Numerical control machine tool for machining wooden handle

A technology for processing machine tools and processing mechanisms, applied in the field of machine tools, can solve the problems of lack of automatic feeding, clamping, and cycle processing devices, backward technology, and high labor intensity of workers, so as to improve automation and production efficiency, reduce labor intensity, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

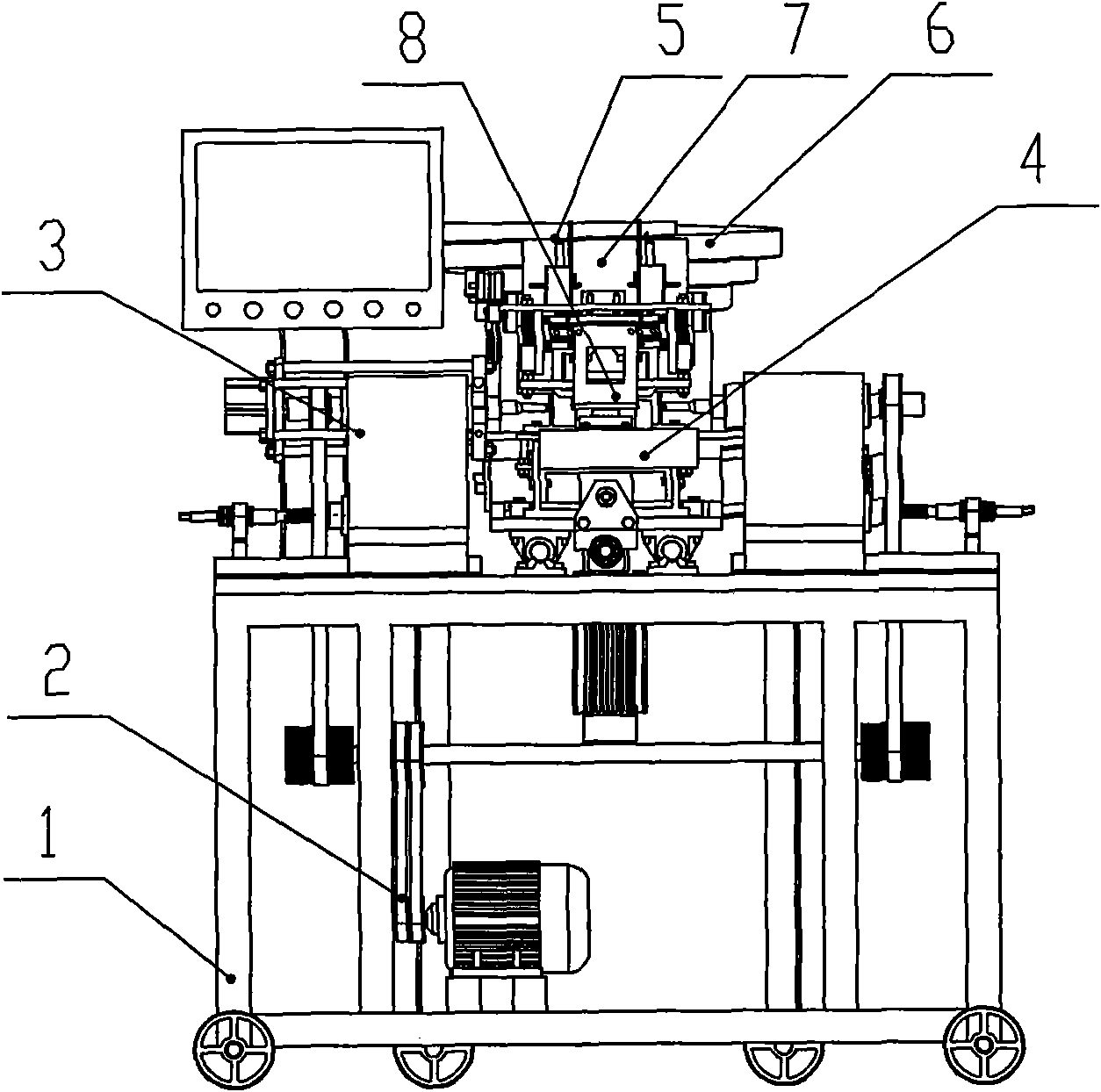

[0036] see figure 1 and figure 2 , a kind of numerical control wooden handle processing machine tool comprises frame 1, motor 2 and numerical control system, and clamping device 3 is installed on described frame 1, is provided with processing mechanism 4 in clamping device 3, and the upper end of processing mechanism 4 is provided with feeding assembly5.

