Comprehensive recycling and harmless disposal method for zinc hydrometallurgy high leaching residue

A technology of harmless treatment and wet zinc smelting, which is applied in the fields of process efficiency improvement, photographic process, instruments, etc., and can solve problems such as increasing the complexity of solidification process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

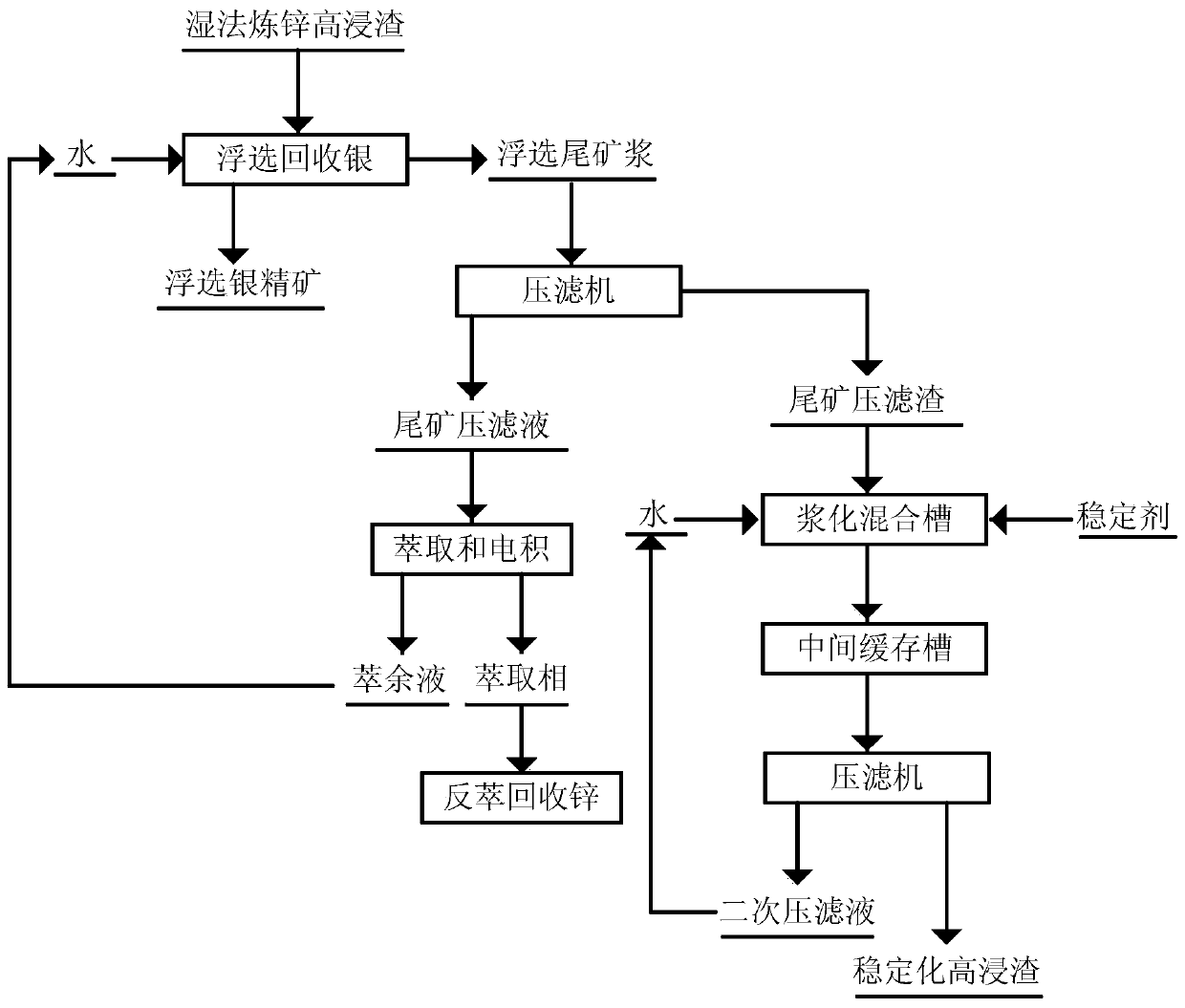

[0036] Process such as figure 1 shown;

[0037] The flotation tailings slurry obtained by flotation and recovery of silver from the high leaching slag of the hydrometallurgy; the flotation tailings slurry is subjected to pressure filtration to obtain the tailings press filter liquid and the tailings press filter residue; the solid content of the tailings press filter residue contains Ag ≤80g / t; the mass percentage of water in the tailings press filter residue is 25%; the tailings press filtrate is used in the extraction and electrowinning steps of hydrometallurgy to recover zinc, and the water-soluble zinc in it is recovered in the form of electrolytic zinc; The raffinate is recycled as water in the step of silver recovery by flotation;

[0038] Add water to the tailings press filter residue and stir to adjust the slurry. Add water to stir and adjust the slurry. Use a slurry mixing tank with a stirring speed of 280r / min. The amount of water is 1.0 times the total mass of the ...

Embodiment 2

[0042] Method is with embodiment 1, and difference is:

[0043] (1) The mass percentage of water in the tailings press filter residue is 24%;

[0044] (2) The stirring speed of adding water to stir and paste is 220r / min. The amount of water is added according to 1.2 times of the total mass of the high leaching slag of wet method zinc smelting, and the stabilizer is added to stir and mix for 10 minutes; 3% of the mass, industrial magnesia powder accounts for 0.2% of the total mass of the zinc-ferrosite slag in the hydro-smelting process, apatite powder accounts for 0.2% of the total mass of the 0.1% of the total mass of alum slag; lime powder contains 85% of CaO by mass percentage, industrial magnesium oxide powder contains 90% of MgO by mass percentage, and apatite powder contains P by mass percentage 2 o 5 20%;

[0045] (3) The mass percentage of water in the secondary press filter residue of the stirring speed 150r / min of the material in the intermediate buffer tank is 2...

Embodiment 3

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The mass percentage of water in the tailings press filter residue is 26%;

[0050] (2) The stirring speed of adding water to stir and mix slurry is 250r / min, the consumption of water is added according to 0.8 times of the total mass of the high leaching slag of wet method zinc smelting, and the stabilizing agent is added and stirred and mixed for 20min; 4% of the mass, industrial magnesia powder accounts for 0.1% of the total mass of zinc-ferrosite slag in hydro-smelting, apatite powder accounts for 0.1% of the total mass of 0.2% of the total mass of alum slag; lime powder contains 70% of CaO by mass percentage, industrial magnesium oxide powder contains 70% of MgO by mass percentage, and apatite powder contains P by mass percentage 2 o 5 12%;

[0051] (3) The mass percentage of water in the secondary press filter residue of the stirring speed 90r / min of the material in the intermediate buffer tank is 26%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com