High-speed high-precision digital control automatic wood turning machine

A high-precision, automatic car technology, applied to sports accessories, golf balls, woodworking lathes, etc., can solve the problems of low utilization rate of fine bamboo and wood bars, high transmission energy consumption, low production efficiency, etc., to reduce time, CNC High time accuracy and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

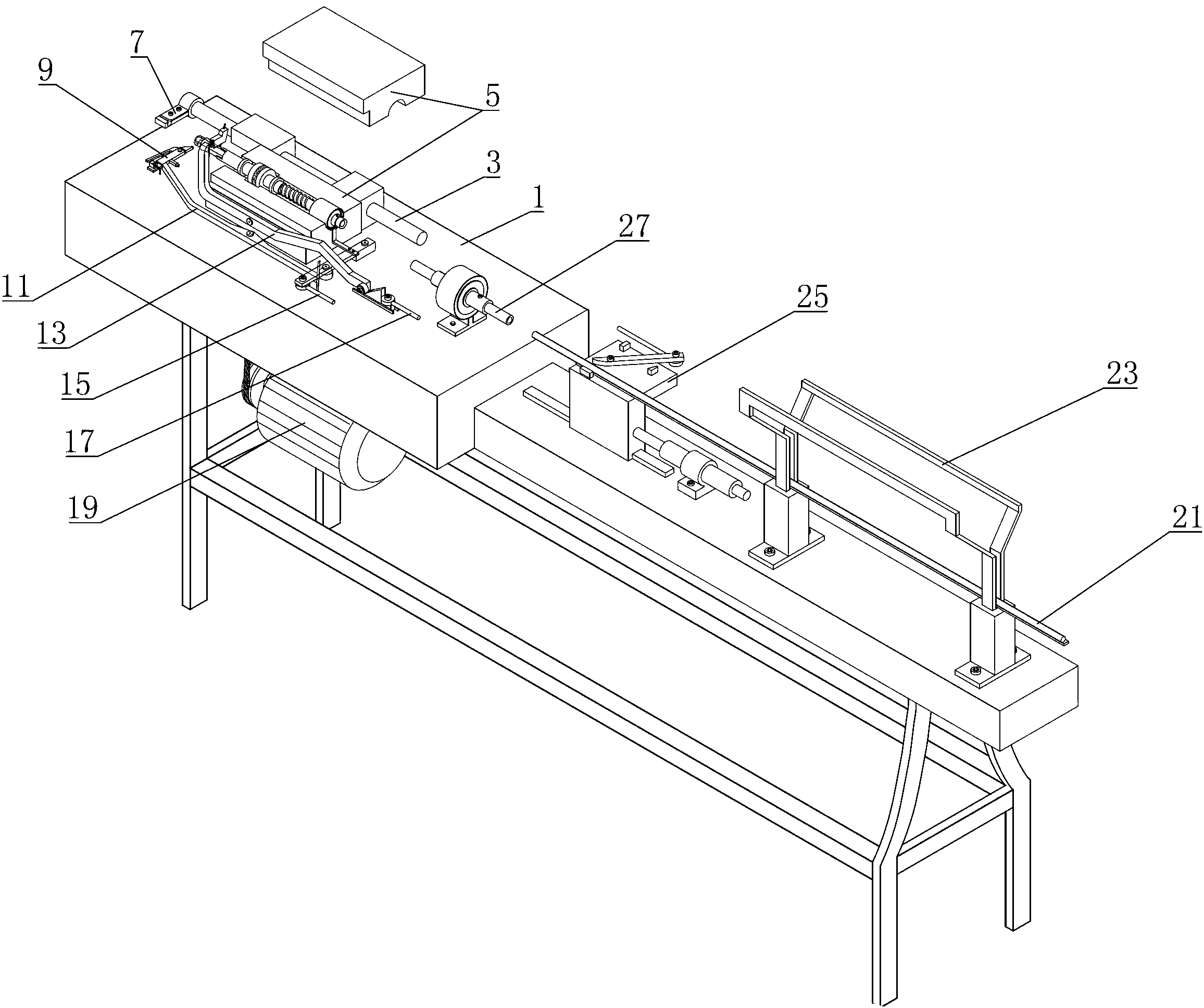

[0041] The present invention will be further described below in conjunction with the accompanying drawings. A high-speed and high-precision numerical control automatic wood turning machine, including a frame (1), a motor (19) and a headstock (5) installed on the frame, including a compressed air source, and a fully automatic production numerical control circuit; it also includes:

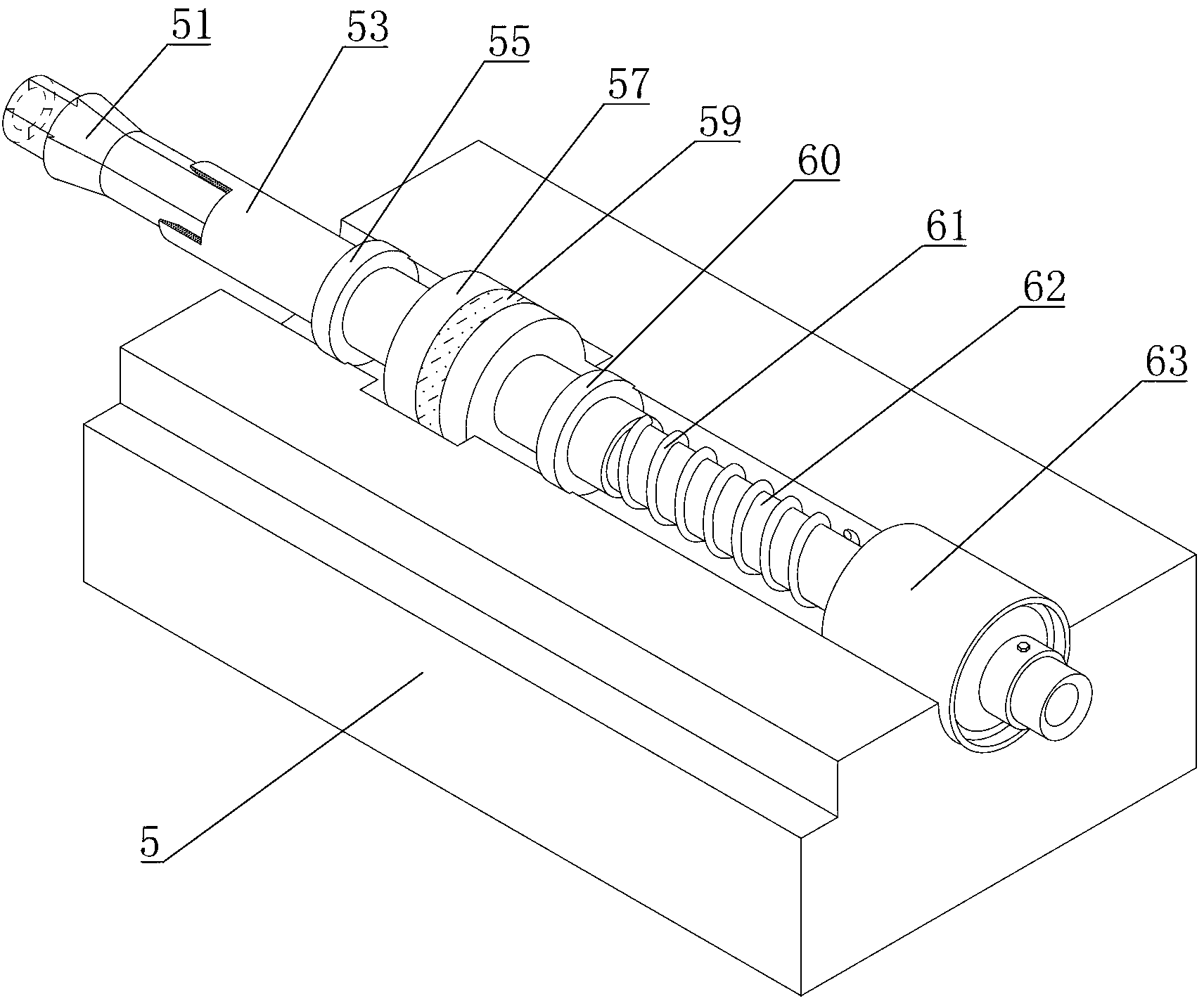

[0042] (a) The headstock (5) is installed to drive the fine bamboo and wood bar rotation mechanism. The rotating mechanism for driving thin bamboo and wood bars has a sleeve (53); the sleeve (53) is fixed with the headstock (5) by bearing I (55), bearing II (60). Two bearings are positioned at the both sides of belt pulley (57) respectively, are combined and fixed and integrated with the frame by the cover of headstock and body. Insert the rod chuck (62) in the sleeve (53). The bar chuck (62) has a claw head (51) at the head, and a slide tube (63) is installed at the tail through the bearing III, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com