[0037] The feeding assembly 5 includes a vibrating feeding device 6 , a discharging device 7 and a feeding device 8 arranged sequentially from top to bottom.

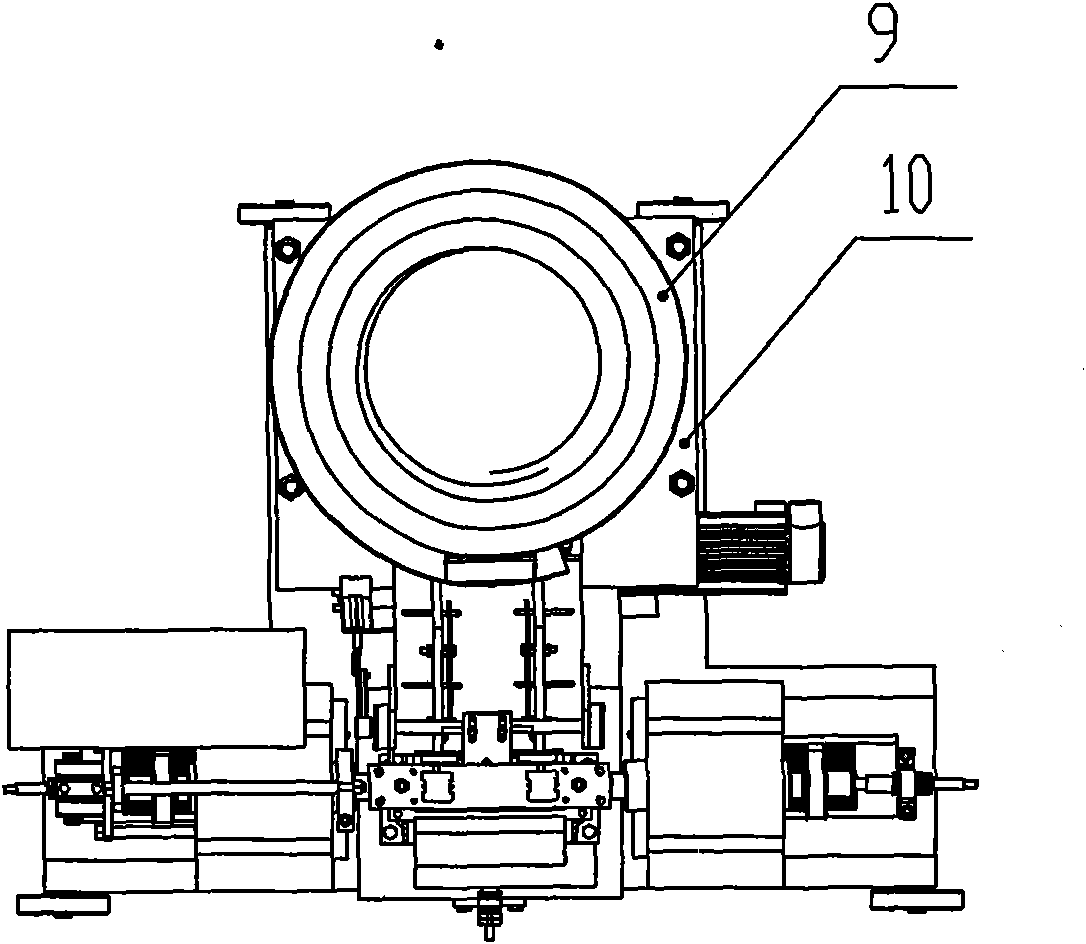

[0038] The vibrating feeding device 6 includes a hopper 9 and a hopper base 10, and the hopper 9 is a spiral structure.

