Spinning printing and dyeing waste water reclamation method, device and application thereof

A technology for textile printing, dyeing and recycling, which is applied in the textile industry wastewater treatment, chemical instruments and methods, and water/sewage treatment, etc. It can solve problems such as difficulty in adapting to rapid changes in water quality, large fluctuations in effluent quality, and increased salt content in reused water. , to achieve the effect of reducing secondary pollution, small footprint and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

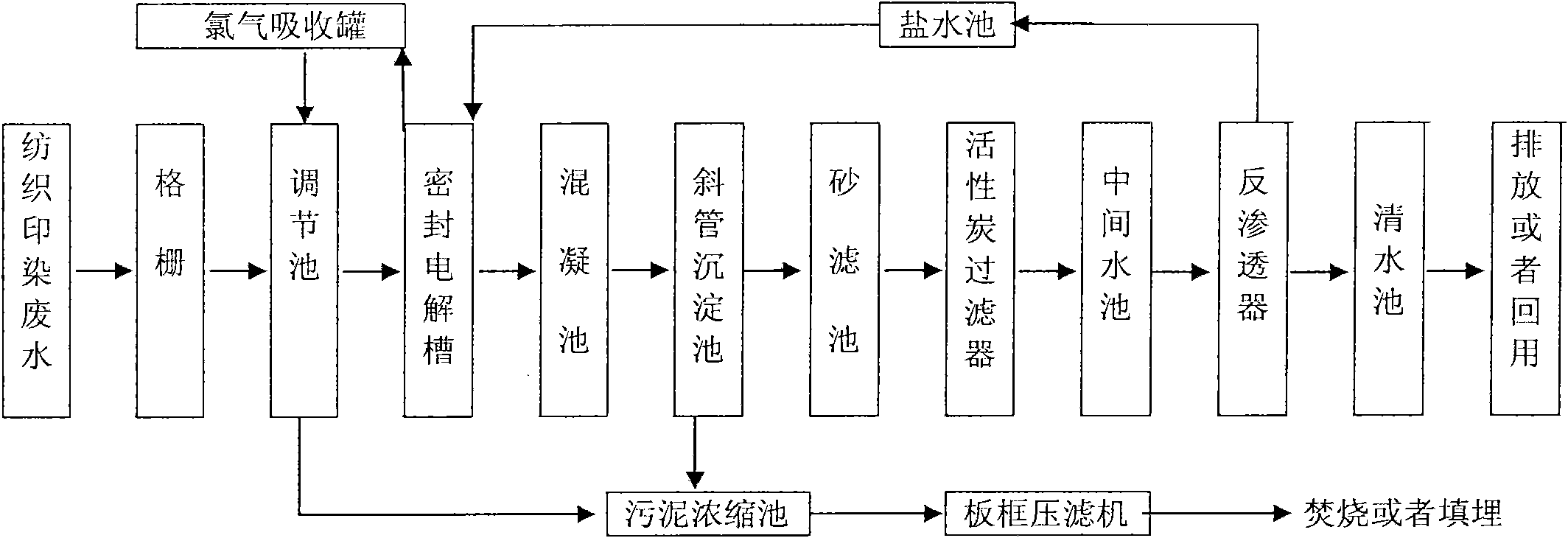

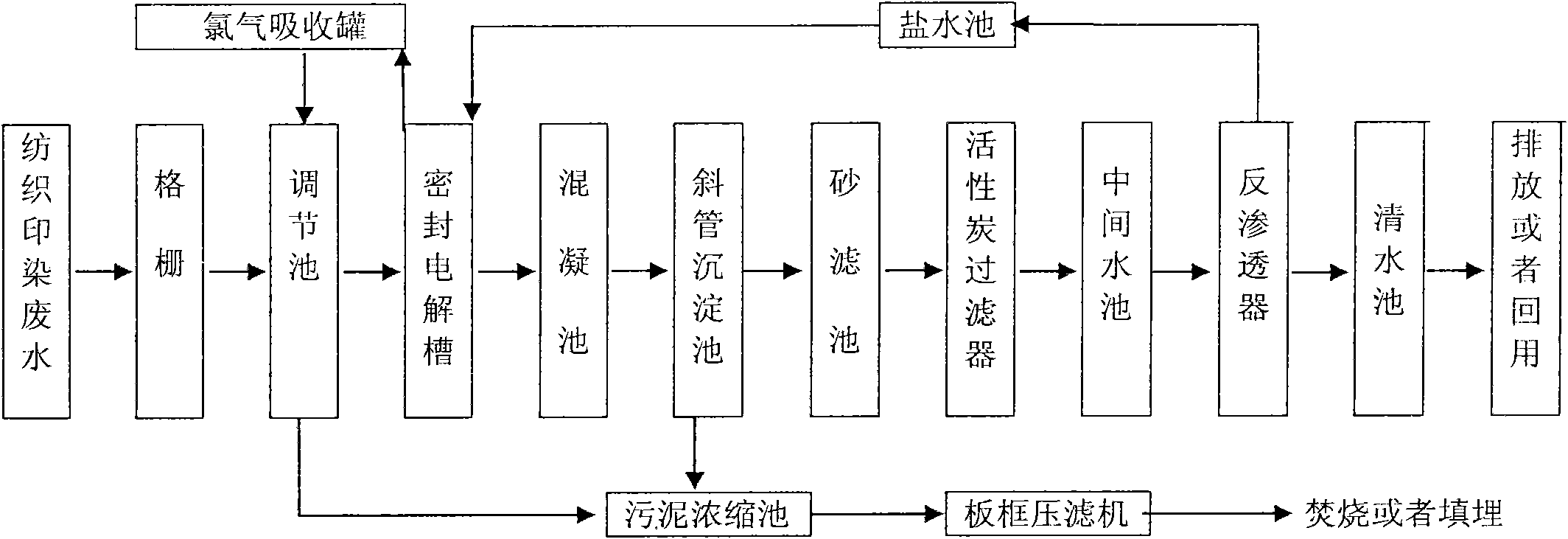

[0039] The device of the method for realizing the recycling of textile printing and dyeing wastewater according to the present invention is as follows: figure 1 Shown:

[0040] Grille (SXZ-VII rotary fine-grid filter, grid gap 0.30mm), regulating pool (6m×6m×6m, the regulating pool plays the role of regulating water volume, and its water inlet is equipped with a perforated diversion groove, which has a uniform The role of water quality, small suspended particles in water can be preliminarily precipitated here), sealed electrolytic cell (box-type non-diaphragm multi-electrode electrolytic cell, 3m×1m×1m), coagulation tank (6m×6m×6m), inclined tube Sedimentation tank (6m×4m×3m), sand filter (4m×3m×5m), activated carbon filter (Detian, CM-10018-2 type activated carbon filter), intermediate pool (6m×6m×6m), reverse The permeator (tubular reverse osmosis device, one-stage multi-stage layout system) and the clean water tank are connected through water pipelines in turn; Connect wi...

Embodiment 2

