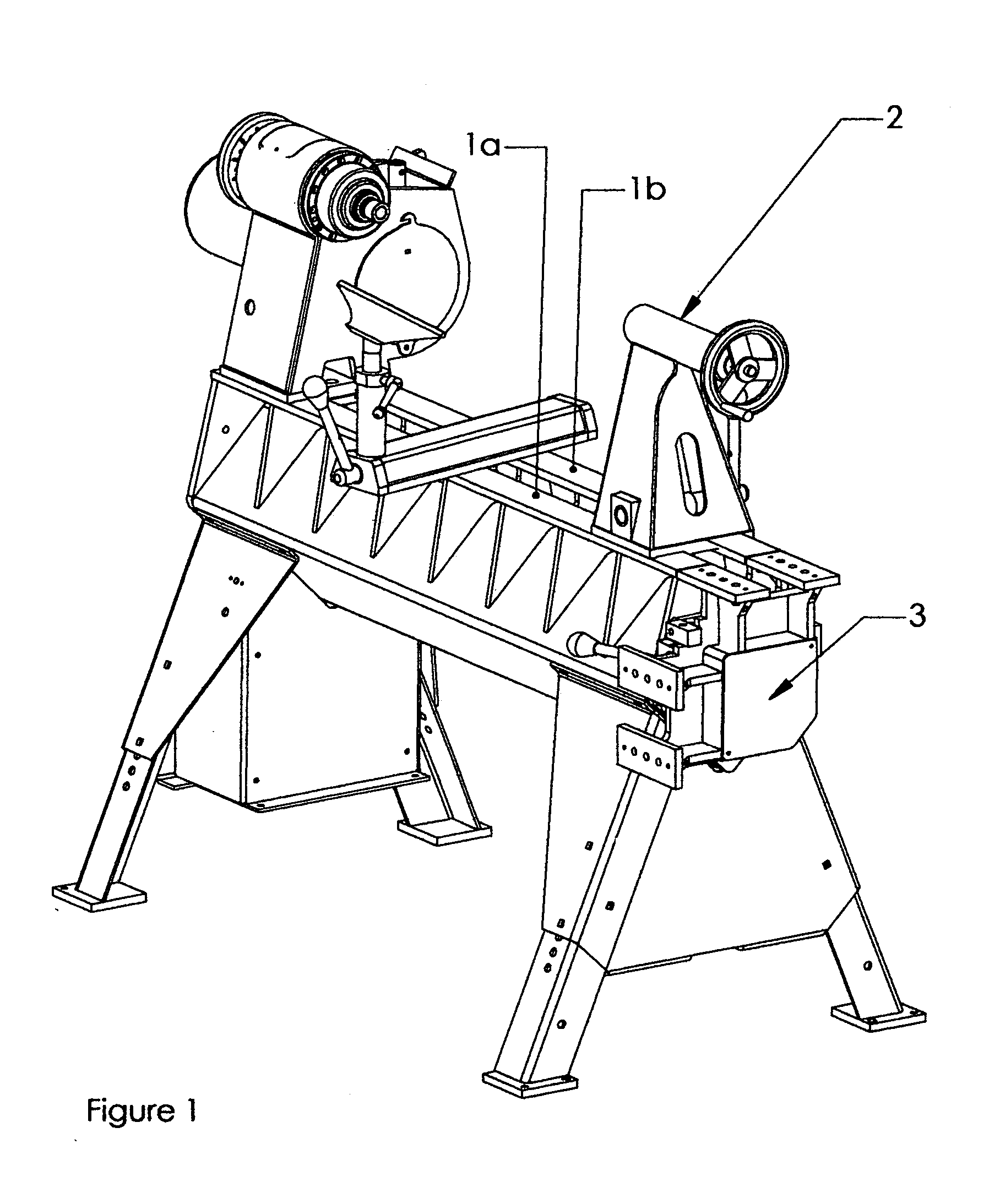

Lathe apparatus

InactiveUS7011002B2Eliminates shaft-flexAvoid accessAutomatic/semiautomatic turning machinesAttachable milling devicesMotor driveEngineering

The lathe provided in accordance with the invention is designed to address the needs of today's bowl and spindle turners. In an exemplary embodiment, the lathe of the invention comes equipped with a 2 hp DC BALDOR motor and a state-of-the-art 3 hp MINARIK pulse-width modulated (PWM) motor drive. It has a continuous power rating of 2 hp and an effective intermittent power rating of nearly 3 hp. The lathe has three speed ranges: 0 to 600 rpm for large bowl turning, 0 to 1200 rpm for standard bowl turning and 0 to 2000 for high-speed bowl turning and finishing. A number of accessory bed extensions are available along with an outboard tool rest and tailstock.

Owner:WOODWORKERS SUPPLY

Method for producing brick by using shale and feldspathic sandstone

InactiveCN101450851AHigh strengthThe characteristics of high strength, in addition, the weight of the fired brick of the present invention is highSolid waste managementWood-turning machinesSocial benefitsBrick

The invention discloses a method for manufacturing bricks by utilization of shale and sandstone, which comprises: mixing the shale, the sandstone, coal refuse and coal dust according to the ratio of 20-25:65-70:10-15:0.25-0.3 by weight portion; adding 15 to 20 weight portions of water into the mixture to be stirred and manufactured into green bricks; placing the green bricks into a kiln for sintering after drying the green bricks, wherein the sintering temperature is between 950 and 1,050 DEG C, and the sintering time is between 20 and 24 hours; and drawing the bricks out of the kiln after performing heat preservation for 5 to 6 hours. The sintered bricks have the advantages of weather resistance, alkali resistance, high strength and light weight. The method changes waste into valuable, saves farmlands, protects land resources, and has good social benefit and economic benefit.

