Comprehensive utilization process for making bricks from municipal sludge and construction waste

A technology for construction waste and sludge, which is applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. , the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

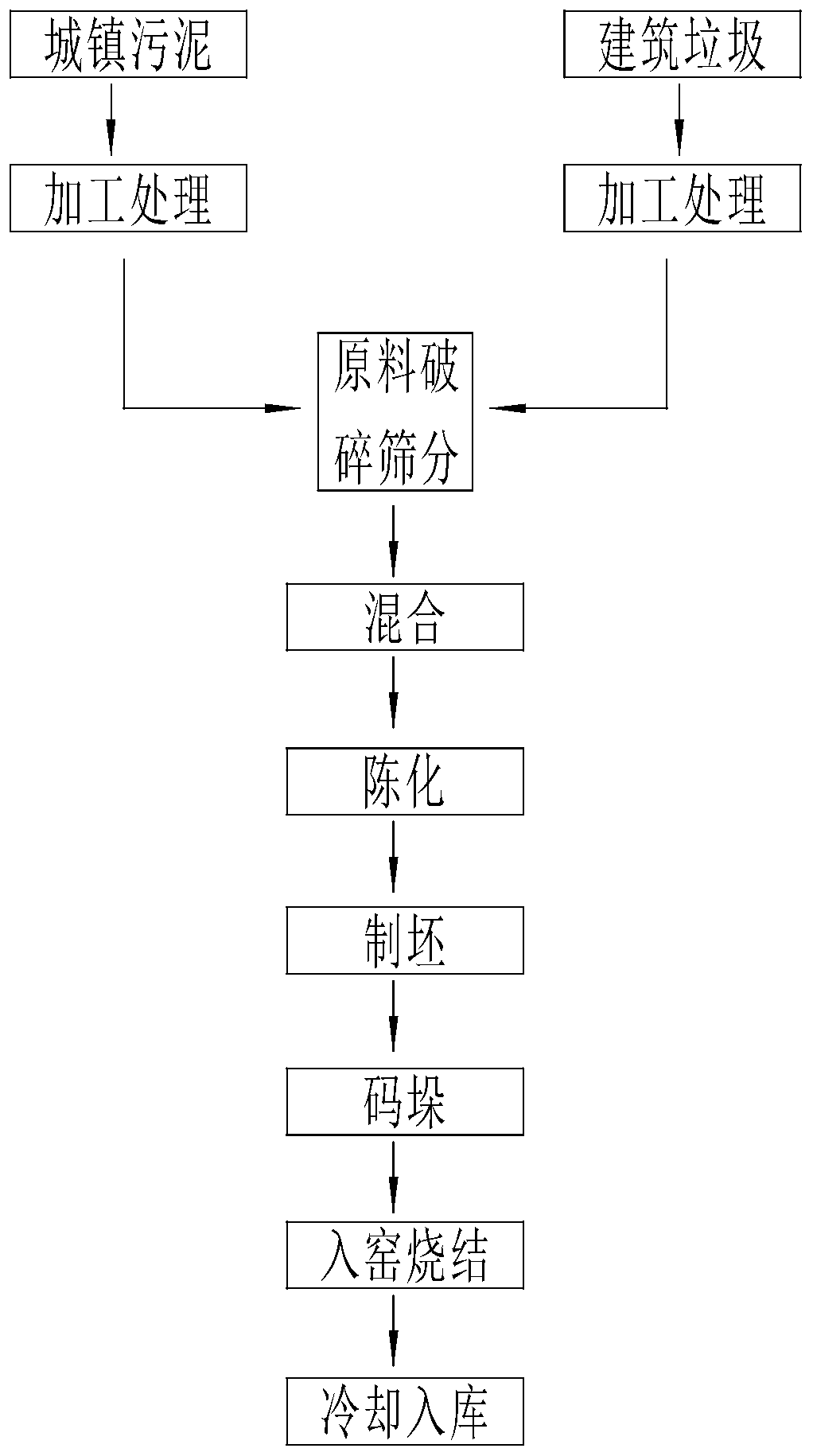

[0019] The process steps are as follows: urban sludge and construction waste are processed separately, then raw materials are crushed and screened → mixed → aged → billet making → stacking → kiln sintering → cooling and storage; the specific implementation steps are as follows:

[0020] Crushing and screening of raw materials: crushing and screening the sludge regeneration fuel and ultra-fine powder formed after urban sludge and construction waste are processed, the ultra-fine powder constitutes sintering material, and the sludge regeneration fuel is used as fuel;

[0021] Mixing: Mix the crushed and screened superfine powder and sludge regeneration fuel, and transport the mixed mixture to the aging warehouse;

[0022] Aging: The mixture is aged in the aging warehouse, so that various raw materials can be fully infiltrated and contacted, and the aging time is 36-40h;

[0023] Billet making: the aged mixture is extruded into specific adobe strips under the action of an extruder...

Embodiment 2

[0028] The superfine powder of the construction waste is 70%-80%, the sludge regenerated fuel is 21%-30%, and the sum of the composition weights of the above components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com