Construction waste treatment method

A construction waste and treatment method technology, applied in the direction of construction waste recycling, recycling technology, solid waste removal, etc., can solve the problems of air dust, sewage pollution, large land, etc., to save land, protect the ecological environment, expand employment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

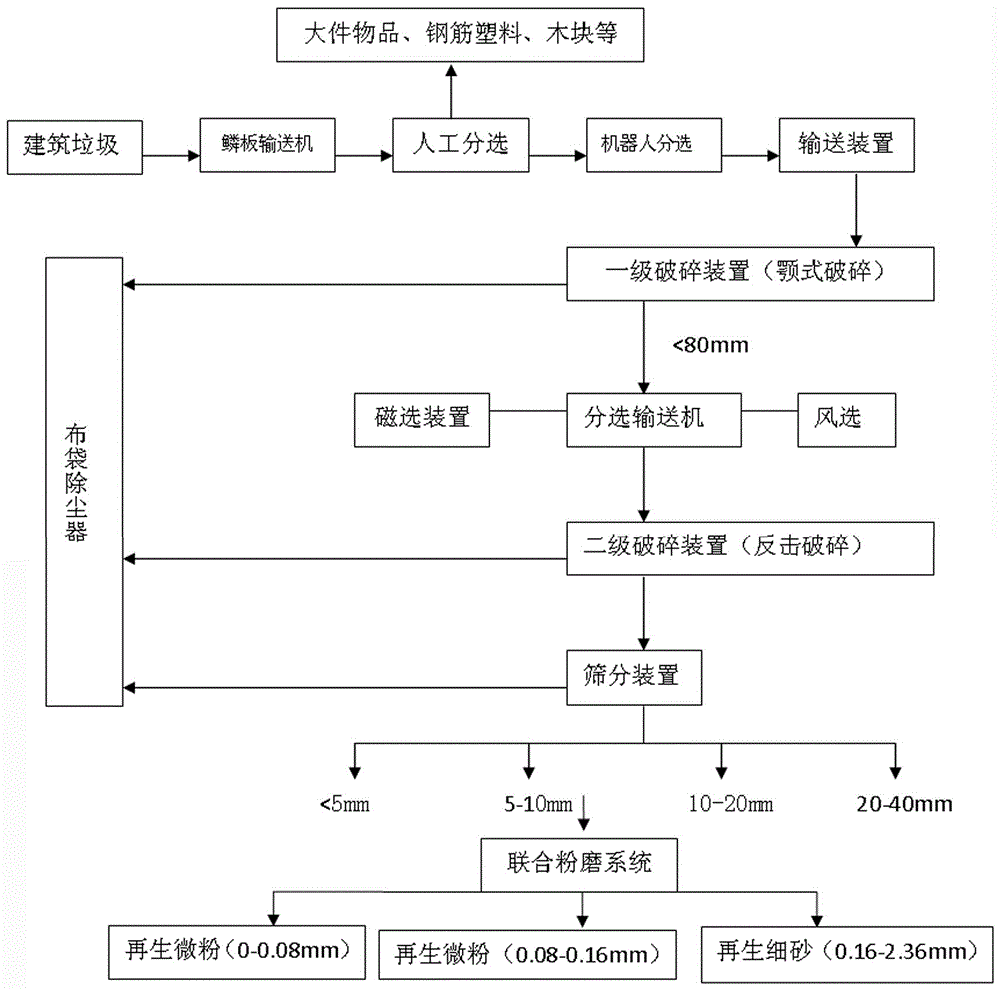

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] Such as figure 1 As shown, the present invention adopts a pure physical and chemical treatment process without incineration, adopts a fully enclosed operation, and dust removal, noise, dust and sewage control meet environmental requirements.

[0025] The usable part of construction waste accounts for 85%, including concrete, broken bricks, wood, glass, ceramics, paper packaging, plastics, and dust, etc., which can be recycled after treatment. The unusable part accounts for 15%, which is transported to the landfill for safe landfill after crushing and sorting.

[0026] The construction waste recycling product line of the present invention is divided into four categories, which are respectively a recycled micro-powder production line, a block forming production line, a water-stabilized mixture production line and a fuel rod production line.

[0027] The recycled micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com