a woodworking machine

A woodworking lathe and bed technology, applied in the field of woodworking machine tools, can solve the problems of affecting the processing and forming speed and forming effect of wood, unable to fix the added part of wood, poor balance and stability of wood, etc. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

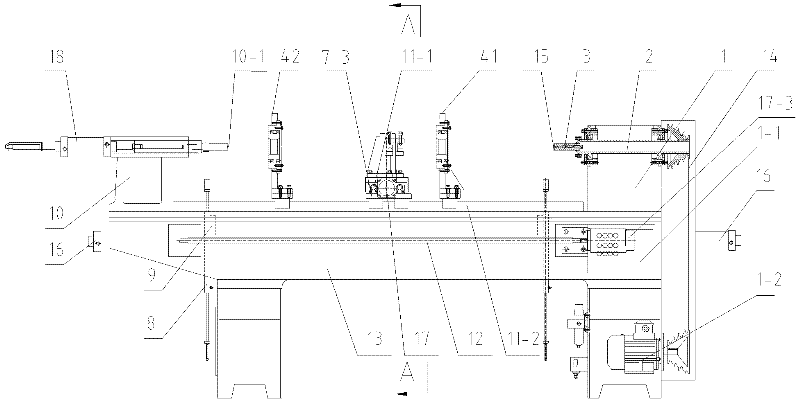

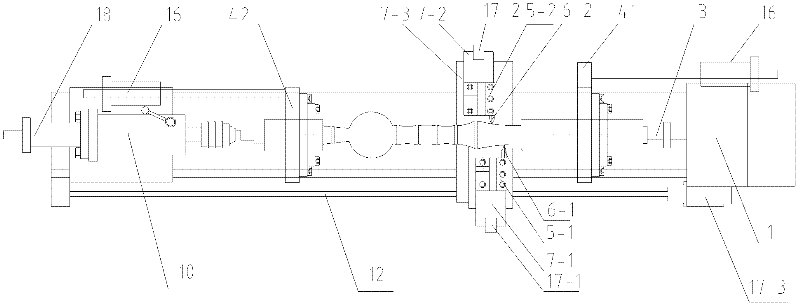

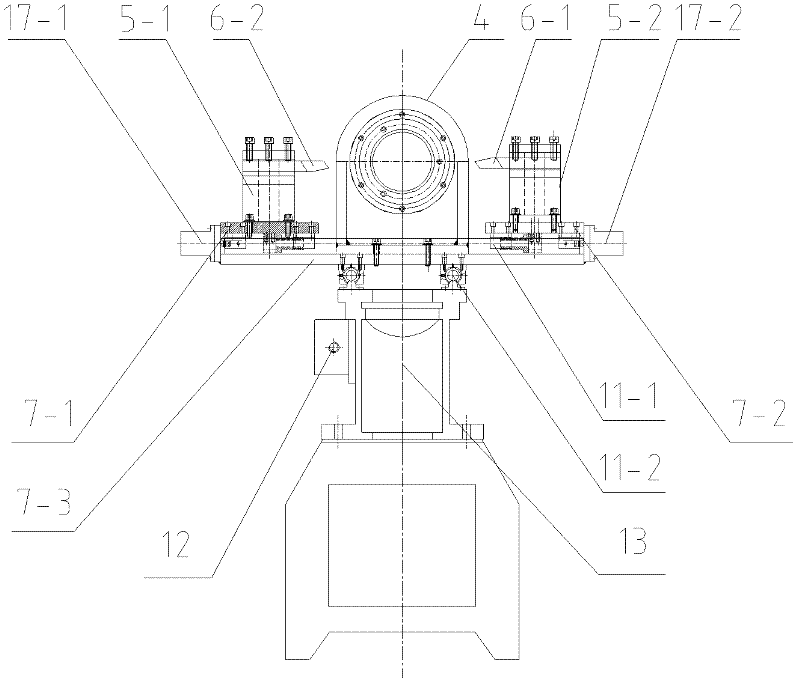

[0038] Such as figure 1 , figure 2 and image 3 As shown, a kind of woodworking lathe, including the headstock 1, the main shaft 2, the clamping head 3, the movable tool holder 4, the tool holder 5, the turning tool 6, the sliding plate 7, the feeding cylinder 8, the rod type upper Material rack 9, tailstock 10, guide rail 11, lead screw 12, bed 13, stepping motor 17; wherein, the control panel 1-1 is set outside the headstock 1, and the frequency conversion motor for driving the main shaft 2 is set inside the headstock 1 1-2, the frequency conversion motor 1-2 is connected to the main shaft 2 through a transmission belt 14; the inner end of the main shaft 2 is fixed with a chuck 3; the top of the chuck 3 is evenly provided with four cone points 15; the bed 13 is provided with two groups of rod-type feeding racks 9, tailstock 10, guide rail 11, and lead screw 12; the upper end of the rod-type feeding rack 9 is provided with a 90 ° V-shaped groove (not shown), and its lower ...

Embodiment 2

[0048] Such as Figure 5 , Figure 6 and Figure 7 As shown, a kind of woodworking lathe, including the headstock 1, the main shaft 2, the clamping head 3, the movable tool holder 4, the tool holder 5, the turning tool 6, the sliding plate 7, the feeding cylinder 8, the rod type upper Material rack 9, tailstock 10, guide rail 11, lead screw 12, bed 13, stepping motor 17; wherein, the control panel 1-1 is set outside the headstock 1, and the frequency conversion motor for driving the main shaft 2 is set inside the headstock 1 1-2, the frequency conversion motor 1-2 is connected to the main shaft 2 through a transmission belt 14; the inner end of the main shaft 2 is fixed with a chuck 3; the top of the chuck 3 is evenly provided with four cone points 15; the bed 13 is provided with two groups of rod-type feeding racks 9, tailstock 10, guide rail 11, and lead screw 12; the upper end of the rod-type feeding rack 9 is provided with a 90 ° V-shaped groove (not shown), and its lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com