Hazardous waste incineration system and hazardous waste incineration method

A technology for hazardous waste and waste, applied in the field of hazardous waste incineration system, can solve the problems of occupying land resources, high landfill costs, blockage, etc., and achieve the effect of saving land resources, reducing landfill volume, and realizing recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

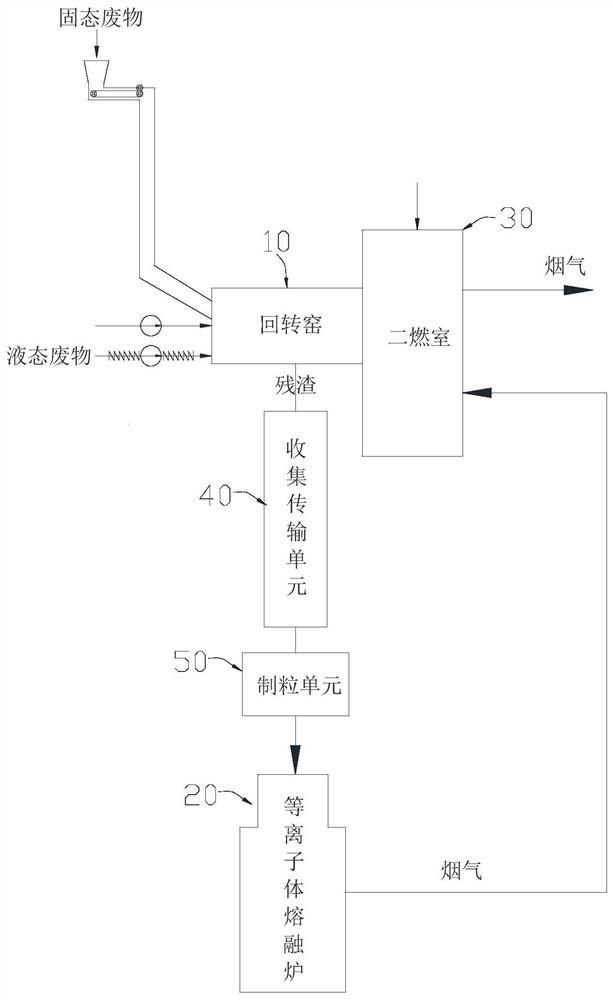

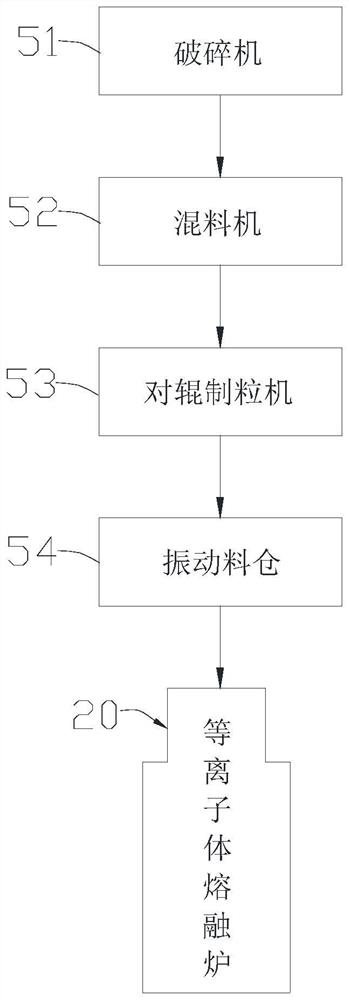

[0039] Such as figure 1 As shown, the hazardous waste incineration system according to an embodiment of the present invention includes a connected rotary kiln 10 , a plasma melting furnace 20 and a secondary combustion chamber 30 . The rotary kiln 10 is used to incinerate hazardous wastes to form residues. The plasma melting furnace 20 is used to process the residue by plasma melting to form a glass body. The secondary combustion chamber 30 refuels the flue gas discharged from the rotary kiln 10 and the plasma melting furnace 20 to remove harmful components in the flue gas.

[0040] Wherein, the discharge port of the rotary kiln 10 is connected to the plasma melting furnace 20 to transport the residue formed after inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com