Owner:冯玉存

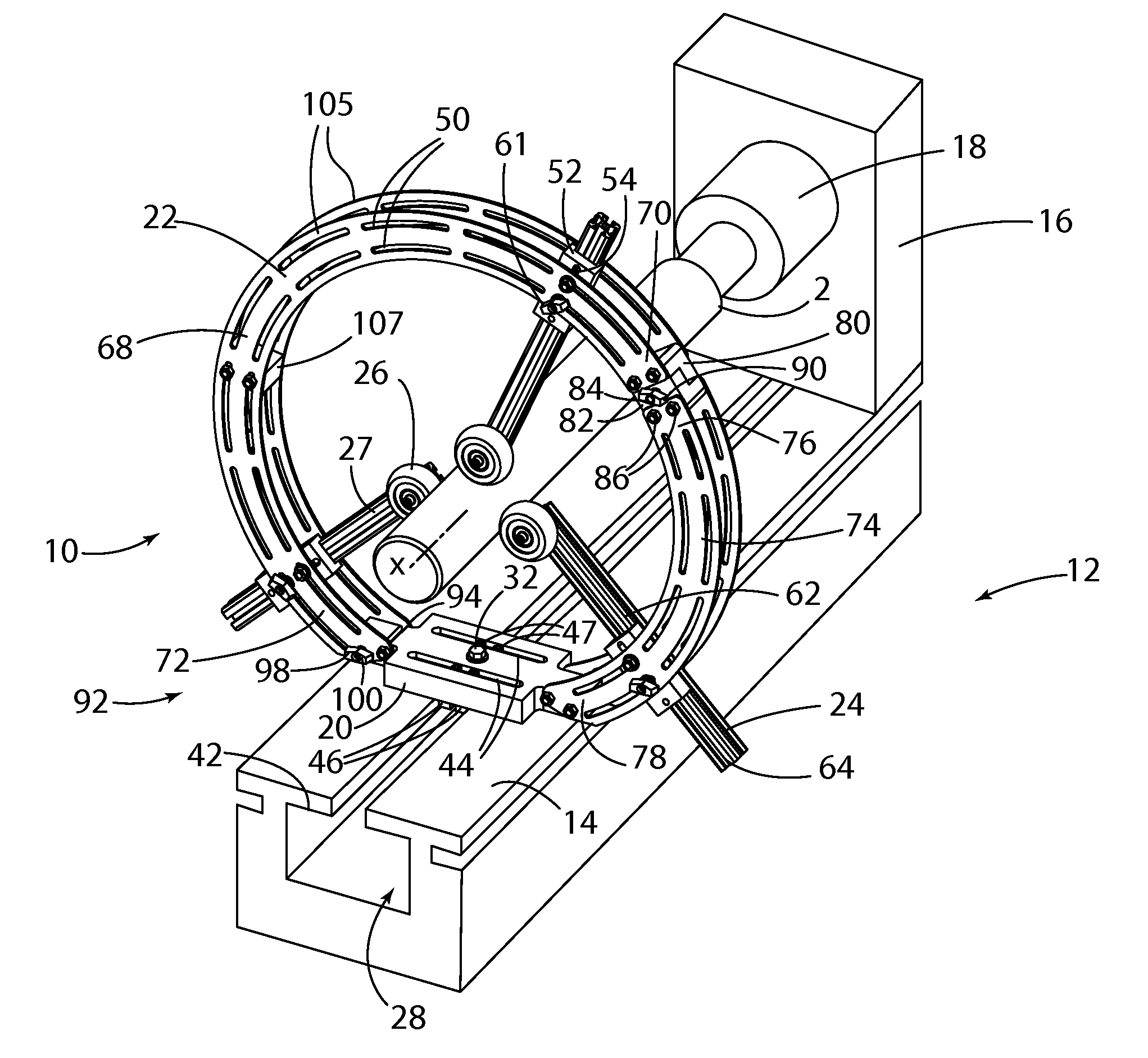

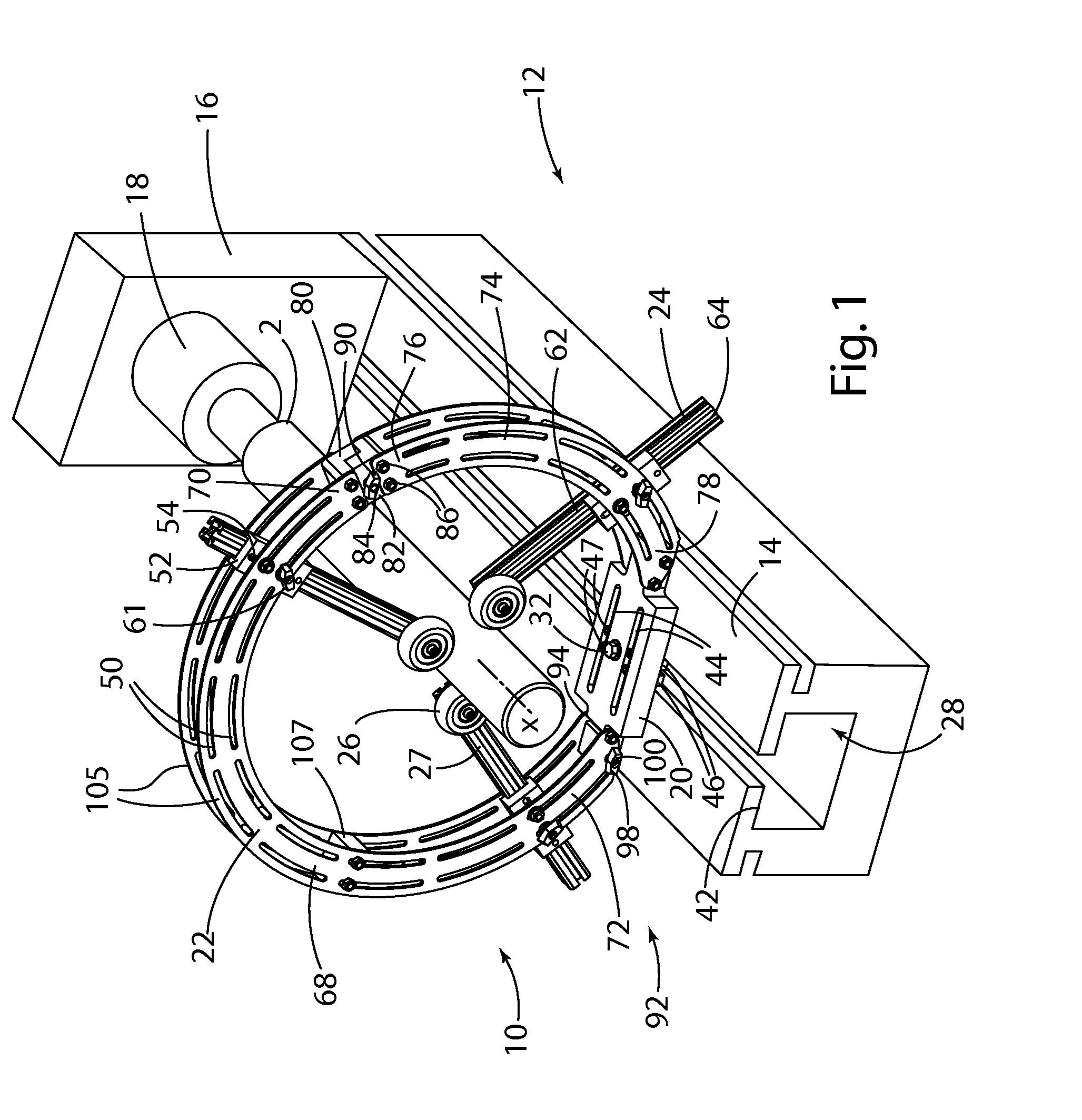

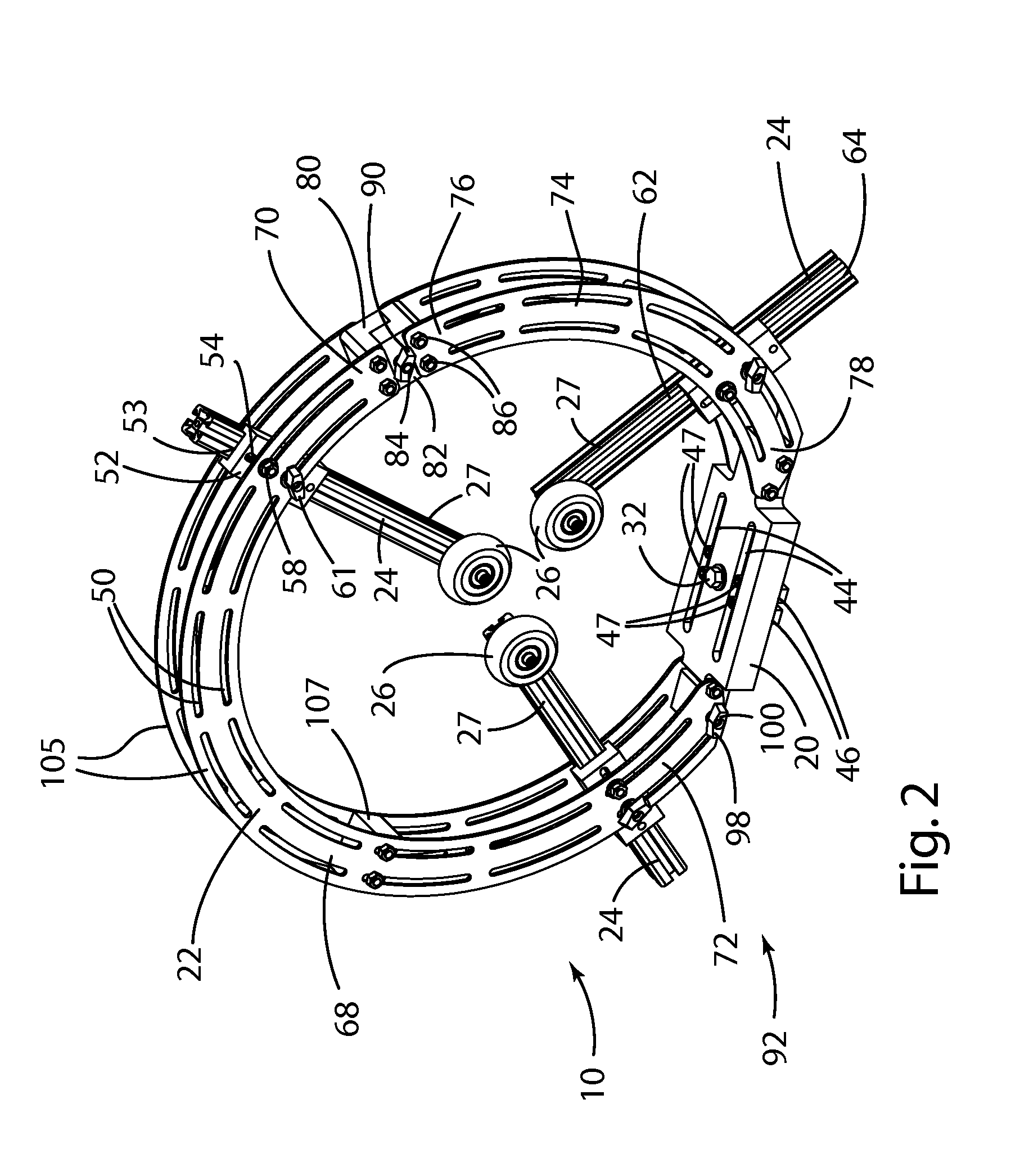

Lathe work piece support tool

A work piece support rest is provided for turning a work piece on a rotating lathe having a lathe bed, headstock, and a headstock spindle, where the work piece is attached to the headstock spindle. The support rest includes an adjustable base releasably attached to the slotted way of the bed via a locking plate and a pair of laterally adjustable way spacers moveable within a laterally extending slot that engage each side of the slotted way. A multi-piece outer ring is releasably attached to the adjustable base. A plurality of roller slides are releasably and adjustably attached to the outer ring, such that each of the roller slides extends radially inwardly and has a roller disposed at an inward distal end thereof for supporting the work piece.

