High-strength alkali-resistant composite brick based on waste reutilization and preparation method of high-strength alkali-resistant composite brick

A technology for reusing and compounding bricks, applied in the field of building materials, can solve the problem of high production cost, and achieve the effects of reducing production cost, increasing consumption, and enhancing alkali corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

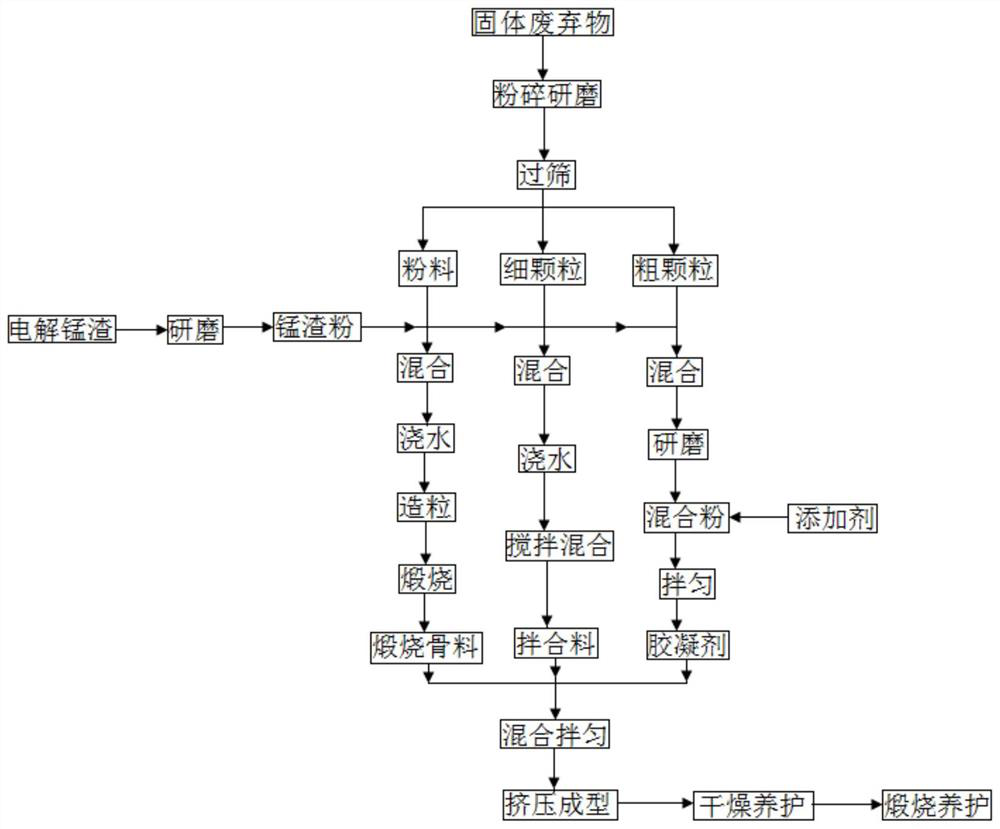

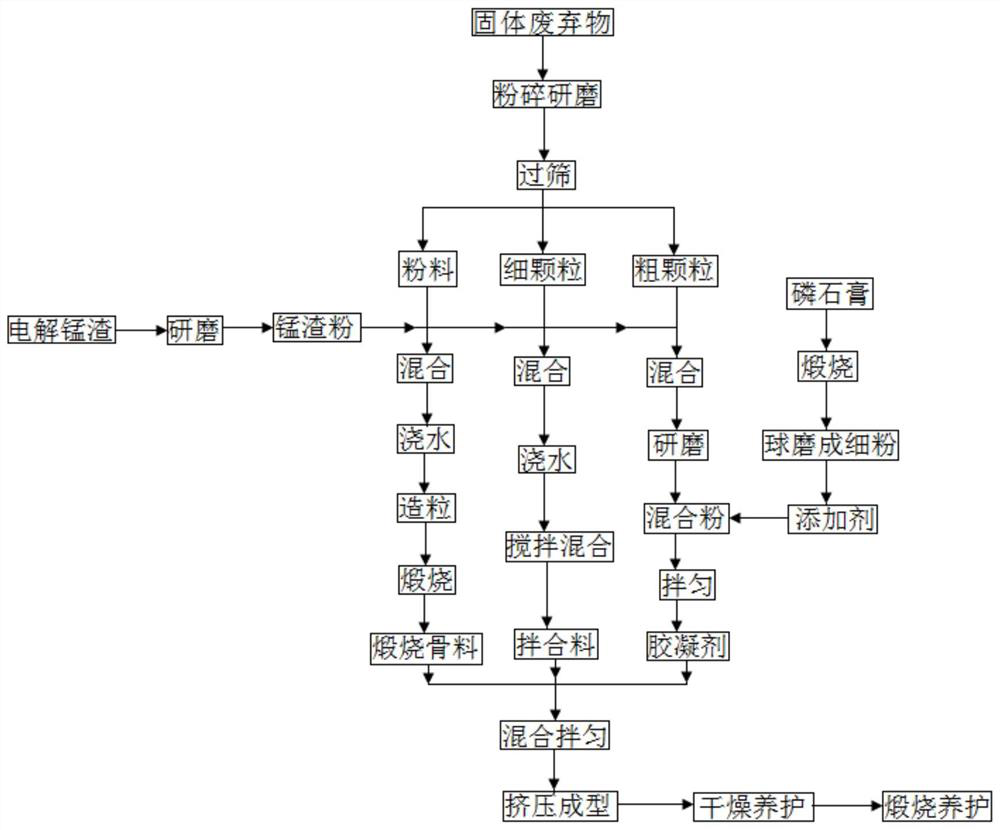

[0031] Such as figure 1 As shown, in some embodiments, the method for preparing high-strength alkali-resistant composite bricks based on waste recycling comprises the following steps:

