Integrated treatment process for clindamycin hydrochloride production wastewater

A technology for clindamycin hydrochloride and production wastewater, which is applied in water/sewage treatment, natural water treatment, special compound water treatment, etc. It can solve the problems of inability to meet treatment requirements, clean water, high power consumption, and high operating costs. The effect of reducing the amount of landfill, stable operation and rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

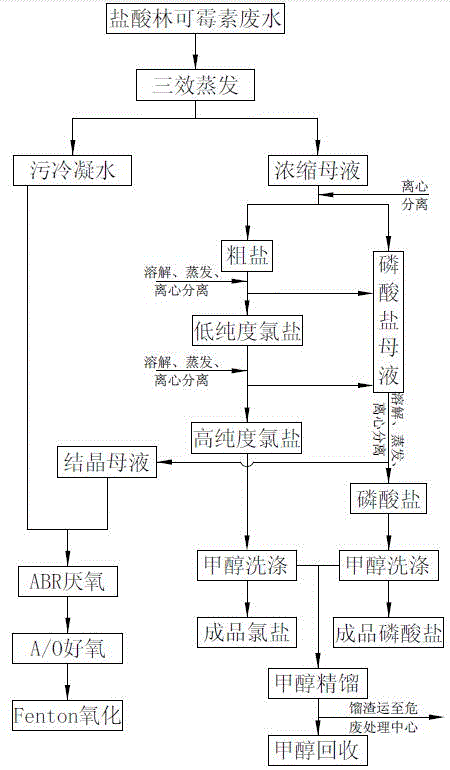

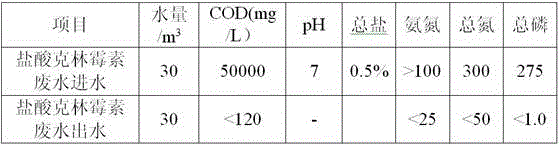

[0032] In view of the water quality characteristics of clindamycin hydrochloride wastewater, the integrated treatment method of the present invention can be used to achieve the stable operation of each treatment unit, the discharge of effluent up to the standard, and the treatment goals of economical efficiency. The specific treatment method steps are as follows:

[0033] (1) The mixed collection of clindamycin hydrochloride production wastewater and other cleaning wastewater is directly pumped to the sewage treatment system. The sewage treatment system first performs three-effect evaporation and concentration on the sewage, and then centrifuges to separate the salt-containing organic matter;

[0034] (2) In the salt refining workshop, after the crude salt is completely dissolved, the steam pressure is controlled to 0.18-0.22Mpa, the temperature in the kettle is 70-80°C, and the concentration is started. In the later stage of concentration, the density is checked every 30 minute...

Embodiment 2

[0038] The specific processing steps are as follows:

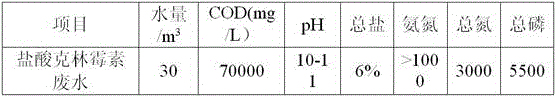

[0039] (1) The mixed collection of clindamycin hydrochloride production wastewater and other cleaning wastewater is directly pumped to the sewage treatment system. The sewage treatment system first performs three-effect evaporation and concentration on the sewage, and then centrifuges to separate the salt-containing organic matter;

[0040] (2) In the salt refining workshop, after the crude salt is completely dissolved, the steam pressure is controlled to 0.18-0.22Mpa, the temperature in the kettle is 70-80°C, and the concentration is started. In the later stage of concentration, the density is checked every 30 minutes. When the density ρ=1.38-1.40 , start centrifugation to obtain low-purity chlorine salt; after the low-purity chlorine salt is completely dissolved, control the steam pressure to 0.18-0.22Mpa, the temperature in the kettle is 70-80°C, and start to concentrate. In the later stage of concentration, check the de...

Embodiment 3

[0044] The specific processing steps are as follows:

[0045] (1) The mixed collection of clindamycin hydrochloride production wastewater and other cleaning wastewater is directly pumped to the sewage treatment system. The sewage treatment system first performs three-effect evaporation and concentration on the sewage, and then centrifuges to separate the salt-containing organic matter;

[0046] (2) In the salt refining workshop, after the crude salt is completely dissolved, the steam pressure is controlled to 0.18-0.22Mpa, the temperature in the kettle is 70-80°C, and the concentration is started. In the later stage of concentration, the density is checked every 30 minutes. When the density ρ=1.38-1.40 , start centrifugation to obtain low-purity chlorine salt; after the low-purity chlorine salt is completely dissolved, control the steam pressure to 0.18-0.22Mpa, the temperature in the kettle is 70-80°C, and start to concentrate. In the later stage of concentration, check the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com