Pipe gallery sludge and riverway bottom mud collaborative resource treatment and utilization method

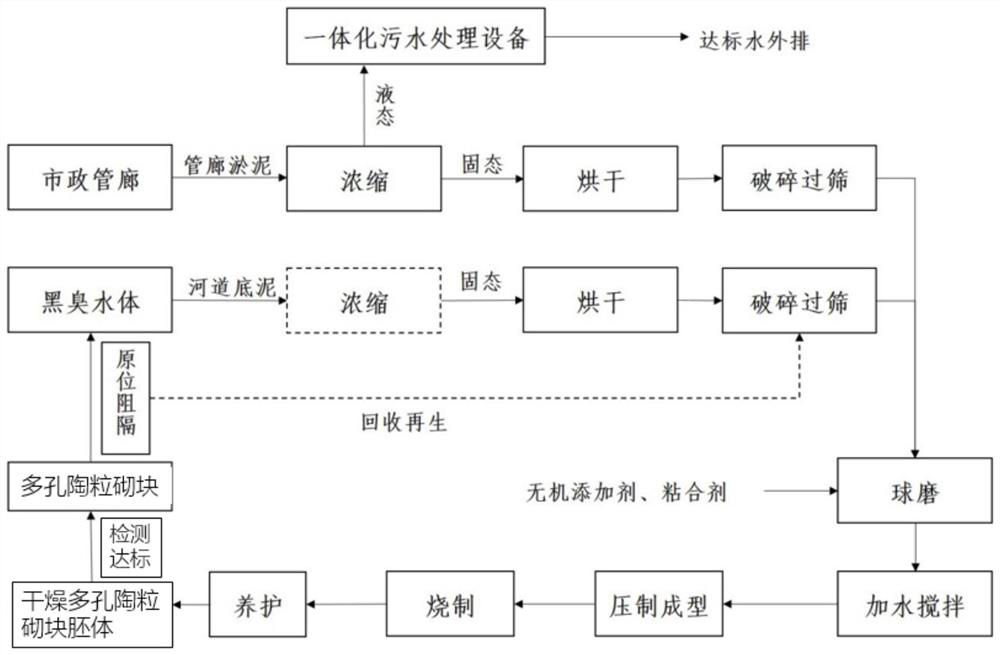

A technology for river sediment and resource utilization, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of peculiar smell, large floor space and low drying efficiency in the production process, and achieves small floor space and dehydration. High efficiency and less odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043]Example: Concentrate the silt of the municipal pipe gallery and the river sediment of the black and odorous water body through gravity sedimentation, respectively transport the sewage in the upper layer to the integrated sewage treatment equipment for sewage treatment, discharge it after reaching the standard, and concentrate the lower layer respectively Pipe gallery silt and concentrated river bottom silt, both of which have a sludge concentration of 10g / L;

[0044] Dry the obtained concentrated pipe gallery silt and concentrated river bottom mud respectively to obtain dried pipe gallery silt and dry river bottom mud with a water content of 25%;

[0045] The dry pipe gallery silt and the dry river bottom mud are respectively crushed through a 160-mesh sieve to obtain the pipe gallery sludge powder and the river bottom mud powder;

[0046] Add 25kg of pipe gallery silt powder, 25kg of river bottom mud powder, 15kg of diatomaceous earth and 1kg of water glass into the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com