Adjustable wood lathe

A woodworking lathe and turning tool technology, which is applied to woodworking lathes, wood processing appliances, manufacturing tools, etc., can solve the problem that the height of the head 2 and the tailstock 4 cannot be adjusted, the diameter range of the workpiece is limited, and it cannot be adapted to the processing of workpieces with larger diameters, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

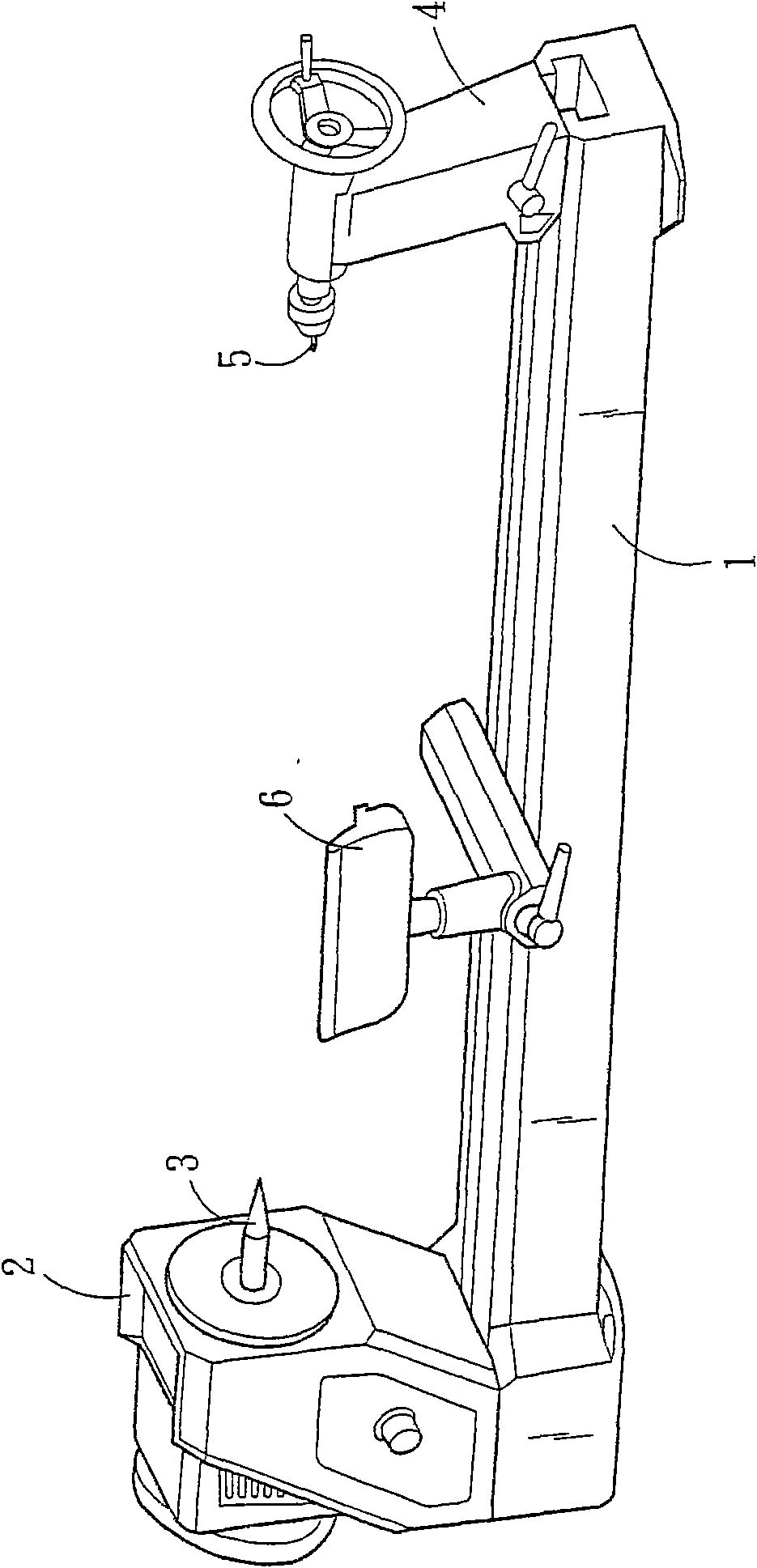

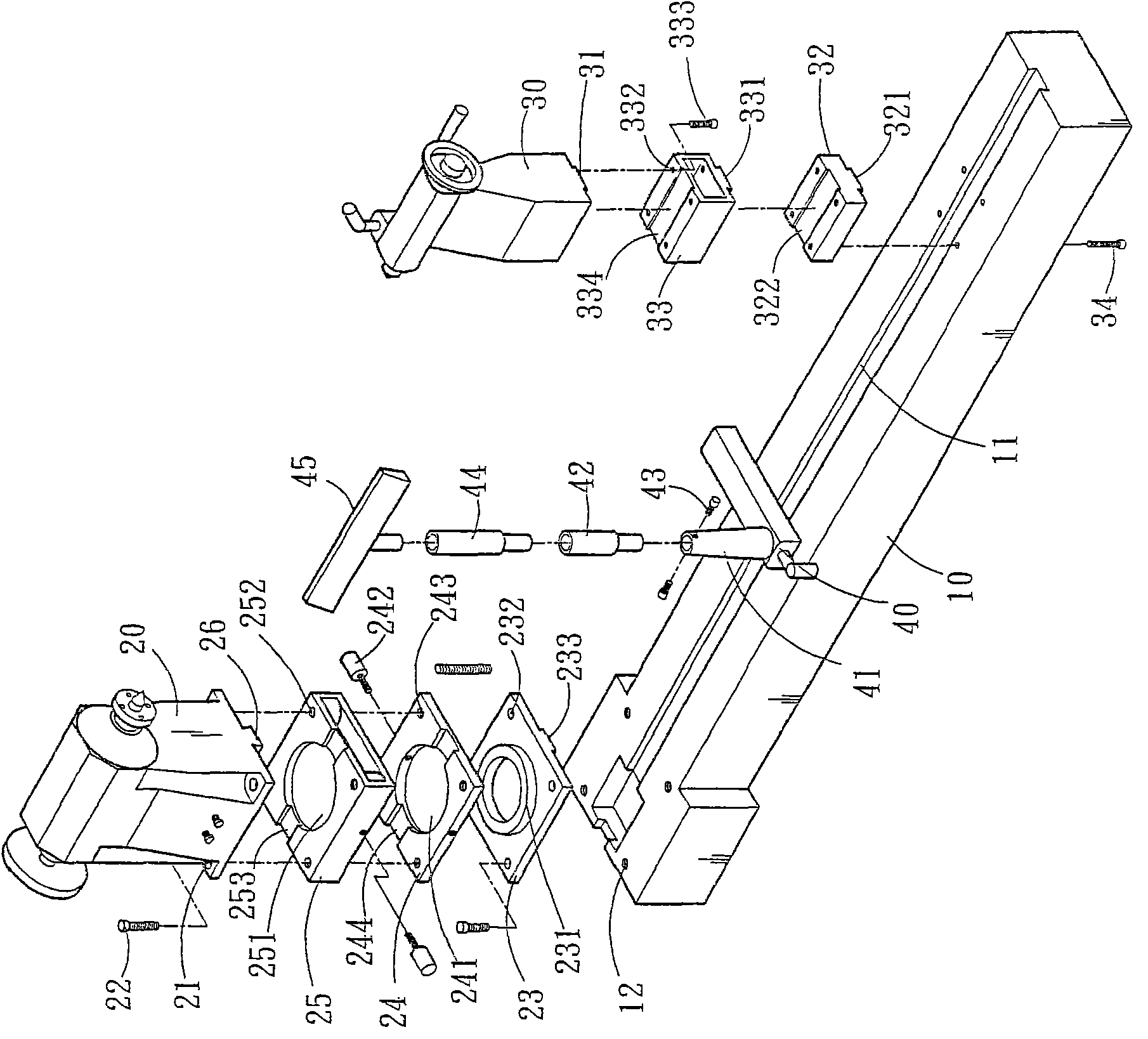