Owner:CARTER PRODS

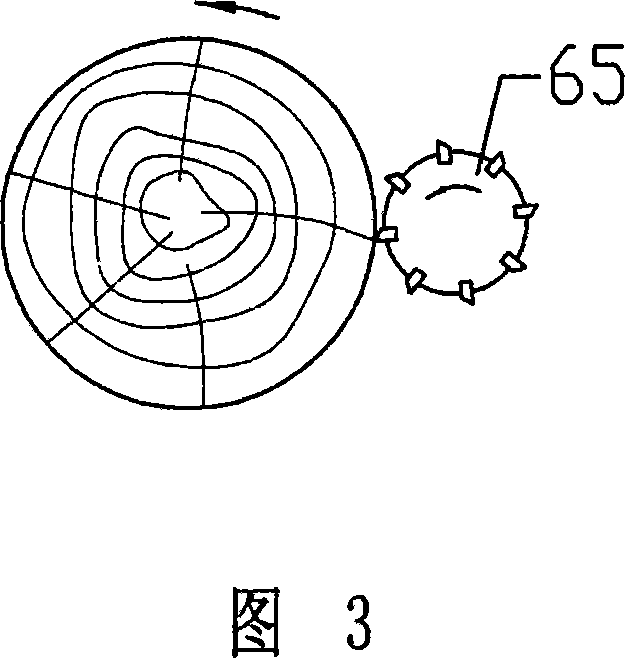

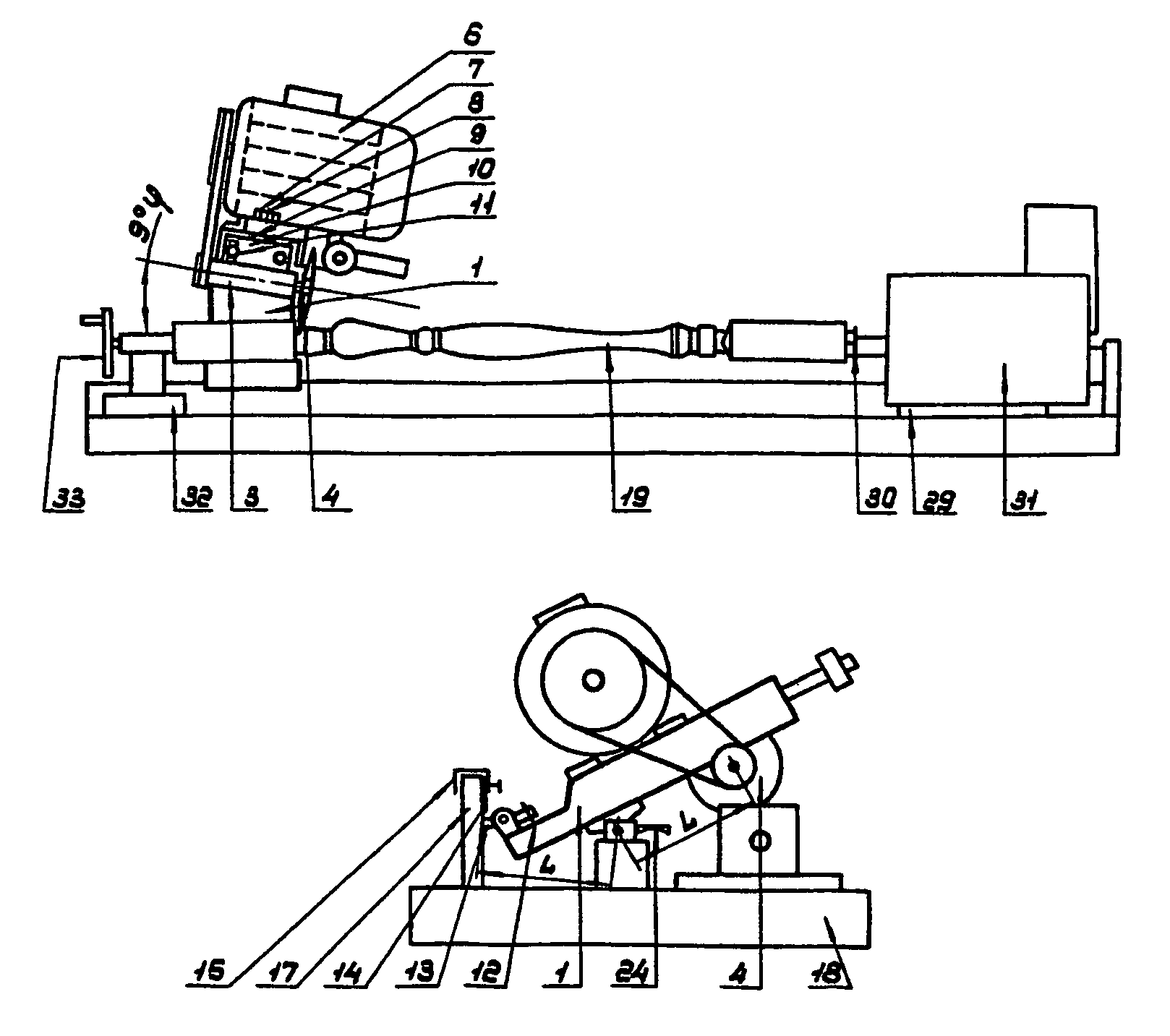

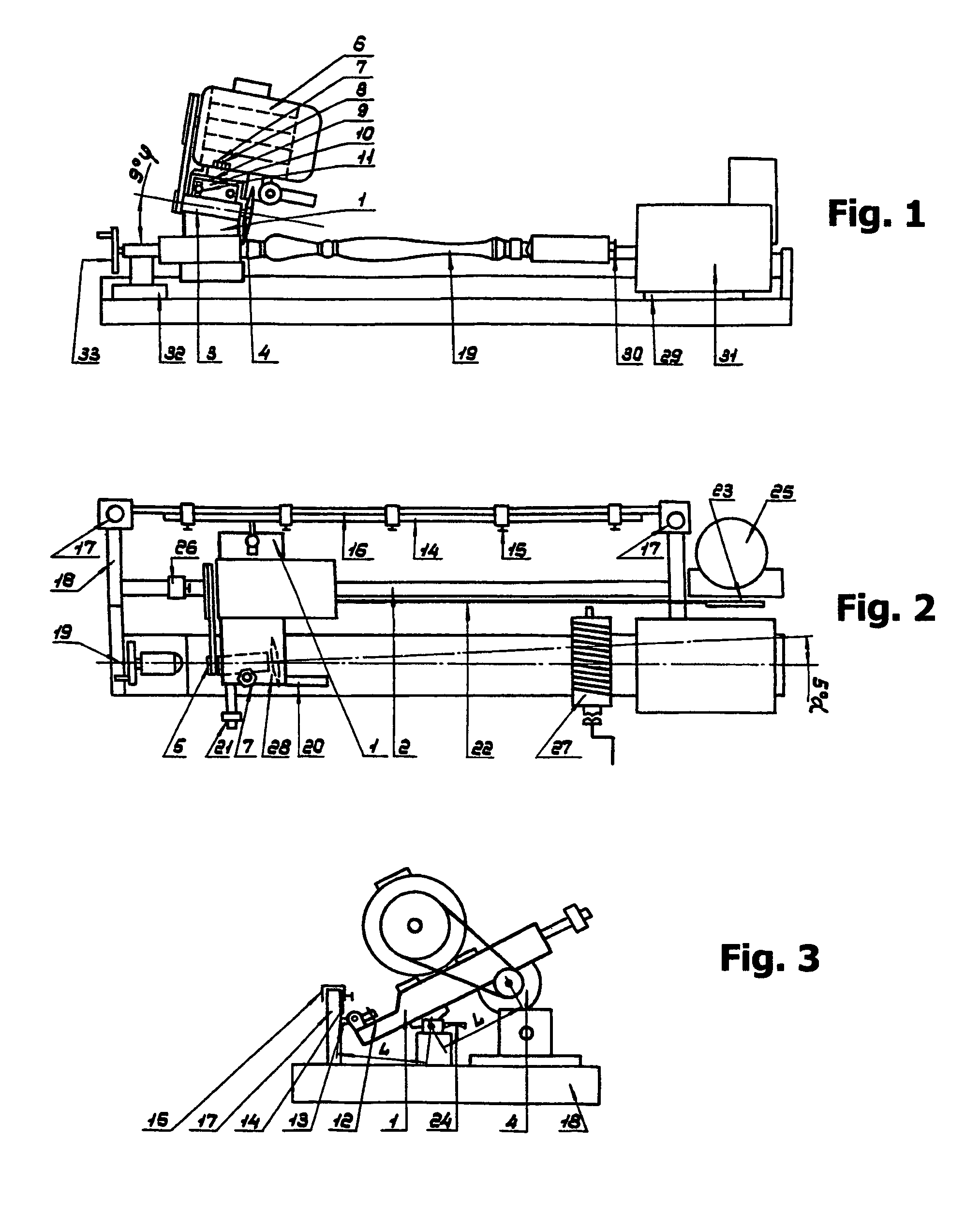

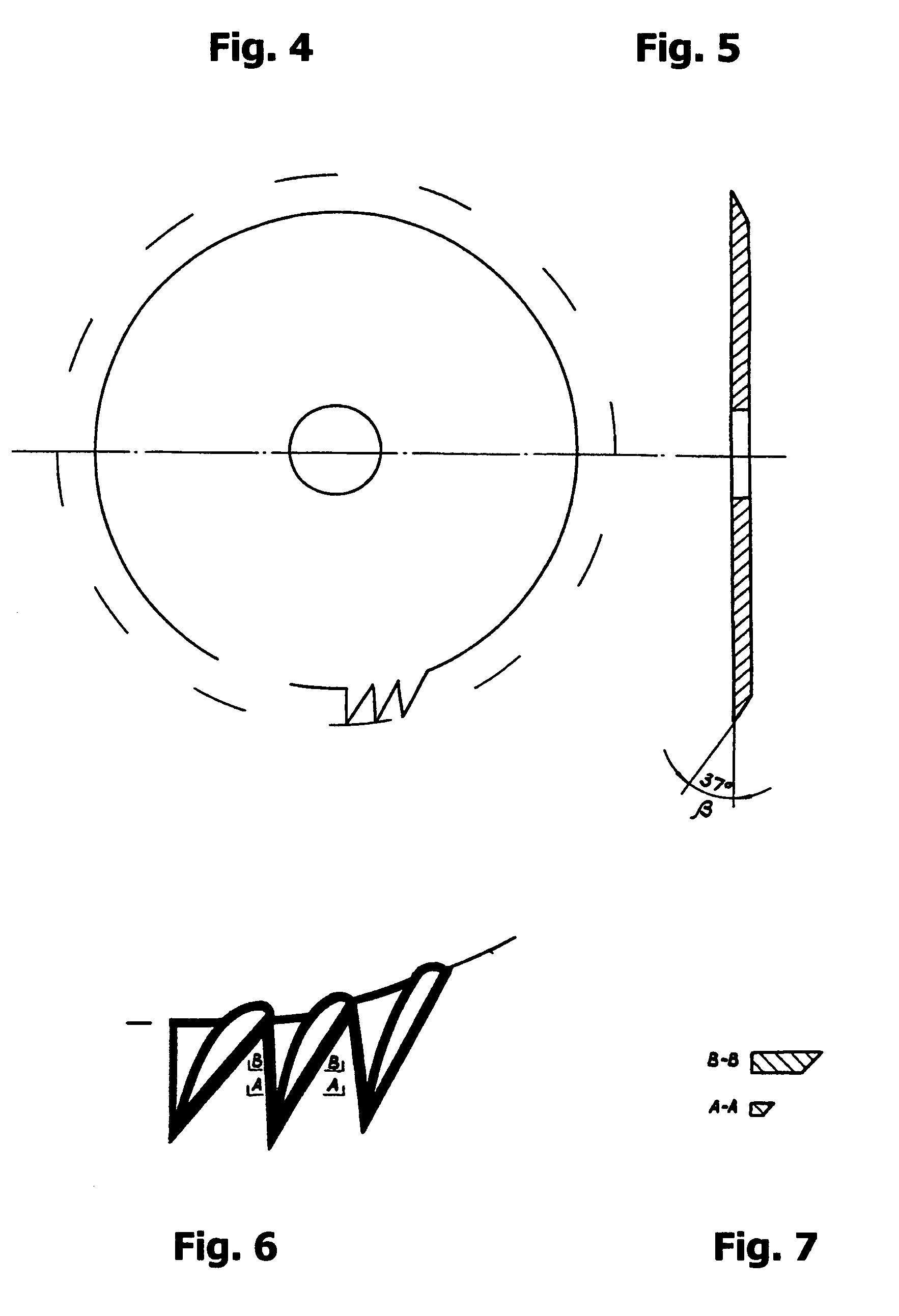

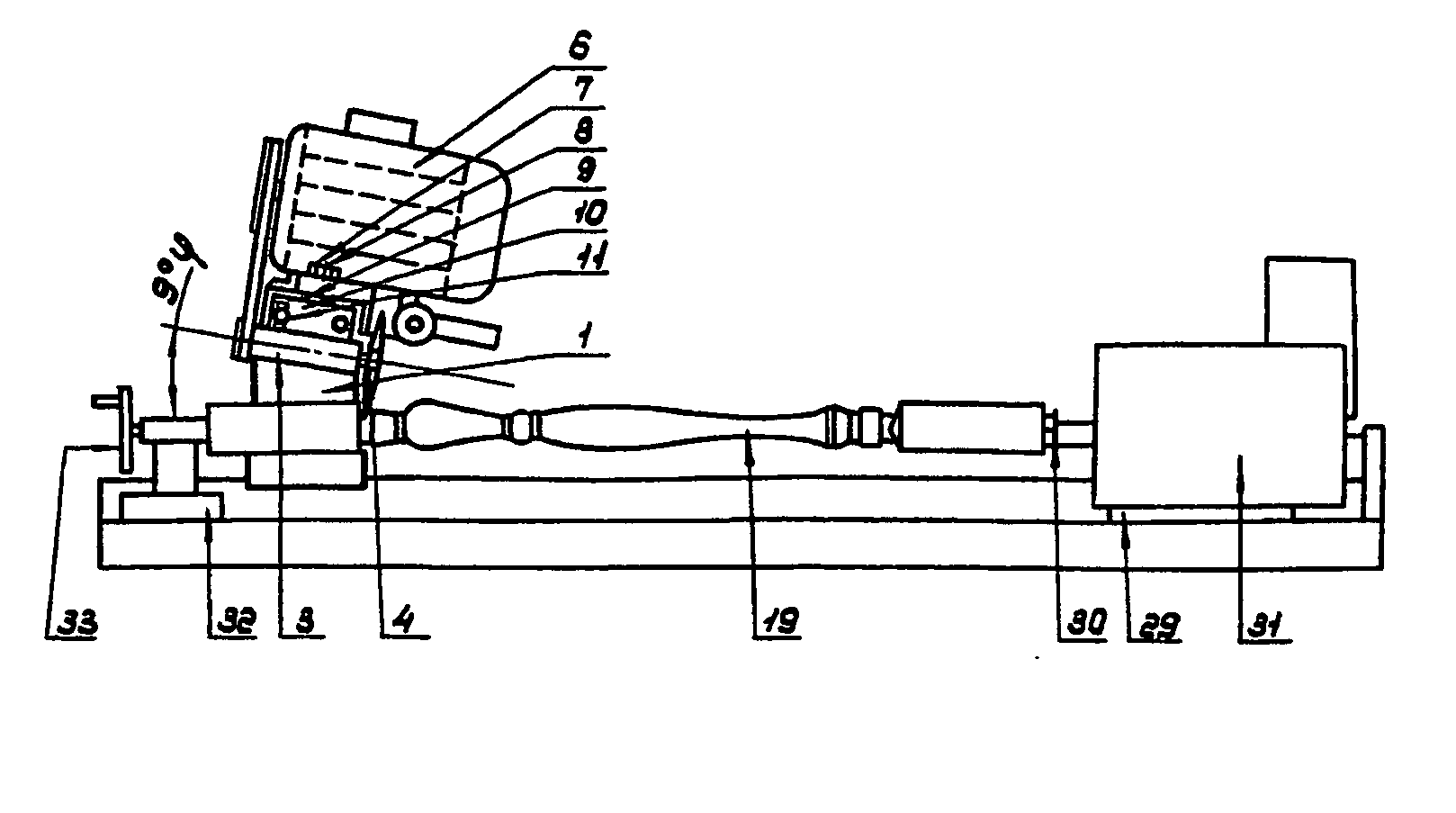

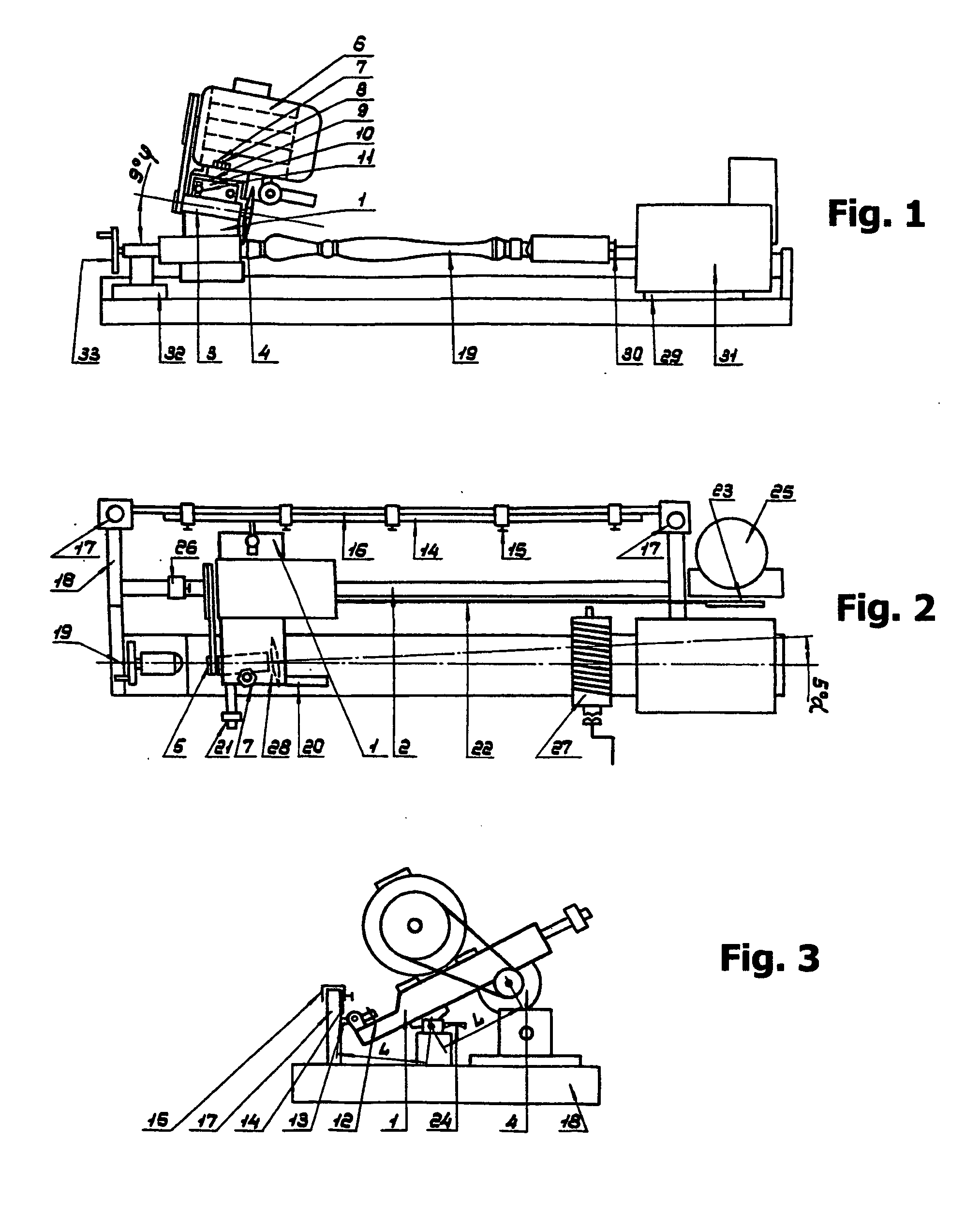

Device to produce round cross-section articles with complicated profiled surfaces

InactiveUS6994001B2Improve accuracyImprove productivityLathesAutomatic/semiautomatic turning machinesProduction rateContact time

A lathe attachment device is disclosed for producing long articles with complicated profiles. The device contains a beveled multi-teeth cutter driven to rotate in a direction opposite the rotation of a billet to ensure a very short period of contact time between an individual cutting tooth and the article. The cutter is slightly tilted towards the billet in both horizontal and vertical plane. The teeth of the cutter are shaped to each have a pointed end facing the rough part of the billet. Provisions are made to draw the cutter along the billet. The device allows producing a smooth finished long article with complicated surface profile in a single pass with high productivity. Due to limited contact time, it offers extended life of the cutter. The device is used most advantageously to produce long wood articles.

Owner:TECH COMMLIZATION

Woodworking Machining Apparatus

InactiveUS20130048149A1Prevent disengagementWood-turning machinesProfiling/shaping machinesEngineeringWoodworking machine

A woodworking machining apparatus includes a bed, a machining assembly, a driving mechanism and a clamping mechanism. The clamping mechanism is mounted on the bed and is movable relative to the machining assembly. The clamping mechanism has a height adjuster and a holding adjuster. The height adjuster includes a height adjusting base, a sliding rod, first connecting rod, a second connecting rod, a height adjusting lever and a stabilizing board for stably lifting the holding adjuster. The holding adjuster includes a holding base, two clamping sheets and a holding lever for keeping a wood workpiece in a middle of the holding adjuster. The wood workpiece is clamped between the clamping sheets and is lifted by the height adjuster. Therefore, an axis of the wood workpiece can be aligned with the machining assembly.

Owner:LIU RONG CHENG

Woodturning tool

A woodturning tool for creating containers has a first rigid arm, and a second rigid arm. The first rigid arm has two ends with a cutting blade at the first end. The second rigid arm has two ends with a guiding device at the first end. The cutting blade and the guiding device are operatively aligned. The first and second rigid arms are adapted to move relative to one another.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

