A concrete mixing plant using construction waste as raw material

A concrete and building technology, applied in mixing plants, cement mixing devices, unloading devices, etc., can solve problems such as adverse effects on physical and mental health, difficulties, waste of valuable resources, etc., to meet the needs of a large number of concrete production and realize secondary utilization , The effect of reducing the amount of landfill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

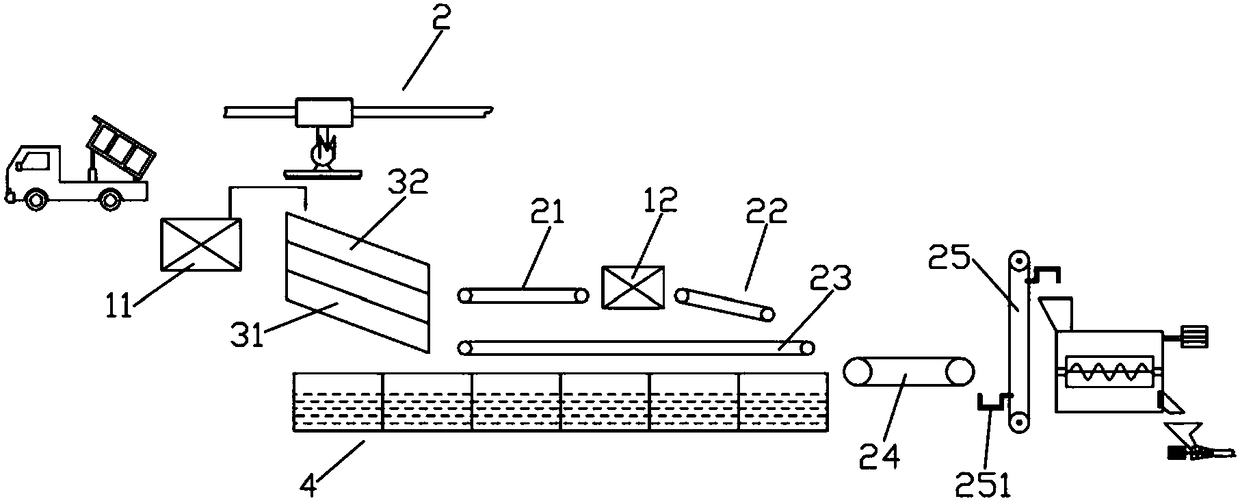

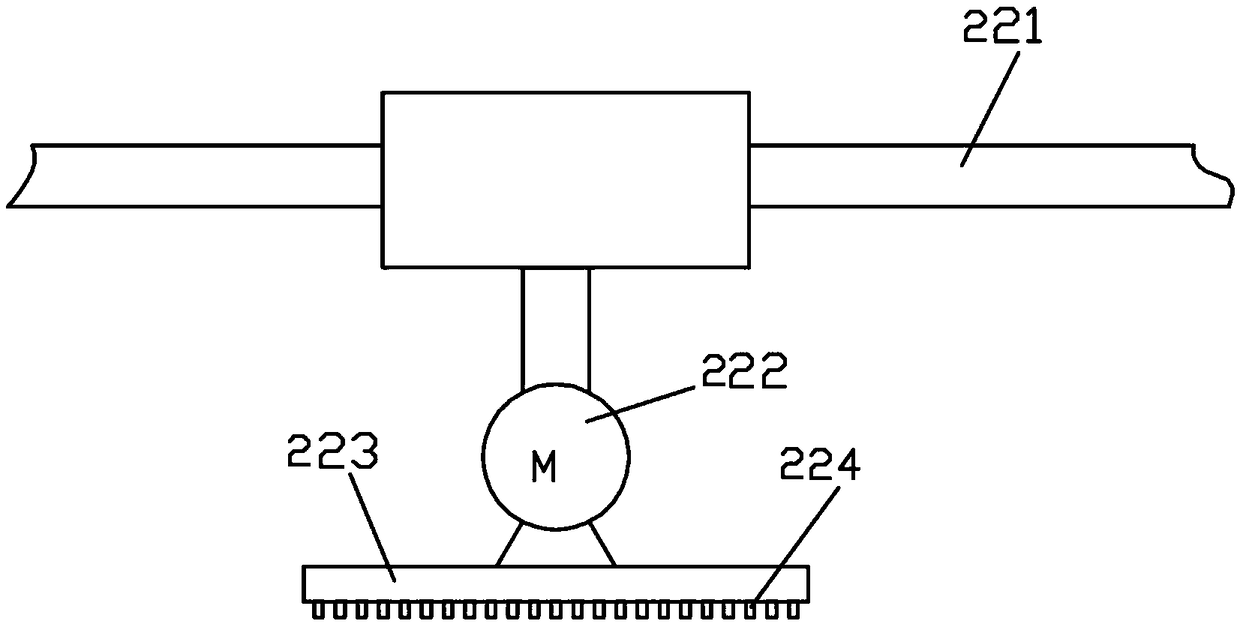

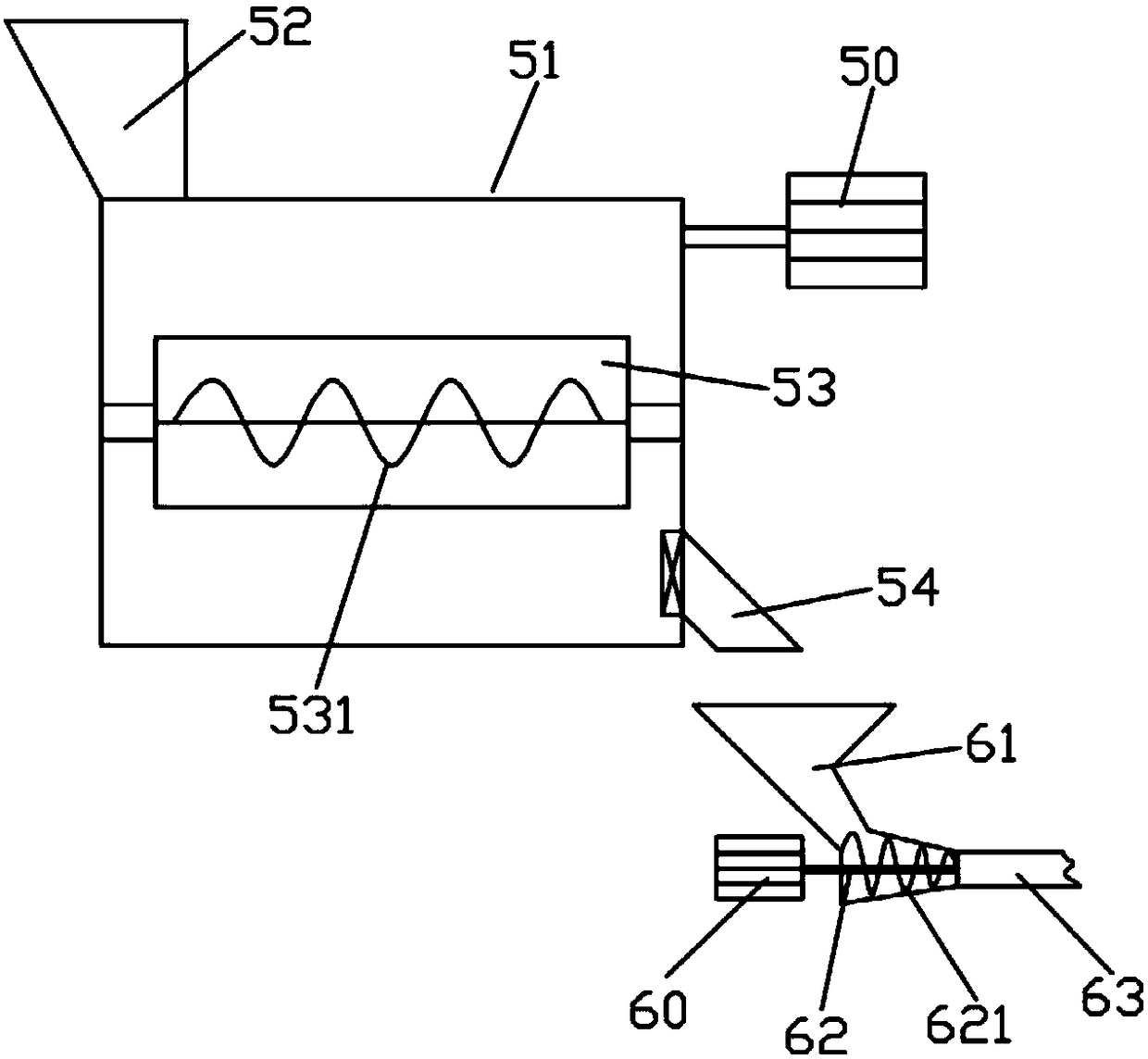

[0018] Such as figure 1 As shown, a concrete mixing plant using building waste as raw materials includes an aggregate supply system, a weighing system, a lifting system, a mixer system, and a control system 240. The aggregate supply system includes a primary crusher 11 and a double-layer vibration screener. , The conveying unit, the secondary crusher 12 and the receiving water tank 4. The primary crusher 11 performs primary crushing of the construction waste transported by the transport vehicle to obtain primary aggregates, and sends the primary aggregates to the double-layer vibrating screener. The vibrating screening machine includes an upper vibrating screening unit 32 and a lower vibrating screening unit 31. The screen mesh size of the upper vibrating screening unit 32 is larger than the screening mesh size of the lower vibrating screening unit 31. The conveying unit includes a first conveyor belt 21 and a second conveyor belt 22. And the third conveyor belt 23, the primary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com