Automatic vacuum-adsorption working table

A vacuum adsorption and workbench technology, which is applied to woodworking lathes, manufacturing tools, wood processing appliances, etc., can solve the problems of reducing work efficiency and increasing operation complexity, and achieves the effect of ensuring adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

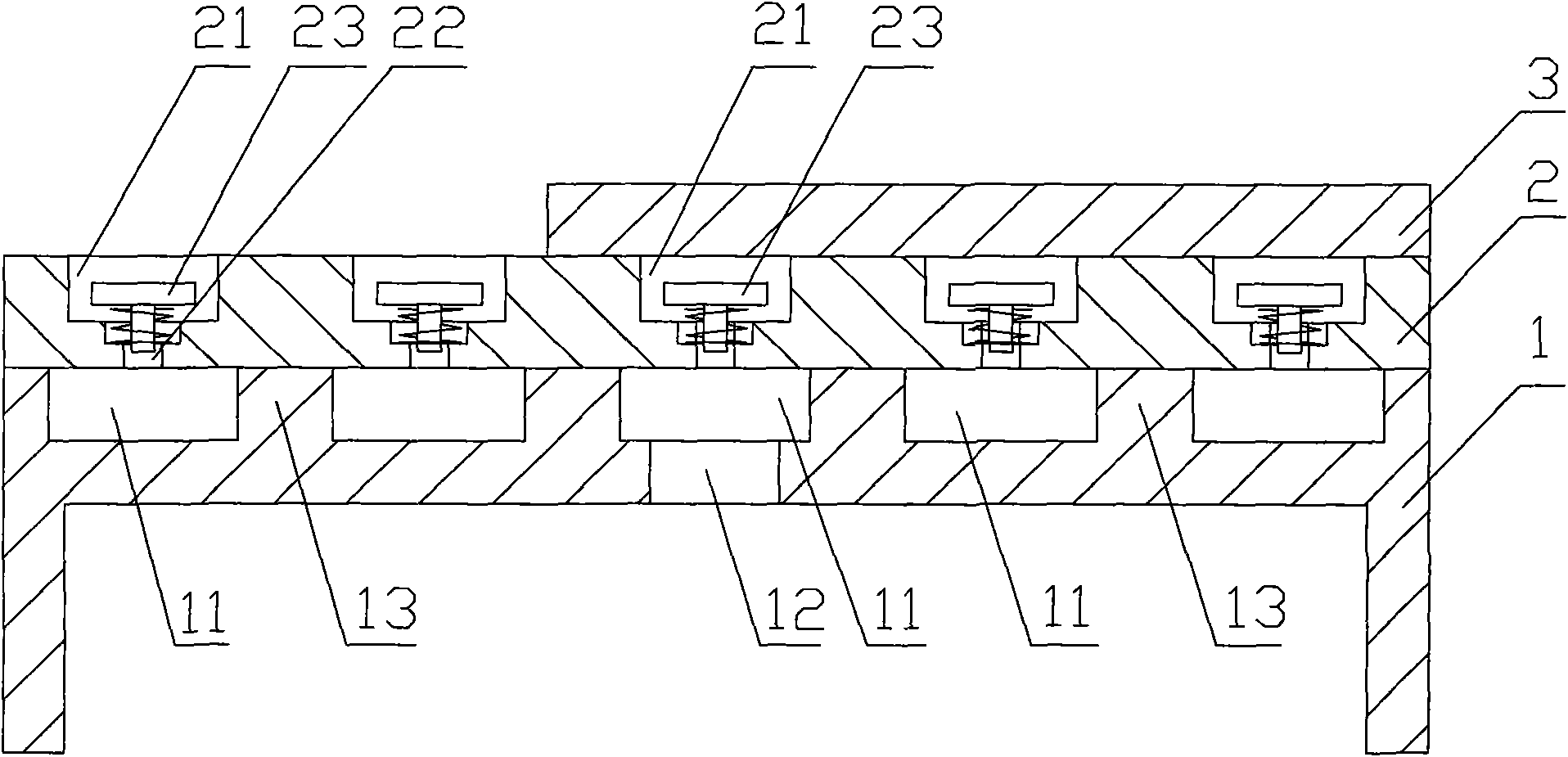

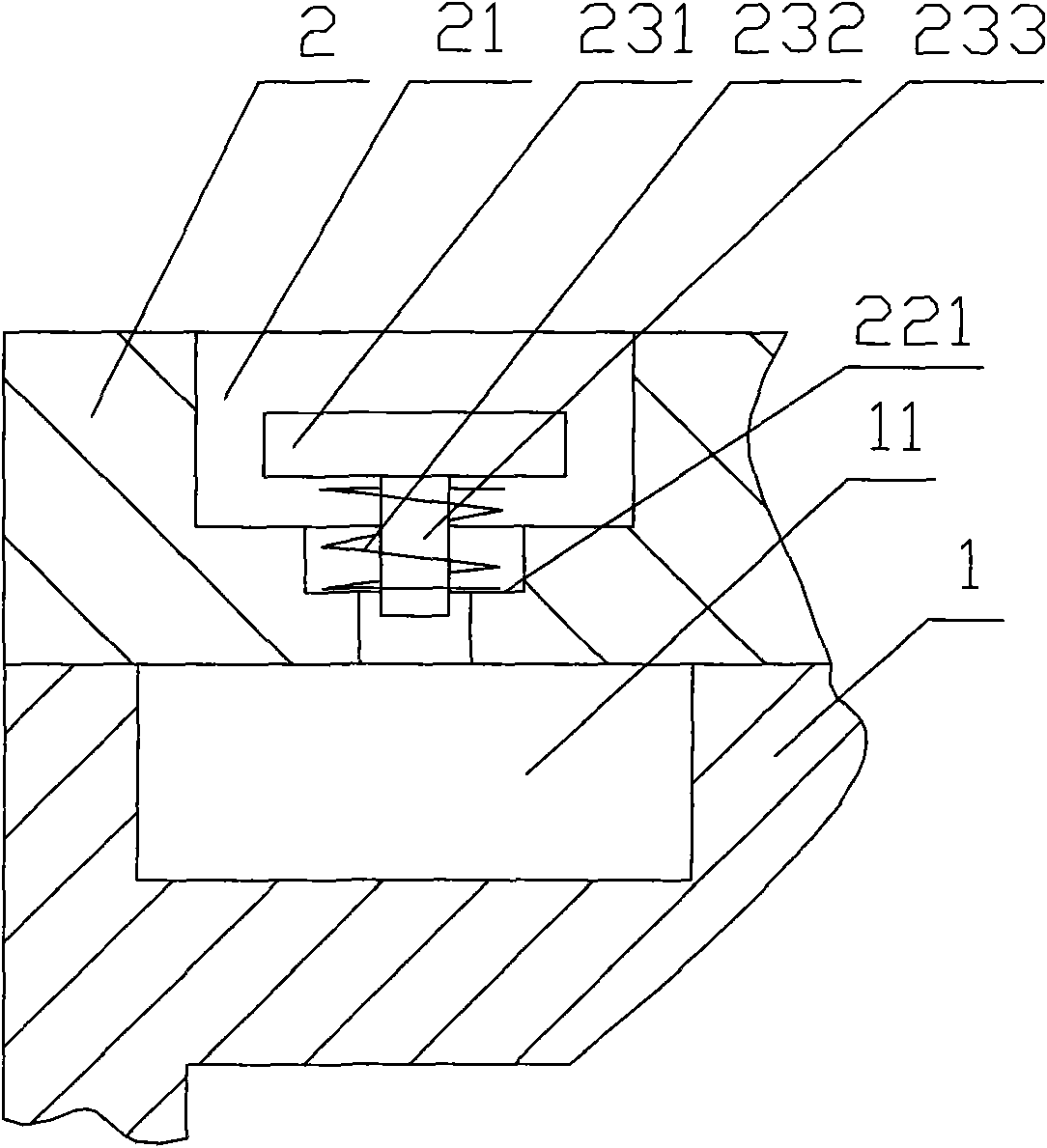

[0028] Example as figure 1 and 2 As shown, the present invention includes a vacuum workbench 1 and an adsorption workbench 2 . The vacuum table 1 has a rectangular plate structure as a whole, but it is not limited to this structure. A large vacuum groove 11 is arranged on the vacuum table 1 . Several protrusions 13 are arranged on the bottom surface of the vacuum groove 11 . The height of the protrusion 13 is the same as the height of the edge of the vacuum groove 11, and the upper surface of the protrusion 13 is a plane. The setting of the boss 13 needs to ensure that all parts in the vacuum groove 11 are connected. The vacuum groove 11 is also in communication with the suction hole 12 . The suction hole 12 is used to be connected with the vacuum device. The suction hole 12 is arranged at the center of the vacuum groove 11 to increase the suction speed of the vacuum device.

[0029] The adsorption workbench 2 also has a rectangular plate structure as a whole, but it is...

