Process for manufacturing mud environment protection brick

A manufacturing method and technology of environmentally friendly bricks, which are applied to clay products, other household appliances, household appliances, etc., to achieve the effect of saving clay resources and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

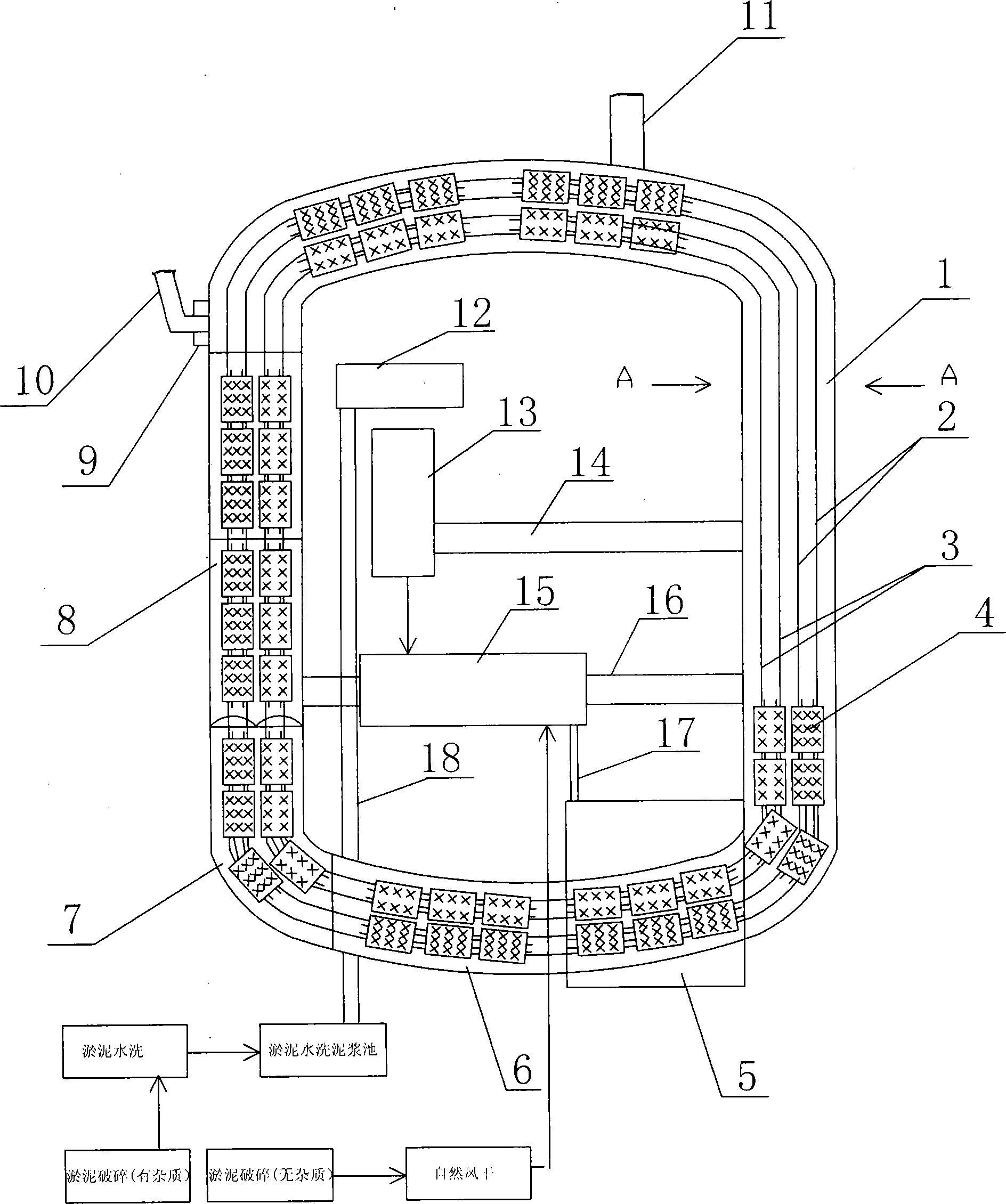

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] As shown in the figure, the manufacturing method of the silt environmental protection brick according to the present invention comprises the following steps:

[0019] 1) Sludge crushing: crush the fresh silt dredged from the river with a crusher.

[0020] If the crushed sludge contains impurities, the crushed sludge must be washed with a sieve, and the washed mud flows into the washing mud tank, and the impurities remain on the sieve and removed in time, while the mud in the washing mud tank passes through the hydraulic sludge The conveying pipeline 18 is input to the silt settling tank 12 to make the mud settle and age, and then the above-mentioned sedimented and aged mud is put into the feeder, and then sent to the silt drying room 13 for drying by the feeder.

[0021] If there is very little impurity in the crushed sludge, the crushed sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com