[0042] (1) Textile printing and dyeing wastewater (printing and dyeing wastewater mainly based on reactive dyes, with a treatment capacity of 100t / d) goes through the grid to remove fibers and large particles with a particle size greater than 3mm, then enters the regulating tank, and then lifts it to the electrolytic tank with a pump After mixing with the saturated sodium chloride brine pumped into the brine pool, indirect electrocatalytic oxidation is carried out. During electrolysis, adjust the molar concentration of sodium chloride in the wastewater to 0.005mol / L, and the DC current to 137mA / cm 2 , The hydraulic retention time is 85min.

[0043] (2) The effluent from indirect electrocatalytic oxidation flows into the coagulation tank and is mixed evenly with PAC (commercially available, with a dosage of 80mg / L wastewater) and PAM (commercially available, with a dosage of 0.5mg / L wastewater). Slag-water separation is carried out in the inclined tube sedimentation tank, and ...

Embodiment 3

[0049] (1) Textile printing and dyeing wastewater (printing and dyeing wastewater mainly composed of cationic dyes, with a treatment capacity of 370t / d) goes through the grid to remove fibers and large particles with a particle size greater than 3mm and then enters the regulating tank. The role of primary precipitation. Then use a pump to lift it into the electrolytic tank and mix it with the saturated sodium chloride brine pumped into the brine pool, and then carry out indirect electrocatalytic oxidation. During electrolysis, adjust the molar concentration of sodium chloride in the wastewater to 0.87mol / L, and the direct current to 15mA / cm 2 , The hydraulic retention time is 15min.

[0050] (2) The effluent from indirect electrocatalytic oxidation flows into the coagulation tank and is mixed with PAC (commercially available, with a dosage of 215mg / L waste water) and PAM (commercially available, with a dosage of 1.2mg / L waste water) in order to produce precipitation and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com