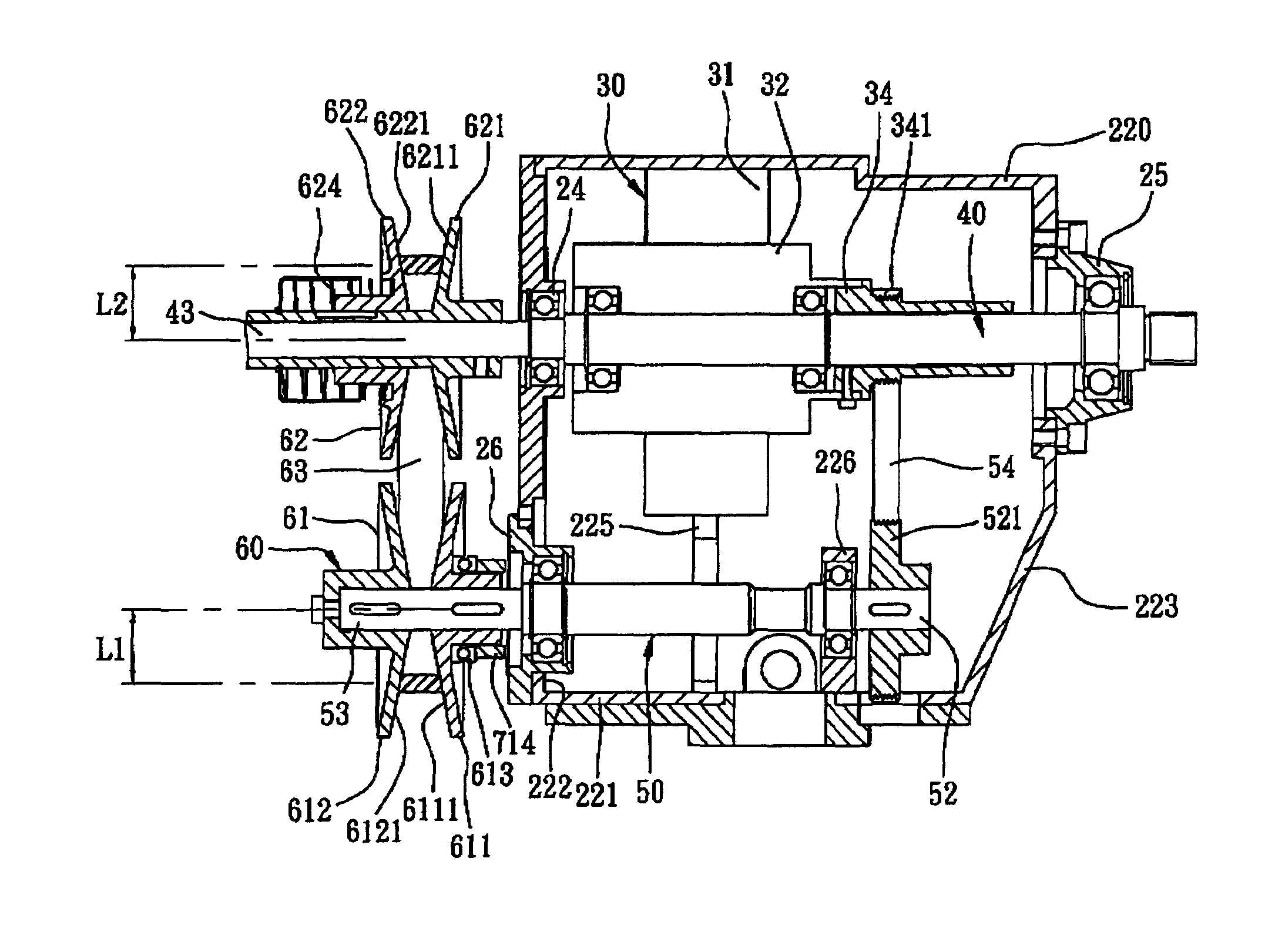

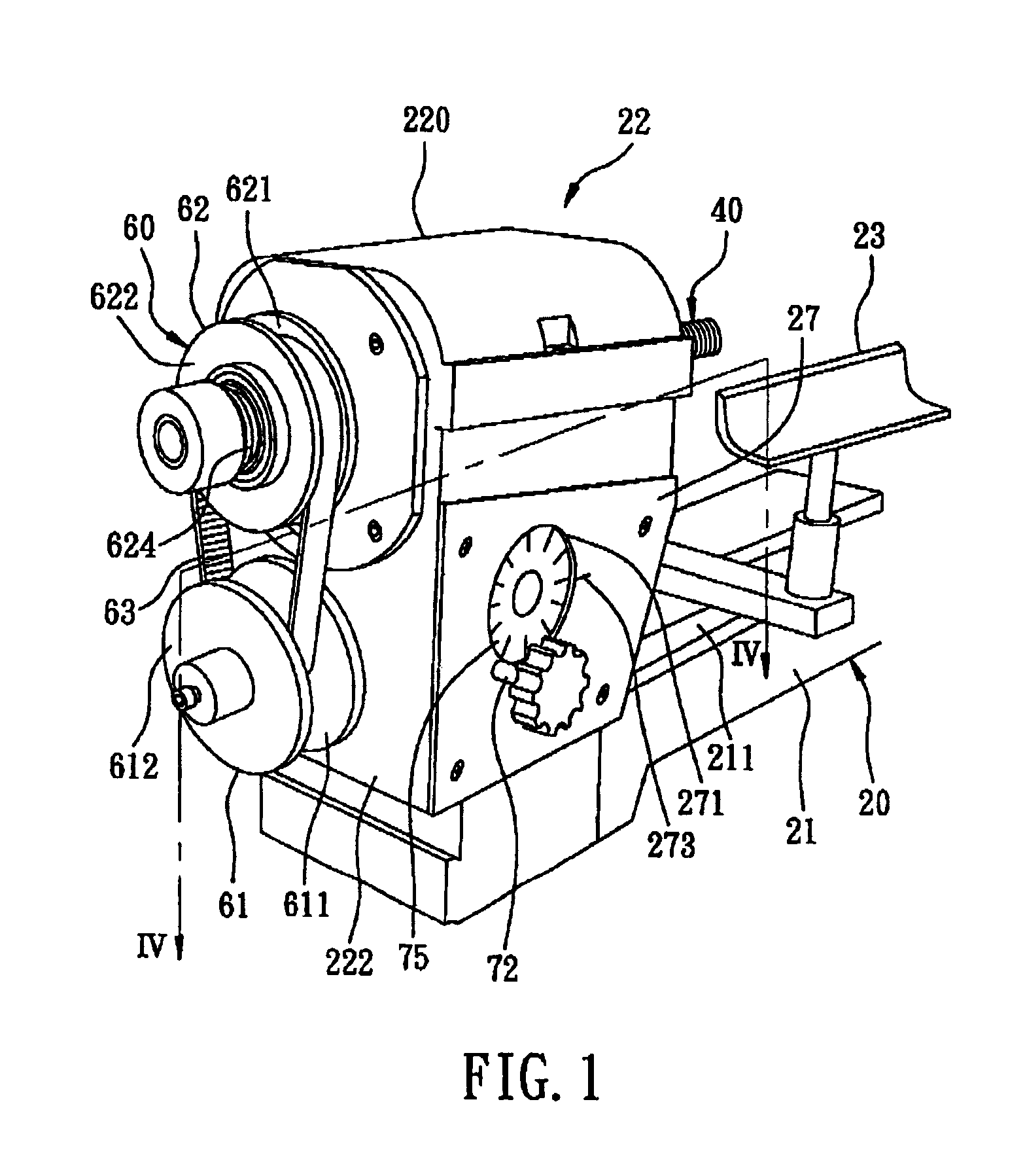

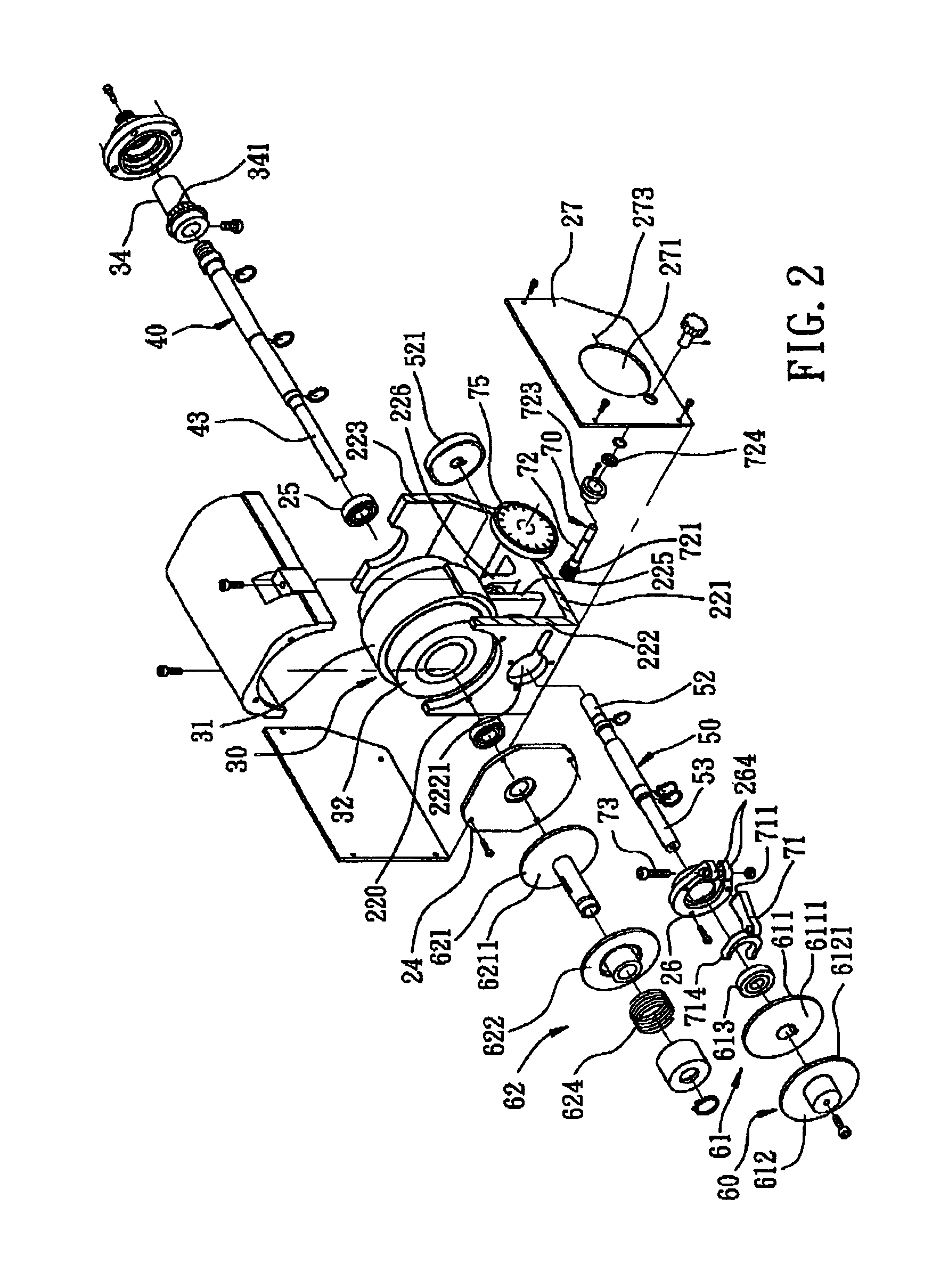

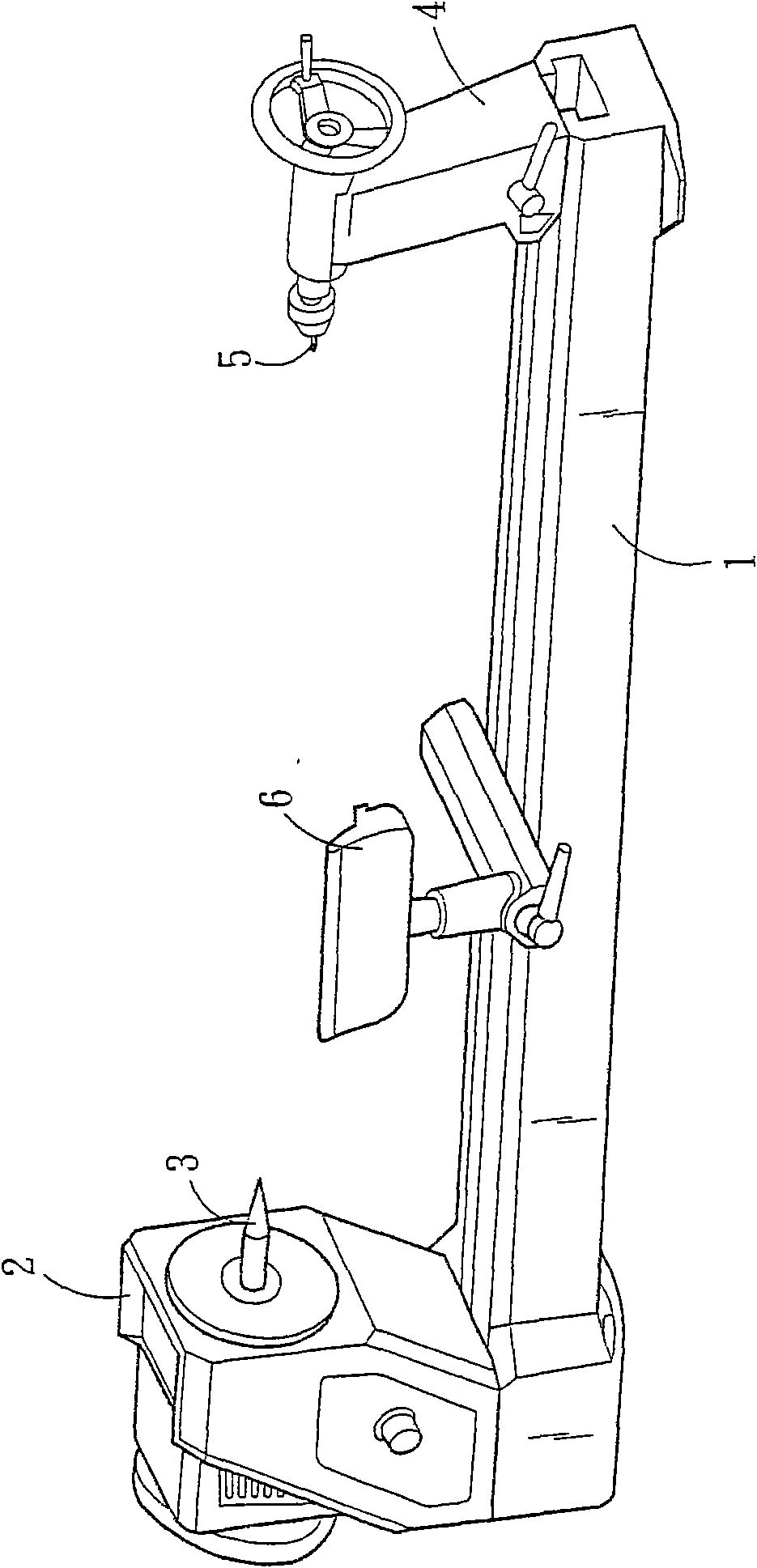

Wood-turning lathe

A wood-turning lathe includes a spindle and a drive shaft journalled to a headstock housing. A motor is mounted in the headstock housing, and includes a rotor. A torque converter includes a first wheel that co-axially surrounds the spindle and that is securely coupled to the rotor, a second wheel mounted securely on the drive shaft, and a belt trained on the first and second wheels, thereby increasing torque of the drive shaft. A speed change device includes a first pulley unit mounted on the drive shaft and defining a first belt-engaging surface, a second pulley unit mounted on the spindle and defining a second belt-engaging surface, and a non-elastic belt interconnecting the first and second pulley units and frictionally contacting the first and second belt-engaging surfaces.

Owner:LIAO HUI CHUAN

Adjustable wood lathe

The invention provides an adjustable wood lathe which comprises a lathe station, a lathe head, a tail seat, a lathe tool seat, a lathe tool rack, a group of lathe head cushion block, at least one tail seat cushion block and at least one sleeve. The adjustable wood lathe can form a structural mode for processing work pieces of different diameters by different combinations and is particularly suitable for processing work pieces with larger diameters.

