Preparation method of large-volume mining and dressing powder mortar

A large-volume, powder-based technology, which is applied in the field of large-volume mining and dressing powder mortar preparation, can solve the problems of poor mortar volume stability, poor freeze-thaw resistance of mortar, and reduced bond strength, so as to save raw material costs , Improve water retention rate and antifreeze performance, reduce the effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

[0022] The preparation method of large-volume mining and dressing powder mortar of the present invention comprises the following steps:

[0023] Step 1, powder pretreatment process: drying, raw material analysis, sieving, screening;

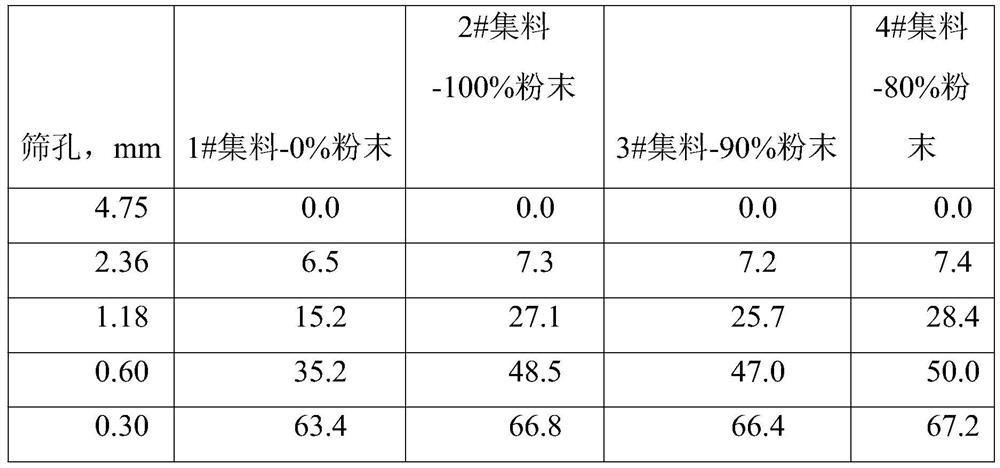

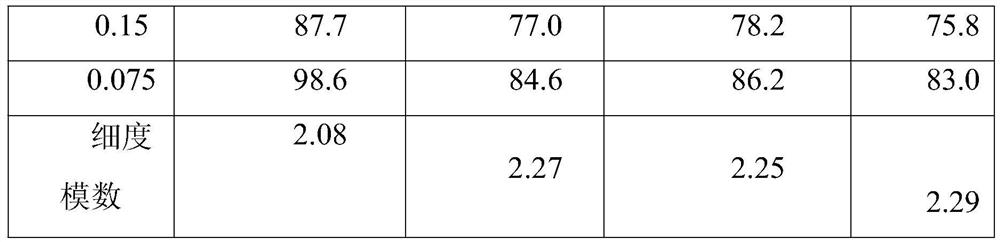

[0024] Step 2, mixing the powder with natural sand, adjusting the aggregate gradation after mixing, and controlling the fineness modulus of the aggregate;

[0025] Step 3: Put half of the blended aggregate with well-controlled gradation into a container equipped with an agitator, add cement, high-efficiency thickening powder, and class II fly ash mixed cementitious materials into the aggregate, stir evenly, and then add The other half is mixed with aggregate, add appropriate amount of water, stir evenly and obtain slurry;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com