Multi-station numerically-controlled wood lathe

A woodworking lathe and multi-station technology, applied in the direction of woodworking lathes, manufacturing tools, wood processing equipment, etc., can solve the problems of inconvenient installation of woodworking workpieces, affecting the processing of workpieces, and low degree of automation, so as to save manpower and electric energy costs, improve Processing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

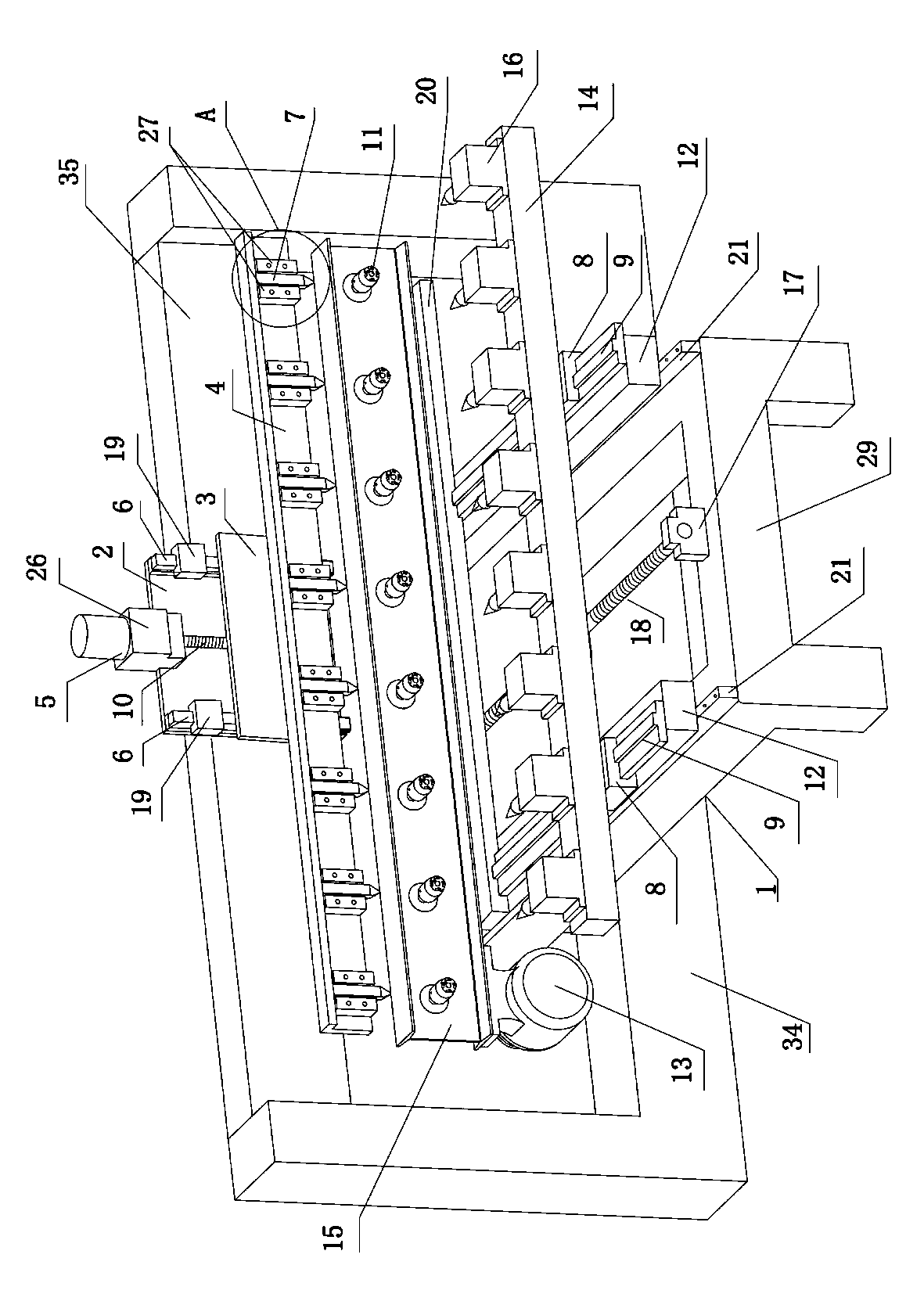

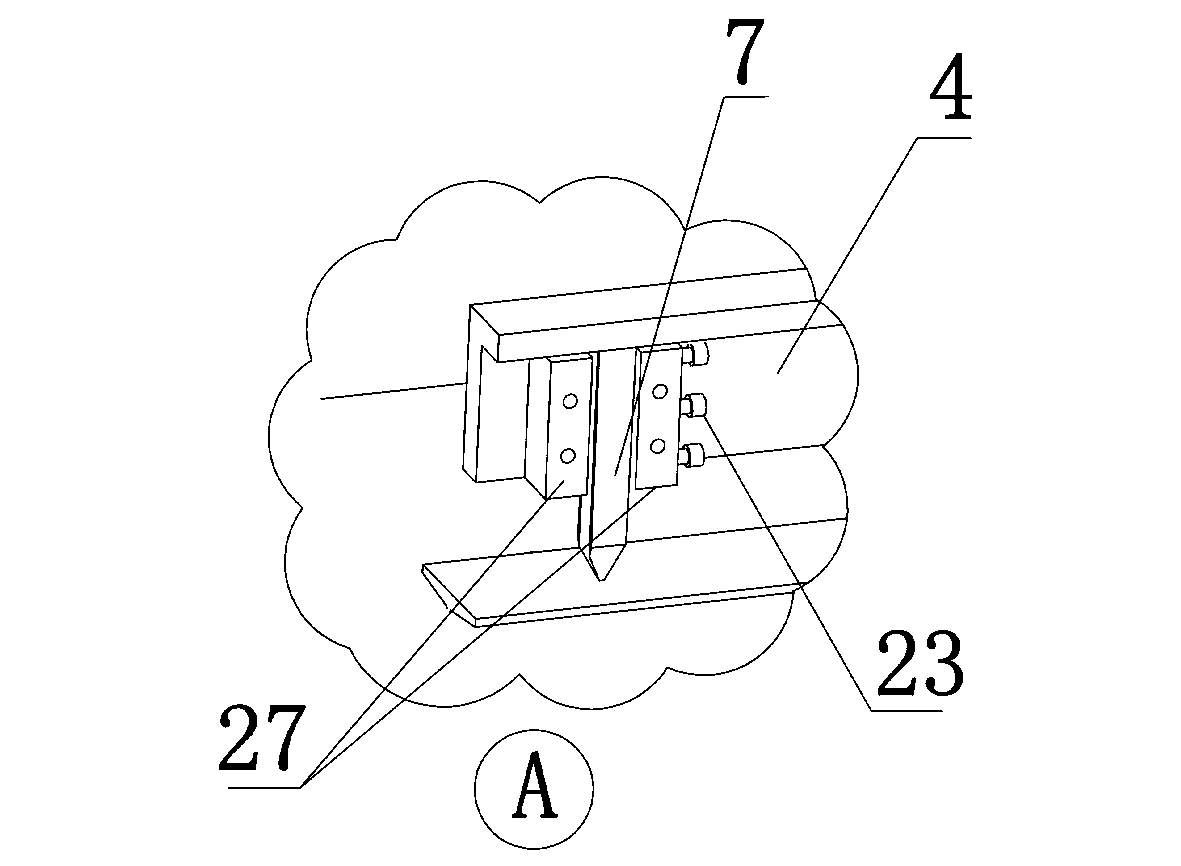