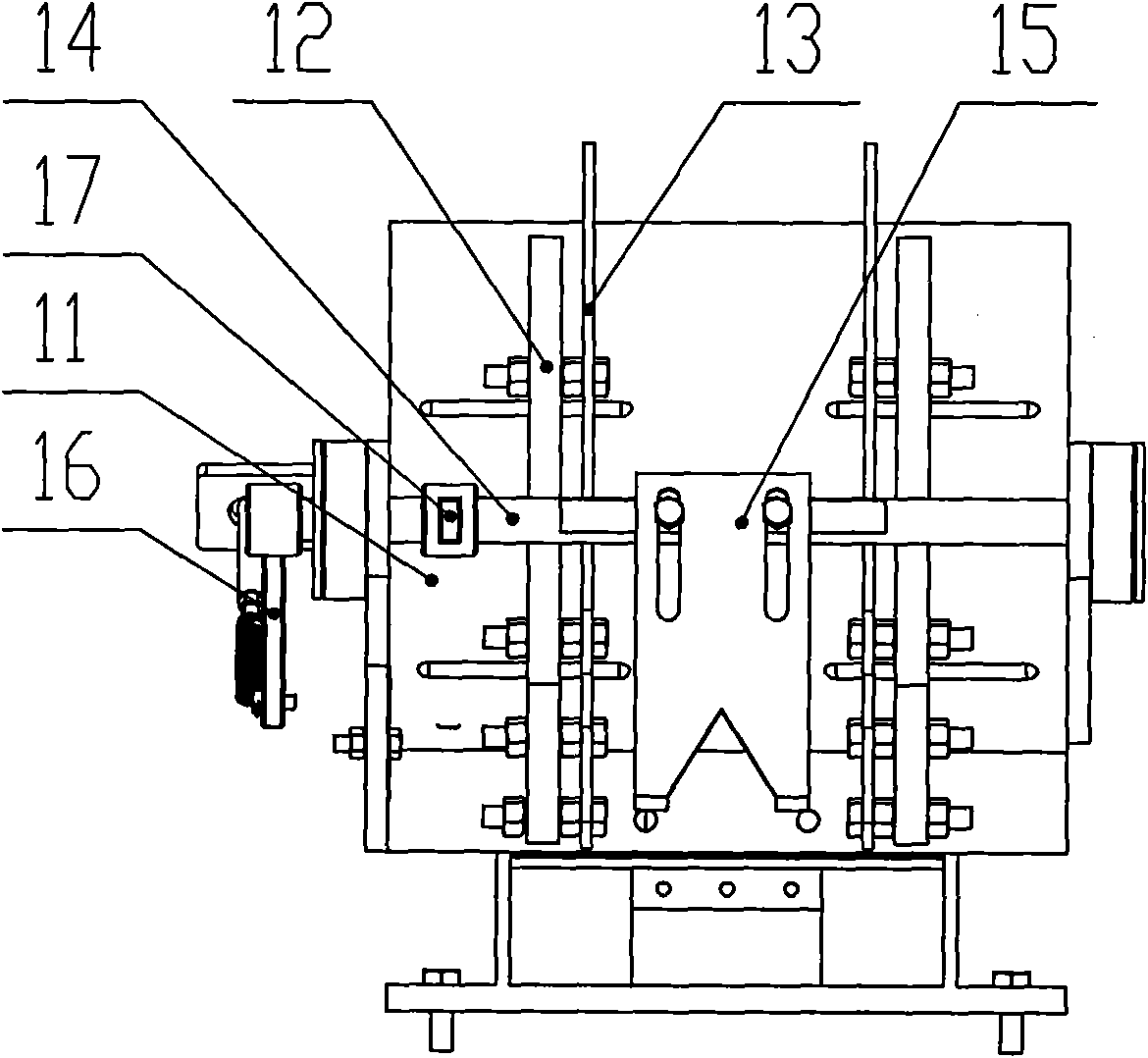

[0039] The discharge device 7 is fixed on the hopper base 10, see image 3 and Figure 4 , the discharge device 7 includes a discharge base 11, a discharge plate 12 is symmetrically fixed on the discharge base 11, and a material limiter 13 is arranged in the discharge plate 12. By adjusting the distance of the material limiter 13, it can be pr...

Embodiment 2

[0049] First, according to the shape of the wooden handle or the requirements of the drawing, the AC3F graphic programming numerical control system is used to complete the programming of the machining program, and to set the position of the turning tool and forming knife and install the chip removal device. After all preparations are completed, the round bar blank is loaded into the vibrating In the hopper 9 of the feeding device 6 and turn on the power, the vibrating feeding device 6 works, when the round bar blanks are arranged up and down in the discharge device 7 along the slideway of the hopper 9, the processing program is started, the material limiting mechanism works, and the number of pieces is limited. 15 is opened, and after sending a round bar blank, the number-limiting piece 15 is closed (every time a processing cycle is completed, the number-limiting piece is opened once). In the groove, at this time, the center of the round bar blank coincides with the centers of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com