Assembly type manhole

An inspection well, prefabricated technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as unfavorable urban traffic, high construction risk, low strength, etc., to achieve high construction quality and reduce environmental pollution. , The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

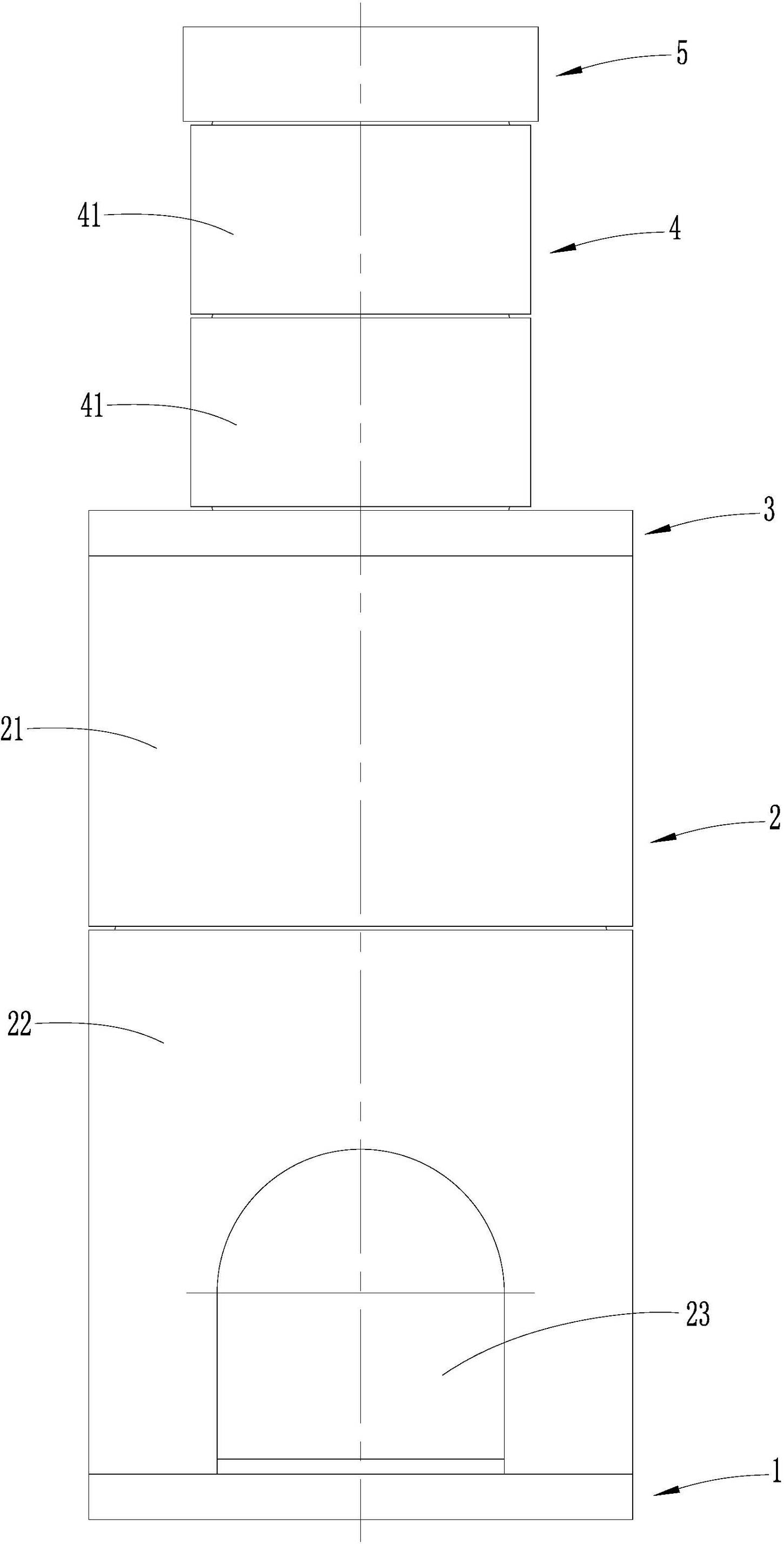

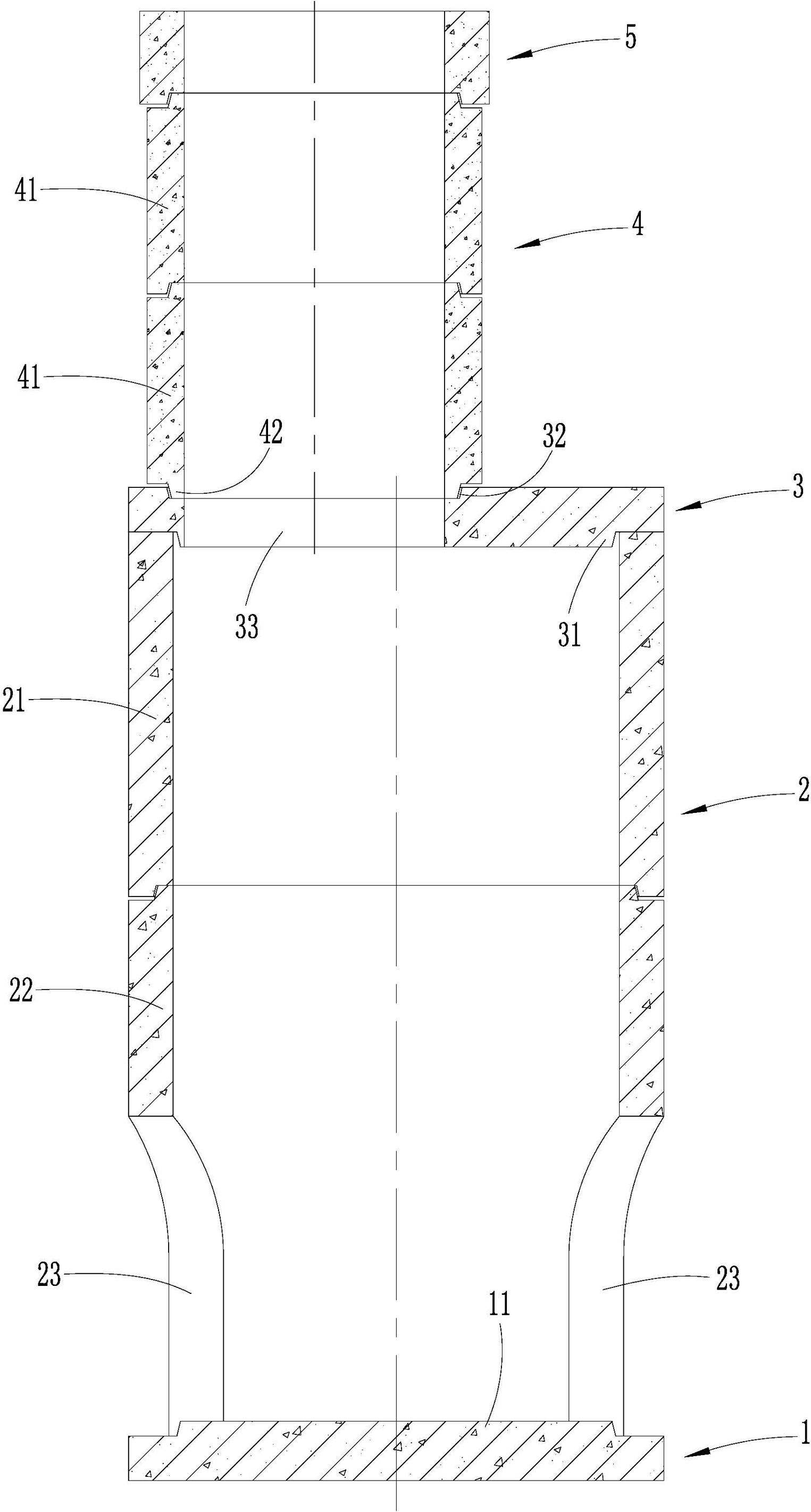

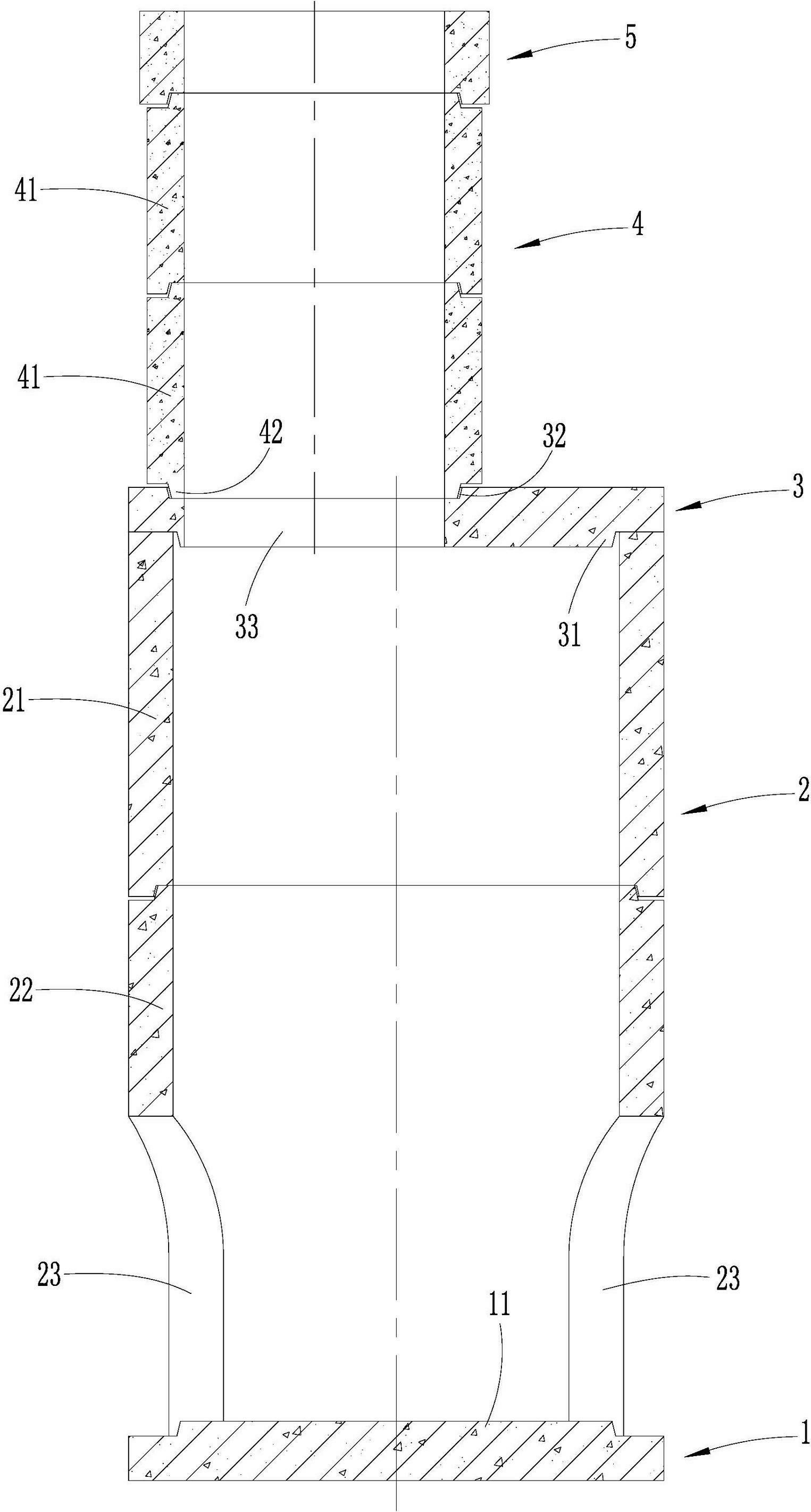

[0023] see figure 1 , figure 2 :

[0024] The shape of the inspection well is circular, and the inspection well includes bottom plate 1, well chamber 2, cover plate 3, well shaft 4, well ring 5, and well cover connected in sequence from bottom to top (for the sake of succinct explanation, the accompanying drawings Manhole covers are not shown).

[0025] The well chamber 2 is formed by connecting the upper well chamber 21 and the lower well chamber 22 up and down, and the joints in the vertical direction of the two are tongue-and-groove connections (comprising the lower tongue-and-groove, the upper tongue-and-groove, the lower tongue-and-groove, tongue-and-groove are not shown in the accompanying drawings). The part number of the upper tongue and groove), the upper end surface of the upper well chamber 21 is a plane, and the lower end of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com