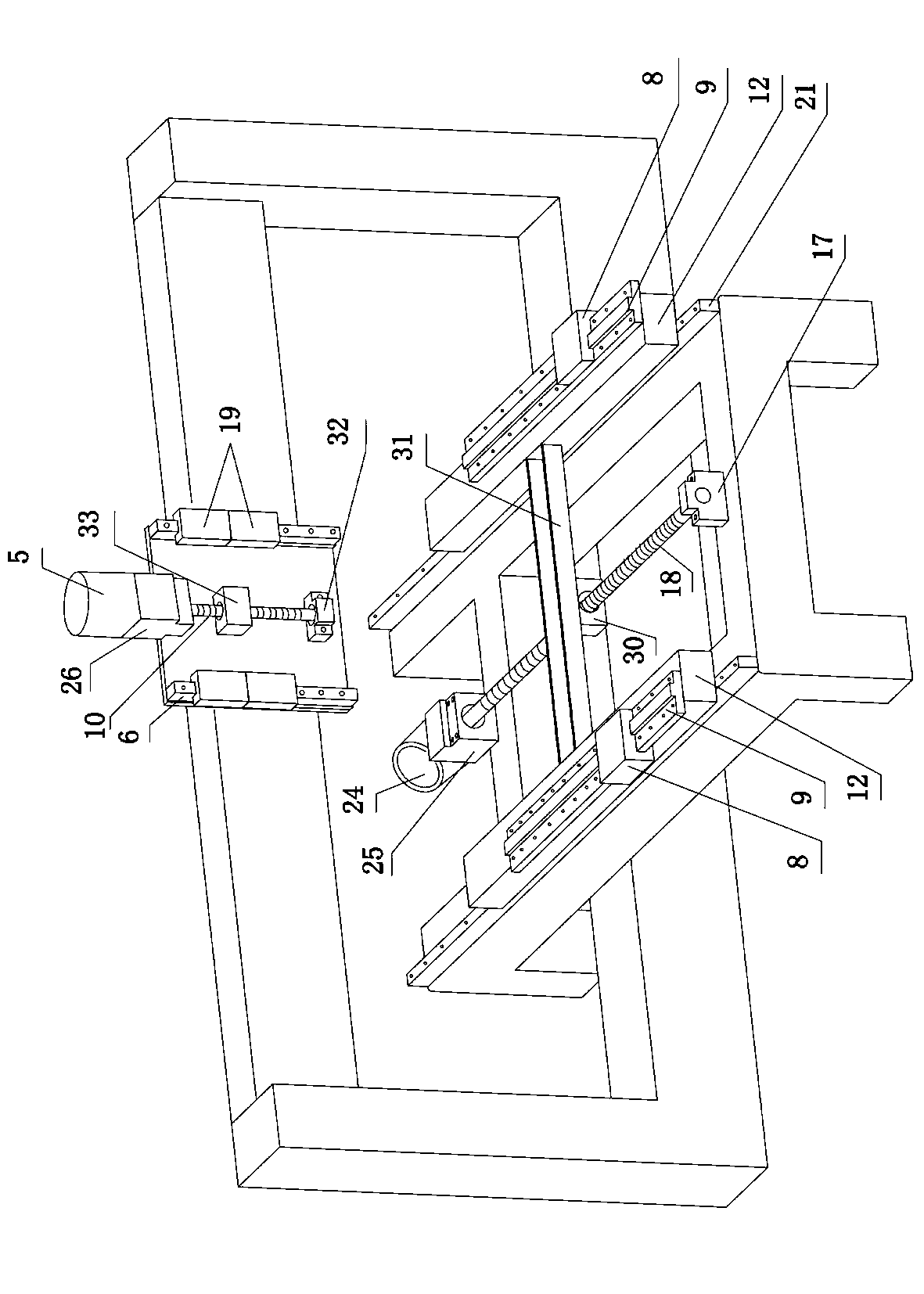

[0023] Refer to attached figure 1 , 2 , 3, 4, a multi-station CNC woodworking lathe, including a frame (1) and a crossbeam (35) fixed on the top of the frame and arranged horizontally and horizontally, the frame (1) consists of an H-shaped base (29) and a U Base (34) constitutes, on the side of crossbeam (35), be provided with the tool rest (4) that is used to install several cutters (7), between crossbeam (35) and cutter rest (4), be provided with and be fixed on crossbeam (35) ) plate (2), on the plate (2) is provided with a vertical drag block (19) connected to the vertically arranged vertical guide rail (6), and at the same time, between the beam (35) and the tool holder (4) is provided with a The vertical dragging plate (3) connected with the vertical dragging block (19), the above-mentioned tool holder (4) is fixed on the vertical dragging plate (3), and the vertical dragging block (19) is set on the plate (2) to drive along the vertical guide rail (6) Moving driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com