Owner:宋孟宜

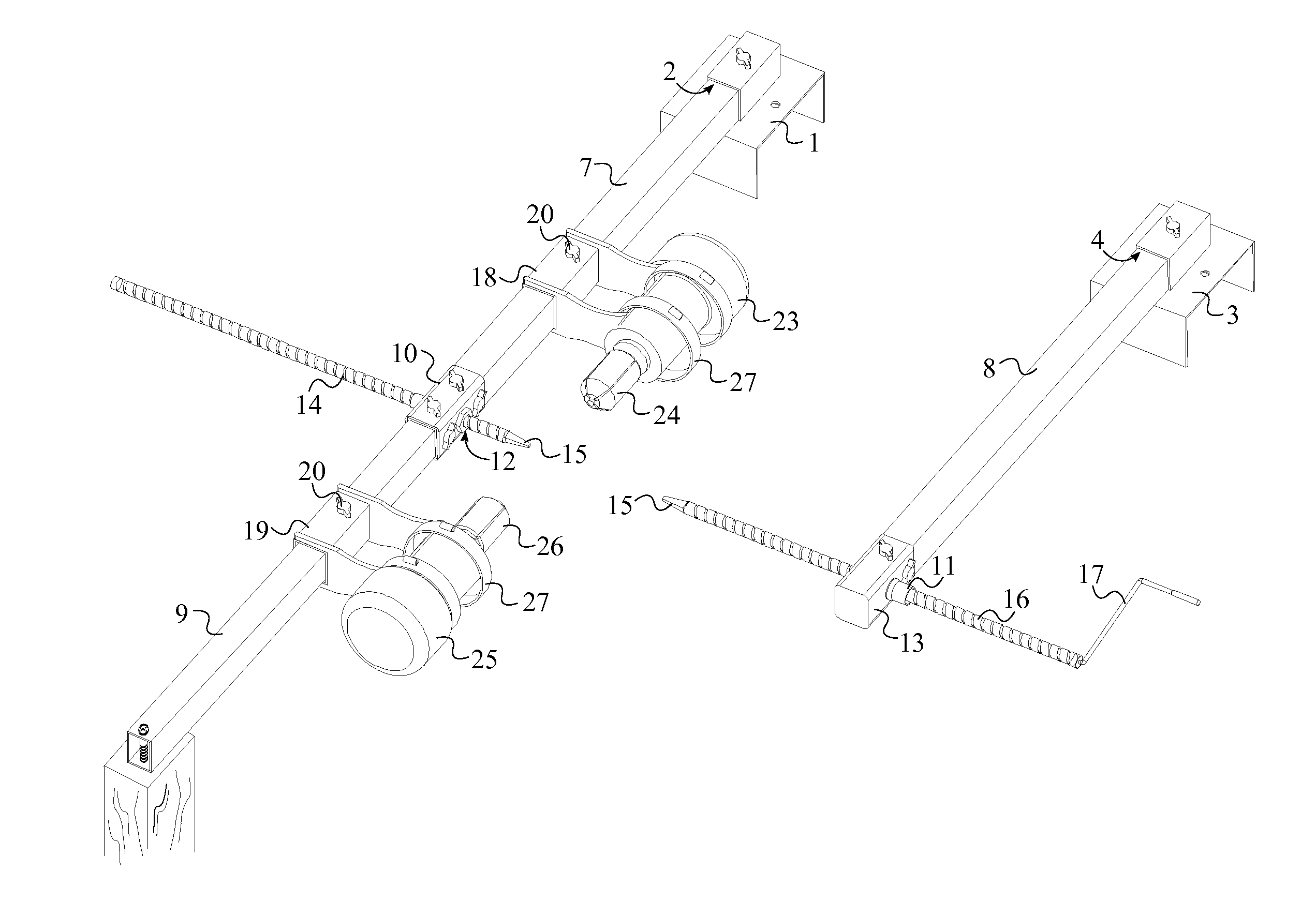

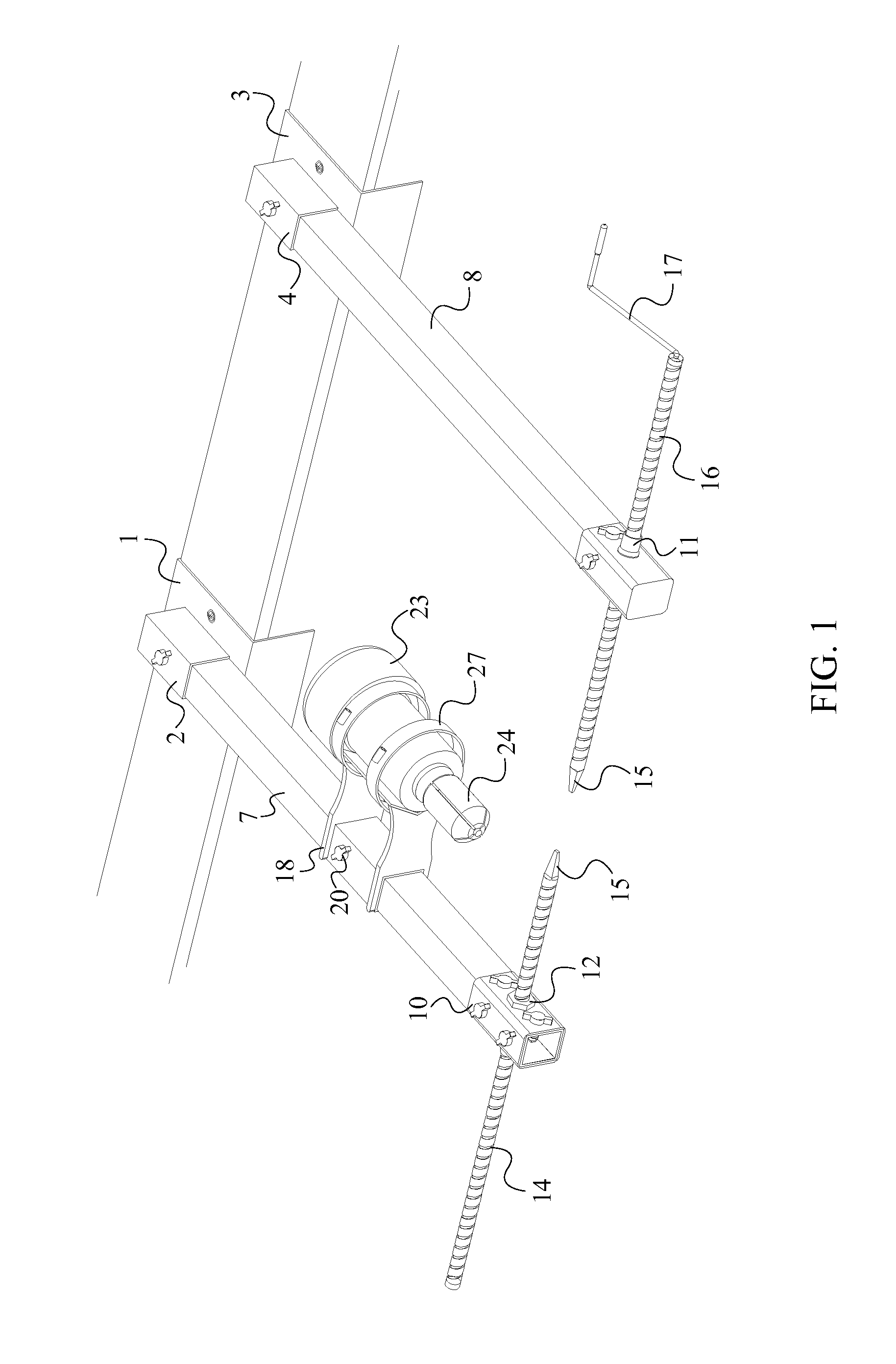

Router Jig for Producing Tenons

An apparatus used for cutting tenons consists of a plurality of mounting brackets, a plurality of arms, a motor, and a pair of threaded rods. The plurality of mounting brackets attaches the apparatus to an external platform. The motor is mounted onto one of the plurality of arms allowing the motor to slide along the length of the arm. The log in which the tenon is to be cut is placed in between the pair of threaded rods. By rotating the log with the use of one of the threaded rods or with the use of a drill, the log makes contact with the motor. The rotating motion of both the log and also the motor, results in a tenon being cut on the log. Additionally, two motors can also be used in tenon cutting such that a tenon with different diameters can be cut simultaneously.