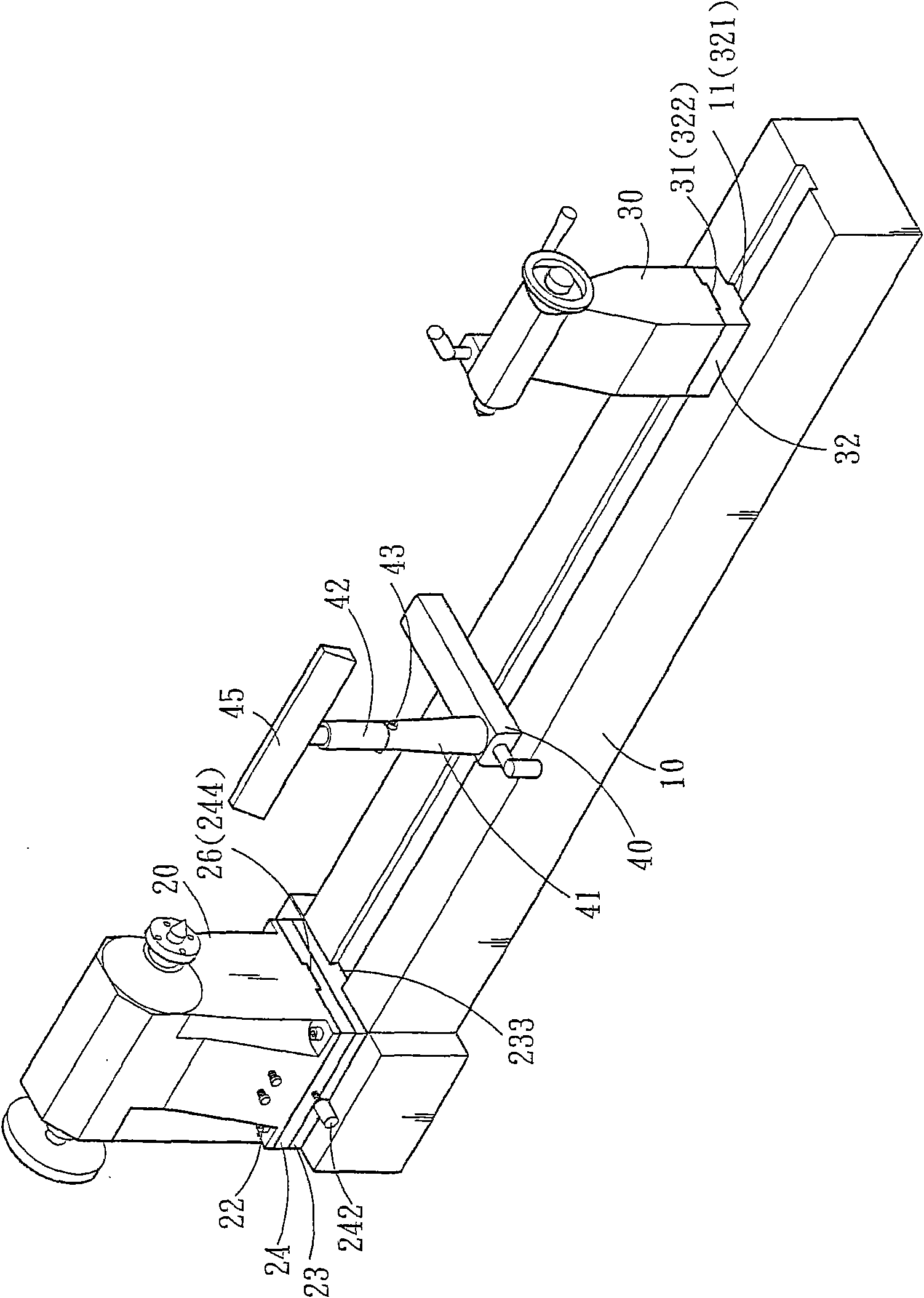

[0019] see figure 2 , with reference to image 3 , Figure 4 , the adjustable woodworking lathe of the present invention comprises a machine platform 10, a machine head 20 arranged at one end of the machine platform, a tailstock 30 arranged at the other end of the machine platform, a turning tool seat 40 arranged in the middle of the machine platform, and a A group of headstock spacers of the machine head 20, two tailstock spacers 32, 33 for raising the tailstock 30, and two bushings 42, 44 for raising the turning tool rest 40. A thimble for clamping a rod-shaped workpiece is oppositely provided on the headstock and the tailstock, a turning tool rest 45 is arranged above the turning tool seat, and a group of head pads include a base plate 23 and two nesting plates 24,25.

[0020] The machine table 10 is provided with a dovetail groove 11 for installing the base plate 23 in the headstock 20 or a group of headstock blocks, the tailstock 30 or tailstock blocks 32, 33 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com