A treatment method for rapid reduction of domestic waste and energy recovery

A domestic waste and energy recovery technology, applied in the direction of waste treatment, solid waste removal, etc., can solve the problems of increased cost, inability to achieve separation, easy corruption, etc., achieve simple separation and reprocessing, and facilitate the effect of secondary separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

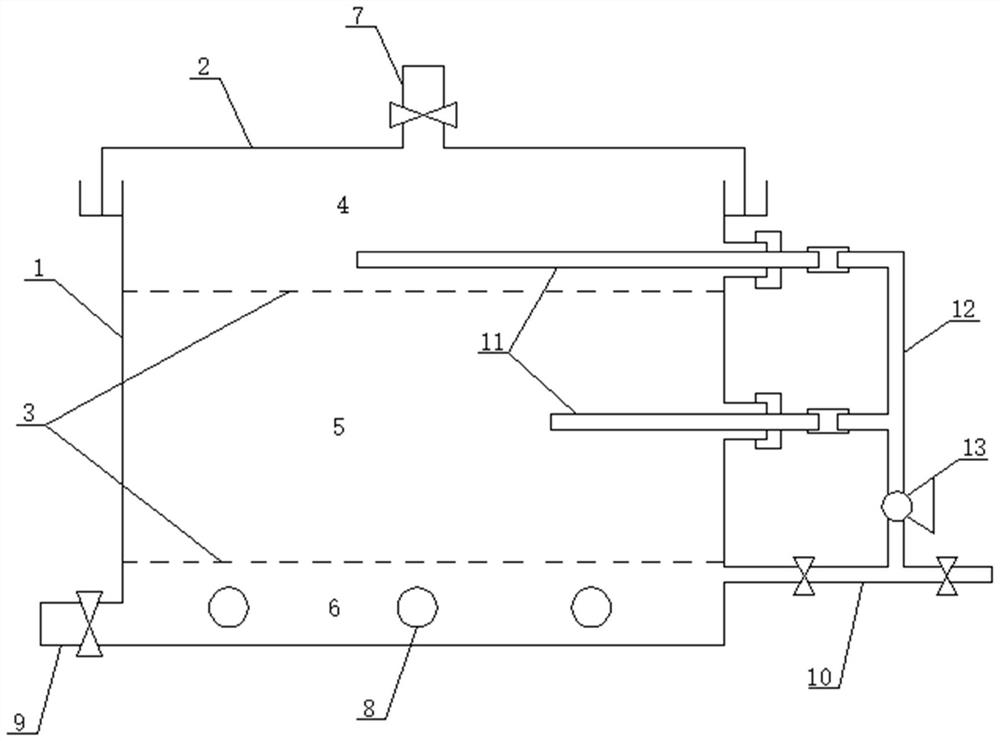

Method used

Image

Examples

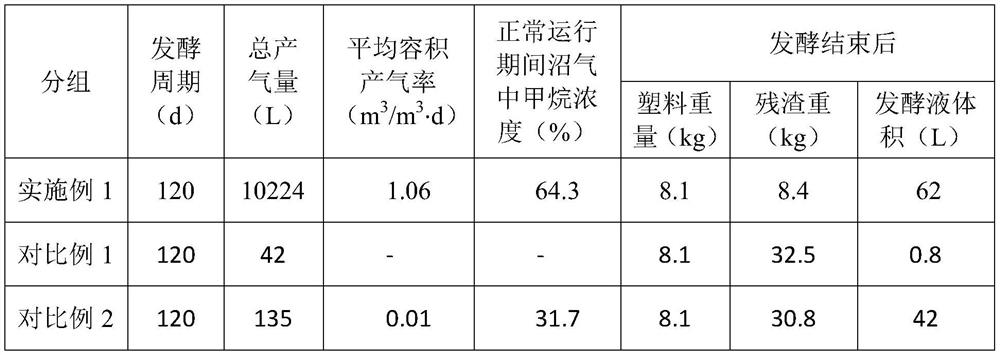

Embodiment 1

[0039] Collect 7-day domestic garbage in a certain area of Chengdu, average sampling and pretreatment with broken bags. After testing, the composition ratio is as follows:

[0040] Classification Leaves the fabric Glass Metal non-recyclable paper ashes plastic Kitchen waste Mass ratio 2.50% 1.60% 2.60% 0.40% 7.30% 1.60% 17.90% 66.10%

[0041] Note: The weight of each part of garbage includes the plastic bags used for packaging.

[0042] The effective volume of the fermentation tank is 80L (dry fermentation tank 64L: 40cm*40cm*40cm+ percolation tank 16L). Put the above-mentioned domestic garbage into the dry fermentation zone of the sequencing batch type anaerobic dry fermentation tank. After testing, this batch feeds 64L and weighs about 41.5kg. After sealing the fermenter, add 40L of pre-acclimated liquid inoculum, connect the gas meter, and ferment at 35±2°C. The leachate is refluxed from the bottom of the sequencing batch anaer...

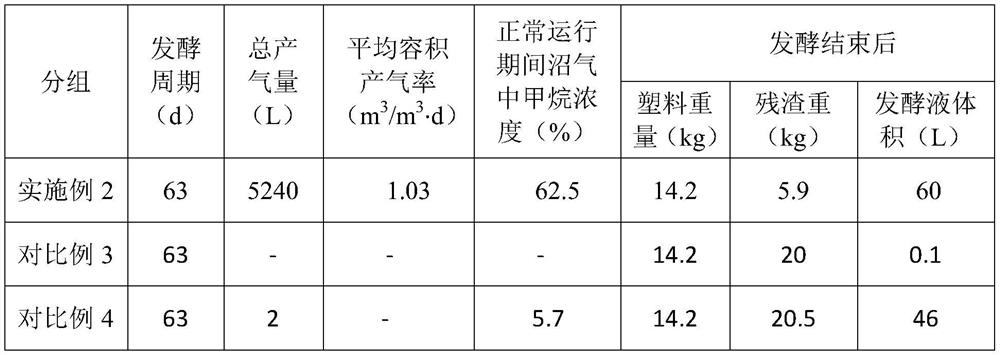

Embodiment 2

[0051] Collect 7-day domestic garbage in a certain area of Chengdu, average sampling and pretreatment with broken bags. After testing, the composition ratio is as follows:

[0052] Classification Leaves the fabric Glass Metal non-recyclable paper plastic Kitchen waste Mass ratio 3.3% 2.6% 1.8% 1.2% 7.5% 37.3% 46.3%

[0053] Note: The weight of each part of garbage includes the plastic bags used for packaging.

[0054] The effective volume of the fermentation tank is 80L (dry fermentation tank 64L: 40cm*40cm*40cm+ percolation tank 16L). Put the above-mentioned domestic garbage into the dry fermentation zone of the sequencing batch type anaerobic dry fermentation tank. After testing, this batch feeds 64L and weighs about 34.3kg. After sealing the fermenter, add 47L of pre-acclimated liquid inoculum, connect the gas meter, and ferment at 35±2°C. The leachate is refluxed from the bottom of the sequencing batch anaerobic dry fermenter to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com