Owner:SMITH LESLIE G

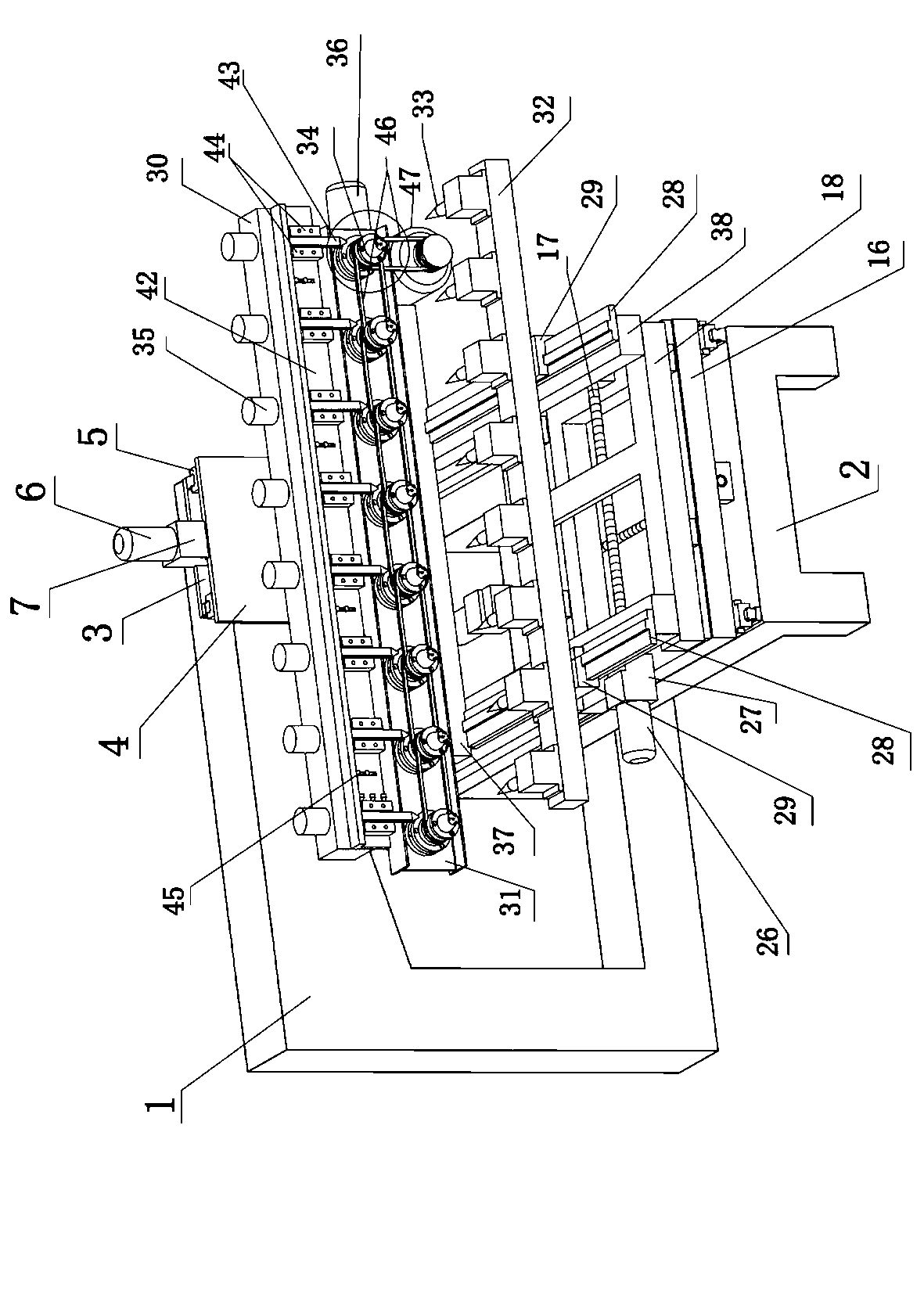

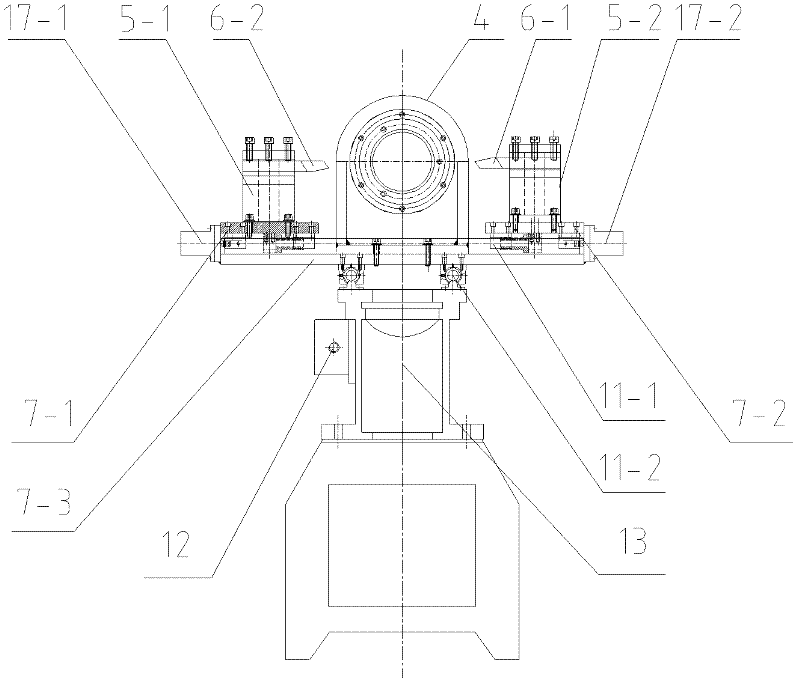

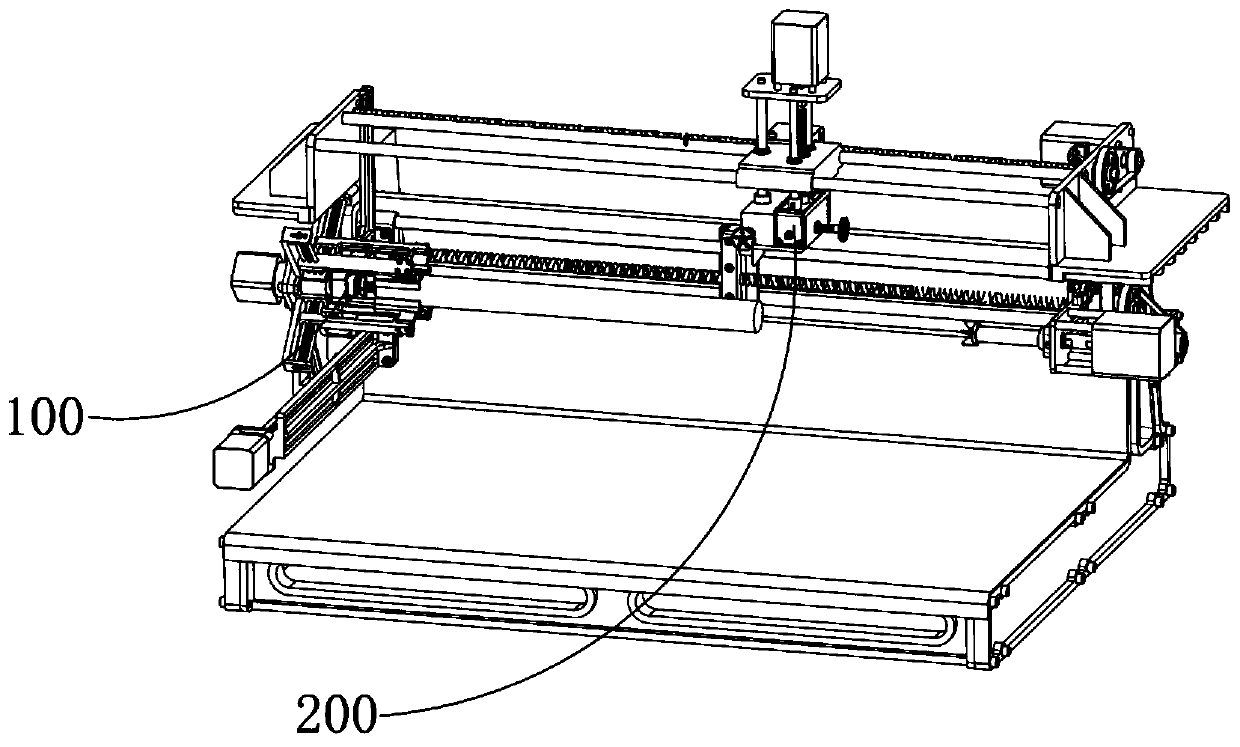

Multi-station numerically-controlled wood lathe

ActiveCN102699962AImprove processing efficiencySave labor costWood-turning machinesWoodworking machineWoodworking machinery

The invention relates to a multi-station numerically-controlled wood lathe and belongs to the technical field of a woodworking machine. The multi-station numerically-controlled wood lathe comprises a rack, and a cross beam fixed above the rack and horizontally transversely arranged, wherein the rack is comprises an H-shaped base and a U-shaped base; a toolframe for mounting a plurality of tools is arranged on the side of the cross beam; a plate block fixed on the cross beam is arranged between the cross beam and the toolframe; a vertical dragging block connected with a vertically arranged vertical guide rail is arranged on the plate body; simultaneously, a vertical dragging plate connected with the vertical dragging block is arranged between the cross beam and the toolframe; the toolframe is fixed on the vertical dragging plate; a drive mechanism 1 for driving the vertical dragging block to move along the vertical guide rail is arranged on the plate block; two horizontally longitudinally arranged longitudinal guide rails are arranged on the H-shaped base; a sliding block 2 capable of sliding along the longitudinal direction of the guide rail is arranged on the longitudinal guide rail; workpiece clamping devices of which the quantity is the same as that of the tools are arranged on the sliding block 2; and a drive mechanism 2 capable of driving the sliding block 2 to move along the longitudinal guide rail is arranged on the H-shaped base.

