Construction method of a waste incineration ash pile

A waste incineration ash and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as pollution and high environmental costs, and achieve the effects of avoiding high energy consumption, large pores, and reducing landfill volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

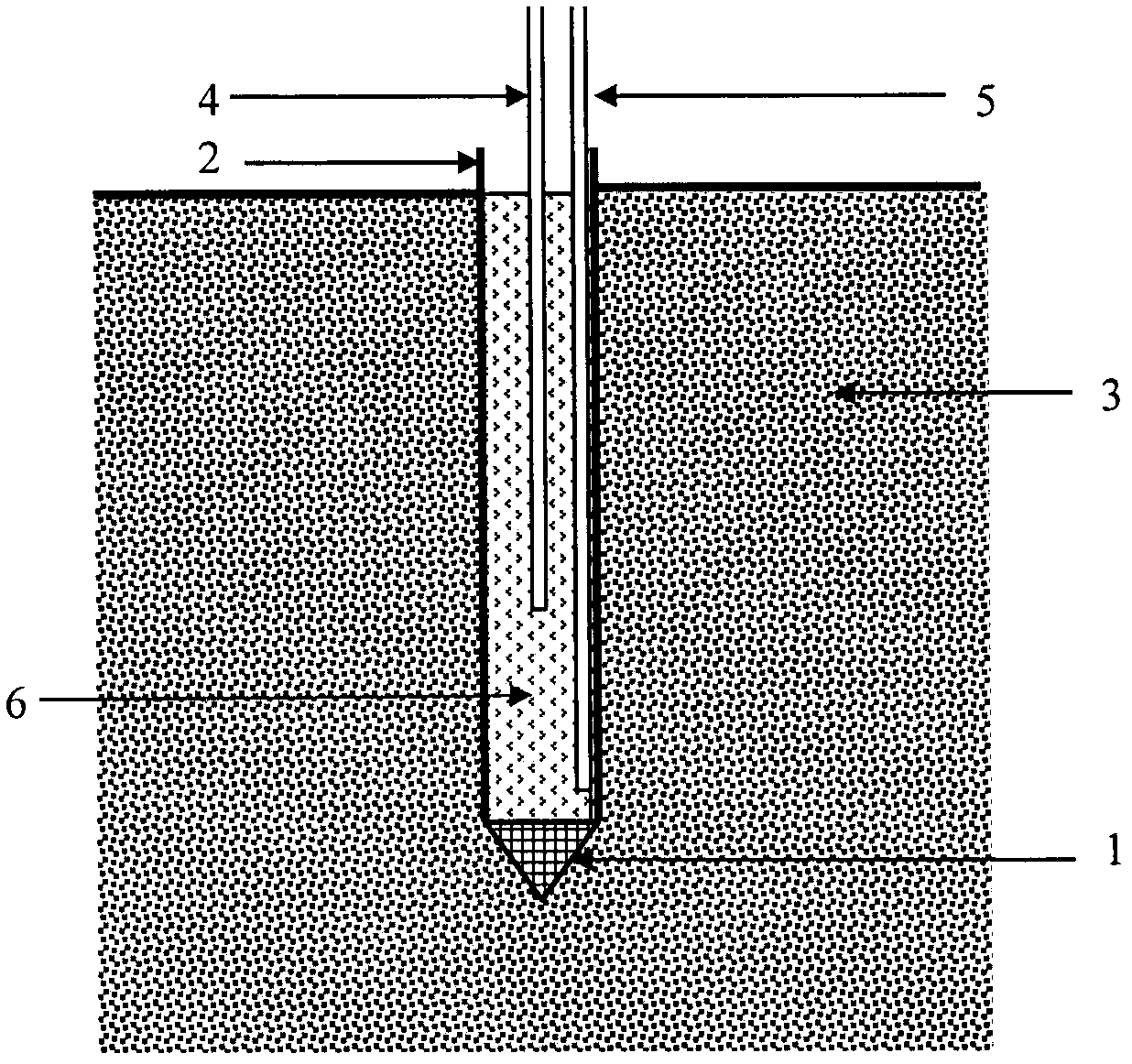

[0038] In this example, a construction method of waste incineration ash piles is used to construct composite foundations. The design pile length is 9.0m, and the pile diameter is 0.6m. The steps of the method are as follows:

[0039] a. Sink the steel pipe 2 with the concrete prefabricated pile point 1 into the foundation 3 to a depth of 9.0m to make a pile hole;

[0040] b. Mix the bacteria liquid with medium sand and waste incineration ash first, then add 0.05mol / L calcium chloride solution and mix to form a mixture;

[0041] c. Pour the mixture into the steel pipe 2 that has been submerged in the foundation in advance, and bury the grouting pipe 4 and the grouting pipe 5 in the mixture 6 during the process of pouring the mixture, and the grouting pipe 4 is buried in the center of the pile hole On the axis and the height of the bottom nozzle from the bottom of the pile hole is 3.0m, the slurry pumping pipe 5 is buried along the inner wall of the steel pipe 2 and the height o...

Embodiment 2

[0048] In this example, a construction method of waste incineration ash piles is used for the construction of composite foundations. The design pile length is 12.0m and the pile diameter is 0.5m. The steps of the method are as follows:

[0049]a. Sink the steel pipe 2 with the concrete prefabricated pile tip 1 into the foundation 3 to a depth of 12.0m to make a pile hole;

[0050] b. Mix the bacteria liquid with medium sand and waste incineration ash first, then add 0.05mol / L calcium chloride solution and mix to form a mixture;

[0051] c. Pour the mixture into the steel pipe 2 that has been submerged in the foundation in advance, and bury the grouting pipe 4 and the grouting pipe 5 in the mixture 6 during the process of pouring the mixture, and the grouting pipe 4 is buried in the center of the pile hole On the axis and the height of the bottom nozzle from the bottom of the pile hole is 4.0m, the slurry pumping pipe 5 is buried along the inner wall of the steel pipe 2 and the...

Embodiment 3

[0058] In this example, a construction method of waste incineration ash piles is used to construct drainage consolidation foundations. The design pile length is 12.0m and the pile diameter is 0.4m. The steps of the method are as follows:

[0059] a. Sink the steel pipe 2 with the concrete prefabricated pile tip 1 into the foundation 3 to a depth of 12.0m to make a pile hole;

[0060] b. Mix the bacteria liquid with medium sand and waste incineration ash first, then add 0.05mol / L calcium chloride solution and mix to form a mixture;

[0061] c. Pour the mixture into the steel pipe 2 that has been submerged in the foundation in advance, and bury the grouting pipe 4 and the grouting pipe 5 in the mixture 6 during the process of pouring the mixture, and the grouting pipe 4 is buried in the center of the pile hole On the axis and the height of the bottom nozzle from the bottom of the pile hole is 4.0m, the slurry pumping pipe 5 is buried along the inner wall of the steel pipe 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com