[0032] (1) Grinding the electrolytic manganese slag until the specific surface area is 800-1000m 2 / kg, to get manganese slag powder; the specific surface area of manganese slag powder is not limited to 800-1000m 2 / kg, can be any value within this range, for example: 800m 2 / kg, 850m 2 / kg, 880m 2 / kg, 900m 2 / kg, 910m 2 / kg, 940m 2 / kg, 970m 2 / kg, 1000m 2 / kg, etc., you can also choose a value larger than this specific surface area, for example: 1100m 2 / kg, 1140m 2 / kg, 1200m 2 / kg, 1400m 2 / kg, 1800m 2 / kg etc.

[0033] (2) crushing and grinding the solid waste, and sieving to prepare powder, fine particles and coarse particles;

[0034] (3) Mix the powder with manganese slag powder, water, granulate, and calcinate to obtain the calcined aggregate;

[0035] (4) Mix the fi...

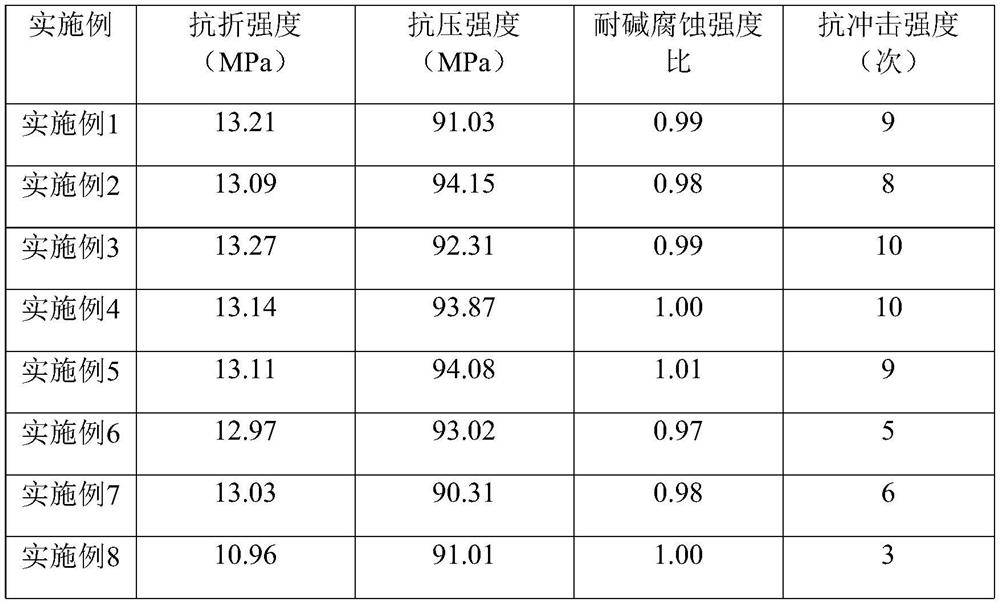

Embodiment 1

[0049] (1) Grinding the electrolytic manganese slag until the specific surface area is 800m 2 / kg, to get manganese slag powder;

[0050] (2) Grinding the solid waste, and sieving to prepare powder with a particle size of <0.2 mm, fine particles with a particle size of 0.2-3 mm, and coarse particles with a particle size of 3-10 mm;

[0051] (3) Mix the powder and manganese slag powder at a mass ratio of 1:1, water, granulate into particles with a particle size between 3-5mm, and calcinate at a temperature of 1000°C for 0.5h to obtain calcined aggregate;

[0052] (4) Mix fine particles and manganese slag powder at a mass ratio of 1:0.5, water until the moisture content is 6%, and stir at 300r / min for 2 hours to obtain the mixture;

[0053] (5) Mix manganese slag powder and coarse particles at a mass ratio of 1:2, and send them into a grinder to grind until the specific surface area is ≥ 2000m 2 / kg to get mixed powder; then add an additive accounting for 3% of the mixed powd...

Embodiment 2

[0057] (1) Grinding the electrolytic manganese slag until the specific surface area is 1000m 2 / kg, to get manganese slag powder;

[0058] (2) Grinding the solid waste, and sieving to prepare powder with a particle size of <0.2 mm, fine particles with a particle size of 0.2-3 mm, and coarse particles with a particle size of 3-10 mm;

[0059] (3) Mix the powder and manganese slag powder at a mass ratio of 1:4, water, granulate into particles with a particle size between 3-5mm, and calcinate at a temperature of 1200°C for 3 hours to obtain calcined aggregate;

[0060] (4) Mix fine particles and manganese slag powder at a mass ratio of 1:2, water until the moisture content is 8%, and stir at 500r / min for 3 hours to obtain the mixture;

[0061] (5) Mix manganese slag powder and coarse particles at a mass ratio of 1:4, and send them into a grinder to grind until the specific surface area is ≥ 2000m 2 / kg to get mixed powder; then add an additive accounting for 7% of the mixed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com