Cement stabilized macadam mixture doped with waste incineration slag

A technology for cement-stabilized gravel and waste incineration slag, which is applied in the field of highway construction materials, can solve the problems affecting the road performance, low strength and resource utilization rate limitation of cement-stabilized gravel mixture, and achieves the promotion of an environment-friendly society. , the effect of reducing the use and improving the utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The cement-stabilized gravel mixture prepared in this example includes the following components in terms of mass percentage: 31.5% of 4.75mm-13.2mm slag pellets, 29.8% of slag, 4.5% of cement, 25.8% of aggregate, and 8.4% of water.

[0033] The slag pellets include the following components in terms of mass percentage: 32.6% of 0-2.36mm waste incineration slag, 6.5% of cement, 32.5% of fly ash, 7.8% of activator, and 20.6% of water. Wherein, the stimulating agent is a mixture of calcium hydroxide and anhydrous sodium sulfate with a mass ratio of 5:1.

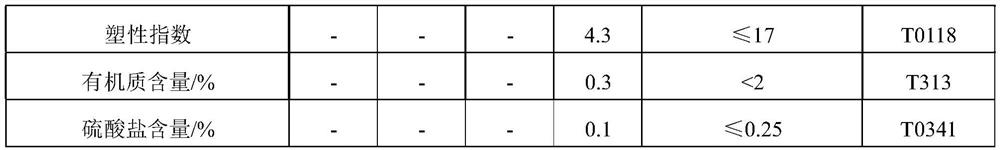

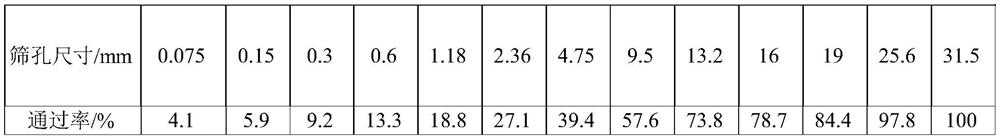

[0034] The slag is 0-4.75mm waste incineration slag, and the 0-4.75mm waste incineration slag is the waste incineration slag that has been pretreated through magnetic separation, iron removal, air selection, eddy current separation and other processes. After screening, the particle size range is 0 ~4.75mm. The performance test result is: the apparent density is 2.32g / cm 3 , The water absorption rate is 11.7%.

[0035] O...

Embodiment 2

[0068] In this embodiment, the cement-stabilized gravel mixture mixed with waste incineration slag comprises the following components in terms of mass percentage: 4.75mm-13.2mm slag pellets 31.2%, slag 30.3%, cement 4.1%, aggregate 26.1% , Water 8.3%.

[0069] The slag pellets include the following components in terms of mass percentage: 32.6% of 0-2.36mm waste incineration slag, 6.5% of cement, 32.5% of fly ash, 7.8% of activator, and 20.6% of water. Wherein, the stimulating agent is a mixture of calcium hydroxide and anhydrous sodium sulfate with a mass ratio of 5:1.

[0070] The slag is 0-4.75mm waste incineration slag, and the 0-4.75mm waste incineration slag is the waste incineration slag that has been pretreated through magnetic separation, iron removal, air selection, eddy current separation and other processes. The cement uses ordinary silicon with a strength grade of 42.5. Salt cement, the fly ash is grade I fly ash, the aggregate is limestone, the calcium hydroxide ...

Embodiment 3

[0079] In this embodiment, the cement-stabilized gravel mixture mixed with garbage incineration slag comprises the following components in terms of mass percentage: 4.75mm-13.2mm slag pellets 30.0%, slag 30.1%, cement 4.4%, aggregate 26.9% , Water 8.6%.

[0080] The slag pellets include the following components in terms of mass percentage: 32.6% of 0-2.36mm waste incineration slag, 6.5% of cement, 32.5% of fly ash, 7.8% of activator, and 20.6% of water. Wherein, the stimulating agent is a mixture of calcium hydroxide and anhydrous sodium sulfate with a mass ratio of 5:1.

[0081] The slag is 0-4.75mm waste incineration slag, and the 0-4.75mm waste incineration slag is the waste incineration slag that has been pretreated through magnetic separation, iron removal, air selection, eddy current separation and other processes. The cement uses ordinary silicon with a strength grade of 42.5. Salt cement, the fly ash is grade I fly ash, the aggregate is limestone, the calcium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com