Owner:NANTONG OUKE CNC EQUIP CO LTD

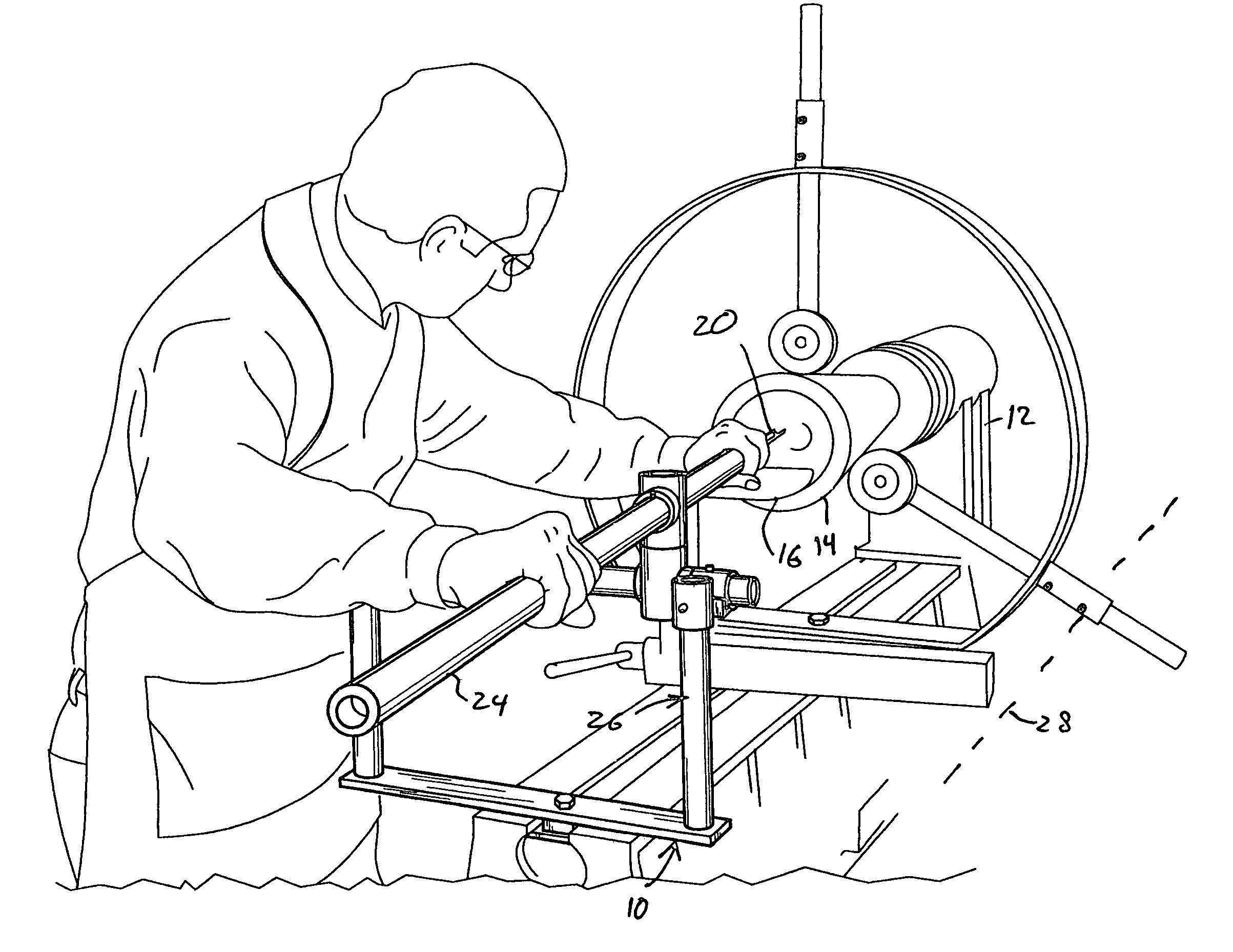

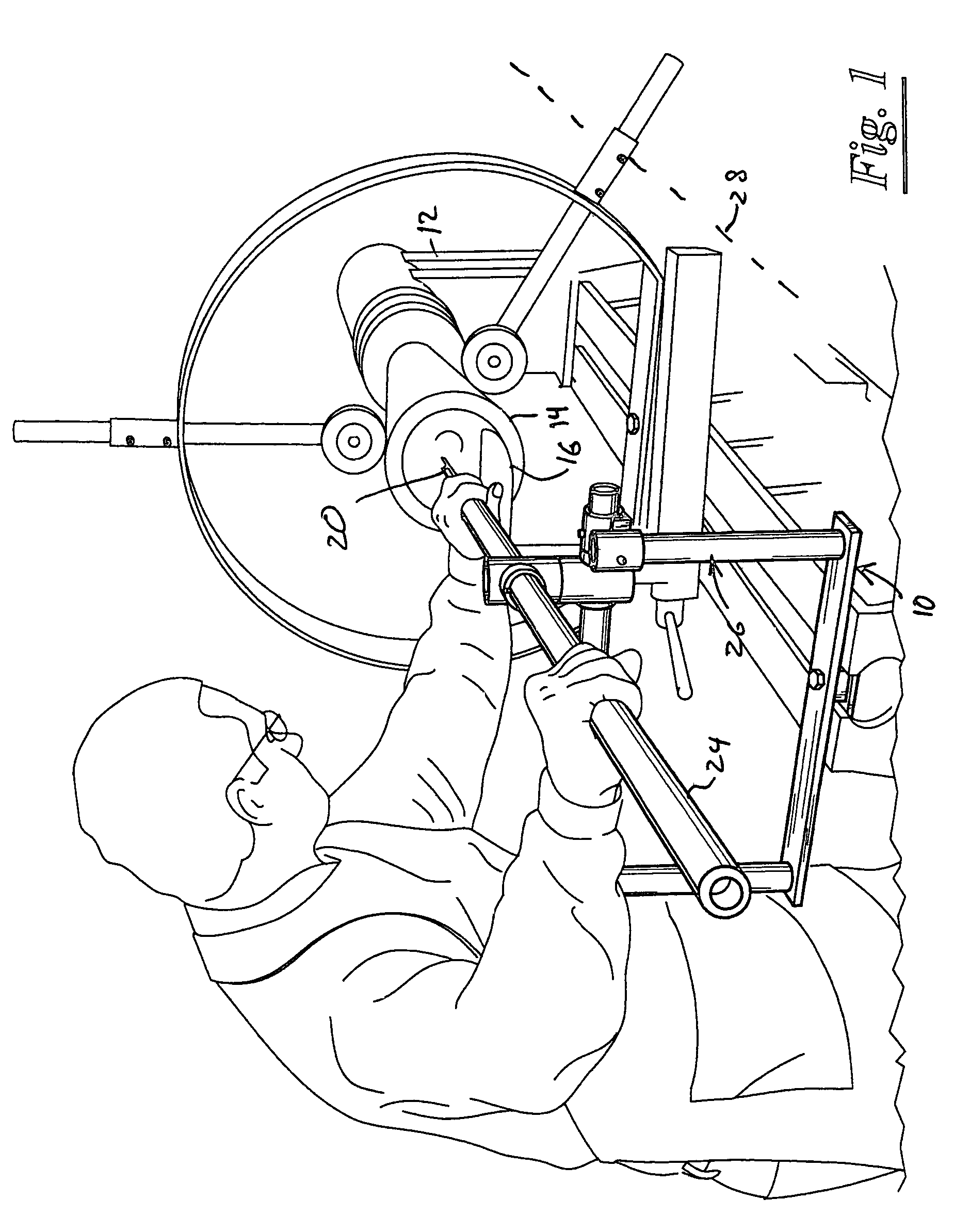

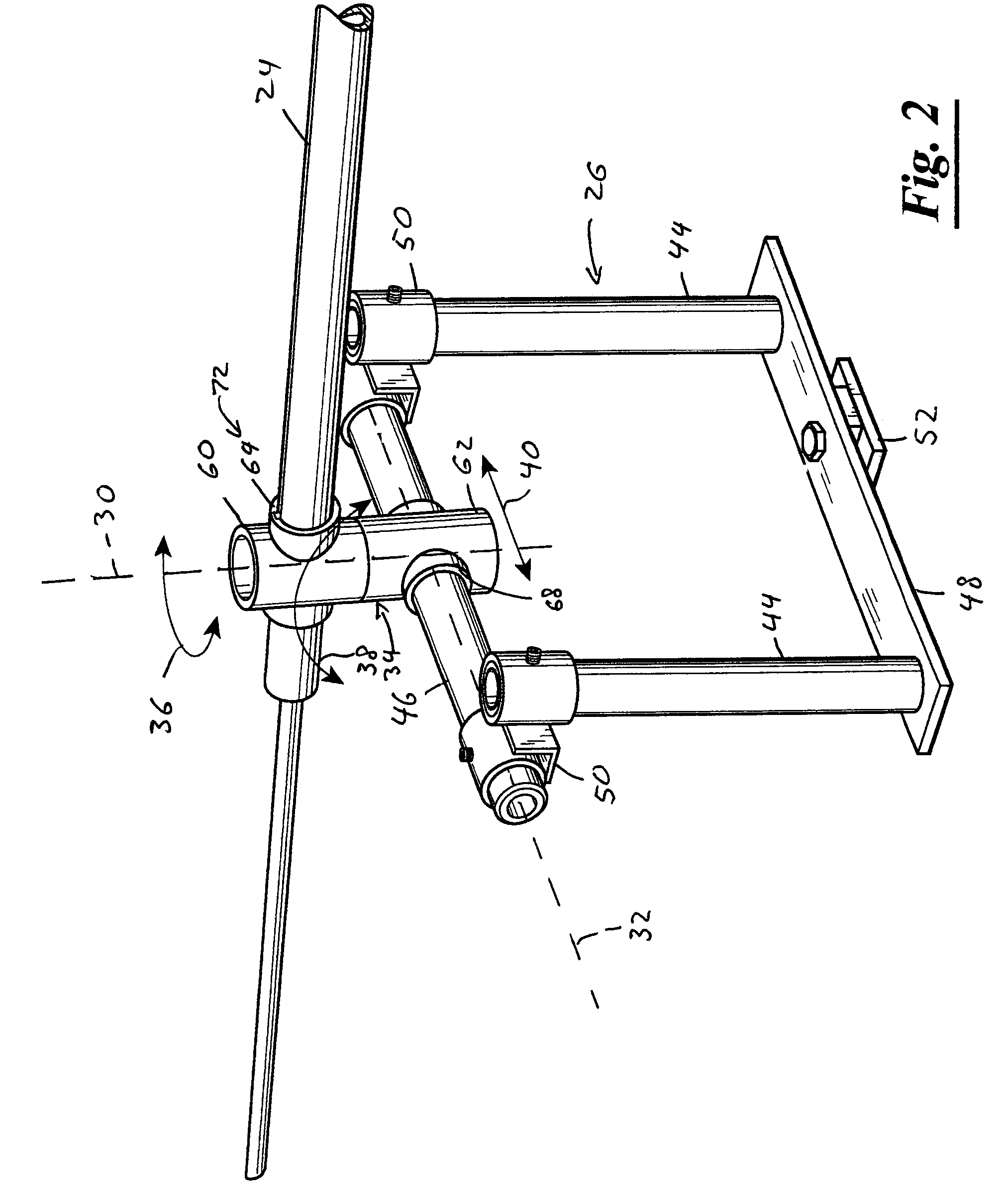

Hollowing system

A hollowing system for a lathe having a tool rest. The hollowing system comprises a boring member, and a stabilization assembly. The boring member is adapted to support a tool such that at least one of the boring member and the tool extend past and engage the tool rest. The stabilization assembly is mountable adjacent to the lathe. The stabilization assembly supports the boring member such that the boring member extends generally parallel to a longitudinal axis of the lathe. The stabilization assembly has a vertical axis and a horizontal axis. The stabilization assembly is adapted to prevent downward movement of the tool when the stabilization assembly is mounted adjacent to the lathe and the tool is positioned on the tool rest. The stabilization assembly is provided with an articulation assembly. The articulation assembly supports the boring member and permits horizontal movement of the boring member about the vertical axis, while also permitting lateral movement of the boring member in a horizontal direction.

Owner:TSDR

Device to produce round cross-section articles with complicated profiled surfaces

InactiveUS20040226155A1Improve accuracyImprove productivityLathesAutomatic/semiautomatic turning machinesProduction rateContact time

A lathe attachment device is disclosed for producing long articles with complicated profiles. The device contains a beveled multi-teeth cutter driven to rotate in a direction opposite the rotation of a billet to ensure a very short period of contact time between an individual cutting tooth and the article. The cutter is slightly tilted towards the billet in both horizontal and vertical plane. The teeth of the cutter are shaped to each have a pointed end facing the rough part of the billet. Provisions are made to draw the cutter along the billet. The device allows producing a smooth finished long article with complicated surface profile in a single pass with high productivity. Due to limited contact time, it offers extended life of the cutter. The device is used most advantageously to produce long wood articles.

Owner:TECH COMMLIZATION

Tilt away tailstock attachment for lathes

ActiveUS20060272459A1Reliable lockingTake advantage ofLathesTailstocks/centresEngineeringBed extension

Woodturners who make bowls frequently find that the unoccupied tailstock limits the path of the tool handle. The normal solution is to manually remove the tailstock from the lathe and set it on the floor or a work bench. Tailstocks can be heavy and manual removal and reinstallation might be needed several times during the production of a single piece. The invention provides a means to get the tailstock out of the turners way via a short bed extension that is pivotally mounted on the end of the lathe bed. To use it, the tail stock is slid back onto the extension, a hold down is released, and the tailstock is tilted away from the user. After tilting, a second set of ways lines up with the existing bed, allowing full use of the additional length afforded by the invention. The invention allows the tailstock to be easily returned to its normal position.

Owner:ENGLISH BRENT W

Lathe for positioning and locking main shaft circumference

InactiveCN109318312AReduce mistakesQuality improvementTailstocks/centresAuxillary equipmentEngineeringMachine tool

The invention relates to the technical field of woodworking lathes, in particular to a lathe for positioning and locking a main shaft circumference. The lathe comprises a bed frame, a workbench is fixedly arranged on the end face of the bed frame, a tail needle main body box is arranged on the workbench, a tail needle adjusting handle is fixedly arranged on the right side of the tail needle main body box, a tail needle corresponds to the tail needle adjusting handle is arranged on the left side of the tail needle main body box, a cutter fixing table is arranged on the left side of the tail pinand located on the workbench, a cutter is fixedly arranged on the cutter fixing table, a pressing handle is fixedly arranged on the end face of the cutter, a cutter feeding adjusting handle is fixedly arranged below the cutter and located on the workbench, and a main case is arranged on the workbench and is located on the left side of the cutter fixing table. The application range of the machinetool is expanded, so that the uniform processing becomes accurate and easy, positions of a belt wheel and a fan belt are carved, the accessory is coordinated with the conical pin, so that multiple functions of the accessory are realized, and the structure of the machine becomes simple and compact.

Owner:殷宪勇

Special articulating tool holder

This is a tool device called a Special Articulating Tool Holder for a Lathe. The device provides a new and unique device to permit deep hollowing of wood or other materials with a controlled, repeatable method. The preferred embodiment of the device is comprised of multiple (two or more) articulating joints—the first of the multiple articulating joints is secured to a tool holder with features to hold cutting tools—and the last of the multiple articulating joints is secured to an essentially vertical mounting post. The mounting post is held in place by a base means which mounts either horizontally or vertically to the machine base as determined by the machine configuration.

Owner:THOMPSON RAY P +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com