Embodiment 2

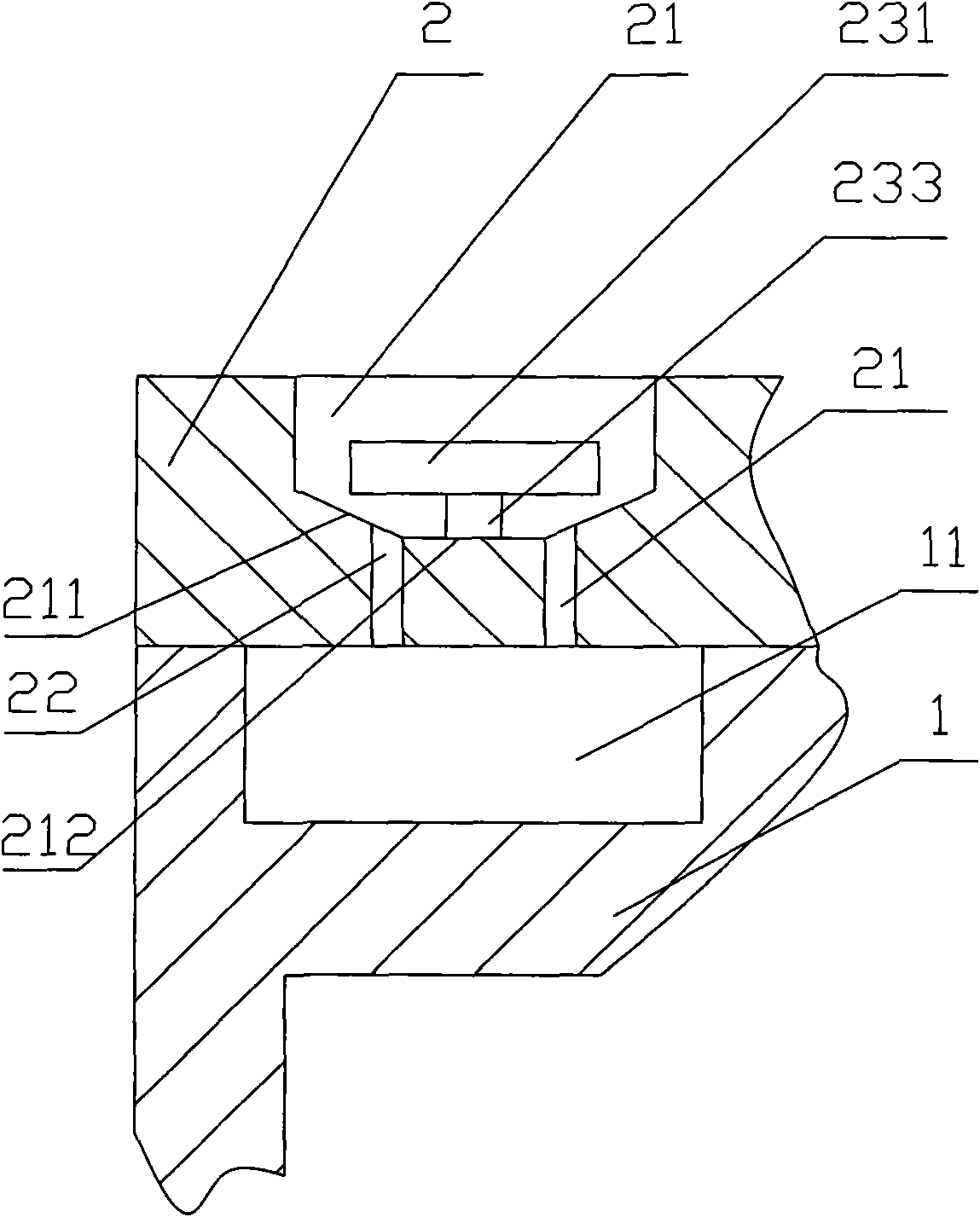

[0033] Example two such as image 3 As shown, the structure of the vacuum workbench 1 in the second embodiment and the connection mode between the vacuum workbench 1 and the adsorption workbench 2 are exactly the same as those in the first embodiment. The difference is the setting of the adsorption workbench 2 and the automatic closing device 23 .

[0034] The adsorption workbench 2 is provided with several adsorption grooves 21 . The difference from the first embodiment is that the bottom surface of the adsorption grooves 21 is set as an inverted conical surface 211 , and the bottom surface of the conical surfaces 211 of the adsorption grooves 21 is set as a plane 212 . Several adsorption holes 22 are arranged on the conical surface 211 of the adsorption groove 21 , and the centers of the adsorption holes 22 are arranged on a circle centered on the center of the conical surface 211 .

[0035] The automatic closing device 23 includes a cover plate 231 and a support rod 233 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com